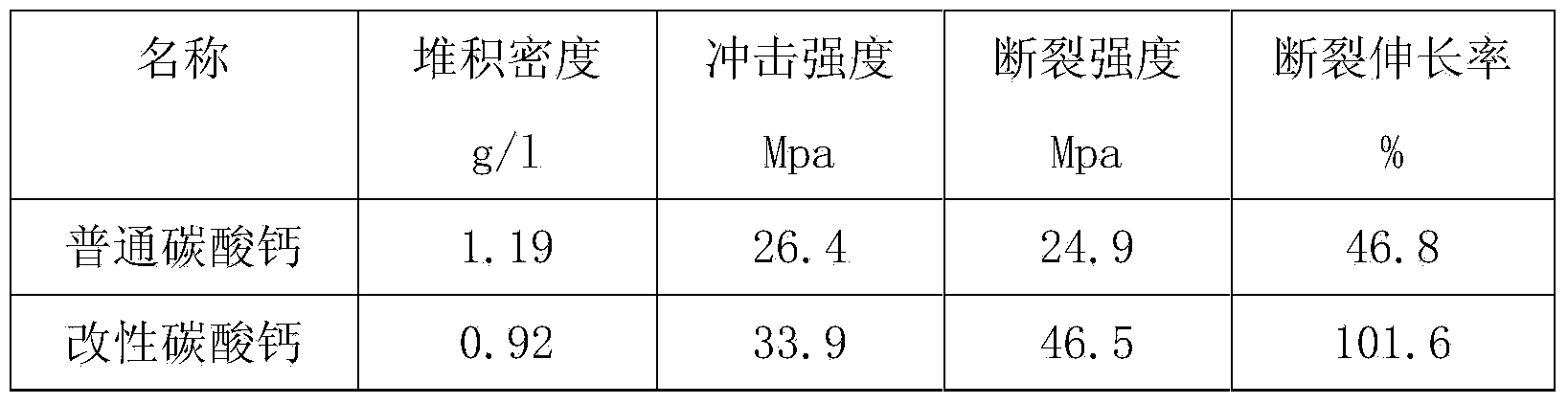

High-dispersity modified calcium carbonate and preparation method thereof

A calcium carbonate, dispersity technology, applied in chemical instruments and methods, dyed low molecular organic compound treatment, dyed high molecular organic compound treatment and other directions, can solve problems such as bubbles, defects, deformation, etc., achieve simple production process and reasonable formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] The present invention will be described in detail below through specific examples.

[0014] A modified calcium carbonate with high dispersion is prepared from the following raw materials in parts by weight (kg): calcium carbonate 85, diffusing agent NNO1, itaconic acid 4, diacetone acrylamide 5, dibutyltin maleate 1, Polybutylene succinate 4, polyaluminum chloride 2, mica powder 2, easily dispersible fiber 2, straw ash 2, modified titanium dioxide 3;

[0015] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): aluminum hydroxide 2, nano titanium dioxide 50, silicon carbide 4, methyl methacrylate 5, antimony trioxide 3, terephthalic acid 3, horse Dioctyl maleate 3, ethylene glycol 5, water 50; the preparation method is to first add methyl methacrylate, nano-titanium dioxide, aluminum hydroxide, ethylene glycol, and water and stir evenly to form a suspension. Dry down to a water content of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com