A fesibcr/sio 2 Preparation method of nanocrystalline soft magnetic composite iron core

A nanocrystalline soft magnetic and iron core technology, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic core manufacturing, magnetic objects, etc., can solve the problem of reducing the electromagnetic properties of soft magnetic composite powder and materials, the reaction process is difficult to control, and insulation coating Inhomogeneity and other problems, to achieve the effect of being suitable for popularization, good frequency stability, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

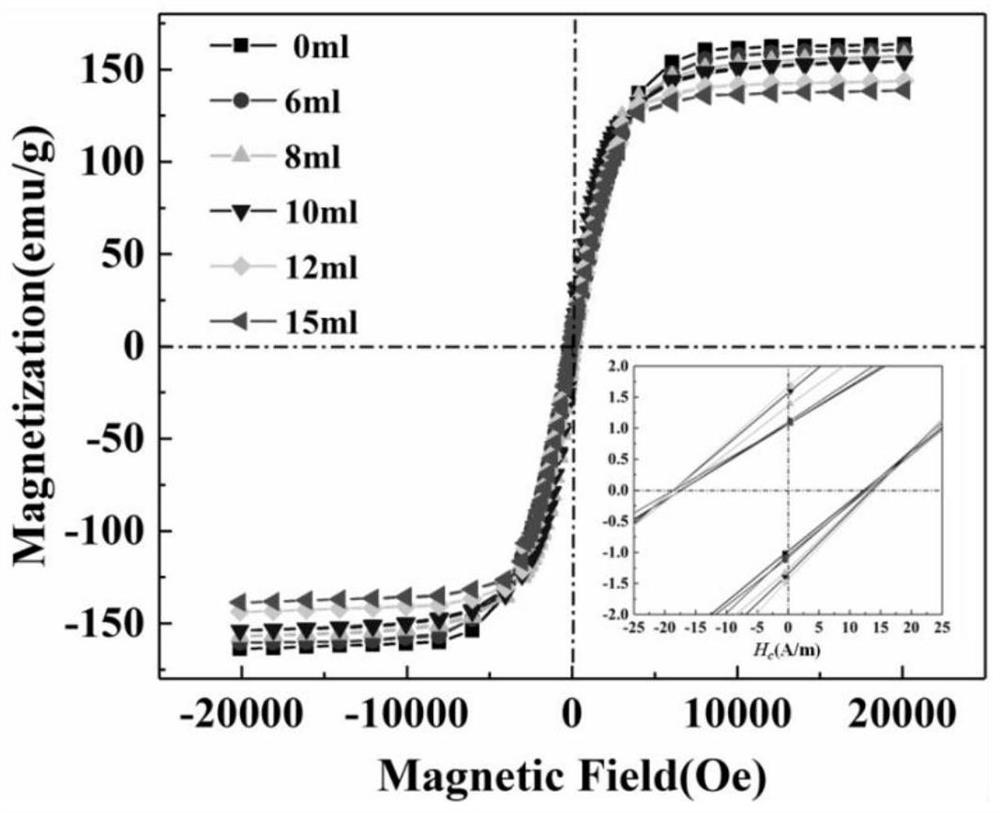

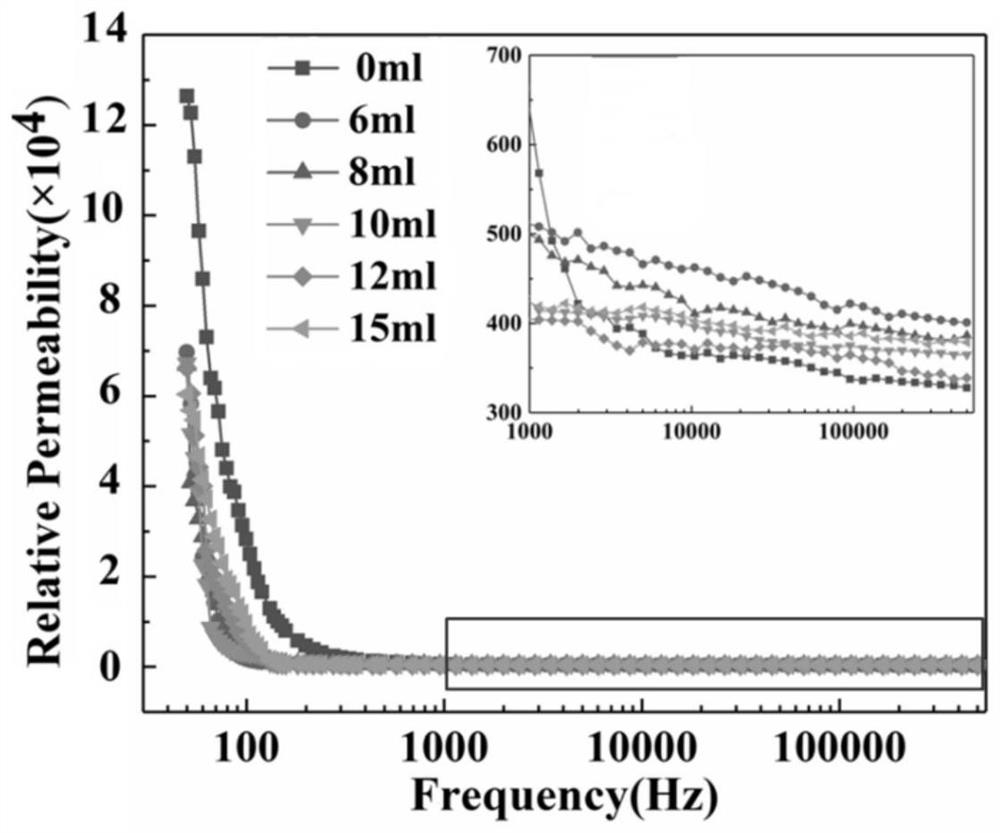

Embodiment 1-6

[0030] A FeSiBCr / SiO2 A method for preparing a nanocrystalline soft magnetic composite iron core, the method is carried out in the following steps:

[0031] (1) Add 50g of FeSiBCr amorphous powder and 300ml of absolute ethanol into a three-necked flask, mechanically stir (750r / min) at room temperature to disperse for 5min, add 50mL of ethanol / water solution (40mL of ethanol, the rest is deionized water) and continue to disperse 15min, put the solution in a constant temperature water bath and heat it to 40°C; dissolve 3.4g of silane coupling agent (APTES) in absolute ethanol to prepare 50mL solution and add it to the solution in the three-necked flask to surface FeSiBCr amorphous powder modified to obtain FeSiBCr amorphous powder solution.

[0032] (2) Prepare tetraethyl orthosilicate / ethanol solution and ammonia water / water / ethanol solution, draw them into 50mL syringes A and B respectively (syringe A: tetraethyl orthosilicate X mL, balance of absolute ethanol; syringe B: Amm...

Embodiment 7-12

[0041] A FeSiBCr / SiO 2 A method for preparing a nanocrystalline soft magnetic composite iron core, the method is carried out in the following steps:

[0042] (1) Add 50g of FeSiBCr amorphous powder and 300ml of absolute ethanol into a three-necked flask, mechanically stir (750r / min) at room temperature to disperse for 5min, add 50mL of ethanol / water solution (40mL of ethanol, the rest is deionized water) and continue to disperse After 15 minutes, the solution was placed in a constant temperature water bath and heated to 50°C; 3.4 g of silane coupling agent (APTES) was dissolved in absolute ethanol to prepare 50 mL of the solution and added to the solution in the three-necked flask to surface the FeSiBCr amorphous powder. modified to obtain FeSiBCr amorphous powder solution.

[0043] (2) Prepare tetraethyl orthosilicate / ethanol solution and ammonia water / water / ethanol solution, draw them into 50mL syringes A and B respectively (syringe A: tetraethyl orthosilicate X mL, balance...

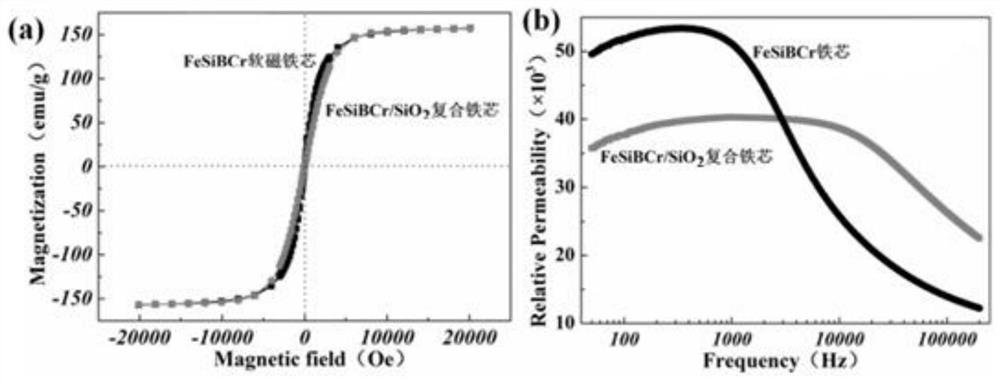

Embodiment 13

[0050] A FeSiBCr / SiO 2 A method for preparing a nanocrystalline soft magnetic composite iron core, the method is carried out in the following steps:

[0051] (1) Add 50g of FeSiBCr amorphous powder and 300ml of absolute ethanol into a three-necked flask, mechanically stir (750r / min) at room temperature to disperse for 5min, add 50mL of ethanol / water solution (40mL of ethanol, the rest is deionized water) and continue to disperse After 15 minutes, the solution was placed in a constant temperature water bath and heated to 50°C; 3.4 g of silane coupling agent (APTES) was dissolved in absolute ethanol to prepare 50 mL of the solution and added to the solution in the three-necked flask to surface the FeSiBCr amorphous powder. modified to obtain FeSiBCr amorphous powder solution.

[0052] (2) Prepare tetraethyl orthosilicate / ethanol solution and ammonia / water / ethanol solution, draw them into 50mL syringes A and B respectively (syringe A: 10mL of tetraethyl orthosilicate, 40mL of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com