Preparation method of layered nano-mordenite molecular sieve

A mordenite and layered nanotechnology, which is applied in the field of synthesis of zeolite molecular sieves, can solve the problems of environmental pollution, the size of synthetic particles is larger than 1.0, and the synthesis of nano-mordenite has not yet been reported, and achieves the effects of less pollution and low synthesis cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix 2.698g of CTATos and 80g of water, heat it in a constant temperature water bath at 60 ℃ for 2 hours to form a solution A; mix 2.107g of sodium hydroxide with 67.8ml of deionized water, stir until clear, and add Aluminum isopropoxide was heated in a constant temperature water bath at 60°C for 1 hour. After the aluminum isopropoxide was completely dissolved, 17.428g of silica sol was slowly added dropwise to it, and then the original temperature was kept constant, and stirred for two After 2 hours, solution B was formed; finally, solution B was added dropwise to solution A, and the stirring was continued for 2 hours. After crystallization for 5 days, it was subjected to conventional suction filtration, washed with deionized water, dried, and then calcined at 550°C for 5 hours to obtain a solid product. The initial molar composition of each component of the mixture is: SiO 2 : Al 2 o 3 =30, Na 2 O: SiO 2 =0.64,H 2 O:SiO 2 =102.

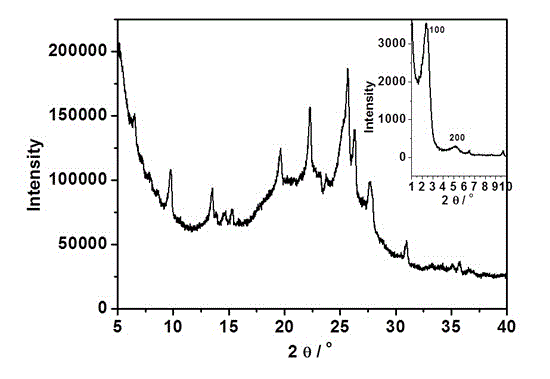

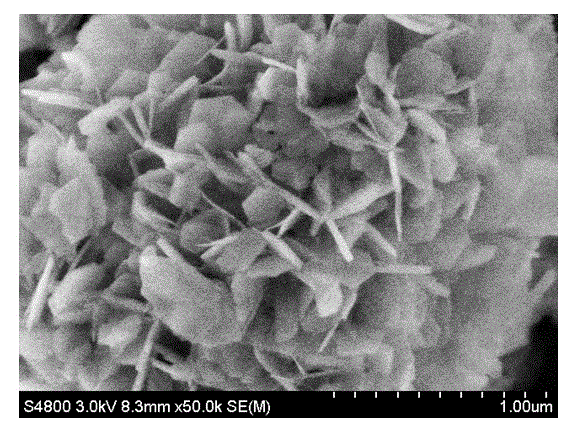

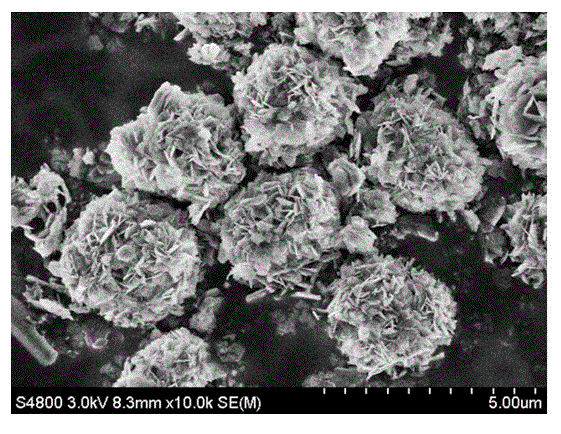

[0029] After X-ray analysis,...

Embodiment 2

[0031] Except that the silicon source in Example 1 was changed to fuming silica gel, other preparation conditions were the same as in Example 1, and the obtained solid product was analyzed as layered mordenite.

Embodiment 3

[0033] Except that the silicon source in Example 1 was changed to water glass, other preparation conditions were the same as in Example 1, and the obtained solid product was analyzed as layered mordenite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com