Preparation process of modified calcium carbonate with good dispersibility

A technology with good dispersibility and preparation process, which can be applied in the treatment of dyed low-molecular-weight organic compounds, dyed high-molecular organic compounds, and fibrous fillers. problems such as poor performance, to achieve the effect of simple preparation process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

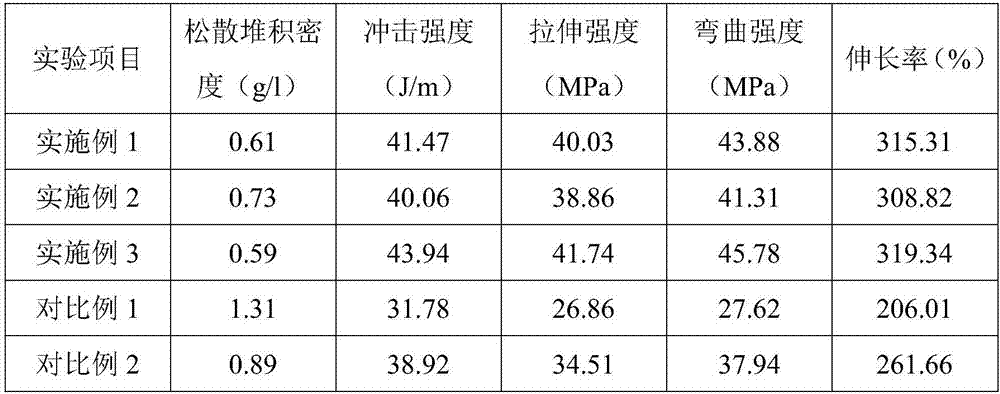

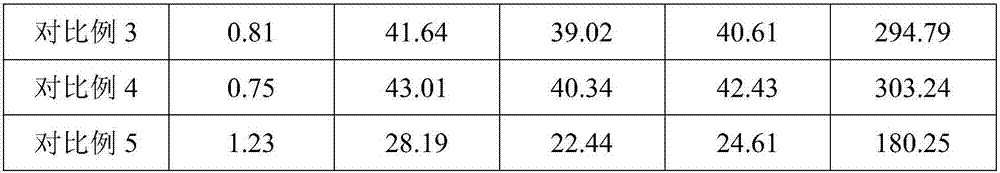

Examples

preparation example Construction

[0029] The preparation method of the good modified calcium carbonate of described dispersibility, comprises the following steps:

[0030] S1: Select marble, limestone, etc. transported from the material field to clean and remove impurities, dry the stone to remove surface moisture, and then use a crusher to crush the stone to obtain calcium carbonate fragments;

[0031] S2: transporting the broken calcium carbonate obtained in step S1 into a vertical mill and synchronously adding grinding aids and grinding to obtain calcium carbonate fine stone powder;

[0032] S3: classifying the calcium carbonate fine stone powder prepared in step S2 with a classifier to obtain calcium carbonate powder of 800-1200 mesh;

[0033] S4: Add the calcium carbonate powder prepared in step S3 into a high-speed mixer, then add sodium dodecylbenzenesulfonate, zinc isooctanoate, and a molecular sieve catalyst, heat up to 92-103°C, and set the temperature at 1100-1300r / min The speed is stirred at a hig...

Embodiment 1

[0038] A modified calcium carbonate with good dispersibility, in parts by weight, comprising the following raw materials: 142 parts of broken calcium carbonate, 4 parts of grinding aids, 3.3 parts of sodium dodecylbenzenesulfonate, 0.4 parts of zinc isooctanoate , 0.1 part of molecular sieve catalyst, 0.7 part of sodium diethylenetriaminepentacarboxylate, 0.1 part of acrylate regulator, 0.5 part of 3-aminopropyltriethoxysilane, phthalic acid di(2-ethylhexyl) 1.8 parts of ester, 0.4 part of modified polyacrylate, 0.3 part of hexenylbisstearamide, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.4 parts, 0.1 parts of polyacrylamide, 0.5 parts of calcium soap stabilizer;

[0039] The grinding aid, in parts by weight, comprises the following raw materials: 13 parts of potassium lignosulfonate, 6 parts of triethanolamine, 4 parts of zinc stearate;

[0040] The preparation method of the good modified calcium carbonate of described dispersibility, comprises the foll...

Embodiment 2

[0048] A modified calcium carbonate with good dispersibility, in parts by weight, comprising the following raw materials: 130 parts of broken calcium carbonate, 3 parts of grinding aids, 2.2 parts of sodium dodecylbenzenesulfonate, 0.2 parts of zinc isooctanoate , 0.1 part of molecular sieve catalyst, 0.5 part of sodium diethylenetriamine pentacarboxylate, 0.1 part of acrylate regulator, 0.4 part of 3-aminopropyltriethoxysilane, bis(2-ethylhexyl) phthalate 1.2 parts of ester, 0.3 part of modified polyacrylate, 0.2 part of hexenylbisstearamide, 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole 0.2 parts, 0.1 parts of polyacrylamide, 0.3 parts of calcium soap stabilizer;

[0049] The grinding aid, in parts by weight, comprises the following raw materials: 10 parts of potassium lignosulfonate, 4 parts of triethanolamine, and 3 parts of zinc stearate;

[0050] The preparation method of the good modified calcium carbonate of described dispersibility, comprises the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com