Synthesis of novel efficient extractant oxamide for light rear earth element and extraction separation method

An extractant and light rare earth technology, which is applied in the field of oxamide extractant for separating light rare earth, can solve the problems of unsatisfactory separation effect, unstable properties, easy emulsification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

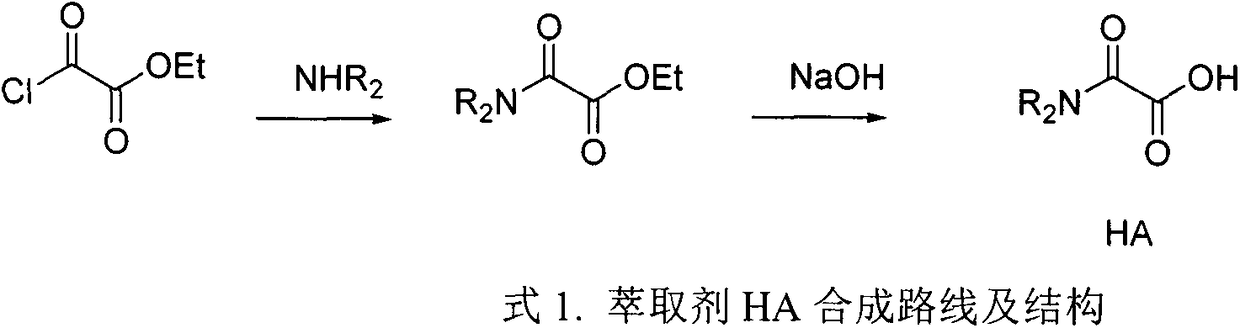

[0006] Example 1.N, the preparation of N-dihexyl oxalic acid (HA6)

[0007] 10ml of monoethyl oxalyl chloride was dissolved in 30ml of dichloromethane, and 30ml of a dichloromethane solution of di-n-butylamine (15ml) and triethylamine (20ml) was added dropwise in an ice-water bath. After 1 hour, spin the reaction solution to dryness, add 20ml of ethanol, 20ml of 0.2M sodium hydroxide aqueous solution, reflux for 5 hours, add hydrochloric acid to acidify, evaporate most of the solvent, then add 50ml of dichloromethane, wash with water three times, separate the phases with anhydrous The organic phase was dried over sodium sulfate, concentrated and purified by silica gel chromatography (dichloromethane as eluent) to obtain a light brown viscous liquid with a purity of 92% and a yield of 76%.

[0008] 1H NMR (CDCl3 / TMS) δ / ppm: 1.20 (s, 1H), 3.32-1.25 (m, 12H), 0.85 (m, 6H).

example 2

[0009] Example 2.N, the preparation of N-diisooctyl oxalic acid (HA8)

[0010] 10ml of monoethyl oxalyl chloride was dissolved in 30ml of dichloromethane, and 30ml of a dichloromethane solution of diisooctylamine (20ml) and triethylamine (20ml) was added dropwise in an ice-water bath. After 1 hour, spin the reaction solution to dryness, add 20ml of ethanol, 20ml of 0.2M sodium hydroxide aqueous solution, reflux for 5 hours, add hydrochloric acid to acidify, evaporate most of the solvent, then add 50ml of dichloromethane, wash with water three times, separate the phases with anhydrous The organic phase was dried over sodium sulfate, concentrated and purified by silica gel chromatography (dichloromethane as eluent) to obtain a light brown viscous liquid with a purity of 90% and a yield of 75%.

[0011] 1 HNMR (CDCl 3 / TMS) δ / ppm: 3.06-3.56 (m, 4H), 1.63 (d, 2H), 1.24 (s, 16H), 0.87 (t, 12H)

example 3

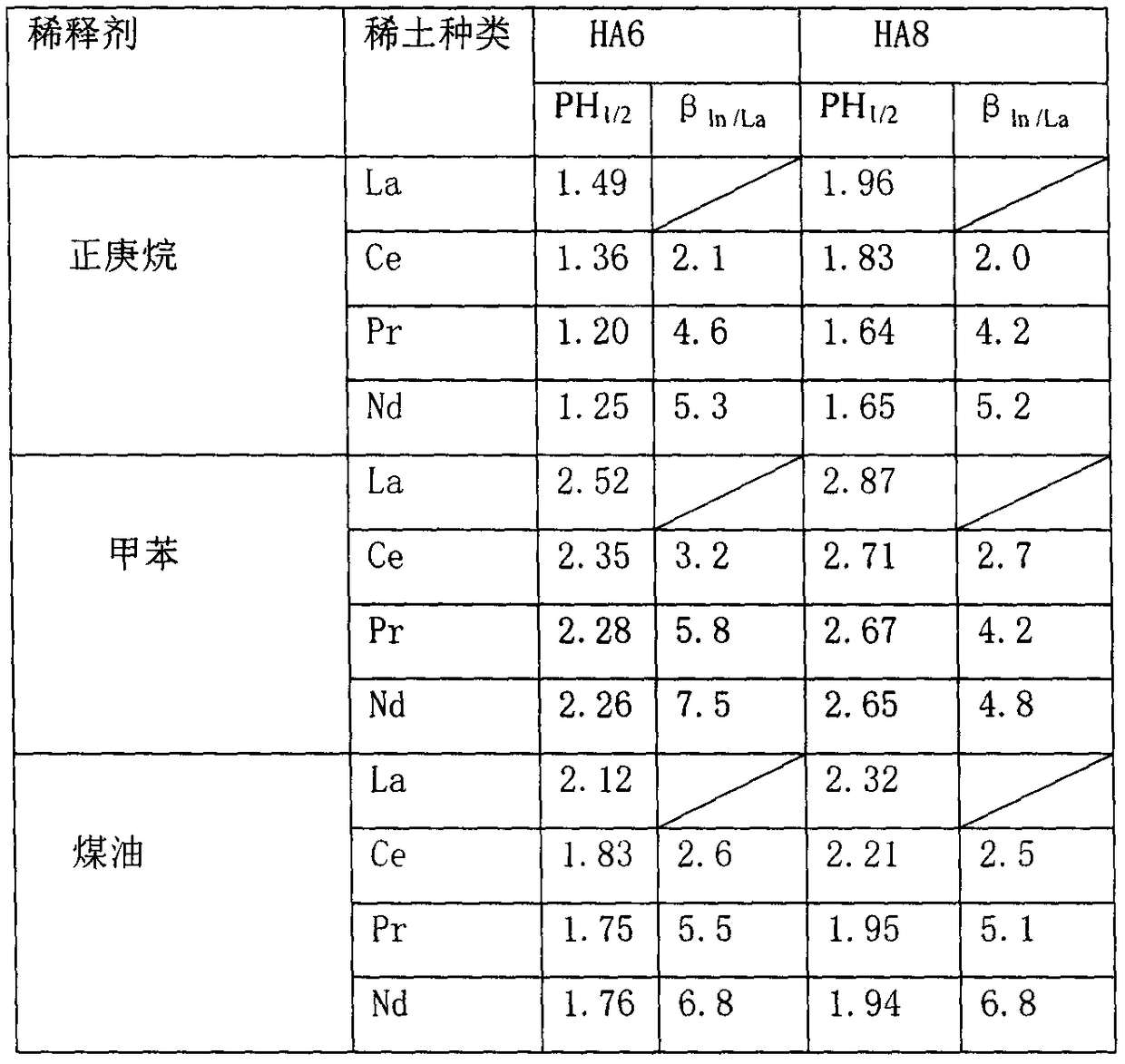

[0012] Example 3.HA6, HA8 compare the extraction performance of light rare earth

[0013] Extraction process: prepare a 0.005M single rare earth hydrochloric acid solution; dissolve the extractant in the diluent to prepare a 0.06M solution; ±1℃)

[0014] Shake in a water-bath shaker for 60 minutes until the extraction is balanced; after phase separation, measure the concentration of rare earth ions in the water phase, and then calculate the content of rare earth in the organic loading phase through material balance, so as to obtain the extraction rate. The results are shown in Table 1.

[0015] Table 1. Extraction studies of light rare earths with dialkyl oxamide extractants.

[0016]

[0017] Remarks: 1. Distribution ratio: the ratio of the concentration of metal ions in the organic phase to the concentration of metal ions in the aqueous phase at extraction equilibrium;

[0018] 2. The separation coefficient β represents the ratio of the distribution ratio of two differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com