Honeycomb-like oxygen-doped carbon nitride photocatalyst, preparation method and applications thereof

A carbon nitride light and oxygen doping technology, applied in the field of photocatalytic materials, can solve problems such as limitation and high energy consumption, and achieve the effects of strong practicability, improved photocatalytic performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the honeycomb oxygen-doped carbon nitride photocatalyst of the present embodiment comprises the following steps:

[0026] S1. After dicyandiamide and oxamide are uniformly mixed, they are fully ground in a mortar to obtain a mixture, wherein the amount of dicyandiamide is 2g, and the molar weight of oxamide accounts for 1%, 2% of the molar weight of dicyandiamide respectively. %, 3%, 4%, 5%;

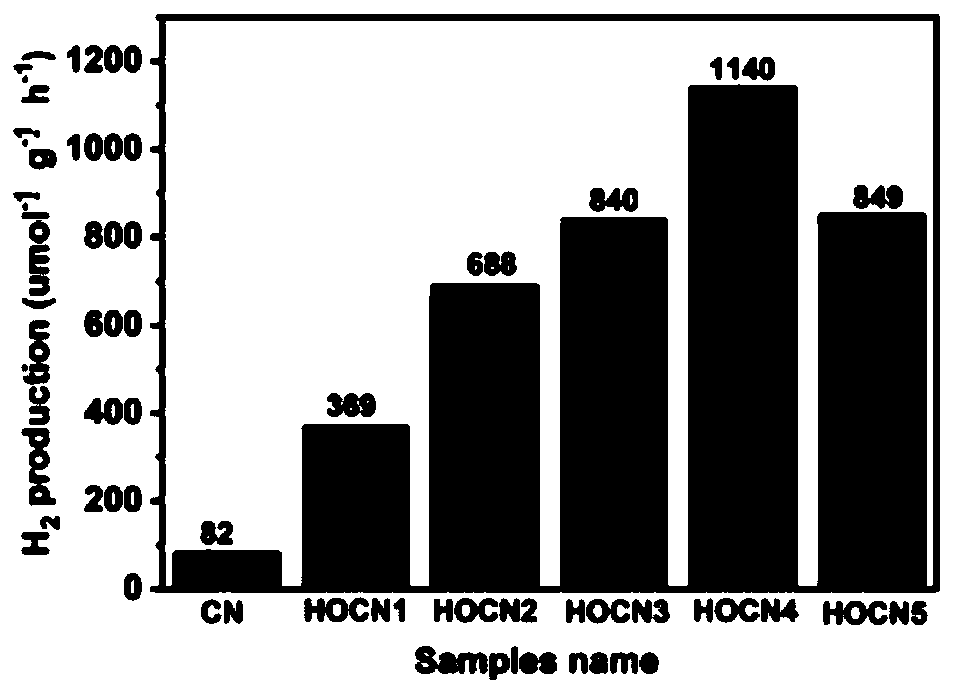

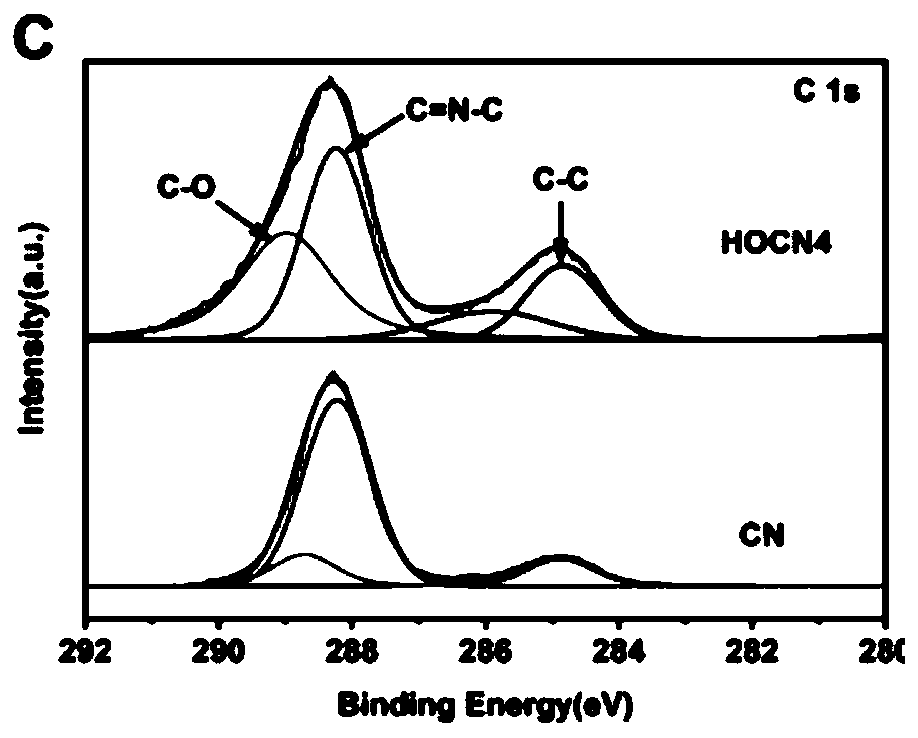

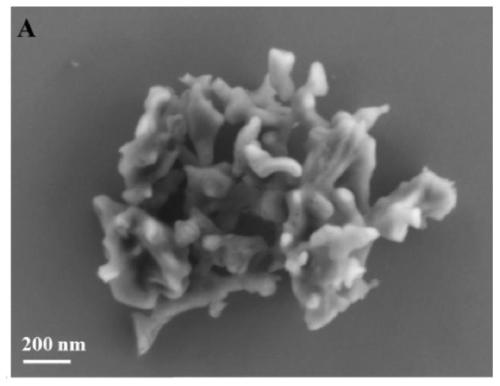

[0027] S2. Put the mixture into a muffle furnace and calcine it step by step: first raise the temperature to 110°C at 1.5°C / min; then raise the temperature to 600°C at 5°C / min and keep it warm for 3 hours. After the sample is naturally cooled to room temperature, the obtained sample is collected by grinding, which is the honeycomb oxygen-doped carbon nitride (HOCN) series photocatalyst. The samples whose molar amounts of oxamide are respectively 1%, 2%, 3%, 4%, and 5% of the molar amounts of dicyandiamide are represented as HOCN1, HOCN2, HOCN3, HOCN4, an...

Embodiment 2

[0029] The preparation method of the honeycomb oxygen-doped carbon nitride photocatalyst of the present embodiment comprises the following steps:

[0030] S1. After dicyandiamide and oxamide are uniformly mixed, they are fully ground in a mortar, wherein the amount of dicyandiamide is 2g, and the amount of oxamide added is 4% of the molar amount of dicyandiamide;

[0031] S2. Put the mixture into a muffle furnace and calcine it step by step: first raise the temperature to 120°C at 1°C / min; After the sample was naturally cooled to room temperature, the obtained sample was collected by grinding, which was the honeycomb oxygen-doped carbon nitride (HOCN-1) photocatalyst.

Embodiment 3

[0033] The preparation method of the honeycomb oxygen-doped carbon nitride photocatalyst of the present embodiment comprises the following steps:

[0034] S1. After uniformly mixing dicyandiamide and oxamide, grind them thoroughly in a mortar, wherein the amount of dicyandiamide is 2g, and the amount of oxamide added is 0.01% of the molar amount of dicyandiamide;

[0035] S2. Put the mixture into a muffle furnace and calcine it step by step in stages: first raise the temperature to 90°C at 2°C / min; then raise the temperature to 500°C at 6°C / min and keep it warm for 1 hour. After the sample was naturally cooled to room temperature, the obtained sample was collected by grinding, which was the honeycomb oxygen-doped carbon nitride photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com