Sludge iron-supported multiphase photo-Fenton catalytic material and preparation method thereof

A catalytic material and sludge technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of high cost, and achieve the effect of reducing the addition amount, reducing cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of digested sludge loaded iron heterogeneous photo-Fenton catalyst:

[0026] Put 10 g of digested sludge in 20 ml (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O aqueous solution, magnetically stirred at room temperature for 3 h and then centrifuged. The obtained solid was dried and calcined at 350 °C for 5 h in an air atmosphere in a muffle furnace, and cooled to room temperature to obtain a digested sludge-supported iron heterogeneous photo-Fenton catalyst.

[0027] The effects of different types of iron precursors on the catalytic activity of the prepared heterogeneous photo-Fenton catalysts were studied. Keeping other conditions unchanged, the distribution uses 1 M FeSO 4 ·7H 2 O, (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O, FeCl 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was prepared as a catalyst for the iron precursor, and its photo-Fenton catalytic degradation efficiency for rhodamine B was tested, and the degradation rate of the pseudo-first-order reaction kinetics was as follo...

Embodiment 2

[0029] Preparation of digested sludge loaded iron heterogeneous photo-Fenton catalyst:

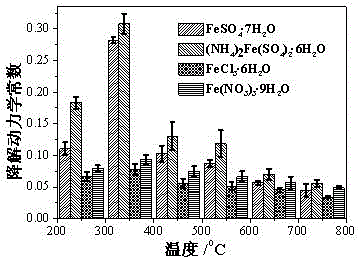

[0030] As in Example 1, the difference is that the calcination temperature in the muffle furnace ranges from 250-750°C. Test its photo-Fenton catalytic degradation efficiency of rhodamine B, pseudo-first-order reaction kinetics degradation rate as figure 1 It can be seen that the photo-Fenton catalyst prepared at 350 ℃ has the best catalytic effect.

Embodiment 3

[0032] Preparation of digested sludge loaded iron heterogeneous photo-Fenton catalyst:

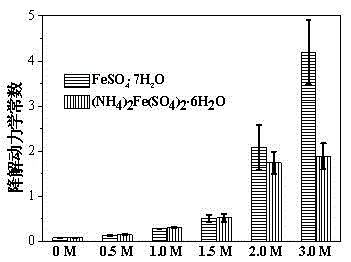

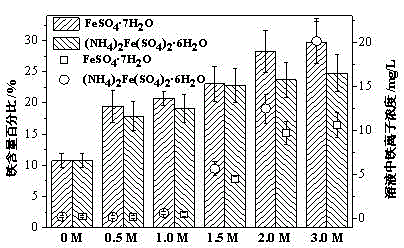

[0033] As in Example 1, the difference is that the iron precursor FeSO 4 ·7H 2 O and (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2The photo-Fenton catalytic degradation efficiency of rhodamine B by the prepared catalysts with O concentration ranging from 0-3 M, the pseudo-first-order reaction kinetics degradation rate as figure 2 As shown, the results of the corresponding iron content in the catalyst and the residual amount of iron ions in the solution after degradation are as follows image 3 shown. Combined with the results of the residual amount of iron ions in the solution after degradation, it can be known that 1 M (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 The photo-Fenton catalyst prepared by O aqueous solution is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com