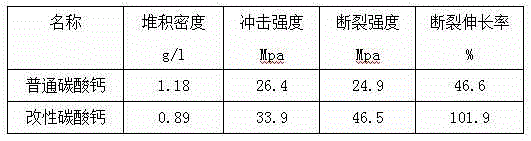

Multi-purpose ultrafine modified calcium carbonate and preparation method thereof

A multi-purpose, calcium carbonate technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing low-molecular organic compound treatment, etc., can solve problems such as defects, cracking, deformation, etc., and achieve the effect of avoiding waste of raw materials and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below through specific examples.

[0015] A multi-purpose superfine modified calcium carbonate, prepared from the following raw materials in parts by weight (kg): light calcium carbonate 85, EPDM rubber 6, zinc stearate 2, ferrocene 1, mono Glyceryl Stearate 2, Cetyl Alcohol 1, Tween 80 1, Epoxy Castor Oil 2, Quartz Powder 2, Polyformaldehyde 6, Lignosulfonate 1, Modified Titanium Dioxide 3;

[0016] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): nano-titanium dioxide 50, magnesium hydroxide 2, ethyl cellulose 4, n-butyl acrylate 5, quartz powder 3, polyisobutylene 3, alkyd resin 3 , terpineol 2, water 50; the preparation method is to first add n-butyl acrylate, nano-titanium dioxide, magnesium hydroxide, ethyl cellulose, and water to stir evenly to form a suspension, and dry it at 45-50°C until the water content 2-3%, then immediately...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com