Boron-containing fuel-rich propellant

A fuel-rich propellant and fuel technology, applied in non-explosive fillers/gelling agents/thickeners, offensive equipment, non-explosive stabilizers, etc. reduce problems, achieve the effects of improving comprehensive performance, improving primary combustion efficiency, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

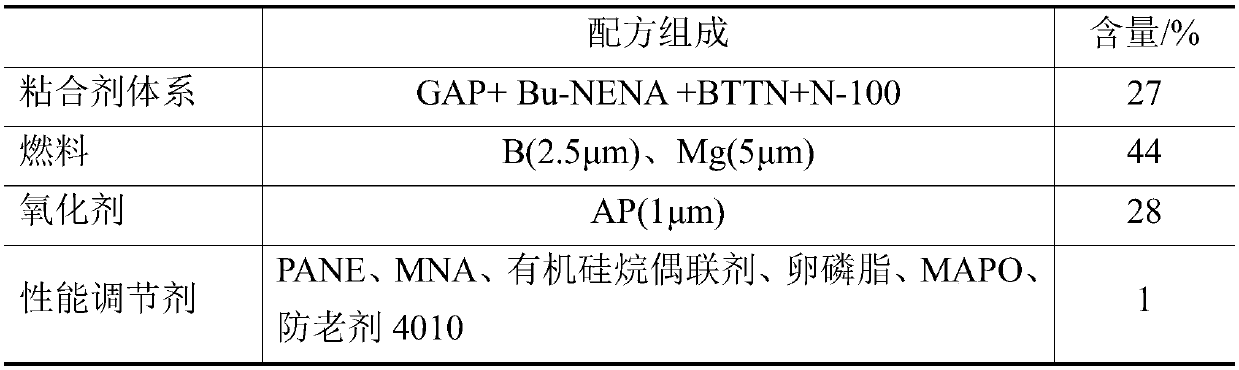

[0034] (1) Propellant composition

[0035]

[0036] (2) Propellant performance

[0037] Propellant charge environment: temperature 28°C, humidity 86.1%

[0038]

Embodiment 2

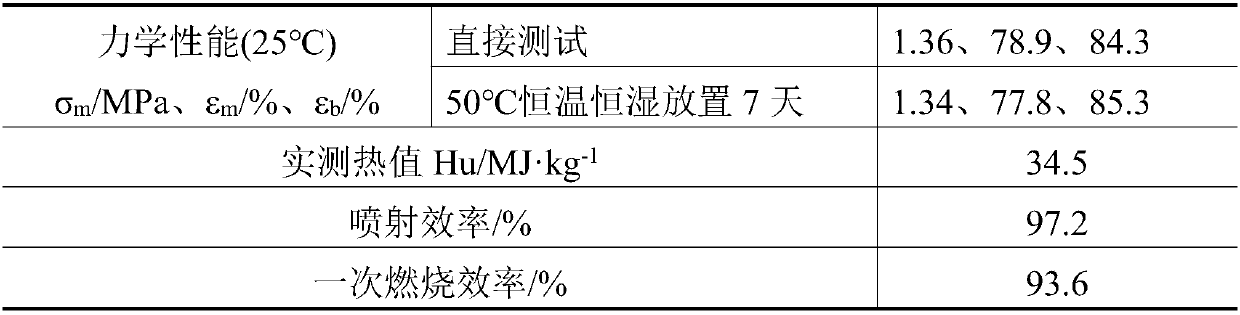

[0040] (1) Propellant composition

[0041]

[0042] (2) Propellant performance

[0043] Propellant charge environment: temperature 30°C, humidity 75.8%

[0044]

Embodiment 3

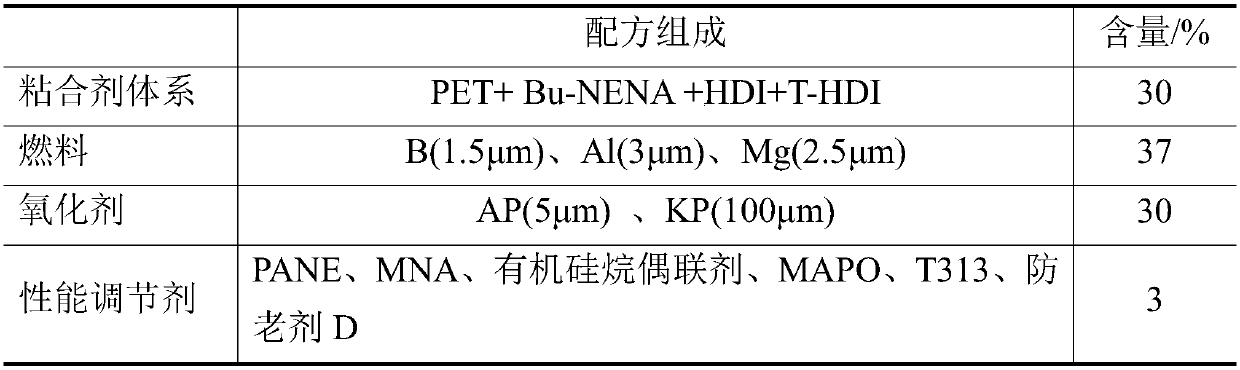

[0046] (1) Propellant composition

[0047]

[0048] (2) Propellant performance

[0049] Propellant charge environment: temperature 29°C, humidity 77.8%

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com