Titanium dioxide-metal organic framework array with uniformly and continuously coated nuclear-sheath structure, and preparation method and application of titanium dioxide-metal organic framework array

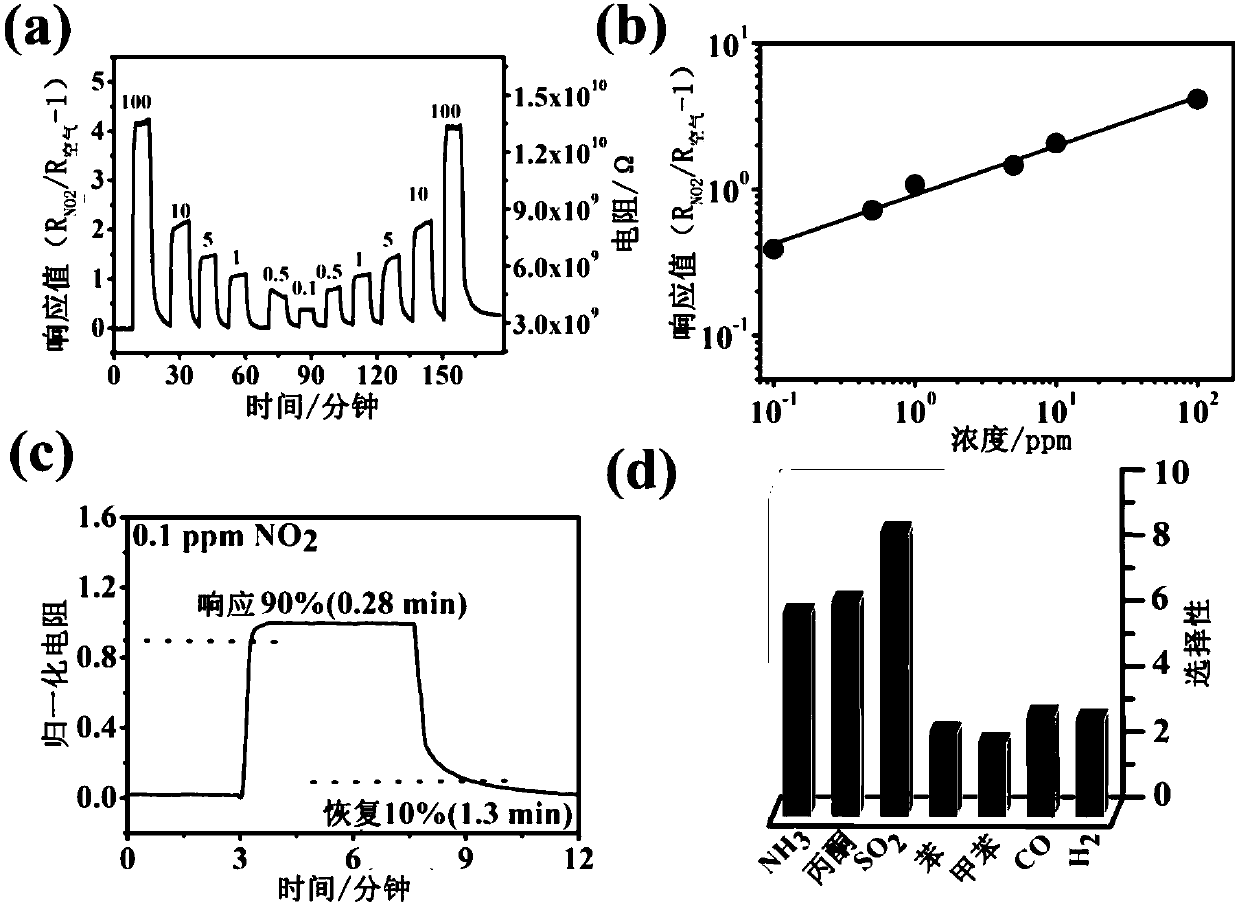

A metal-organic framework and titanium dioxide technology, applied in chemical instruments and methods, separation methods, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as uncontrollable thickness and uniformity, unsatisfactory photocatalytic activity, etc. , to achieve the effects of wide visible light response range, fast response-recovery ability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] As mentioned above, the present invention provides a method for preparing a titanium dioxide-metal organic framework array, the preparation method comprising the following steps:

[0054] 1) Prepare ligand organic solution, titanium source organic solution, ligand organic solution and titanium source organic solution respectively;

[0055] 2) The substrate with the titanium dioxide array is immersed in the ligand organic solution in step 1) for the first seed preparation, and then immersed in the titanium source organic solution for the second seed preparation, and the metal-organic framework seed is prepared. A substrate of a crystalline titania array;

[0056] Optionally, the first seed crystal preparation and the second seed crystal preparation can be repeated in sequence;

[0057] 3) The substrate of the titanium dioxide array with the metal organic framework seed crystal in step 2) is immersed in the mixed solution of the ligand organic solution and the titanium s...

preparation example 1

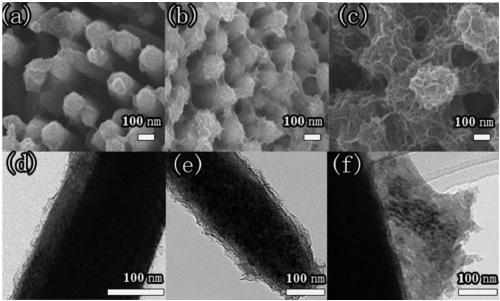

[0077] Al first 2 o 3The substrate was ultrasonically washed in a solvent of 1:1:1=acetone:isopropanol:water for half an hour, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Tetrabutyl titanate solution was repeatedly deposited on Al by pull coating method 3-5 times 2 o 3 After the substrate, a uniform layer of TiO was prepared by pyrolysis at 450°C for 15 minutes 2 seed layer. Then, after stirring and mixing 0.4mL tetrabutyl titanate and 12mL 6M HCl aqueous solution, it was transferred to a 20mL reaction kettle, and the above TiO 2 The seed wafer was immersed in the solution face down, and the reaction vessel was sealed. After reacting at 150°C for 4 hours, the TiO 2 Array substrates were thoroughly washed with deionized water and dried in air.

Embodiment 1

[0079] 0.3mmol organic ligand bdc-(NH 2 ) x (x=0, 1 and 2) were dissolved in 20 mL of a mixed solution of anhydrous dimethylformamide (DMF) and anhydrous methanol (the volume ratio of DMF and methanol was 9:1). Dissolve 0.15 mmol of tetrabutyl titanate in 20 mL of a mixed solution of anhydrous dimethylformamide (DMF) and anhydrous methanol (the volume ratio of DMF and methanol is 9:1). The multi-step thermal seeding method adopts the method of immersing the substrate with the titanium dioxide array in the organic solution of the above ligand and growing it at 150°C for 12 hours for the first seed crystal preparation, and then immersing the substrate with the titanium source organic solution at 150°C for 12 hours for the second seed crystal preparation. Secondary seed crystal preparation, the substrate of the titanium dioxide array with the metal organic framework seed crystal is prepared, which is the substrate of the titanium dioxide array with the metal organic framework se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com