Biodegradable alternative aliphatic polyester amide and preparation method thereof

A polyester amide and aliphatic technology, applied in the field of polymer materials, can solve problems such as high structure, and achieve the effects of broad application prospects, easy orientation and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of biodegradable alternating aliphatic polyester amide, the process is as follows:

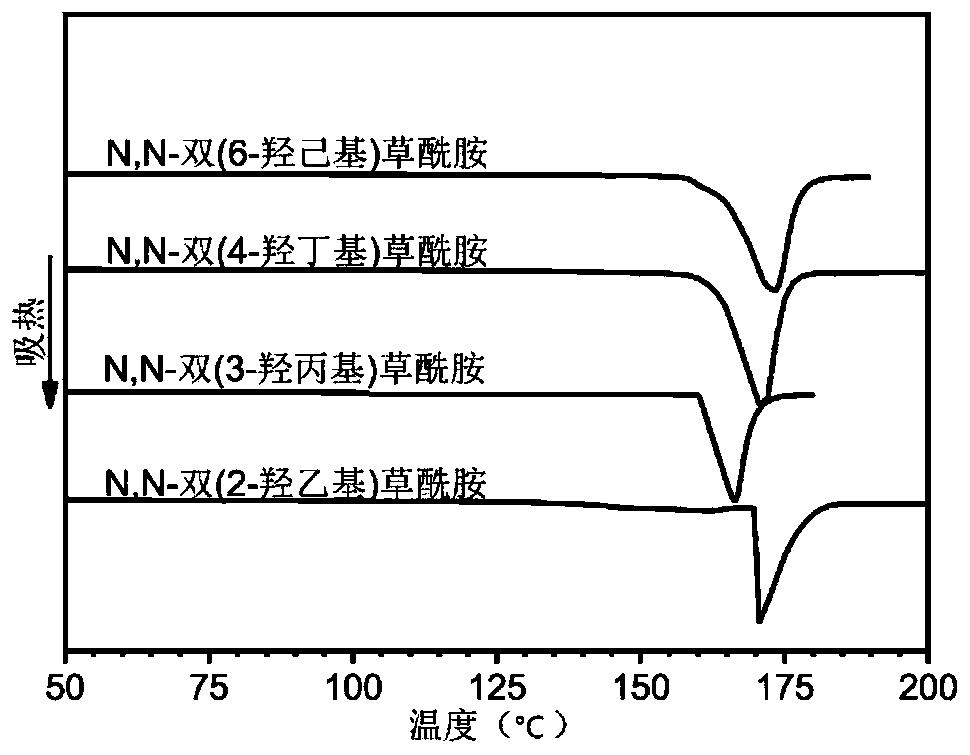

[0058] (1) Add 186.7g (3mol) of ethanolamine and 200ml methanol into a 2L three-necked flask, and under mechanical stirring, pass N 2 , and stabilize the system temperature at 0°C, then slowly add 303.67g (1.5mol) dibutyl oxalate through the normal pressure funnel for about 2 hours, after the dropwise addition is completed, continue the reaction for 0.5 hours, cool to below 0°C and suction filter, and use Wash with 150ml*3 methanol and dry in a vacuum oven at 50°C for 24 hours to obtain 210g of N,N-di(2-hydroxyethyl)oxamide, such as figure 1 Shown, its Tm (melting point) is 171 ℃;

[0059] (2) Weigh 176.17g (1mol) of N,N-di(2-hydroxyethyl)oxamide, 146.14g (1mol) of adipic acid, 0.0332g of tin protochloride and 0.1612g of ammonium dihydrogen phosphate and mix them evenly. Nitrogen replacement three times, in N 2 In the atmosphere, react at 200°C for 3 hours;

[0...

Embodiment 2

[0070] A preparation method of biodegradable alternating aliphatic polyester amide, the process is as follows:

[0071] (1) Preparation of straight chain oxamide diol: 225.3g (3mol) of 3-amino-1-propanol and 250ml methyl alcohol are added in the 2L three-necked flask, under mechanical stirring, pass into N 2 , and stabilize the system temperature at 20°C, then slowly add 219.2g (1.5mol) diethyl oxalate through the normal pressure funnel for about 2 hours, continue the reaction for 1.5 hours after the dropwise addition, cool to below 5°C and filter with suction, and use 150ml *3 Washed with methanol, dried in a vacuum oven at 50°C for 24 hours to obtain 229.8g of N,N-di(3-hydroxypropyl)oxamide, such as figure 1 As shown, its Tm is 166°C;

[0072] (2) Weigh 204.2g (1mol) of N,N-di(3-hydroxypropyl)oxamide, 146.14g (1mol) of adipic acid, 0.1752g of stannous octoate and 0.1752g of diammonium hydrogen phosphate, and mix them evenly under nitrogen gas permutation three times, at N ...

Embodiment 3

[0076] A preparation method of biodegradable alternating aliphatic polyester amide, the process is as follows:

[0077] (1) Preparation of straight-chain oxamide diol: 267.42g (3mol) of 4-amino-1-butanol and 250ml methanol are added in a 2L three-necked flask, under mechanical stirring, feed N2, and the temperature of the system is stabilized at 20°C, then slowly add 261.29g (1.5mol) dipropyl oxalate through the normal pressure funnel for about 2 hours, continue the reaction for 1.5 hours after the dropwise addition, cool to below 5°C and filter with suction, and wash with 150ml*3 methanol, at 50 Under vacuum oven drying at ℃ for 24 hours to obtain 283.62g N,N-two (4-hydroxybutyl) oxalamide, such as figure 1 As shown, its Tm is 172°C;

[0078] (2) Weigh 255.52g (1mol) of N,N-di(4-hydroxybutyl)oxamide, 118.1g (1mol) of succinic acid, 0.3736g of octyl stannous chloride and 0.7472g of calcium hydrogen phosphate and mix evenly, Nitrogen replacement three times, in N 2 In the at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com