Patents

Literature

44results about How to "Loose packing density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified calcium carbonate with heat-isolating heat-insulating effect and preparation method thereof

InactiveCN104031417AImprove bindingImprove insulation effectPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEpoxyEnvironmental resistance

The invention discloses a modified calcium carbonate with heat-isolating heat-insulating effect. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 5-7 parts of polyphenyl granules, 4-6 parts of hollow glass microballoons, 2-3 parts of adhesive mortar, 2-4 parts of bentonite, 2-3 parts of diatomite, 4-6 parts of epoxide resin, 5-7 parts of phenolic resin glue, 1-2 parts of polyethylene wax, 1-2 parts of zinc stearate and 3-4 parts of modified titanium dioxide. The modified calcium carbonate disclosed by the invention enhances the heat-isolating heat-insulating effect by being added with a small quantity of hollow glass microballoons with environmental-friendly heat-isolating effect and the mortar included in building materials and is enhanced in dispersing effect by being added with the modified titanium dioxide. According to the modified calcium carbonate, a filler produced through a simple production process has good binding force and is suitable for the addition application of a floor, a wall brick, a coating and the like.

Owner:淮南市精兴生物科技股份有限公司

High-temperature-resistant modified calcium carbonate and preparation method thereof

ActiveCN104087027AGood dispersionImprove thermal stabilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEnvironmental resistanceStrong binding

The invention discloses high-temperature-resistant modified calcium carbonate which is characterized by being prepared from following raw materials including, by weight, 85-90 parts of calcium carbonate, 3-4 parts of cationic starch, 1-2 parts of glutinous rice glue, 3-5 parts of magnesium hydroxide, 1-2 parts of bamboo charcoal powder, 3-4 parts of dried fallen leaf powder, 2-3 parts of barium sulfate, 5-7 parts of polyimide, 1-2 parts of polybenzimidazole, 3-5 parts of hydroxyethyl acrylate, 4-6 parts of dimethylformamide, 2-4 parts of sodium sulfide, 2-3 parts of sepiolite fibre and 3-4 parts of modified titanium dioxide. Through addition of the modified titanium dioxide, dispersibility of the calcium carbonate is enhanced. Through addition of the polyimide for coating the calcium carbonate, the calcium carbonate not only has a high-temperature-resistant performance but also is good in compatibility. A crosslinking reaction can be carried out between the polyimide and a film-forming substance in rubber, plastic and coating so that a very strong binding force is generated and product performance is not reduced. Through addition of the sepiolite fibre, the modified calcium carbonate is excellent in thermal-stability, can be decomposed naturally and is safe and environment-protective.

Owner:广州银顺环保塑料实业有限公司

Corrosion-resistant modified calcium carbonate with good comprehensive properties and preparation method of modified calcium carbonate

InactiveCN104312212AGood compatibilityCorrosion resistantPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsBetaineGluconates

The invention discloses a corrosion-resistant modified calcium carbonate with good comprehensive properties. The corrosion-resistant modified calcium carbonate with good comprehensive properties is characterized by being prepared from the raw materials in parts by weight: 90-95 parts of calcium carbonate, 4-6 parts of bisphenol A epoxy resin, 3-5 parts of alkyd resin, 2-3 parts of silicon carbide, 3-3.5 parts of pelelith powder, 2-2.5 parts of zinc carbonate, 1-2 parts of asbestos, 2-3 parts of glass powder, 3-5 parts of polytetrafluoroethylene, 1-2 parts of glycine betaine, 0.8-1.3 part of zinc gluconate and 3-4 parts of modified titanium dioxide. The corrosion-resistant modified calcium carbonate with good comprehensive properties has the characteristic of good compatibility of a high-molecular polymer and also has the characteristic of corrosion resistance because silicon carbide, the pelelith powder, the glass powder, polytetrafluoroethylene and the like are added to cover and modify calcium carbonate; as a result, modified calcium carbonate is high in binding force, and can be used as an industrial filler without reducing the comprehensive properties of the product.

Owner:ANHUI SHENGJIA COLOR PRINTING PACKING

Smooth-type surface-modified calcium carbonate and preparation method thereof

InactiveCN104087026AIncrease brightnessImprove moisture resistancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolyvinyl chlorideStrong binding

The invention discloses a smooth-type surface-modified calcium carbonate and preparation method thereof. The smooth-type surface-modified calcium carbonate is characterized by being prepared from following raw materials, by weight, 85-90 parts of calcium carbonate, 1-2 parts of octaphenyl polyethenoxy ether, 3-5 parts of isopropanol, 1-1.5 parts of polydimethylsiloxane, 1-2 parts of a silane coupling agent kh-570, 5-7 parts of polyurethane resin, 4-6 parts of polyvinyl chloride, 1-2 parts of sodium carbonate, 0.8-1.2 parts of bis(2-dimethylaminoethyl)ether, 2-4 parts of nanometer zinc oxide, 2-3 parts of hectorite powder and 3-4 parts of modified titanium dioxide. Through addition of a surfactant and oil-based substances to calcium carbonate, a bright degree and an anti-damp performance of the calcium carbonate is enhanced. A high-molecular polymer is used for surface modification on the surface of the calcium carbonate. Because a plurality of active groups exist, the surface-modified calcium carbonate has a relative good compatibility with various substances and a strong binding force is generated so that a product, which employs the surface-modified calcium carbonate as filling materials, is not reduced in performances. In addition, through addition of the modified titanium dioxide, a dispersing performance is improved.

Owner:广西民泰纳米科技有限公司

High-dispersity modified calcium carbonate and preparation method thereof

InactiveCN104031418AGood dispersionReasonable formulaPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsCross-linkDispersity

The invention discloses high-dispersity modified calcium carbonate which is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 1-2 parts of a dispersing agent NNO, 4-6 parts of itaconic acid, 5-6 parts of diacetone acrylamide, 1-2 parts of dibutyltin maleate, 4-6 parts of poly(butylene succinate), 2-3 parts of poly(aluminum chloride), 2-4 parts of mica powder, 2-4 parts of easily dispersed fibers, 2-3 parts of straw ash and 3-4 parts of modified titanium dioxide. According to high-dispersity modified calcium carbonate, a formula is reasonable, a production process is simple, the easily dispersed fibers with excellent dispersion performance and modified titanium dioxide are added, the surface of calcium carbonate is modified with macromolecular polymers, unsaturated double bonds in modified calcium carbonate can be subjected to cross-linking reaction together with film-forming substances in rubber, plastics and coatings to generate very strong bonding force, the product performance still cannot be reduced even if a large quantity of modified calcium carbonate is added, and modified calcium carbonate is used for products of plastic additives, pigments, coating aids and the like.

Owner:重庆市琪馨建筑材料有限公司

High-density modified calcium carbonate and preparation method thereof

ActiveCN104031419AHigh densityHigh strengthPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsFiberEpoxy

The invention discloses a high-density modified calcium carbonate which is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of heavy calcium carbonate, 2-4 parts of porcelain clay, 2-3 parts of talcum powder, 2-3 parts of cationic starch, 4-6 parts of urea-formaldehyde resin, 5-7 parts of high-density polyethylene, 3-5 parts of epoxy butyl oleate, 2-3 parts of stearic acid, 1-2 parts of sodium oleate, 2-3 parts of polypropylene staple fibers, 2-2.5 parts of clam shell powder, 3-4 parts of waste rubber powder and 3-4 parts of modified titanium dioxide. The high-density modified calcium carbonate disclosed by the invention is reasonable in formula and simple in production process, enhances the dispersibility by being added with the modified titanium dioxide, is good in product flowability and difficult to adhere, enhances the density and strength of fillers by adopting organic and inorganic matched coating, is good in generated binding force, can not reduce the original mechanical property of a product by being used in large quantities and is low in cost and favorable to popularize and use.

Owner:宁远华创粉体材料有限公司

Modified calcium carbonate having adsorption effect and preparation method thereof

ActiveCN104084175APorousImprove adsorption capacityOther chemical processesPigment treatment with macromolecular organic compoundsFiberPorosity

The invention discloses modified calcium carbonate having an adsorption effect and a preparation method thereof. The modified calcium carbonate is characterized by being prepared from following raw materials comprising, by weight, 90-95 parts of calcium carbonate, 2-3 parts of zeolite molecular sieve, 2-4 parts of wood fiber, 3-4 parts of crushed pine barks, 2-3 parts of azodicarbonamide, 3-4 parts of zircon powder, 2-4 parts of vermiculite powder, 1-1.5 parts of zinc stearate, 4-6 parts of dibutyl phthalate, 4-5 parts of smoked sheet, 5-7 parts of polyvinyl chloride powder and 3-4 parts of modified titanium dioxide. With addition of various natural substances having adsorption functions, such as zeolite molecular sieve, crushed pine barks and vermiculite powder and the like, and addition of foamable components, such as azodicarbonamide, zinc stearate and the like, a surface of the calcium carbonate has porosity and the adsorption effect of the calcium carbonate is enhanced. In addition, the surface of the calcium carbonate is modified by high-molecular polymer so that the modified calcium carbonate has a high-molecular polymer layer and is good in binding force. The modified calcium carbonate is suitable for being used as an additive in environment-protective coating, pigment and building materials.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Modified calcium carbonate with oil-resistant and corrosion-resistant effect and preparation method thereof

ActiveCN104073028AReasonable formulaImprove oil resistancePigment treatment with macromolecular organic compoundsPigment physical treatmentCorrosion resistantCarbon black

The invention discloses modified calcium carbonate with an oil-resistant and corrosion-resistant effect. Modified calcium carbonate is characterized in that modified calcium carbonate is prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 3-5 parts of hollow micro-bead, 2-2.5 parts of white carbon black, 2-3 parts of coarse aggregate, 3-5 parts of coumarone, 5-7 parts of fluororubber, 4-6 parts of butadiene-acrylonitrile rubber, 0.8-1.2 parts of promoter Na-22, 1-2 parts of antioxidant DLTP (dilauryl thiodipropionate), 5-7 parts of polyurethane, 2-4 parts of sepiolite, 2-3 parts of silicon deoxide and 3-4 parts of modified titanium dioxide. High-molecular fluororubber is added to coat the surface of modified calcium carbonate; modified calcium carbonate disclosed by the invention is reasonable in formula, oil-resistant and corrosion-resistant, is assisted by white carbon black so as to increase the oil resistance, is added with an antioxidant component and modified titanium dioxide so as to increase the dispersing performance, and has good flowability and relatively strong binding force; a filling material can be used as an auxiliary agent for plastics, rubber and paper-making; modified calcium carbonate is low in cost.

Owner:淮南市精兴生物科技股份有限公司

Modified calcium carbonate serving as sound absorbing filler and preparation method thereof

ActiveCN104031416AHas sound-absorbing effectImprove sound absorptionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsFiberBrick

The invention discloses modified calcium carbonate serving as a sound absorbing filler. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 4-6 parts of nanometer hollow microspheres, 3-5 parts of aluminum silicate fiber cotton, 3-4 parts of zizania aquatica straw powder, 2-4 parts of expanded perlite, 3-4 parts of activated aluminum oxide, 2-3 parts of ammonium carbonate, 6-8 parts of polycarbonate, 5-6 parts of natural latex, 1-2 parts of alpha-vinyl sodium sulfonate and 3-4 parts of modified titanium dioxide. The modified calcium carbonate disclosed by the invention has excellent sound absorption performance due to addition of the nanometer hollow microspheres and the aluminum silicate fiber cotton, has a large specific surface area as well as sound absorption and adsorption effects due to addition of plant fibers and natural substances, and has increased dispersion performance due to addition of the modified titanium dioxide, so the modified calcium carbonate is applicable to production of additives including sound absorbing bricks, sound absorbing plates, coatings and the like.

Owner:广西贺州市科隆粉体有限公司

Modified calcium carbonate with high specific surface area and preparation method thereof

ActiveCN104059390AGood mechanical propertiesGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolyesterTurpentine

The invention discloses a modified calcium carbonate with a high specific surface area. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90 to 95 parts of calcium carbonate, 4 to 6 parts of methyl methacrylate, 5 to 7 parts of melamine resin, 3 to 4 parts of propanediol sebacate polyester, 2 to 3 parts of cocoanut active charcoal, 2 to 3 parts of coal ash, 1 to 1.5 parts of ammonium bicarbonate, 2 to 3 parts of turpentine, 1 to 2 parts of polysorbate 80 and 2.5 to 3.5 parts of modified titanium dioxide. Based on the improvement of a production process, the calcium carbonate has the good mechanical property; the modified titanium dioxide is added after the calcium carbonate is ground, so that the dispersion effect of the calcium carbonate is increased. The granularity of the modified calcium carbonate is refined, so that the modified calcium carbonate has the high specific surface area so as to increase an absorption effect. The modified calcium carbonate is stable in quality and low in production cost, thereby being suitable for serving as various industrial filling materials.

Owner:CHIZHOU CELT NANO TECH

Preparation process of modified calcium carbonate with good dispersibility

InactiveCN107400258ASimple preparation processEasy to operatePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDiethylenetriamineImpurity

The invention discloses a preparation process of modified calcium carbonate with good dispersibility. The modified calcium carbonate with good dispersibility is prepared from the following raw materials: calcium carbonate crushing substances, grinding aids, sodium dodecyl benzene sulfonate, zinc isoocatanoate, molecular sieve based catalysts, diethylenetriamine sodium pentacarboxylate, regulating agents, 3-aminopropyltriethoxysilane, phthalandione bis(2-ethyl hexyl)ester, modified polyacrylic ester, hexenyl distearamide, 2-(2'-hydroxyl-3',5'-di-tert-butylbenzene)-5-chloridized benzotriazole, polyacrylamide and stabilizing agents. The modified calcium carbonate with good dispersibility is prepared through the steps of stone material cleaning, impurity removal, water removal, crushing, grinding, surface modification, performance regulation, pulverization, drying and the like. The preparation process provided by the invention is simple; the operation is convenient; the industrialization can be easily realized; the produced modified calcium carbonate is applicable to plastics and the like.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Surface treated calcium carbonate powder and preparation method thereof

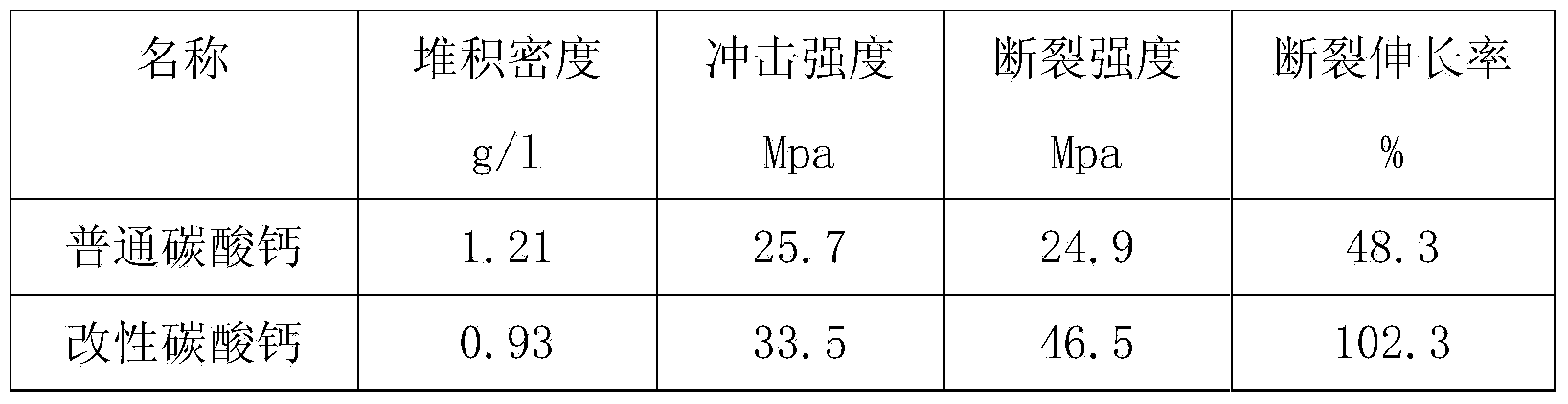

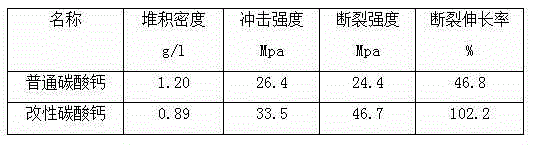

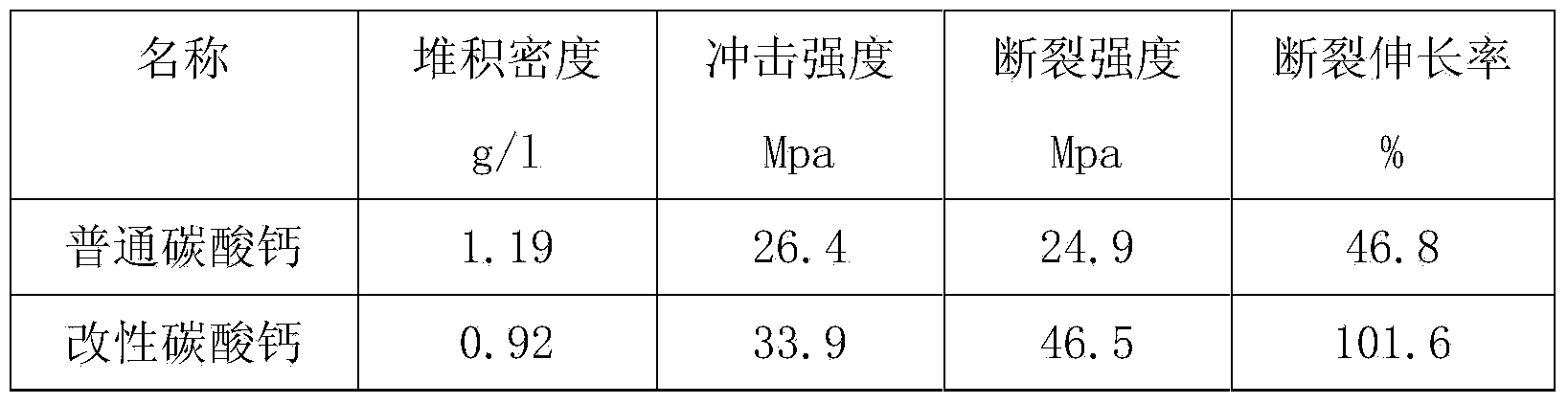

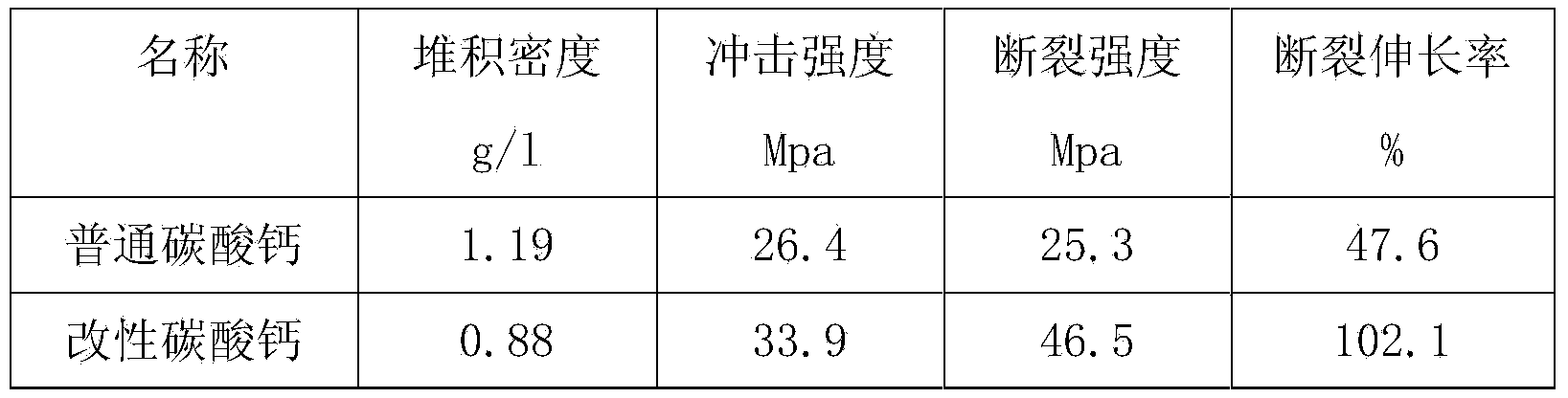

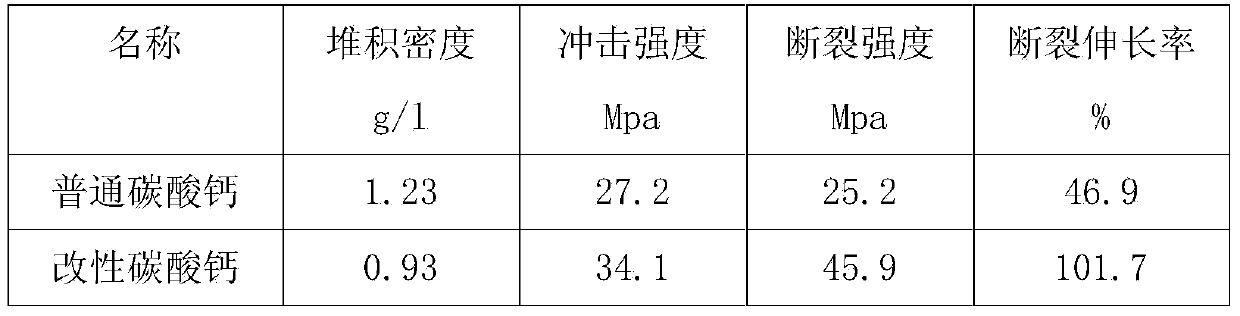

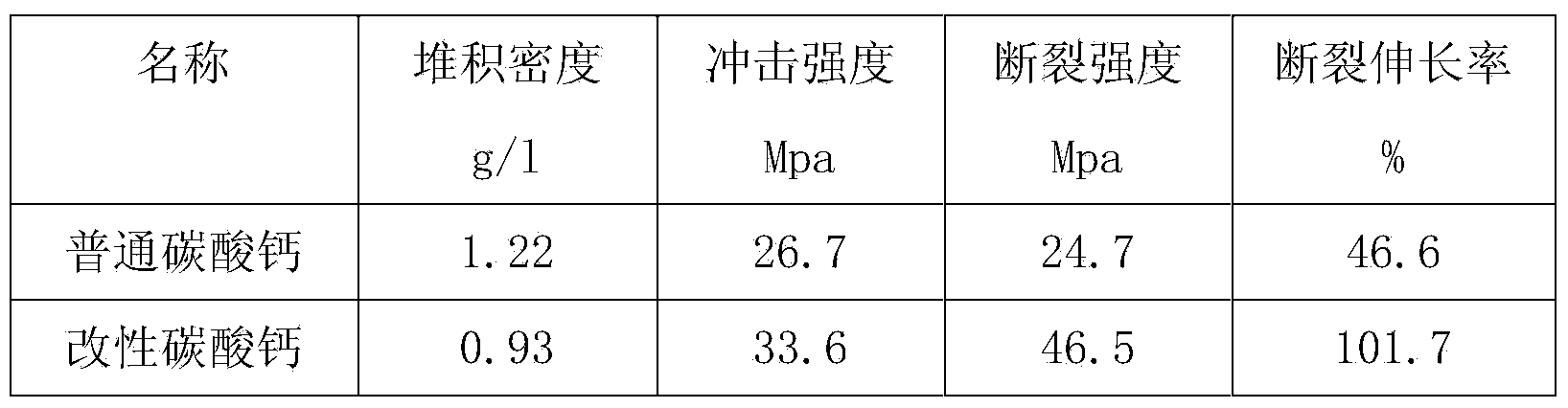

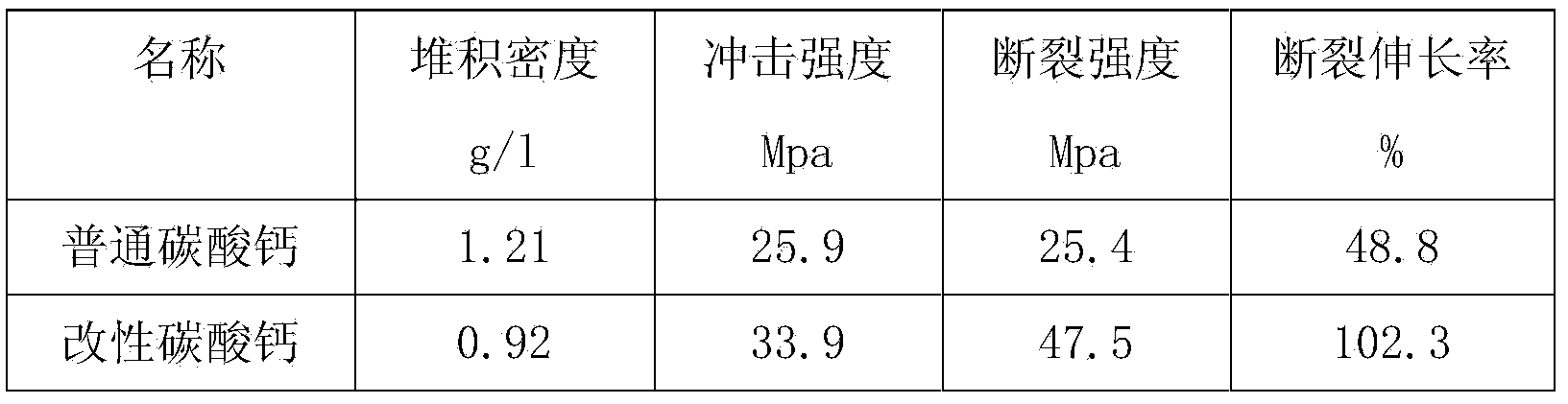

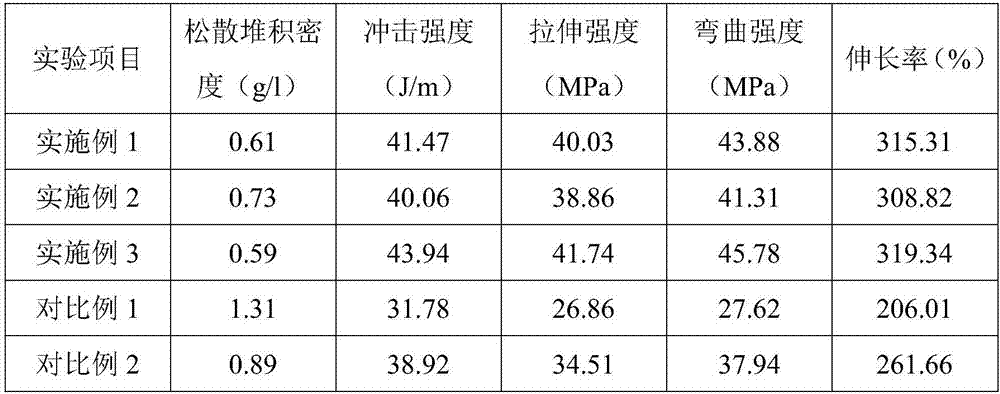

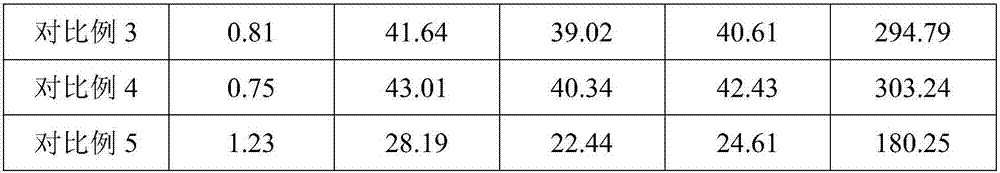

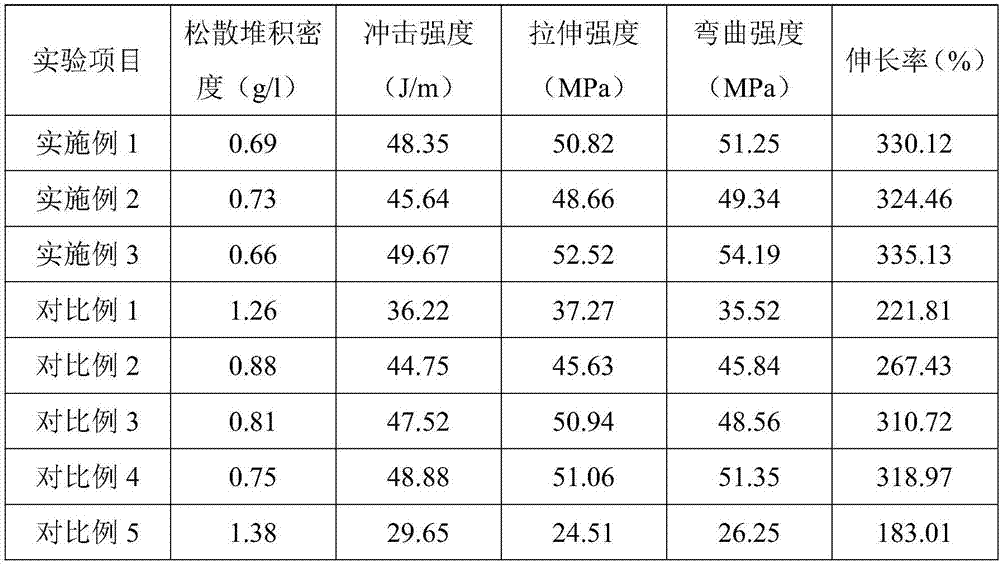

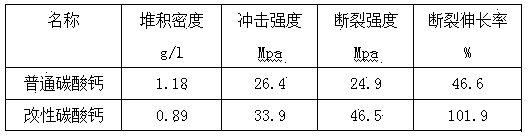

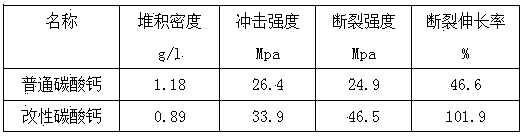

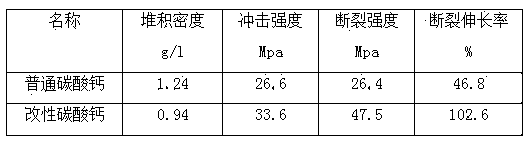

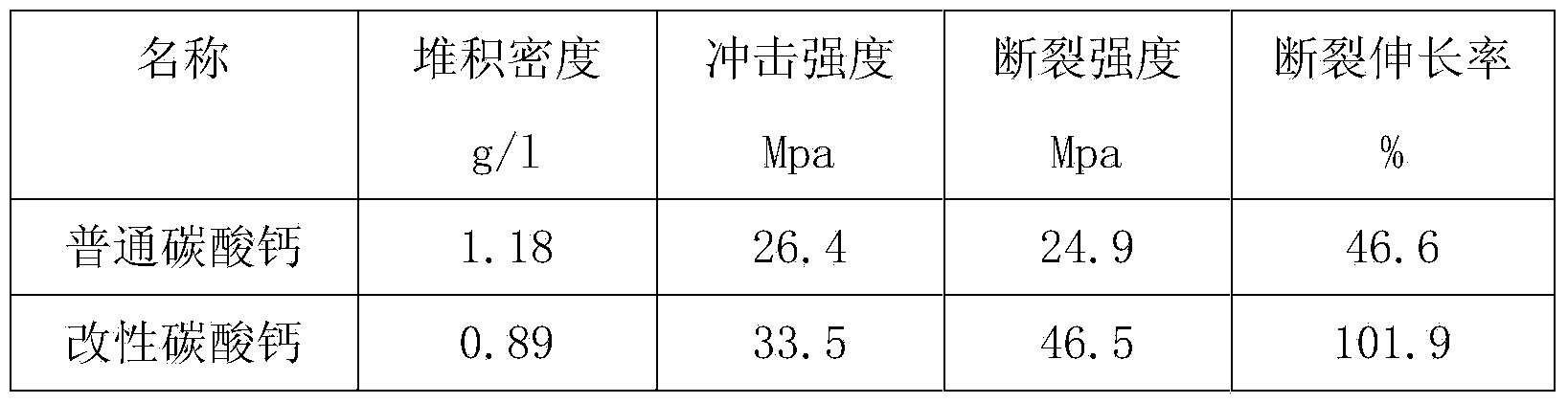

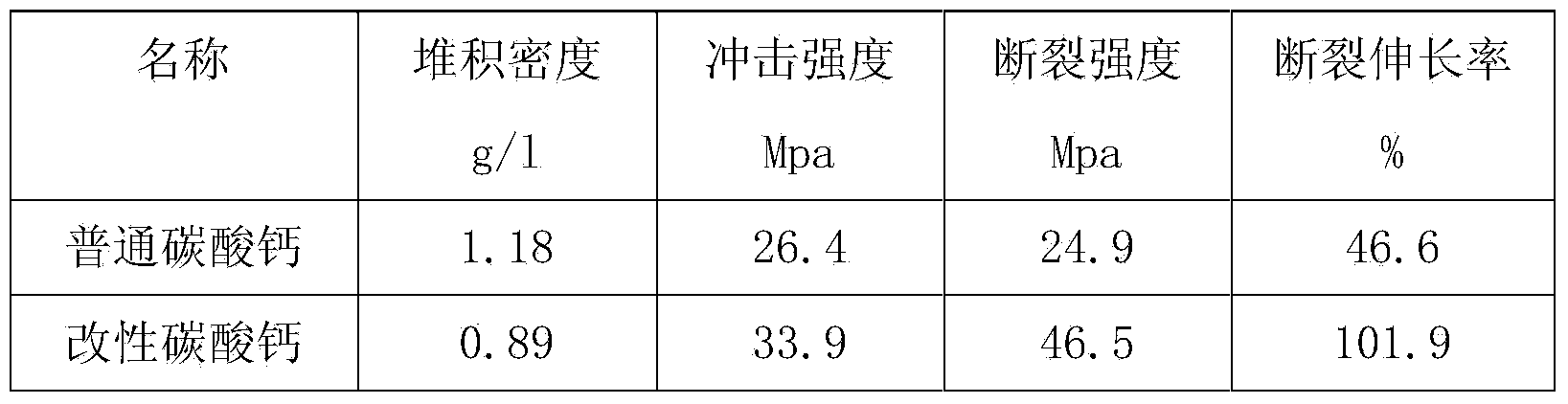

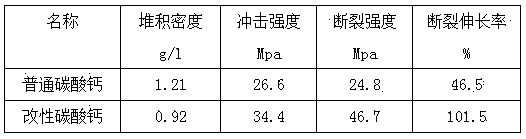

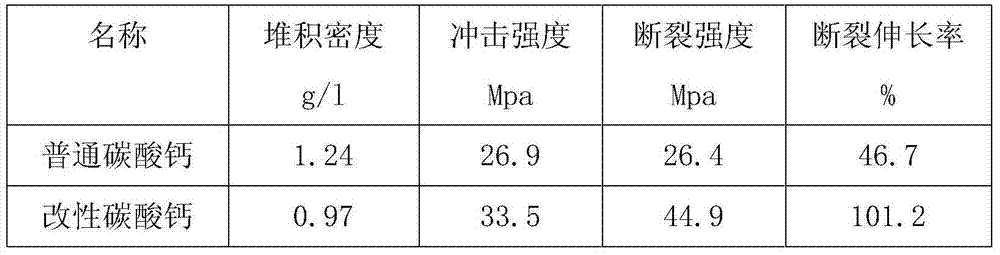

InactiveCN107446382ALoose packing densityImprove mechanical propertiesPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityMechanical property

The invention discloses surface treated calcium carbonate powder and a preparation method thereof. The surface treated calcium carbonate powder is prepared from the following raw materials of broken calcium carbonate, a grinding aid, sodium dodecyl sulfate, aluminum acetylacetonate, magnesium oxide, diethylene triamine sodium pentacarboxylate, a modifier, 3-aminopropyltriethoxysilane, phthalandione bis(2-ethyl hexoate) ester, modified polyacrylate, hexenyl distearamide, 2-(2'-hydroxyl-3',5'-ditert phenyl)-5-benzotriazole chloride, polyacrylamide and a stabilizer. The surface treated calcium carbonate powder is prepared by the steps of stone cleaning, removing impurities, dewatering, breaking, grinding, surface modifying, performance adjusting, smashing, drying and the like. The surface treated calcium carbonate powder disclosed by the invention can be fully dispersed, has small agglomeration after being added into plastic and has good dispersity, and all items of mechanical property of modified calcium carbonate are all remarkably improved.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Modified calcium carbonate with enhanced wear resistance and preparing method thereof

ActiveCN104087025AReduce external frictionAchieving wear resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEpoxyWear resistant

A modified calcium carbonate with enhanced wear resistance is disclosed. The modified calcium carbonate is characterized in that: the modified calcium carbonate is prepared from raw materials 85-90 parts by weight of calcium carbonate, 2-3 parts by weight of quartz powder, 5-7 parts by weight of epoxy resin, 4-6 parts by weight of glycerol triacetate, 6-8 parts by weight of nylon 66, 3-4 parts by weight of molybdenum disulfide, 2-3 parts by weight of copper oxide, 2-3 parts by weight of smashed nut shell, 1-1.5 parts by weight of high-wear-resistance carbon black, 2-3 parts by weight of brown aluminium oxide, 4-6 parts by weight of turpentine, 2-4 parts by weight of liquid paraffin and 3-4 parts by weight of modified titanium dioxide; by addition of the high-wear-resistance carbon black, the molybdenum disulfide and other wear-resistant lubricants, a filling material has a self-lubricating property so as to reduce external friction, thus achieving an effect of wear resistance; and by adoption of the modified titanium dioxide, the dispersion property and the compatibility are enhanced, thus generating strong binding force and not reducing the comprehensive properties of products. The modified calcium carbonate is used as additives for plastics, rubber and coating, and the like.

Owner:浙江环星纳米科技有限公司

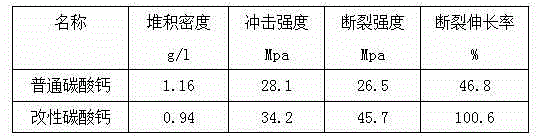

Application of modified calcium carbonate in quartz stone plates

The invention discloses an application of modified calcium carbonate in quartz stone plates. A quartz stone plate comprises the following raw materials in parts by weight: 25-36 parts of modified calcium carbonate, 8-20 parts of a methyl phenyl silicone resin prepolymer, 32-45 parts of an inorganic silicon filler and 10-30 parts of an auxiliary agent. The quartz stone plate is prepared by compression moulding by using the modified calcium carbonate, the methyl phenyl silicone resin prepolymer, the inorganic silicon filler and the auxiliary agent in a corresponding proportion. The modified calcium carbonate is added into the quartz stone plate, has small probability of agglomeration phenomenon, and has good dispersibility, and the various mechanical properties of the modified calcium carbonate are increased notably.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Surface-treated modified calcium carbonate and preparation method thereof

ActiveCN104059391AGood compatibilityImprove bindingPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsFiberMullite

The invention discloses a surface-treated modified calcium carbonate. The invention is characterized in that the surface-treated modified calcium carbonate is prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 1-2 parts of glyceryl tristearate, 1.5-2.5 parts of polyaspartic acid, 3-5 parts of rosin resin, 4-6 parts of nylon 66, 1-1.5 parts of palmitic acid, 2-3 parts of pulverized monkey grass, 2-3 parts of mullite, 1-2 parts of hydroxypropyl cellulose, 0.8-1 part of titanate coupling agent TC-WT and 2.5-3.5 parts of modified titanium dioxide. The calcium carbonate surface is modified by the high-molecular polymer, so that the calcium carbonate has the high-molecular polymer layer; the calcium carbonate has many active groups, and thus, has favorable compatibility with many substances. For example, the unsaturated double bond can generate crosslinking reaction with the film-forming matters in the rubber, plastic and paint to generate very strong binding force, and the use of abundant calcium carbonate as the filler can not lower the properties of the product.

Owner:CHIZHOU CELT NANO TECH

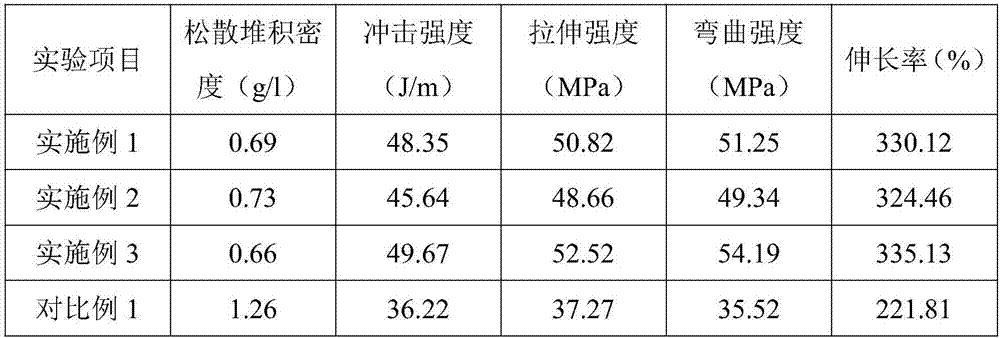

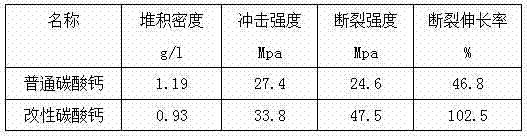

High-performance calcium carbonate used for stone slabs and preparation method of high-performance calcium carbonate

The invention discloses high-performance calcium carbonate used for stone slabs and a preparation method of the high-performance calcium carbonate. The high-performance calcium carbonate used for stone slabs comprises the following raw materials: a calcium carbonate crushed matter, a grinding aid, dioctyl succinic acid sodium sulfonate, stannous chloride, magnesium oxide, pentasodium DTPA, a modifier, 3-aminopropyltriethoxysilane, bis(2-ethylhexyl) phthalate, modified polyacrylate, ethylene bis(stearamide), 2-(2'-3-hydroxy-3',5'-di-tert-phenyl)-5-benzotriazole chloride, polyacrylamide and a stabilizer. The high-performance calcium carbonate is prepared according to the steps of stone slab cleaning, impurity removal, water removal, crushing, grinding, surface modification, performance adjustment, smashing, drying and the like. The high-performance calcium carbonate used for stone slabs is added into the stone slabs, little agglomeration occurs, the dispersibility is good, and the mechanical properties are obviously improved.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Modified calcium carbonate with flame-retardant effect and preparation method thereof

InactiveCN104356690ANo wasteGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersityIsooctyl acrylate

The invention discloses modified calcium carbonate with a flame-retardant effect. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 3-5 parts of carbide slag powder, 3-4 parts of vermiculite powder, 2-4 parts of antimonous oxide, 1-2 parts of asbestos fibers, 2-3 parts of zinc borate, 2-4 parts of ground nutshells, 6-8 parts of iso-octyl acrylate, 5-7 parts of acetyl citrate, 3-5 parts of EVA (ethylene vinyl acetate) wax, 1-2 parts of bromobisphenol a and 3-4 parts of modified titanium dioxide. According to modified calcium carbonate, flame-retardant components such as antimonous oxide and zinc borate are added for coating, and modified titanium dioxide is added after grinding, so that the dispersity is good and the cost increment due to raw material waste cannot be caused; fillers are used for producing assistants such as coatings, pigments and rubber.

Owner:安徽温禾新材料科技股份有限公司

Modified calcium carbonate with enhanced anti-aging effect and preparation method thereof

InactiveCN104387801AHigh strengthImprove bindingPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsButylated hydroxytolueneTert butyl

Disclosed modified calcium carbonate with enhanced anti-aging effect is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 1-2 parts of anti-ageing agent NBC, 6-8 parts of nitrile rubber, 5-6 parts of PVC waste material, 2-3 parts of calcined loess powder, 1-2 parts of 2,6-d-tert-butyl-4-methylphenol, 2-3 parts of tri-hexyl tri-meta-benzoate, 1-2 parts of tetramethylthiuram disulfide, 1-1.5 parts of tung oil, 1-2 parts of vegetable wax, and 3-4 parts of modified titanium dioxide. 2,6-d-tert-butyl-4-methylphenol and other anti-ageing agents and multiple high-molecular polymers are added for coating, the modified calcium carbonate is large in strength and good in binding force, and is increased in dispersing effect by adding modified titanium dioxide. The modified calcium carbonate is reasonable in formula, simple in production technology and low in cost, and is suitable for producing various industrial auxiliary agents.

Owner:安徽温禾新材料科技股份有限公司

Electrical-conductive modified calcium carbonate and preparation method thereof

InactiveCN104327550AConductiveGood compatibilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsCelluloseGraphite

The invention discloses electrical-conductive modified calcium carbonate which is characterized by being prepared from following raw materials including, by weight, 85-95 parts of calcium carbonate, 2-3 parts of silicon carbide, 3-5 parts of aluminum powder, 2-3 parts of graphite, 2-4 parts of precipitated white carbon black, 1-2 parts of copper sulfate, 3-4 parts of thick-hole silica gel, 2-4 parts of cellulose nitrate, 2-3 parts of crushed melia azedarach seeds, 7-9 parts of ABS resin powder, 5-7 parts of urea resin, 4-6 parts of Nadic anhydride and 3-4 parts of modified titanium dioxide. In the invention, the calcium carbonate is coated by electrical-conductive substances, such as the aluminum powder, the graphite and the like, and a high-molecular polymer so that the calcium carbonate has an electrical-conductivity and an excellent compatibility. In addition, by means of the crushed melia azedarach seeds and modified titanium dioxide and the like, the modified calcium carbonate is excellent in dissipating property, is good in binding force and is free of reducing performance of products when being employed as a filling material.

Owner:ANHUI SHENGJIA COLOR PRINTING PACKING

Multi-purpose ultrafine modified calcium carbonate and preparation method thereof

InactiveCN104312211AAvoid wastingEvenly dispersedPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsChemistryLignosulfonates

The invention discloses multi-purpose ultrafine modified calcium carbonate which is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of light calcium carbonate, 6-8 parts of ethylene-propylene-diene-terpolymer rubber, 2-3 parts of zinc stearate, 1-2 parts of ferrocene, 2-3 parts of glycerin monostearate, 1-1.5 parts of cetanol, 1-2 parts of tween 80, 2-4 parts of epoxy caster oil, 2-3 parts of quartz powder, 6-8 parts of acetal homopolymer, 1-2 parts of lignosulfonate and 3-4 parts of modified titanium dioxide. By adopting a special production process, such surfactants as glycerin monostearate and oily substances are added in the grinding process and are ground and dispersed uniformly. Modified titanium dioxide is added after being ground, so that the waste of raw materials is avoided and the cost is lowered. The ultrafine packing disclosed by the invention is suitable for production of functional products such as a functional paper auxiliary, a preservative film auxiliary, a pigment or coating additive and the like.

Owner:ANHUI SHENGJIA COLOR PRINTING PACKING

Hydrophobic lipophilic surface-modified calcium carbonate and preparation method thereof

ActiveCN104130593AAct quicklyPlay the role of cross-linkingPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsTarTitanium tetrachloride

Disclosed hydrophobic lipophilic surface-modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 2-3 parts of glass fiber, 5-7 parts of polylactic acid, 2-3 parts of polydimethylsiloxane, 3-5 parts of epoxidized triglyceride, 3-5 parts of silica sol, 1-1.5 parts of wood tar, 2-3 parts of titanium tetrachloride, 2-3 parts of expanded perlite, and 2.5-3.5 parts of modified titanium dioxide. By adding polydimethylsiloxane, expanded perlite, wood tar and other hydrophobic waterproof compositions and oily high-molecular polymers, the surface of calcium carbonate is changed into hydrophobicity from hydrophilicity, the effect of calcium carbonate with a polymer interface is enhanced, and a modified unsaturated bond gives play to crosslinking effect during processing with a polymer. The hydrophobic lipophilic surface-modified calcium carbonate can be used to fill plastic, rubber, adhesives and the like.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Modified calcium carbonate with hydrophobic, oleophylic and moistureproof effects and preparation method thereof

InactiveCN104356691AImprove surface propertiesGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityPotassium oleate

The invention discloses modified calcium carbonate with hydrophobic, oleophylic and moistureproof effects. The modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 2-3 parts of hectorite, 3-4 parts of dried fallen leaf powder, 2-2.5 parts of dimethyl silicon oil, 4-6 parts of alkyl ketene dimer, 2-3 parts of soybean oil, 1-2 parts of Span 80, 4-5 parts of smoke sheet rubber, 2-2.5 parts of potassium oleate, 5-7 parts of methyl isocyanurate and 3-4 parts of modified titanium dioxide. According to modified calcium carbonate, various oily materials are added and a water-in-oil surfactant is used for coating, so that modified calcium carbonate is good in surface performance, hydrophobic and oleophylic; modified titanium dioxide is added, so that modified calcium carbonate is good in dispersity; in addition, modified calcium carbonate is waterproof, moistureproof and suitable for coatings, pigments, papermaking assistants and the like, and a production process is simple and low in cost.

Owner:ANHUI SHENGJIA COLOR PRINTING PACKING

Modified calcium carbonate with wide applicable strength and preparation method thereof

InactiveCN104031420AReasonable formulaSimple production processPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsZinc hydroxideGlycerol

The invention discloses modified calcium carbonate with wide applicable strength. The applicable modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 3-4 parts of zinc hydroxide, 5-7 parts of butadiene styrene rubber, 2-3 parts of carbon black, 2-4 parts of smectite flour, 2-3 parts of kaolin, 2-4 parts of magnesium silicate, 1-2 parts of antiager RD, 4-6 parts of glycerol triglycerin acid ester, 4-6 parts of polyvinyl acetate, 2-3 parts of dispersible rubber powder and 3-4 parts of modified titanium dioxide. The modified calcium carbonate is reasonable in formula, and simple in production technology, the toughness of a cellulosic fiber is enhanced by reinforcing action on the carbon black, and the modified titanium dioxide is added to coat after the grinding process, so that not only is the dispersibility increased, but also raw materials are saved, and the cost is reduced. The packing disclosed by the invention can be conveniently applied to plastic, rubber, coatings and the like.

Owner:GUANGDONG YUFENG POWDER MATERIAL

Waterproof fireproof modified calcium carbonate and preparation method thereof

ActiveCN104130596AGood dispersionThe surface of the product is smooth and flatPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsEpoxyFiber

Disclosed waterproof fireproof modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 4-6 parts of styrene-maleic anhydride copolymer, 2-3 parts of glass fiber, 3.5-5.5 parts of epoxy resin glue, 2-3 parts of antimony trioxide, 2-3 parts of sepiolite fiber, 0.8-1.2 parts of titanate coupling agent TC-114, 3-5 parts of ethyl silicate, 1-2 parts of trioctyl phosphate, and 2.5-3.5 parts of modified titanium dioxide. According to the modified calcium carbonate, glass fiber, ethyl silicate, trioctyl phosphate and other flame-retardant fireproof raw materials and oily waterproof raw materials are added, and modified titanium dioxide is added, so that the dispersing effect is increased. The modified calcium carbonate is usable as a building filling material. A produced product is smooth and flat in surface and excellent in mechanical properties. The waterproof fireproof modified calcium carbonate has good social popularization value.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Modified calcium carbonate with good elasticity and preparation method thereof

ActiveCN104130592AImprove rigidityIncrease elasticityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSlagPolyvinyl chloride

Disclosed modified calcium carbonate with good elasticity is characterized by being prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 5.5-7 parts of polyvinyl chloride, 5-7 parts of transparent ABS, 4-6 parts of synthetic rubber, 2-3 parts of calcium carbide slag, 1.5-2.5 parts of crude aggregate, 3-5 parts of teflon, 2-3 parts of cationic starch, 2-3 parts of sulfonated lignin, and 2.5-3.5 parts of modified titanium dioxide. By adding transparent ABS and other macromolecular compounds, synthetic rubber and the like into calcium carbonate, calcium carbonate is substantially improved in rigidity, elasticity and stability, also has the characteristics of toughening, reinforcing and relatively good strength, and also is reduced in cost. The provided preparation method is simple and convenient to operate, and is easy to industrialize. The produced filling material is applicable to coatings, rubber, plastic and the like.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Safe, environment-friendly and nontoxic modified calcium carbonate and preparation method thereof

InactiveCN104031293ACause waste of resourcesImprove bindingPigment treatment with macromolecular organic compoundsFiberPolyphenol

The invention discloses a safe, environment-friendly and nontoxic modified calcium carbonate and a preparation method thereof. The modified calcium carbonate is prepared from the following raw materials in parts by weight: 90 to 95 parts of calcium carbonate, 2 to 3 parts of clam shell power, 2 to 3 parts of smashed yellow cinnamon leaves, 4 to 5 parts of alkenyl succinic anhydride, 2 to 3 parts of porous starch, 1 to 2 parts of sodium hyaluronate, 2 to 4 parts of easy-to-disperse fibers, 2 to 3 parts of urea, 4 to 6 parts of potash feldspar powder, 5 to 7 parts of high density polyethylene, 4 to 6 parts of nylon 66, 1 to 2 parts of tea polyphenol and 3 to 4 parts of modified titanium dioxide. The formula of the modified calcium carbonate is formed by adopting environment-friendly raw materials, so that the utilization of waste materials is realized, i.e., the waste of resources is avoided; a large quantity of safe and nontoxic components are added; the surface of the calcium carbonate is modified by utilizing the high-molecular polymers, so that the modified calcium carbonate has a high-molecular polymer layer. Thus, the bonding force of the modified calcium carbonate is enhanced while the performance of the modified calcium carbonate is not decreased. The modified calcium carbonate disclosed by the invention is applied to the production of preservative film aids, degradable plastics additives, pigment or paint additives and other functional products.

Owner:淮南市精兴生物科技股份有限公司

Environmental-friendly modified calcium carbonate with delicate fragrance and preparation method thereof

InactiveCN104387800AGood dispersionGood compatibilityInorganic compound additionPigment treatment with macromolecular organic compoundsFiberDispersity

Disclosed environmental-friendly modified calcium carbonate with delicate fragrance is characterized by being prepared from the following raw materials in parts by weight: 90-100 parts of light calcium carbonate, 3-4 parts of diatomite, 1-2 parts of dipotassium glycyrrhizinate, 3-5 parts of crushed cymbopogon citratus, 2-3 parts of crushed melon seed shell, 2-4 parts of dry orange peel, 2-3 parts of crushed cortex meliae, 2-3 parts of fly ash, 3-4 parts of polylactic acid fiber, 4-6 parts of an itaconate, 4-5 parts of glycidyl acrylate, 3-4 parts of mineral oil, and 3-4 parts of modified titanium dioxide. Cymbopogon citratus, orange peel, cortex meliae and other substances with natural delicate fragrance are added when a high-molecular organic polymer is added, so that the modified calcium carbonate has relatively good compatibility, also is safe and environment-friendly, and also is assisted with modified titanium dioxide with good dispersity. The filler is suitable for producing a papermaking filler, a preservative-film auxiliary agent, a plastic auxiliary agent and the like.

Owner:安徽温禾新材料科技股份有限公司

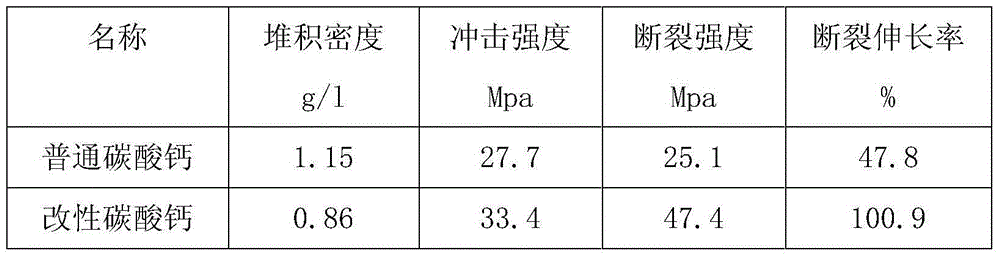

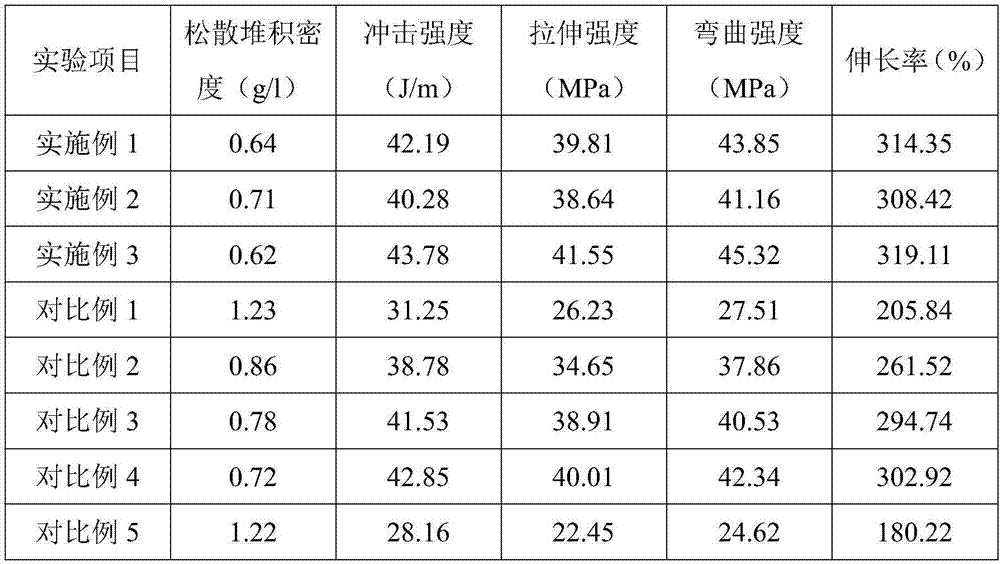

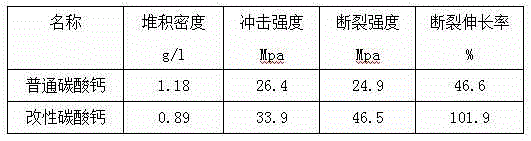

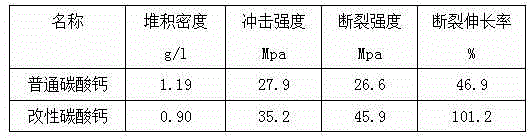

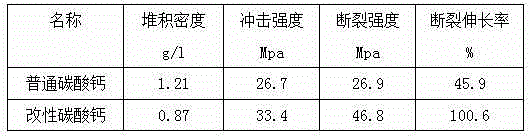

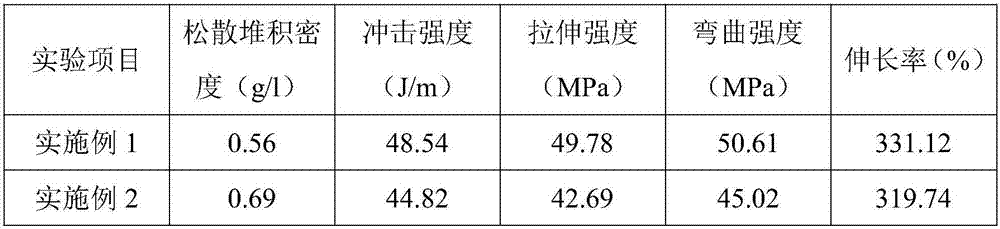

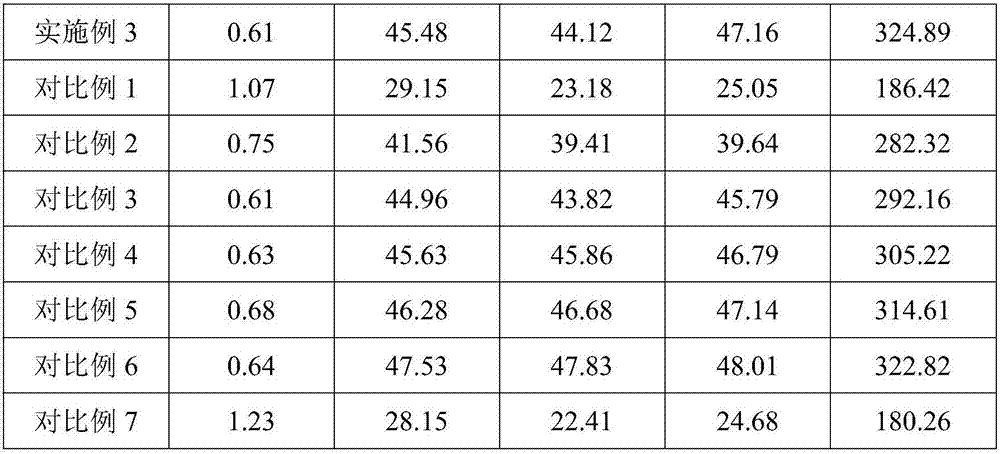

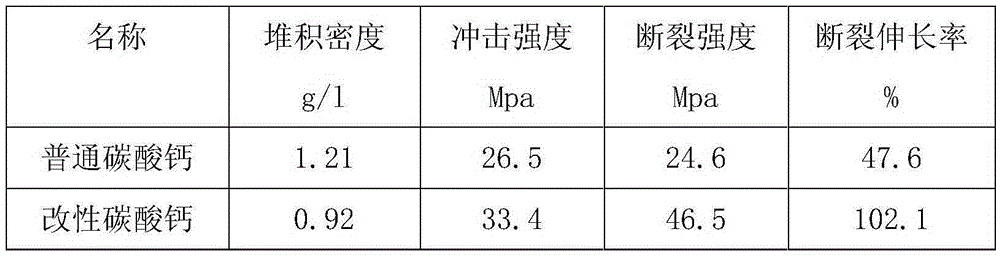

Preparation technology of modified calcium carbonate for plastic

The invention discloses a preparation technology of modified calcium carbonate for plastic. The modified calcium carbonate for the plastic is prepared from raw materials as follows: calcium carbonate, triethanolamine oleic soap, dicyclohexyl peroxydicarbonate, trimethylolpropanetris(3-aziridinylpropanoate), aluminum acetylacetonate, a catalyst, diethylenetriamine potassium pentacarboxylate, a modifier, di-iso-decylphthalate, hexenyl distearamide, 2-(2'-hydroxy-3',5-di-tert-phenyl)-5-benzotriazole chloride, N-ethyl-5-methyl-2-(1-methyl ethyl)cyclohexanecarboxamide and a stabilizer, and the modified calcium carbonate for the plastic is prepared through steps of surface modification, performance adjustment, crushing, drying and the like. The loose bulk density of modified calcium carbonate is significantly reduced, and modified calcium carbonate powder for the plastic is fully dispersed and has slight aggregation and good dispersity after being added to the plastic.

Owner:广西汇智生产力促进中心有限公司

Surface-treated modified calcium carbonate and preparation method thereof

ActiveCN104059391BGood compatibilityImprove bindingPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsFiberMullite

The invention discloses a surface-treated modified calcium carbonate. The invention is characterized in that the surface-treated modified calcium carbonate is prepared from the following raw materials in parts by weight: 85-90 parts of calcium carbonate, 1-2 parts of glyceryl tristearate, 1.5-2.5 parts of polyaspartic acid, 3-5 parts of rosin resin, 4-6 parts of nylon 66, 1-1.5 parts of palmitic acid, 2-3 parts of pulverized monkey grass, 2-3 parts of mullite, 1-2 parts of hydroxypropyl cellulose, 0.8-1 part of titanate coupling agent TC-WT and 2.5-3.5 parts of modified titanium dioxide. The calcium carbonate surface is modified by the high-molecular polymer, so that the calcium carbonate has the high-molecular polymer layer; the calcium carbonate has many active groups, and thus, has favorable compatibility with many substances. For example, the unsaturated double bond can generate crosslinking reaction with the film-forming matters in the rubber, plastic and paint to generate very strong binding force, and the use of abundant calcium carbonate as the filler can not lower the properties of the product.

Owner:CHIZHOU CELT NANO TECH

A kind of modified calcium carbonate with enhanced wear resistance and preparation method thereof

ActiveCN104087025BReduce external frictionAchieving wear resistancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEpoxyWear resistant

A modified calcium carbonate with enhanced wear resistance is disclosed. The modified calcium carbonate is characterized in that: the modified calcium carbonate is prepared from raw materials 85-90 parts by weight of calcium carbonate, 2-3 parts by weight of quartz powder, 5-7 parts by weight of epoxy resin, 4-6 parts by weight of glycerol triacetate, 6-8 parts by weight of nylon 66, 3-4 parts by weight of molybdenum disulfide, 2-3 parts by weight of copper oxide, 2-3 parts by weight of smashed nut shell, 1-1.5 parts by weight of high-wear-resistance carbon black, 2-3 parts by weight of brown aluminium oxide, 4-6 parts by weight of turpentine, 2-4 parts by weight of liquid paraffin and 3-4 parts by weight of modified titanium dioxide; by addition of the high-wear-resistance carbon black, the molybdenum disulfide and other wear-resistant lubricants, a filling material has a self-lubricating property so as to reduce external friction, thus achieving an effect of wear resistance; and by adoption of the modified titanium dioxide, the dispersion property and the compatibility are enhanced, thus generating strong binding force and not reducing the comprehensive properties of products. The modified calcium carbonate is used as additives for plastics, rubber and coating, and the like.

Owner:浙江环星纳米科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com