Gas generant

a technology of generant and gas, applied in the field of gas generating system, can solve the problems of generant that exhibits relatively low sensitivity, etc., and achieve the effects of reducing the filtration requirements of the inflator over time, reducing the sensitivity of the generant, and improving the filtration efficiency of the inflator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

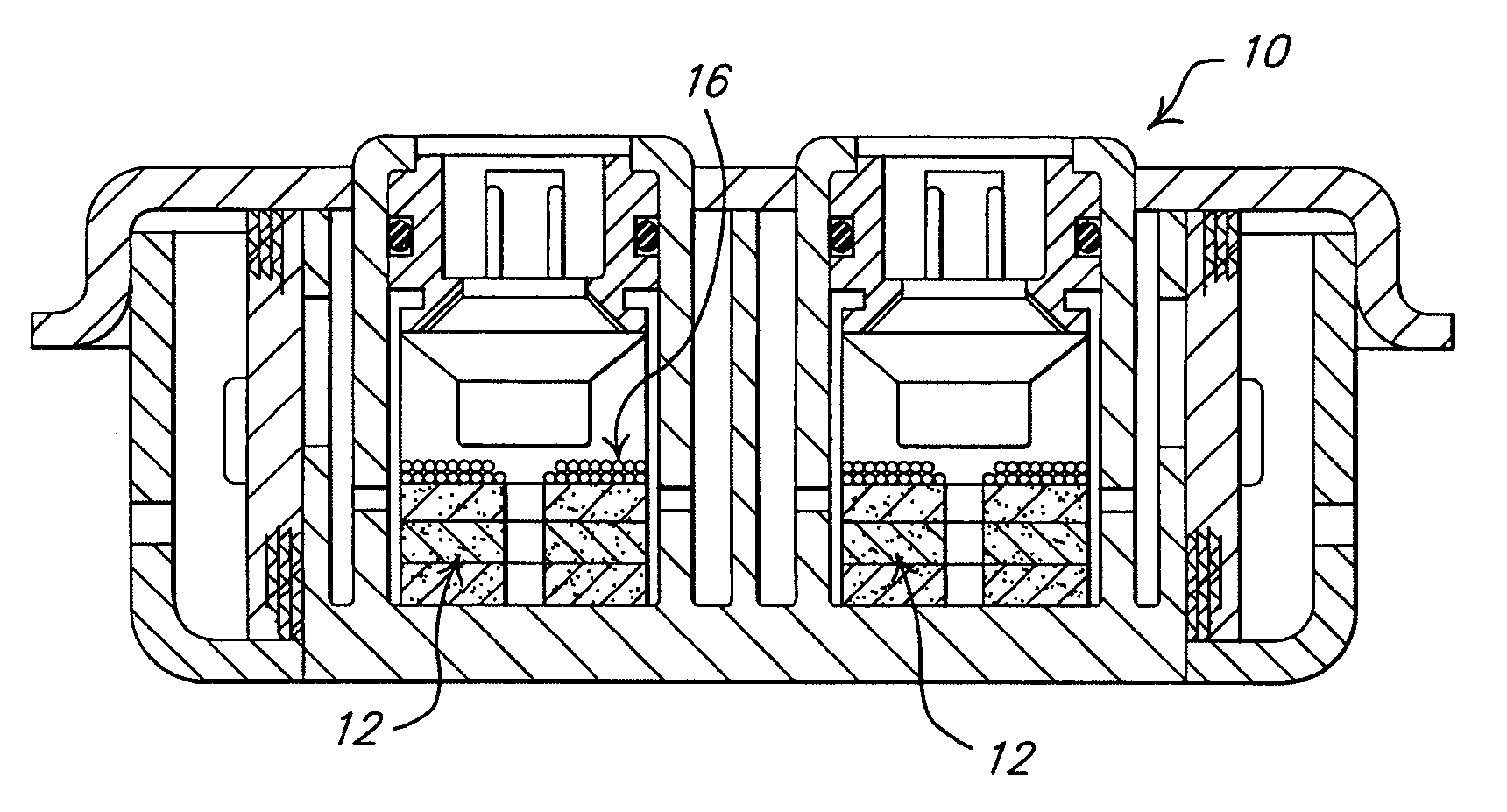

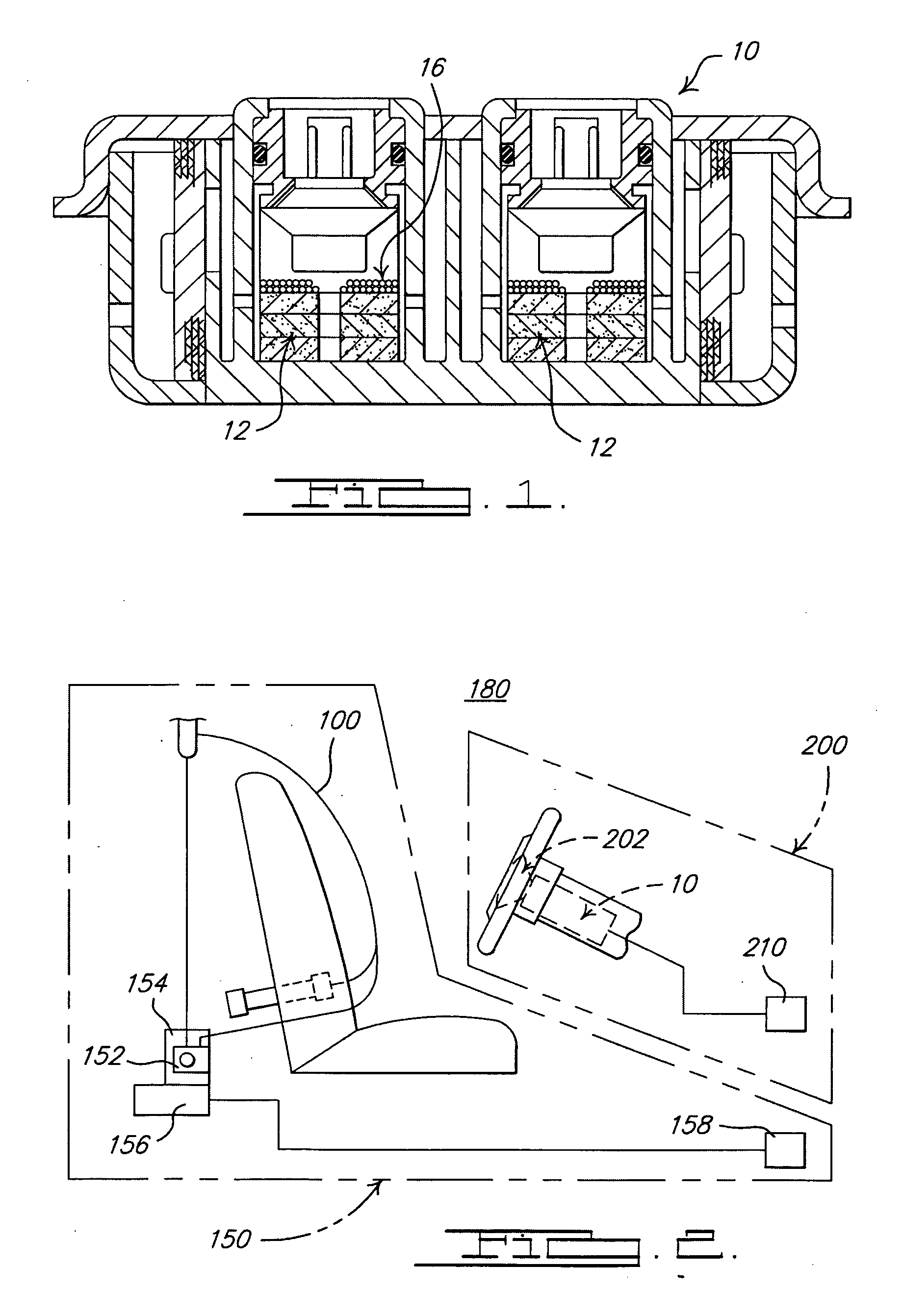

Image

Examples

example 1

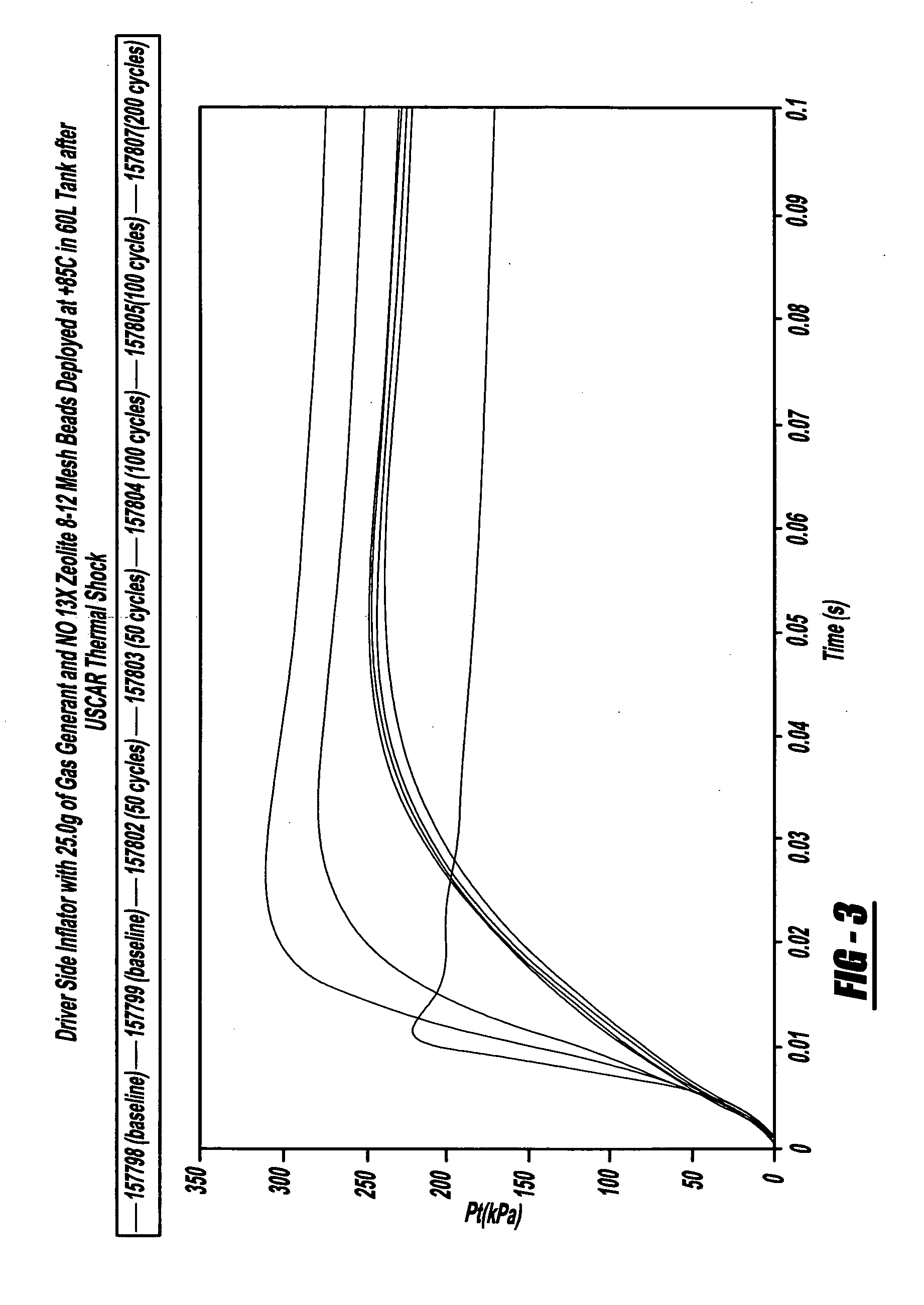

[0033] To form comparative compositions, dry mixes of formulations containing the various constituents described above were prepared in a known manner. The dry material (containing less than 0.2% moisture by mass) was then tableted, loaded into inflators, and subjected to USCAR Thermal Shock conditioning (200 Cycles, −40 C to 90 C). These formulations indicated an increase in aggressive ballistic performance when deployed at 85 C.

[0034] Next, the same process was used to prepare gas generants containing the various constituents described above, and a small amount of additive was added to each inflator. A ratio of 100:1 was used for the mass of gas generant to additive. The additive employed was 13X Type Molecular Sieves because of its inert chemical tendencies and ability to scavenge moisture and other volatiles, and retain these contaminants at relatively higher temperatures such as 107 degrees Celsius. The gas generant contained little moisture (less than 0.2% by mass). After USC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com