Emulsion explosive with long-term storage stability and preparation method thereof

An emulsion explosive, long-term storage technology, used in explosives, non-explosive stabilizers, non-explosive/non-thermal components, etc., can solve problems such as poor stability, achieve good explosion performance, and improve the effect of storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

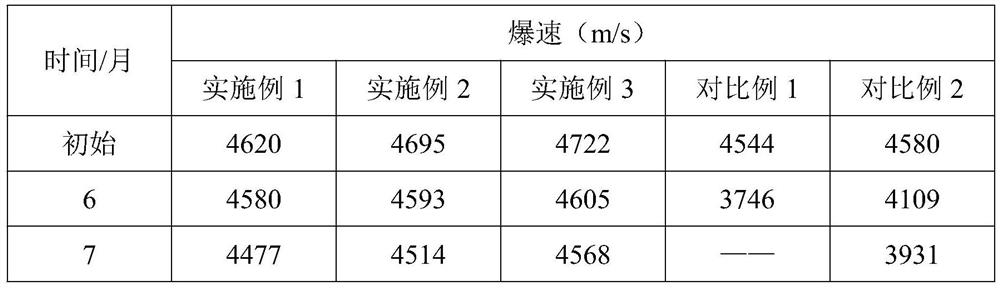

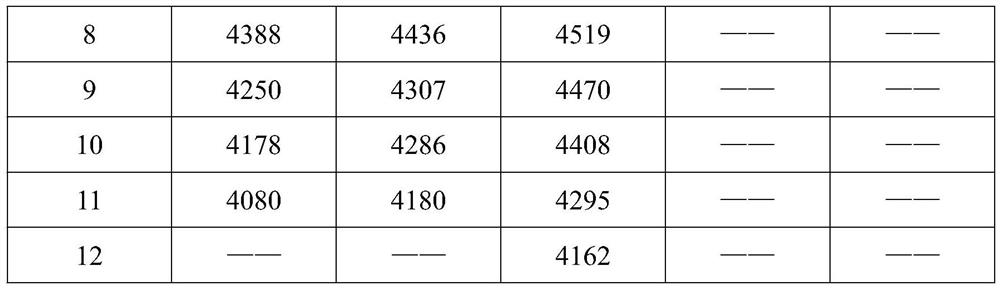

Examples

Embodiment 1

[0023] The emulsion explosive with long-term storage stability proposed by the present invention comprises the following raw materials in parts by weight:

[0024] 70 parts of ammonium nitrate, 5 parts of sodium nitrate, 5 parts of water, 0.1 part of dioctadecyl dimethyl ammonium chloride, 0.1 part of dodecyl hydroxypropyl phosphate betaine, 0.5 parts of Span-800, composite oil phase 3 parts, 0.05 parts of expanded perlite, 0.05 parts of sodium nitrite, 0.1 parts of phosphoric acid.

[0025] The method steps of the above-mentioned emulsion explosive preparation with long-term storage stability that the present invention proposes are as follows:

[0026] S1: preparation of oil phase;

[0027] S2: Preparation of the aqueous phase

[0028] Transport ammonium nitrate, sodium nitrate and water to the water phase tank, melt with steam not higher than 0.4MPa, and store at 92°C;

[0029] S3: emulsification

[0030] Add the oil phase in S1, the water phase in S2, dioctadecyl dimeth...

Embodiment 2

[0036] The emulsion explosive with long-term storage stability proposed by the present invention comprises the following raw materials in parts by weight:

[0037] 80 parts of ammonium nitrate, 15 parts of sodium nitrate, 15 parts of water, 0.5 parts of dioctadecyl dimethyl ammonium chloride, 0.5 parts of dodecyl hydroxypropyl phosphate betaine, 1.5 parts of Span-80, composite oil phase 7 parts, expanded perlite 0.25 parts, sodium nitrite 0.05 parts, phosphoric acid 0.3 parts.

[0038] The method steps of the above-mentioned emulsion explosive preparation with long-term storage stability that the present invention proposes are as follows:

[0039] S1: preparation of oil phase;

[0040] S2: Preparation of the aqueous phase

[0041] Transport ammonium nitrate, sodium nitrate and water to the water phase tank, melt with steam not higher than 0.4MPa, and store at 102°C;

[0042] S3: emulsification

[0043] Add the oil phase in S1, the water phase in S2, dioctadecyl dimethyl am...

Embodiment 3

[0049] The emulsion explosive with long-term storage stability proposed by the present invention comprises the following raw materials in parts by weight:

[0050] 75 parts of ammonium nitrate, 10 parts of sodium nitrate, 10 parts of water, 0.3 parts of dioctadecyl dimethyl ammonium chloride, 0.3 parts of dodecyl hydroxypropyl phosphate betaine, 1 part of Span-80, composite oil phase 5 parts, expanded perlite 0.15 parts, sodium nitrite 0.05 parts, phosphoric acid 0.2 parts.

[0051] The method steps of the above-mentioned emulsion explosive preparation with long-term storage stability that the present invention proposes are as follows:

[0052] S1: preparation of oil phase;

[0053] S2: Preparation of the aqueous phase

[0054] Transport ammonium nitrate, sodium nitrate and water to the water phase tank, melt with steam not higher than 0.4MPa, and store at 97°C;

[0055] S3: emulsification

[0056] Add the oil phase in S1, the water phase in S2, dioctadecyl dimethyl ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com