Device and method for purifying yellow phosphorus tail gas and continuously synthesizing oxamide

A yellow phosphorus tail gas and purification device technology, which is applied in chemical instruments and methods, the preparation of organic compounds, and the preparation of carboxylic acid amides, can solve the problems of high cost of hydrofluoric acid, low product yield and purity, and low level of comprehensive utilization And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

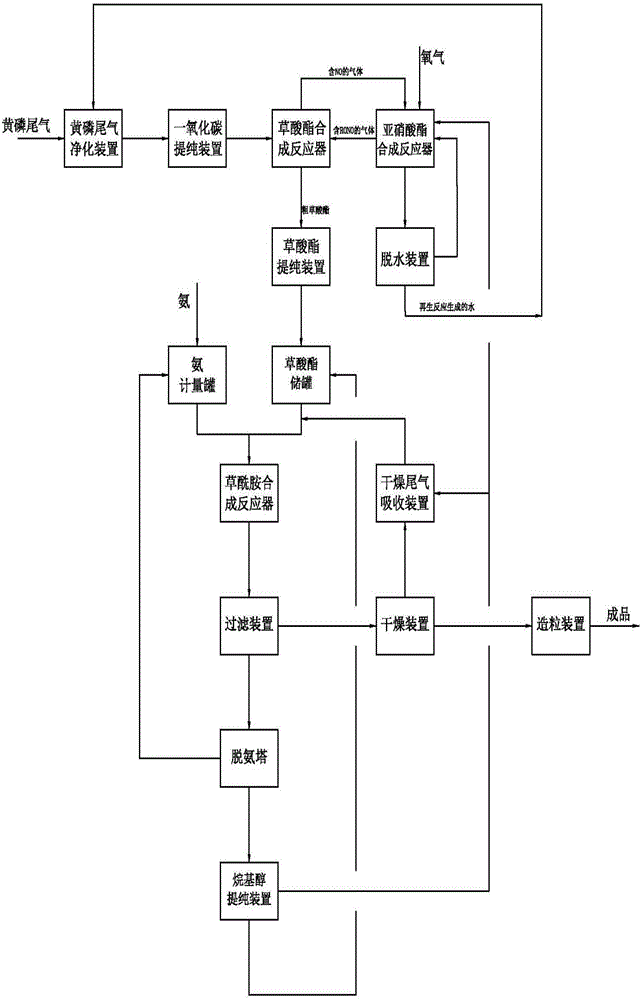

[0037] Such as figure 1 As shown, a device for continuously synthesizing oxamide through purification of yellow phosphorus tail gas includes a yellow phosphorus tail gas purification device, a carbon monoxide purification device, an oxalate ester synthesis device and an oxamide synthesis device connected in sequence.

[0038] The synthetic oxalate unit includes an oxalate synthesis reactor, an alkyl nitrite synthesis reactor and an oxalate storage tank; the CO gas obtained after the yellow phosphorus tail gas passes through the yellow phosphorus tail gas purification device and the carbon monoxide purification device React with the alkyl nitrite produced in the alkyl nitrite synthesis reactor in the oxalate synthesis reactor to obtain dialkyl oxalate, which is purified and enters the oxalate storage tank. The unit for synthesizing oxalate also includes a dehydration unit.

[0039] Described synthesis oxamide device comprises ammonia metering tank, oxamide synthesis reactor, ...

Embodiment 2

[0061]Dimethyl oxalate in Example 1 was replaced with diethyl oxalate. In order to promote the reaction between liquid ammonia and diethyl oxalate, it is necessary to increase the reaction temperature to 110° C. and the reaction pressure to 0.5 MPa (A) during the synthesis of oxamide in Example 1.

Embodiment 3

[0063] The liquid ammonia used in the synthesis of oxamide in Example 1 is replaced by ammonia water. In order to promote the reaction of ammonia water and dimethyl oxalate, the reaction temperature in the synthesis process of oxamide in Example 1 needs to be increased to 85°C, and the reaction pressure constant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com