Method for preparing antioxidant

A technology of di-tert-butyl and hydroxyphenyl, which is applied in the field of preparation of antioxidant-N.N'-di[2-ethyl-3 propionate group] oxalamide, which can solve the problem of low yield and long reaction time and other problems to achieve the effect of increasing yield, improving product quality and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Put 150 grams of 3-(3.5 di-tert-butyl-4-hydroxyphenyl) methyl propionate, 42.4 grams of N.N'-dihydroxyethyl oxalamide, 50 ml of xylene, and 1.5 grams of alkyl stannic acid into 500 ml In the four-neck flask, under the protection of nitrogen, fully mix and stir, and heat the material to 160-190 ° C for 6 hours, after dissolution, decolorization, hot filtration, cooling, crystallization, and drying, N.N'-di[2 -Ethyl-3 (3.5 di-tert-butyl-4-hydroxyphenyl) propionate group] oxamide 140.5 grams, yield 84%, mother liquor recovery can obtain 1.5 grams, yield 9%, total yield is 93 %.

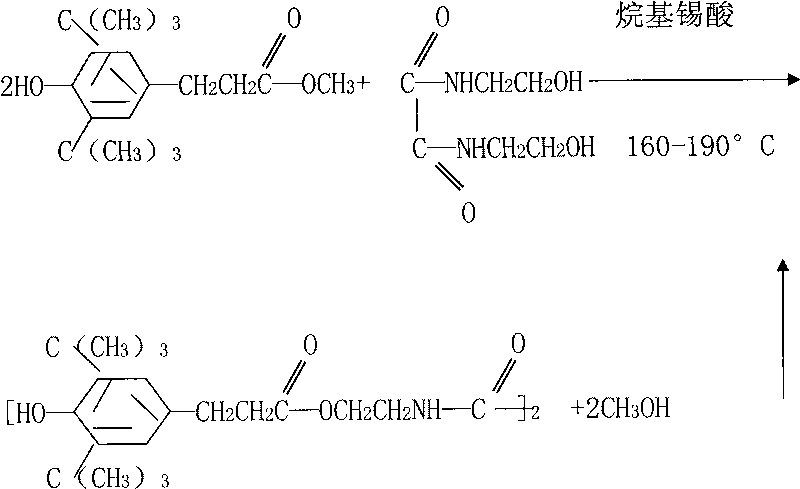

[0012] Reaction equation of the present invention is:

[0013]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com