Low-detonation-velocity emulsified explosive and application thereof

An emulsion explosive, low detonation velocity technology, applied in the directions of explosives, non-explosive stabilizers, non-explosive/non-thermal components, etc., to ensure the effect of explosion welding, high power and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the preparation process of the explosive, an appropriate amount of common clay, an inert substance, is added and mixed to obtain the low detonation velocity emulsified explosive. Specifically, the embodiment of the present invention also provides a method for preparing the above-mentioned cheap new low detonation velocity emulsion explosive, which includes the following steps:

[0050] Weigh the raw materials according to the following mass percentages: 70% to 95% of the basic emulsion explosive; 5% to 30% of ordinary clay;

[0051] Put the basic emulsion explosive in a constant temperature box with a temperature of 60-80°C, keep it warm for 8 minutes to 12 minutes, take it out, mix it with ordinary clay according to the above ratio, and mix it evenly to obtain a low-detonation-velocity emulsion explosive that can be used for explosive welding. Packaging spare.

[0052] Correspondingly, the present invention also provides the application of the above-mentioned low d...

Embodiment 1

[0060] Prepare explosive welding low detonation velocity industrial explosive of the present invention as follows:

[0061] (1) Remove obvious stones and rubble from ordinary clay, then mix it in water according to the mass ratio of 1:12, stir it into mud and let it stand for 2 to 3 days;

[0062] (2) Remove impurities on the water surface, remove the water and take out the fully settled clay at the bottom of the water, pass through a 30-mesh sieve, and then dry until the moisture is not higher than 0.5wt%, and set aside.

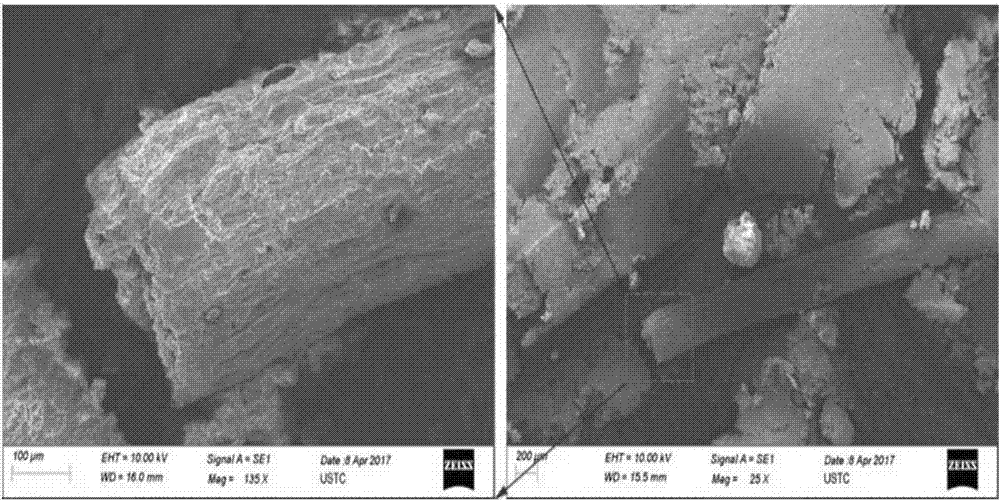

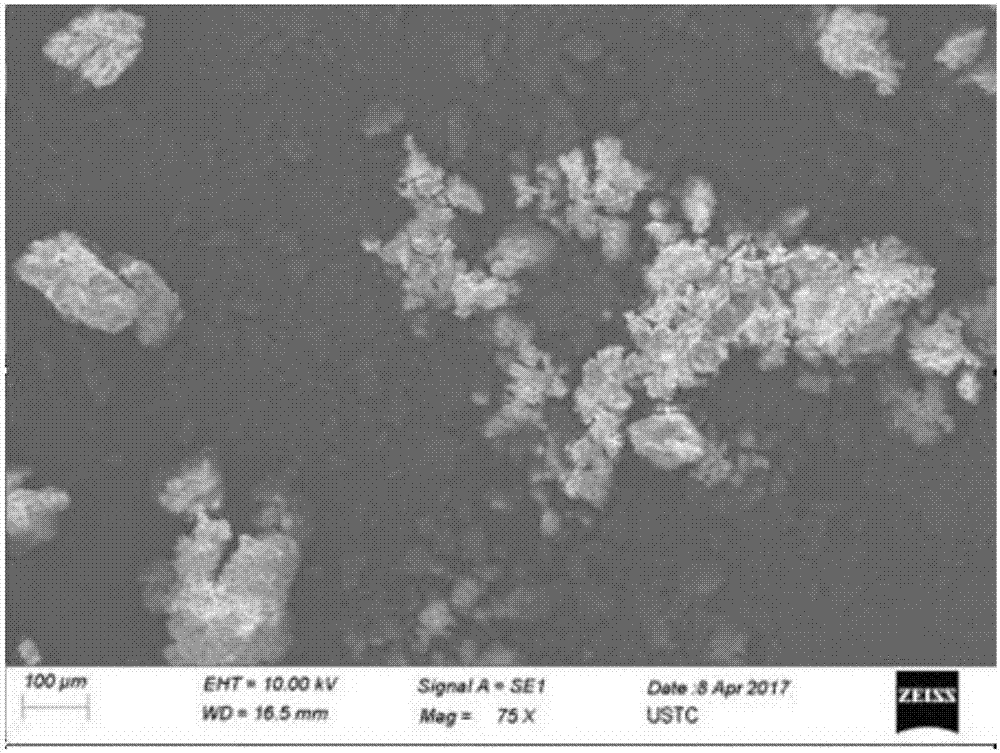

[0063] Wherein, by scanning electron microscope (SEM) analysis, the appearance of the ordinary clay that has not been screened sees figure 1 , figure 1 The left side of the center is the SEM photo of common impurities at 100 μm, and the right side is the SEM photo of unsieved ordinary clay at 200 μm. Morphology of sieved common clay see figure 2 , figure 2 It is the SEM photo of the common clay that has been sieved in Example 1.

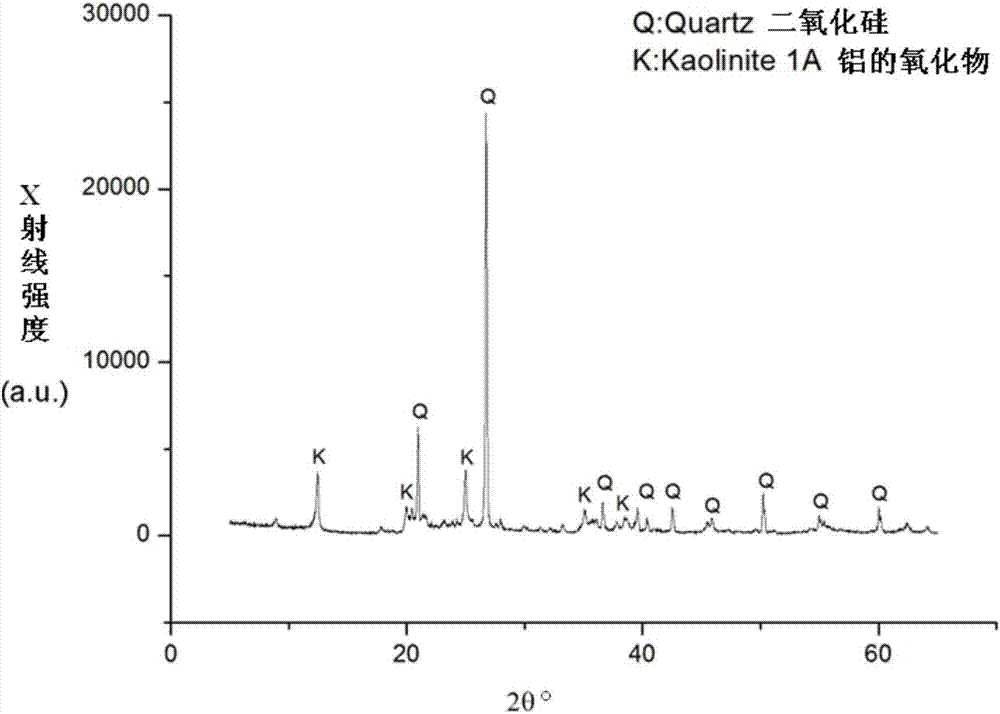

[0064] Carry out X-...

Embodiment 2

[0073] Prepare explosive welding low detonation velocity industrial explosive of the present invention as follows:

[0074] Get 80kg of basic emulsion explosive (prepared by the method in this manual, physically sensitized by expanded perlite), place it in a thermostat at 70°C, take it out after 10 minutes of heat preservation, and add 20kg of dried clay (same as Example 1), Mix evenly, obtain the low detonation velocity emulsion explosive (recorded as experimental group) of the present invention for explosive welding; Its density is 1.10g / m 3 , the detonation velocity is 2450m / s, and the intensity is 9.7mm, which is in line with special fields requiring low detonation velocity such as explosive welding. The explosives of the experimental group were applied to the explosion welding experiment of aluminum plate-stainless steel plate. When the thickness of the explosive was 10mm and the explosion height was 5.0mm, the composite effect of the two plates was good, and a typical wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fierceness | aaaaa | aaaaa |

| Detonation velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com