Patents

Literature

41results about How to "Play the role of cross-linking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cross-linking agent for low concentration guanidine gum pressing crack system and preparation technology thereof

ActiveCN103265943AReduce the dosage of guar gumReduce harmDrilling compositionGlycerolTriethanolamine

The invention discloses a cross-linking agent for a low concentration guanidine gum pressing crack system, comprising the following raw materials by weight: 12.5-20 parts of glycerol, 10-15 parts of borax, 4-6 parts of sodium gluconate, 1.5-2 parts of sodium hydroxide, 0-4 parts of inorganic zirconate, 0-4 parts of triethanolamine, and 49-68 parts of water. The invention further discloses a preparation technology. The beneficial effects comprise that: the cross-linking agent for a pressing crack liquid can substantially raise the usage efficiency of the guanidine gum, greatly reduces a usage amount of the guanidine gum; and in same case, the concentration of the guanidine can reduce 30-50%, the content of the guanidine gum residue reduces more than 30%, and a rock core damage rate relatively reduces more than 20%. The cross-linking agent prepared in the invention has same application with the current cross-linking agent, and accordingly it is convenient for on-site construction.

Owner:四川省博仁达石油科技有限公司

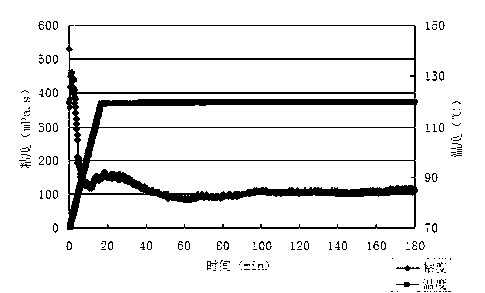

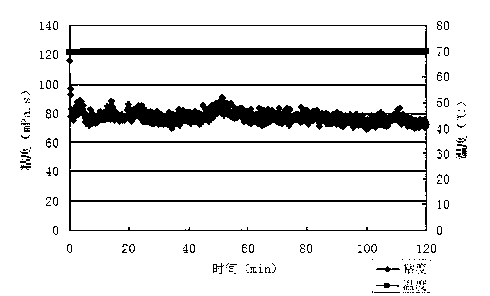

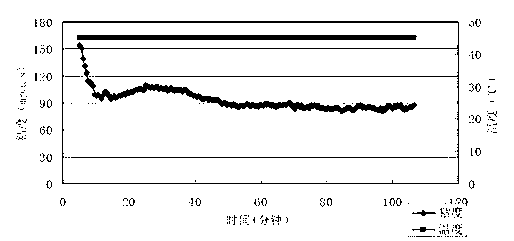

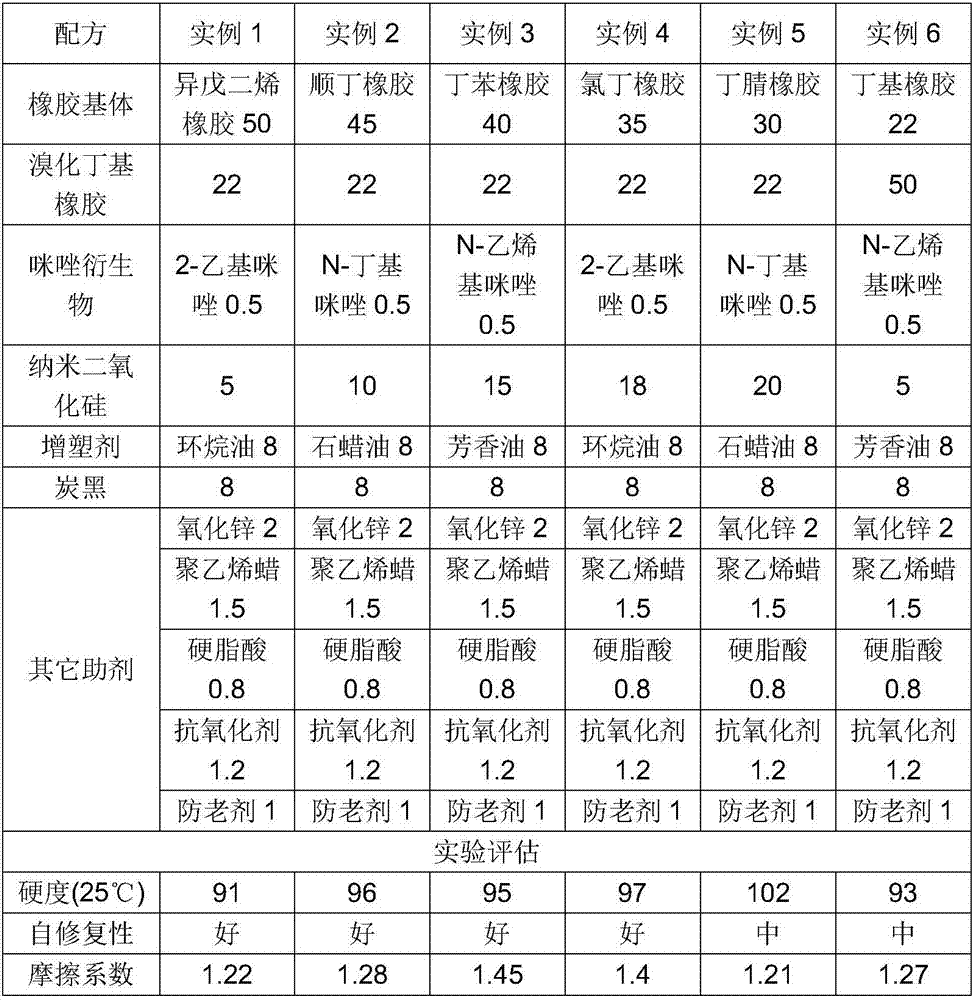

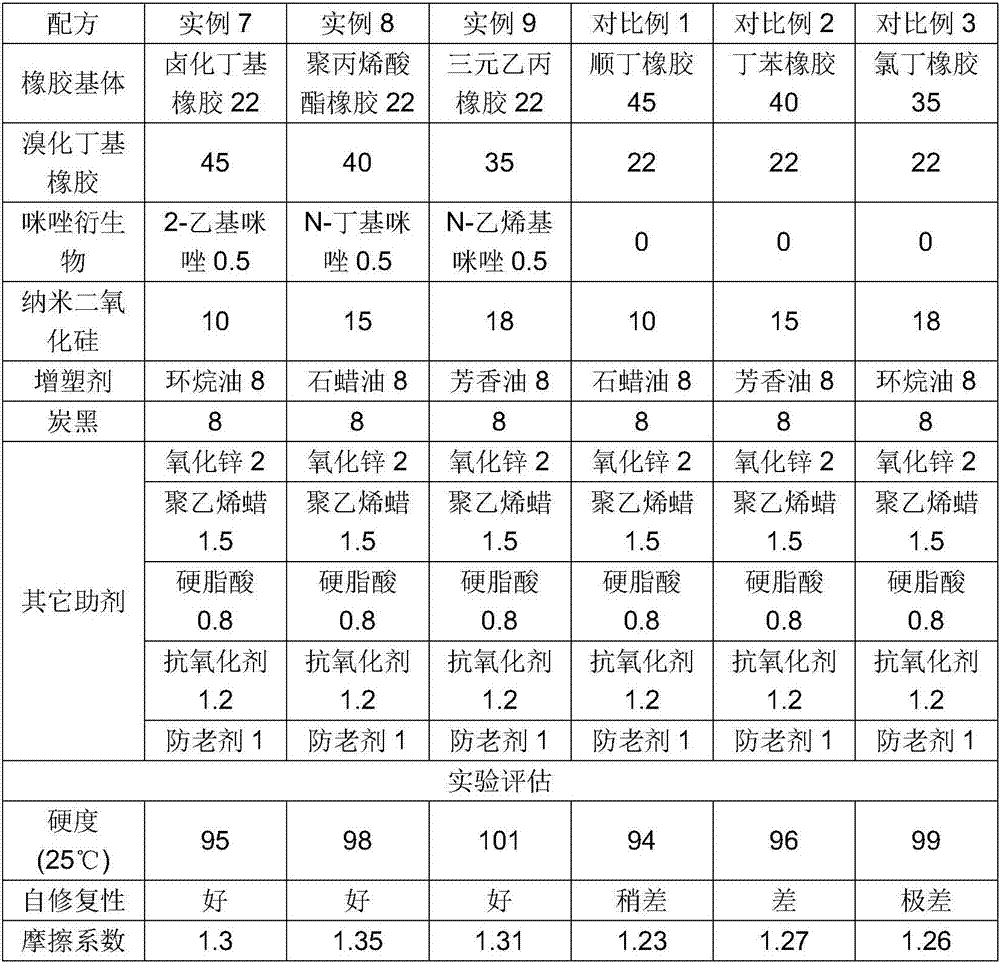

Self-healing antiskid unvulcanizedrubber material and preparation method thereof

The invention discloses a self-healing antiskid unvulcanized rubber material comprising the following components in percentage by weight: 20-50wt% of a rubber matrix, 1-50wt% of brominated butyl rubber, 0.1-0.5wt% of an imidazole derivative, 5-25wt% of nano silicon dioxide, 5-20wt% of a plasticizer, 5-10wt% of carbon black, and 1-5wt% of an auxiliary agent. The invention also discloses a preparation method. The self-healing antiskid unvulcanized rubber material disclosed by the invention has excellent weathering resistance, water tightness and air tightness, has good resistance to chemicals, oils, solvents and the like, can be used for manufacturing a sole material, automobile tires, and antiskid wear-resistant materials in various aspects of processing and manufacturing, and can also be used as a sealing ring and a waterproof material.

Owner:成都微熵科技有限公司

Oil-resistant anti-aging rubber cable material

InactiveCN105949547AImprove reinforcement effectImprove the reinforcing effect and improve the chemical stability of rubberRubber insulatorsFiberButadiene-styrene rubber

The invention discloses an oil-resistant anti-aging rubber cable material which is prepared from the raw materials including, by weight, 3-4 parts of vinyl phenyl silicone oil, 5-7 parts of chlorosulfonated polyethylene powder, 4-5 parts of sulfur, 2-3 parts of palm wax, 7-9 parts of steel wool fiber, 16-20 parts of fluoro-rubber, 12-14 parts of barite powder, 7-9 parts of carbon black, 2-3 parts of ascorbyl palmitate, 2-3 parts of emulsified methyl silicone oil, 0.5-1 part of triphenyl phosphate, 45-56 parts of styrene-butadiene rubber, 55-60 parts of chloroprene rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass micro beads, 3-5 parts of polytetrafluoroethylene, 1-1.3 parts of a silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 parts of diethylene triamine, 0.1-0.2 parts of an accelerator M, 2.6-3 parts of a silane coupling agent kh570, and a proper amount of distilled water. The cable material is excellent in mechanical performance, is not liable to cause circuit fault and is valuable to promote.

Owner:ANHUI CABLE

A soft rubber cable material

InactiveCN105968809AImprove reinforcement effectGood chemical stabilityTetrabromobisphenol APliability

A soft rubber cable material is disclosed. The cable material is prepared from 3-4 parts by weight of tetrabromobisphenol A, 8-11 parts by weight of aluminum hypophosphite, 13-16 parts by weight of ceramic powder, 16-20 parts by weight of carbon black, 55-60 parts by weight of chloroprene rubber, 58-64 parts by weight of silicone rubber, 3-4 parts by weight of bismaleimide, 55-70 parts by weight of natural rubber, 30-40 parts by weight of hollow glass micro beads, 3-4 parts by weight of poly(ethylene oxide), 1-1.3 parts by weight of a silane coupling agent kh550, 2-3 parts by weight of paraffin oil, 3-4 parts by weight of stearic acid, 3-4 parts by weight of hydroxyl silicone oil, 2-3 parts by weight of DCP, 2-3 parts by weight of dioctyl phthalate, 12-16 parts by weight of epoxy resin E44, 0.06-0.1 part by weight of diethylenetriamine, 0.1-0.2 part by weight of an accelerant DA, 2.6-3 parts by weight of a silane coupling agent kh570 and a proper amount of distilled water. The cable material prepared is good in flame retardance and wear resistance, improved in processing performance, increased in toughness and not liable to be fractured and deserves popularization.

Owner:ANHUI CABLE

Acrylic acid-polyaniline composite modified polyurethane coating

InactiveCN105602440AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsGlycerolFire resistance

The invention discloses an acrylic acid-polyaniline composite modified polyurethane coating which is prepared from modified polyurethane emulsion, waterborne acrylic emulsion, waterborne polyaniline emulsion, diphenylmethane diisocyanate, nano-zinc oxide, nano-zinc phosphate, aluminum oxide, wollastonite, boron nitride, barium sulfate, aluminum triphosphate, diethyl aluminum phosphinic acid, calcium chloride, N-methyl pyrrolidone, a defoaming agent, a dispersing agent, a wetting agent, a flatting agent, glycerol, 8-hydroxyquinoline, epoxy resin, a silane coupling agent, polyethylene wax and water. The acrylic acid-polyaniline composite modified polyurethane coating is good in water resistance and corrosion resistance, excellent in heat resistance and weather resistance, high in strength, high in adhesive force with a base material and long in service life, and has the certain fire resistance.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Temperature-sensitive nano aquagel, and preparation method and application thereof

InactiveCN104530332AGood biocompatibilityPlay the role of cross-linkingPharmaceutical non-active ingredientsDrug releaseSolvent

The invention relates to a temperature-sensitive nano aquagel, and a preparation method and application thereof. The nano aquagel is prepared by copolymerizing polyethyleneglycol diacrylate and a methacrylic acid monomer or acrylic acid monomer, the dynamic particle size is 100-500nm, and the minimum critical solution temperature under stomach juice conditions is 15-75 DEG C. The nano aquagel is prepared by polymerizing the acrylic acid or methacrylic acid monomer, the polyethyleneglycol diacrylate and an initiator in a solvent by a precipitation polymerization process. The polyethyleneglycol diacrylate-methacrylic acid copolymer nano aquagel is used as a drug carrier for controlling drug release under human gastrointestinal environmental conditions.

Owner:UNIV OF JINAN

Lanthanum-oxide-modified rubber cable material

InactiveCN105985552AImprove reinforcement effectGood chemical stabilityRubber insulatorsVulcanizationCarbon nanotube

The invention discloses a lanthanum-oxide-modified rubber cable material which is prepared from the following raw materials in parts by weight: 5-6 parts of tantalum carbide, 0.6-0.8 part of lanthanum oxide, 62-68 parts of hydrogenated nitrile-butadiene rubber, 10-13 parts of carbon nanotube, 7-9 parts of nano kaolin, 55-60 parts of chloroprene rubber, 1-1.5 parts of montanin wax, 2-2.4 parts of calcium stearate, 2-3 parts of epoxy soybean oil, 2-3 parts of vulcanization accelerator TMTD, 55-70 parts of natural rubber, 2-3 parts of decabromodiphenyl oxide, 30-40 parts of hollow glass microsphere, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The cable material has favorable flame retardancy, satisfies the requirements for application at high temperature, and has the advantages of favorable aging resistance, favorable oxidation resistance and longer service life.

Owner:JING FENG GRP

Vehicle spraying-free composite material and preparation method thereof

The invention relates to a vehicle spraying-free composite material. The vehicle spraying-free composite material comprises the following raw materials: polypropylene resin, fillers, metal powder, straight-chain alkyl acid salt, cyclopentadiene and an antioxidant, wherein the metal powder adopts double-layer wrapping; the inner layer is wrapped with thermosetting resin; and the outer layer is wrapped with silicon dioxide nanopowder. Meanwhile, the invention also relates to a method for preparing the method. Aluminum powder is wrapped by double layers; the inner is used for reducing the heat conductivity coefficient of the metal powder, so that occurrence of a welding line is reduced; and the outer layer of silicon dioxide nanopowder can prevent physical or chemical change of the metal powder and the inner layer during high-temperature treatment. Due to addition of the straight-chain alkyl acid salt, the compatibility of the powder and the polypropylene base material is improved and occurrence of current ripple is reduced; and due to addition of the cyclopentadiene, crosslinking effect can be achieved and the integral hardness of the material is increased; meanwhile, due to the high-temperature depolymerization characteristic of the cyclopentadiene, the high-temperature processing property of the polypropylene resin is not influenced.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

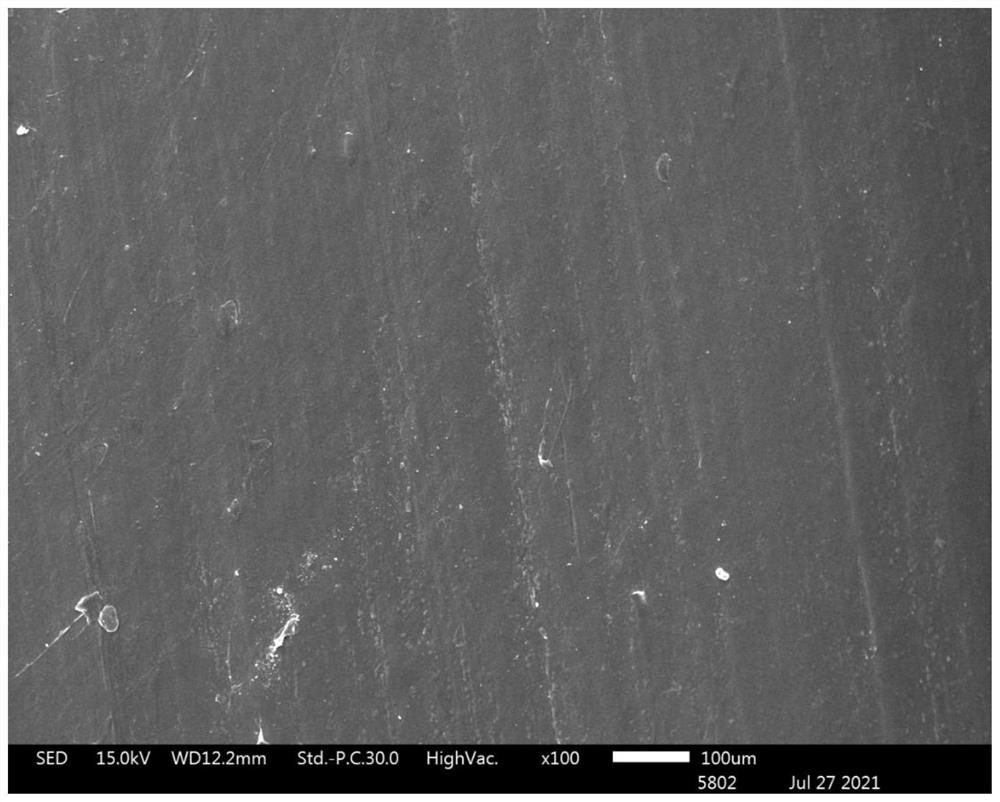

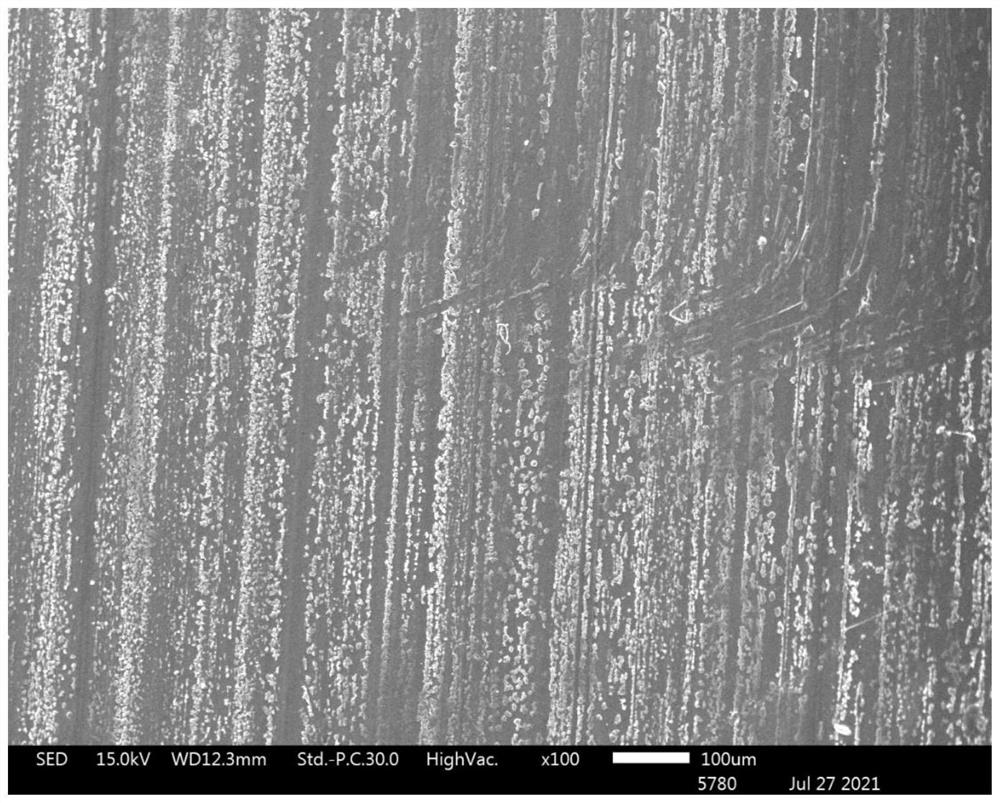

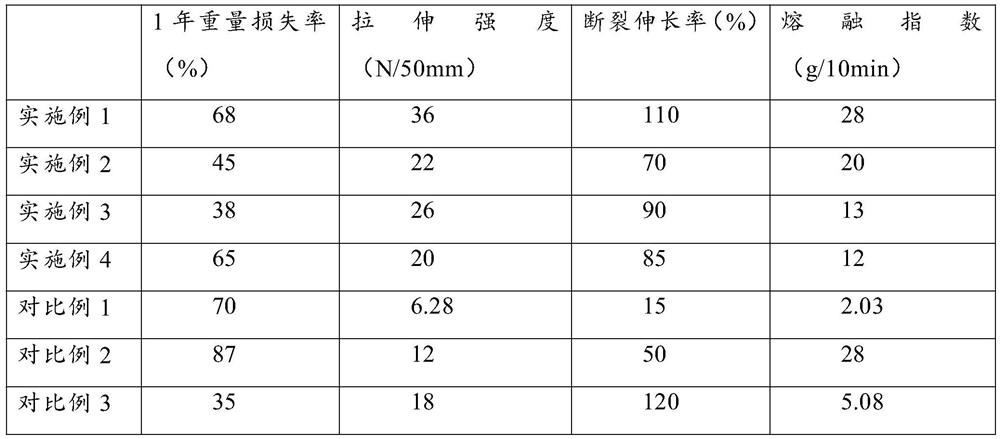

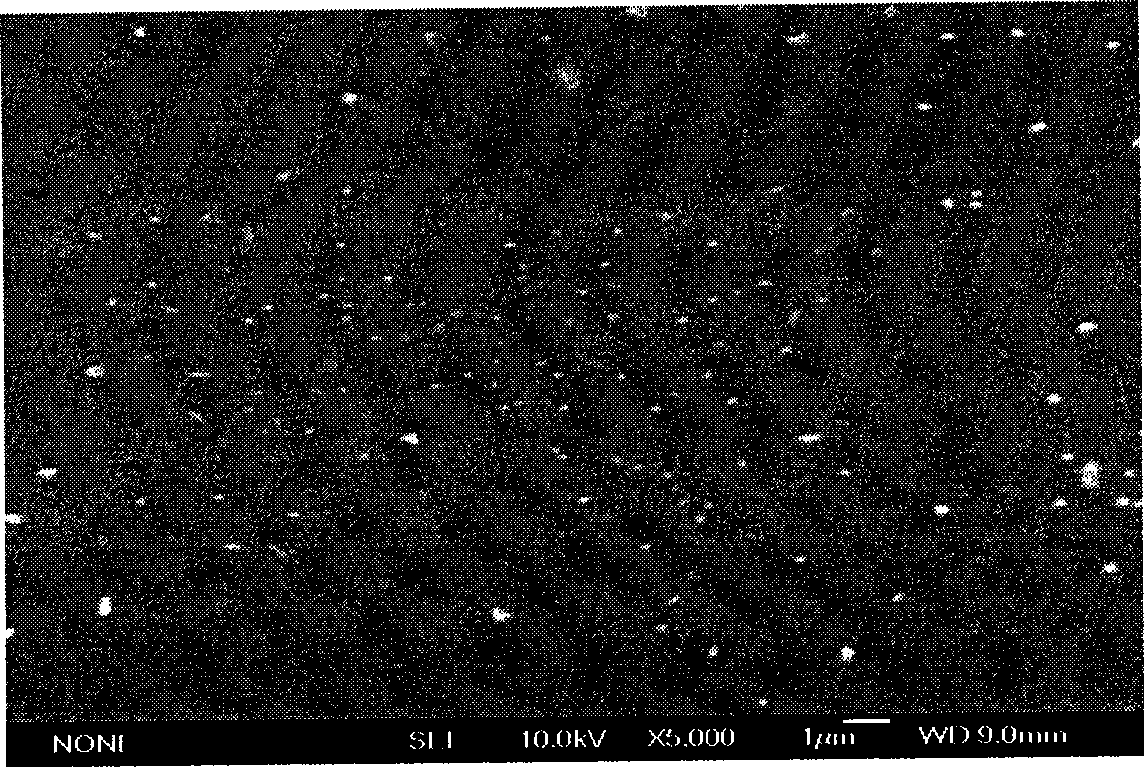

Preparation method of biodegradable cast film

The invention provides a preparation method of a biodegradable cast film, which comprises the following steps: carrying out melt blending on PLA, PBAT and a polyester chain extender in proportion to obtain a composite material, carrying out melt blending on the composite material and a dispersion lubricant to obtain a high-fluidity biodegradable material, and carrying out a cast film forming process on the high-fluidity biodegradable material to obtain the biodegradable cast film. By controlling the blending ratio of PLA and PBAT, the variety and the addition amount of the polyester chain extender and regulating and controlling the flowability of the mixed material, the compatibility of PLA and PBAT is improved, the material reaches the casting grade, and the process conditions of melt blending and casting film forming are further limited, so that the production cost is reduced, and the production efficiency is improved. The finally prepared biodegradable cast film not only has excellent biodegradability, but also has better heat resistance and impact property, good ductility and elongation at break, and soft hand feeling; the preparation method is simple and easy to implement, free of adding of redundant modifiers, low in cost and wide in application prospect.

Owner:湖北拓盈新材料有限公司

Method for preparing PC-PS blend alloy

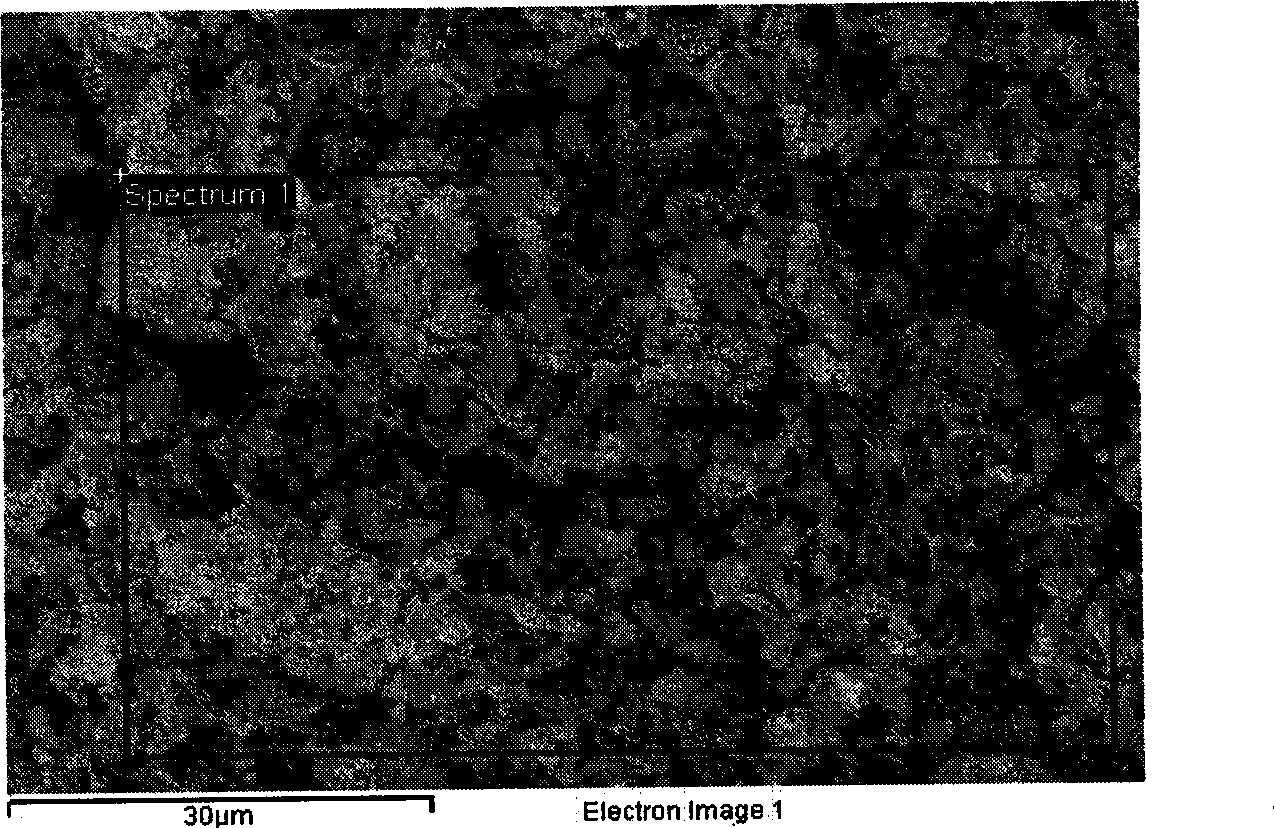

InactiveCN101531809AFeatures that make up for poor UV resistanceEnsure transparencyInorganic particleWeather resistance

A method for preparing PC-PS blend alloy comprises the following steps: after coating PC, PS and SiO2 to prepare high polymer, coating TiO2 and the SiO2 to obtain inorganic particles, and then melting the high polymer and the inorganic particles again to obtain the blend alloy. The method is simple and convenient, easy to operate and realize and short in period. The prepared blend alloy has better ultraviolet resistance, wearing resistance and weather resistance.

Owner:TAIYUAN UNIV OF TECH

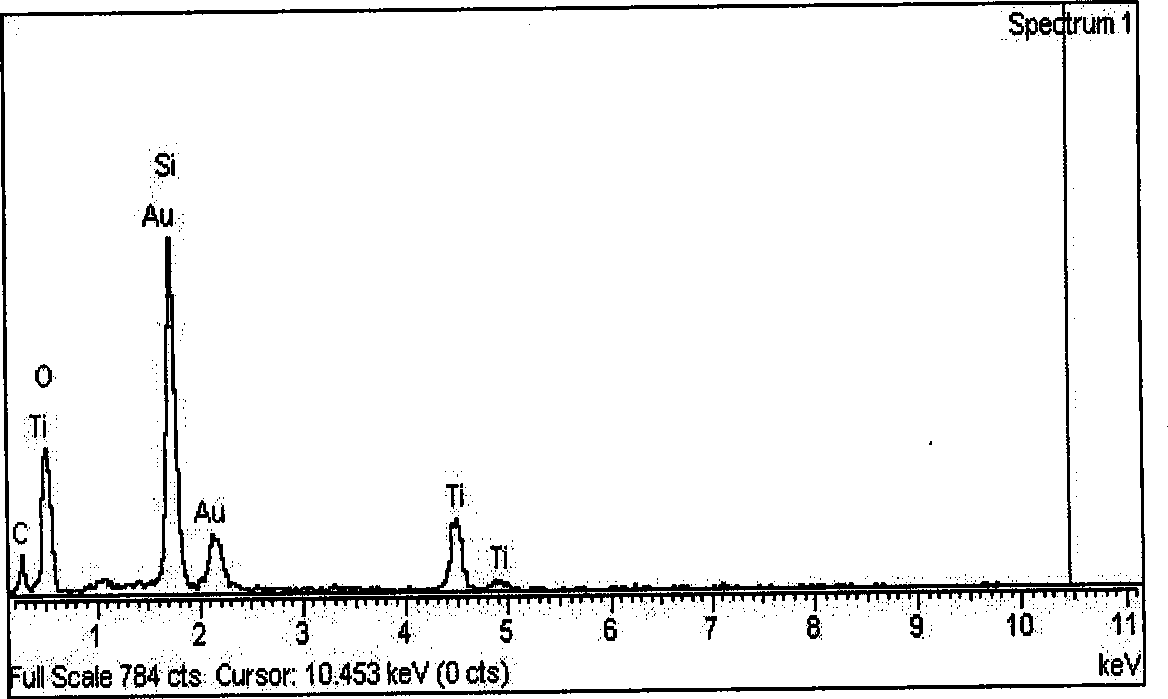

High-weather-resistance solar cell back plate and manufacturing method thereof

ActiveCN108598196ASimple processRaw materials are easy to getSynthetic resin layered productsElectrical equipmentEpoxyElectrical battery

The invention discloses a high-weather-resistance solar cell back plate, successively comprising a first weather resistance layer, an insulation and blocking layer, and a second weather resistance layer from inside to outside, wherein the first weather resistance layer is bonded with the insulation and blocking layer through an adhesion layer, the insulation and blocking layer is bonded with the second weather resistance layer through an adhesion layer; both the first weather resistance layer and the second weather resistance layer are silicon-fluorene fluorine-containing resin material layers; the insulation and blocking layer is a PET (PolyEthylene Terephthalate) layer; the adhesion layer is a blend layer of EVA (Ethylene-Vinyl Acetate copolymer) and JD919 amino tetra-functional epoxy resin. A manufacturing method of the high-weather-resistance solar cell back plate comprises the steps of plasma corona treatment, overlapping, laminating, and curing. The high-weather-resistance solarcell back plate disclosed by the invention has excellent weather resistance, electric insulation property, oxidation resistance, moisture resistance, hydrolysis resistance for preventing hydrolysis ofan adhesive for a long time, and barrier property.

Owner:GUILIN BONENG TECH

Improved composite rubber cable material

InactiveCN105985644AImprove reinforcementHigh chemical stabilityRubber insulatorsInsulated cablesDiethylenetriamineNatural rubber

The invention discloses an improved composite rubber cable material which is prepared from the following raw materials in parts by weight: 8-9 parts of bone black, 5-6 parts of fumed silica, 10-13 parts of quartz powder, 4-6 parts of sepiolite fiber, 55-60 parts of chloroprene rubber, 56-60 parts of silicone rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass beads, 1-1.3 parts of silane coupling agent kh550, 2-3 parts of antioxidant 1035, 1-2 parts of dibutyl phthalate, 1-2 parts of dibutyltin dilaurate, 3-4 parts of oleic acid, 3-5 parts of molybdenum disulfide, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerant DA, 2.6-3 parts of silane coupling agent kh570 and appropriate distilled water. In the invention, the elasticity of the cable material is improved, the properties of insulation, thermal insulation and wear resistance of the cable material are enhanced, and the application range is expanded.

Owner:JING FENG GRP

Preparation method of phosphoric acid-doped polymerized ionic liquid-based composite membranes

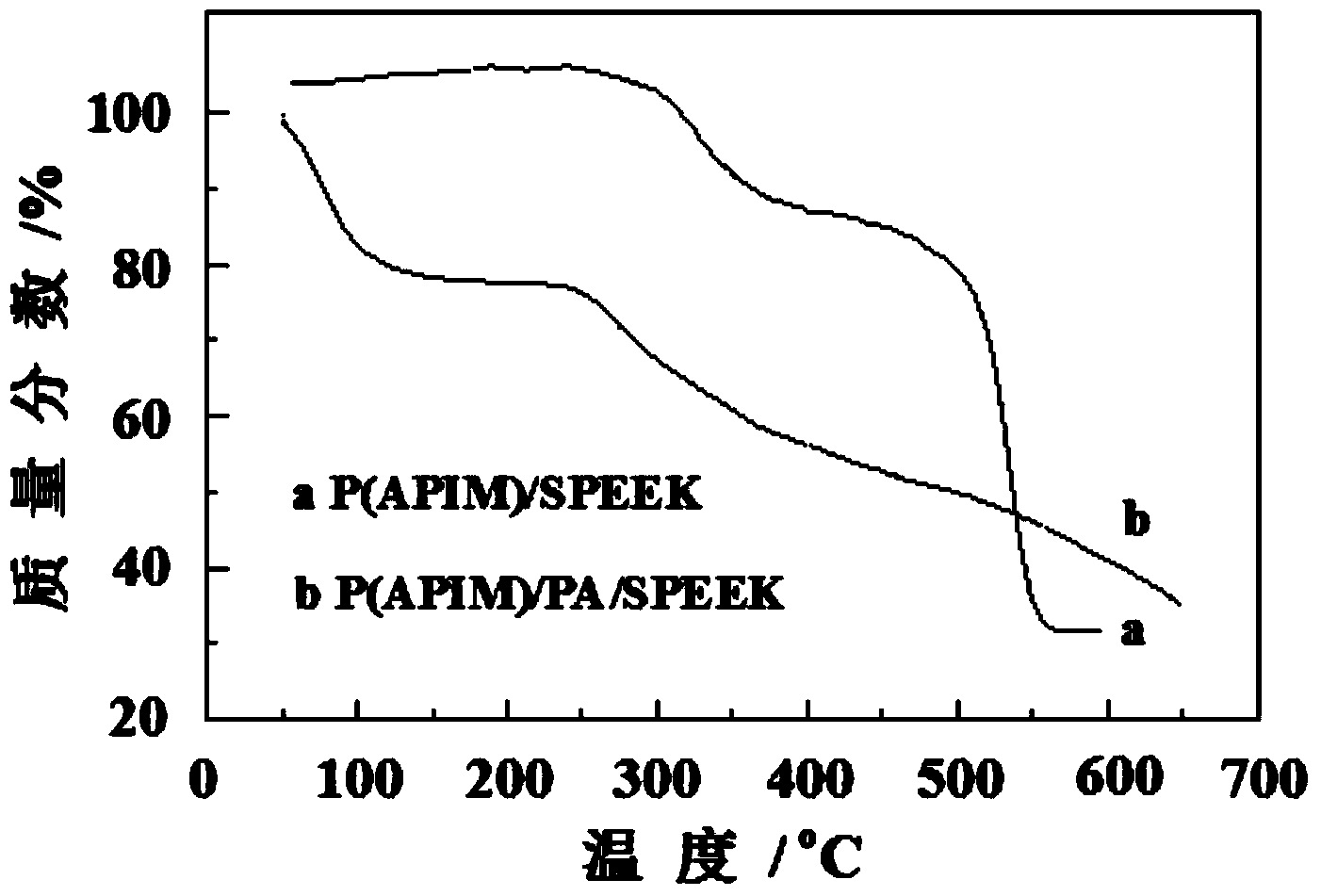

InactiveCN103665412AIncreased tensile strength at breakImprove proton conductivitySolid electrolyte fuel cellsFuel cell detailsPoly ether ether ketoneSolvent evaporation

The invention discloses a preparation method of phosphoric acid-doped polymerized ionic liquid-based composite membranes, and belongs to the technical field of fuel cell. The preparation method comprises following steps: an ionic liquid cationic monomer containing unsaturated double bonds and polymer sulfonated polyether ether ketone are subjected to electrostatic assembly, so that in the presence of an initiator, the unsaturated double bonds in the ionic liquid cationic monomer are broken, and polymerization is realized; solvent evaporation is performed at a temperature of 60 DEG C, and membranes are obtained via tape casting at room temperature; and the membranes dried in a baking oven are hermetically immersed in a strong phosphoric acid solution with a mass concentration of 95 to 100% so as to prepare the phosphoric acid-doped polymerized ionic liquid-based composite membranes. The preparation method is capable of preparing the phosphoric acid-doped polymerized ionic liquid-based composite membranes via assembling of the polymerized ionic liquid with the polymer; the obtained phosphoric acid-doped polymerized ionic liquid-based composite membranes possess excellent mechanical properties and proton conductivity; a novel method is provided for preparing the polymerized ion liquid-based novel composite membranes; and the obtained composite membranes possess potential application values in the field of fuel cell.

Owner:NORTHEASTERN UNIV

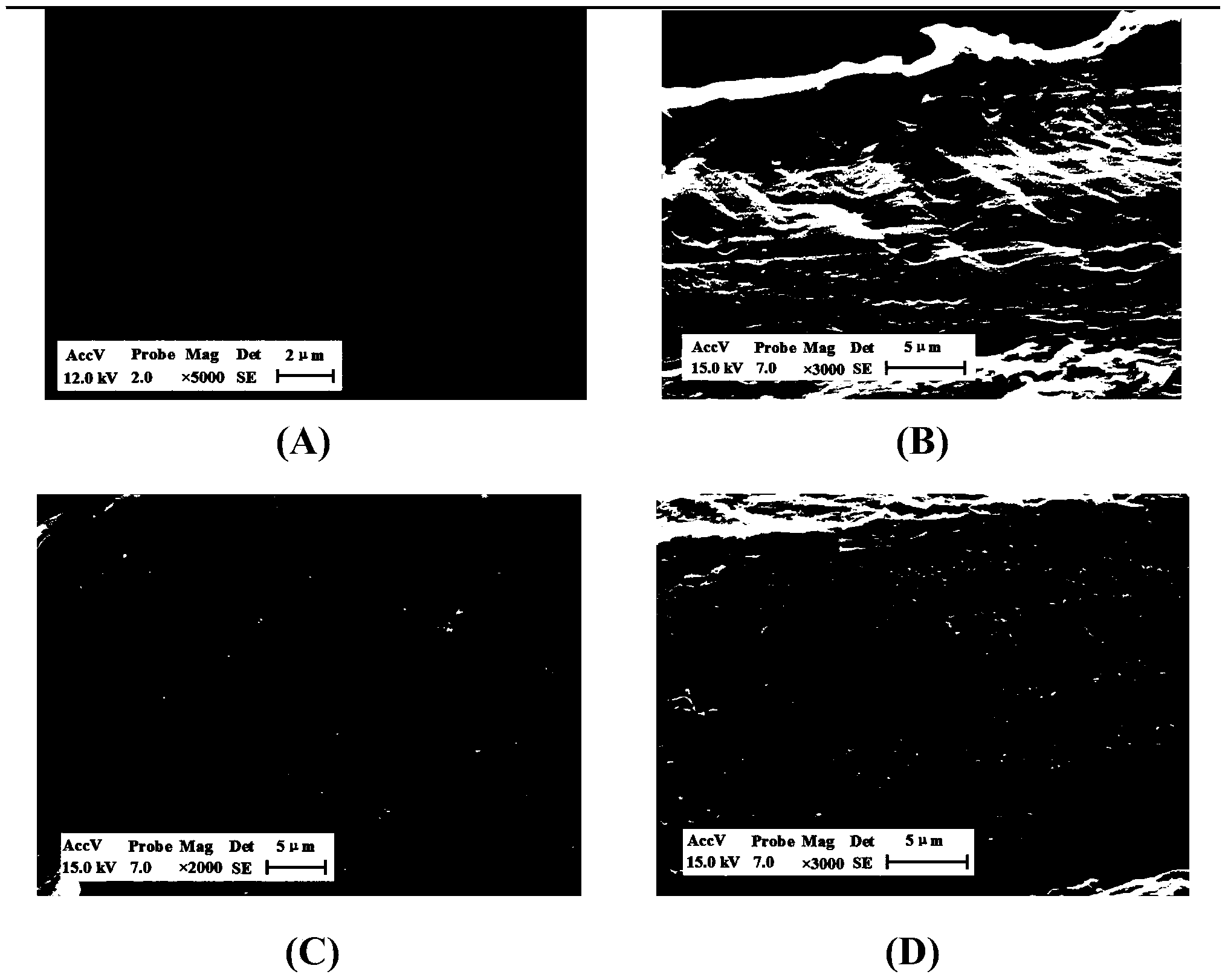

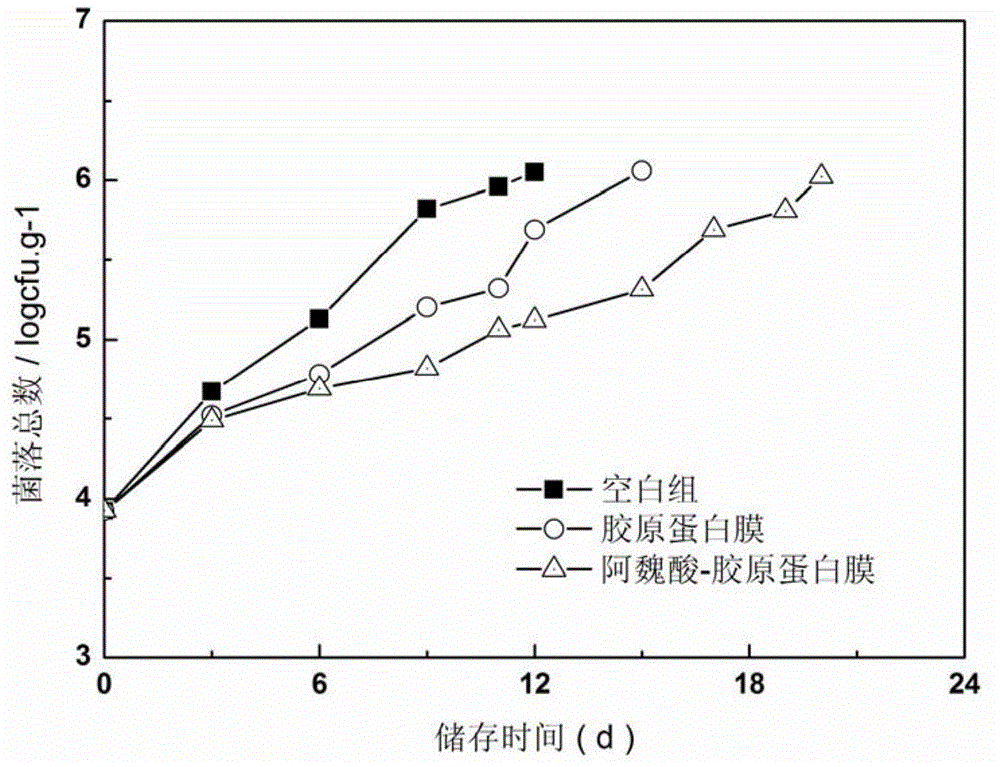

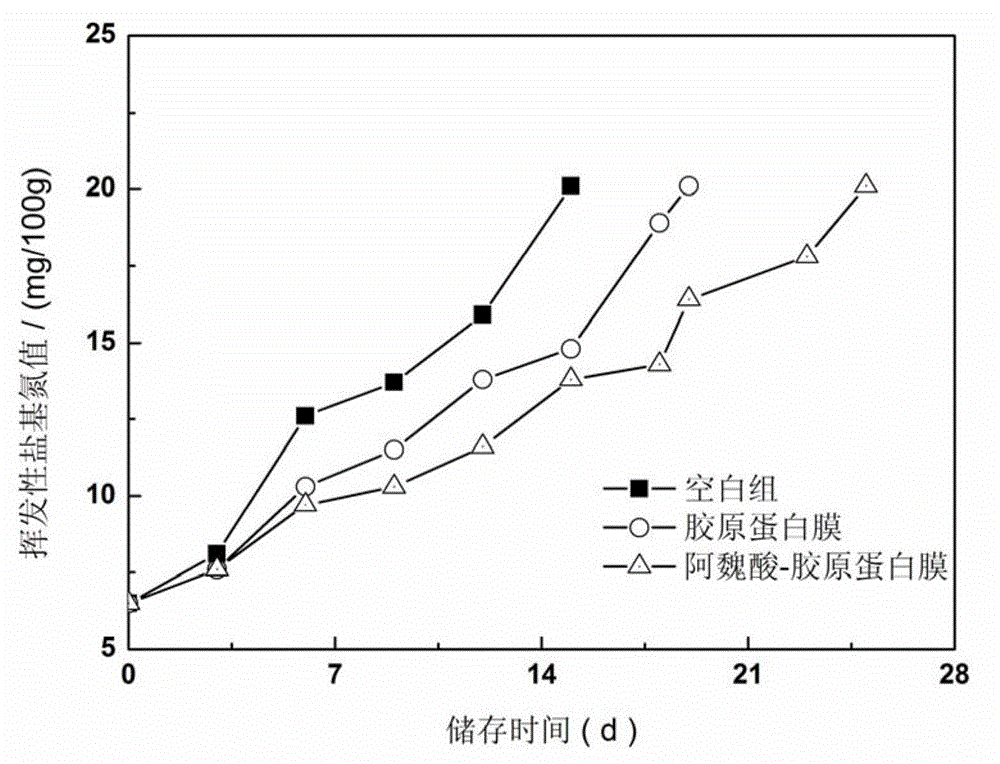

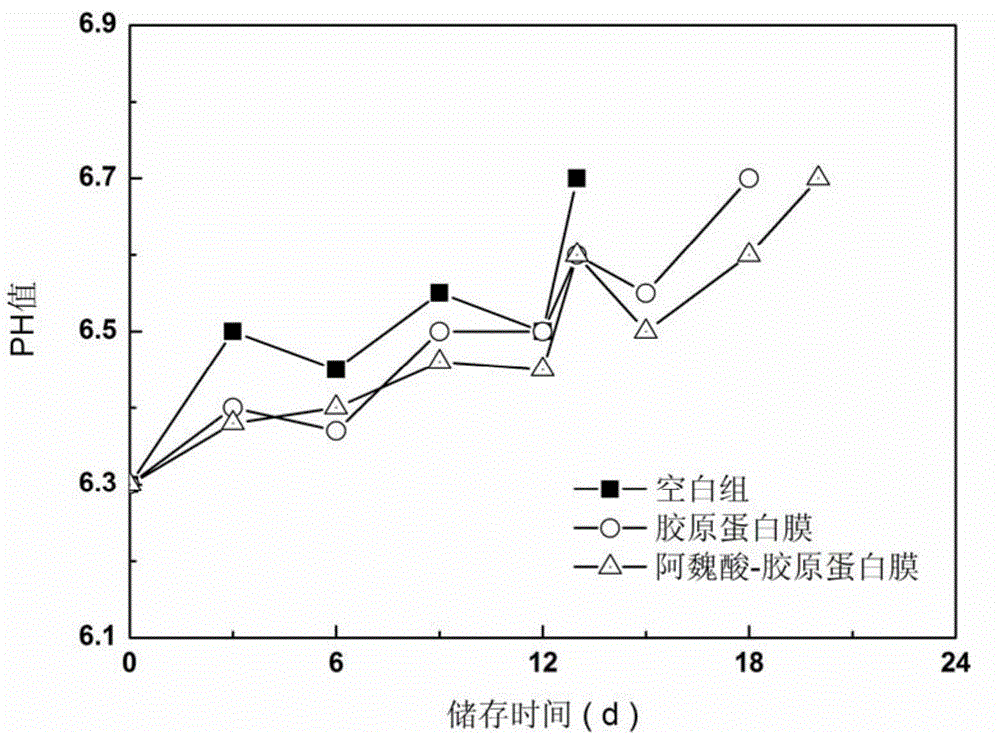

Ferulic acid-collagen antimicrobial film, and preparation method and application thereof

ActiveCN103554532BPlay the role of cross-linkingImprove mechanical propertiesMeat/fish preservation by coatingInhibition zoneGlycerol

The invention discloses a ferulic acid-collagen antimicrobial film, and a preparation method and application thereof. The preparation method comprises the following steps: adding collagen in water, dissolving by stirring at the heat treatment temperature of 60-70 DEG C, sequentially adding glycerol, dialdehyde starch, sodium alginate and ferulic acid, carrying out heat treatment at 60-70 DEG C for 20-30 minutes, removing bubbles in a stirring debubbling machine, running on an organic glass plate, drying after the film forming solution is cooled, cooling at normal temperature, and peeling off the film to obtain the ferulic acid-collagen antimicrobial film. The edible food packaging film has the advantages of high transparency, high barrier property, higher mechanical strength and mold resistance; and the oxford cup method detects that the diameters of inhibition zones of the obtained film for Gram-negative bacteria and Gram-positive bacteria are 17-22mm, and the film has strong antibacterial capacity. The prepared film is used for sausage preservation, and can prolong the shelf life of sausage by 8.5 days.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Heat-resistant rubber cable sheath material

The invention discloses a heat-resistant rubber cable sheath material which is prepared from the following raw materials in parts by weight: 3-4 parts of magnesium stearate, 12-14 parts of mica powder, 8-11 parts of aluminum nitride, 4-6 parts of nano silver fiber, 5-6 parts of urea, 55-60 parts of chloroprene rubber, 2-3 parts of liquid paraffin, 10-13 parts of isoprene rubber, 46-55 parts of cis-1,4-polybutadiene rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass microsphere, 0.3-0.4 part of antioxidant BHT, 2-3 parts of sulfur, 2-3 parts of organobentonite, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The rubber cable sheath has the characteristics of excellent heat resistance, excellent oil resistance, no combustion spreading, chemical corrosion resistance and the like, prolongs the service life of the cable, saves the resources and lowers the cost.

Owner:JING FENG GRP

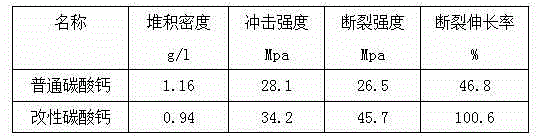

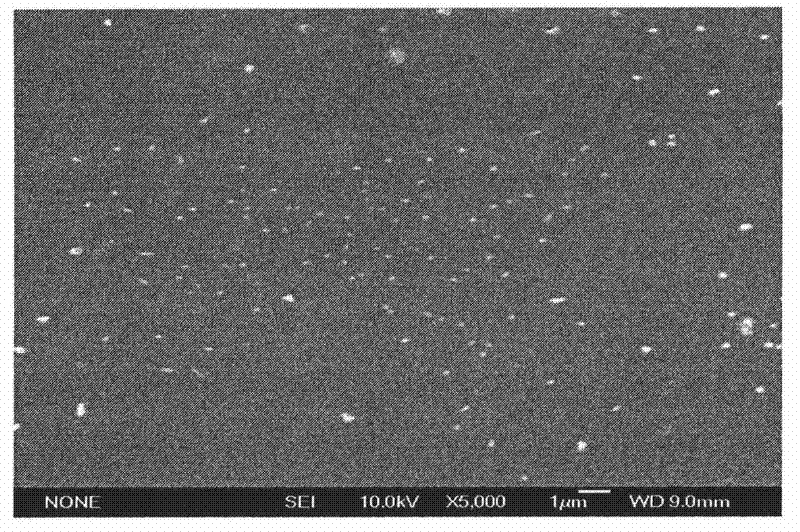

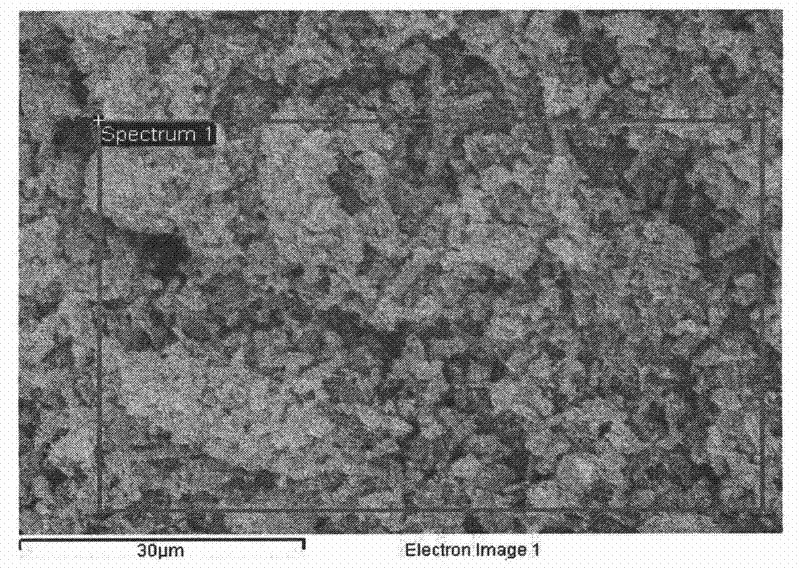

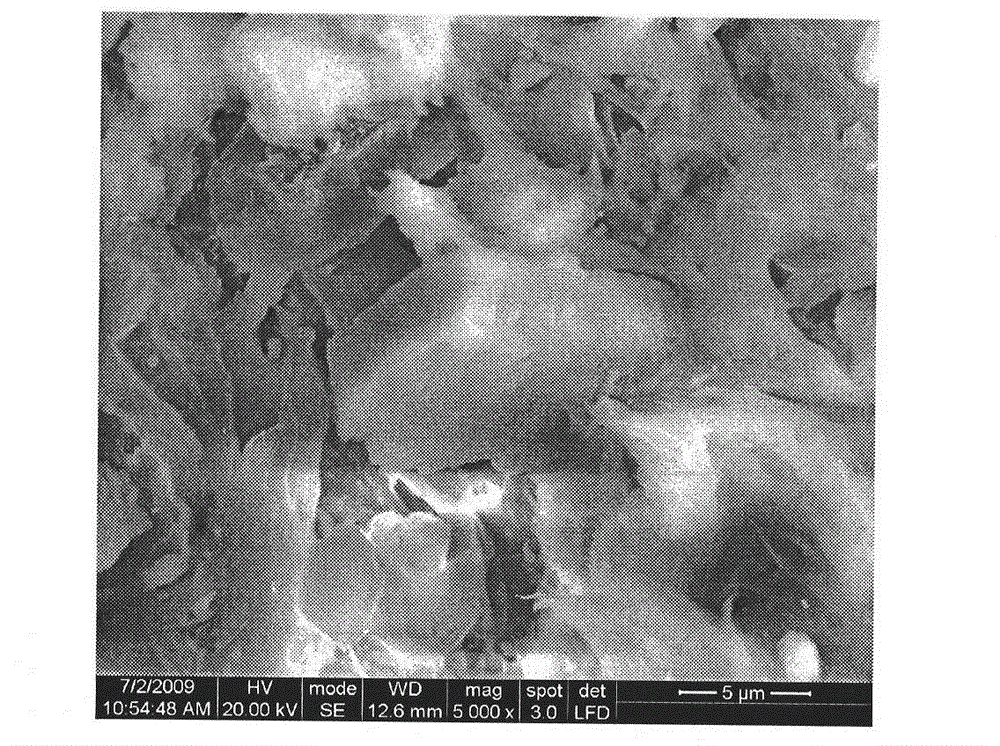

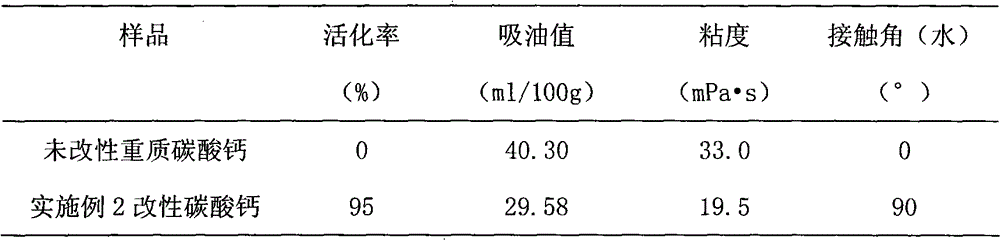

Hydrophobic lipophilic surface-modified calcium carbonate and preparation method thereof

ActiveCN104130593AAct quicklyPlay the role of cross-linkingPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsTarTitanium tetrachloride

Disclosed hydrophobic lipophilic surface-modified calcium carbonate is characterized by being prepared from the following raw materials in parts by weight: 90-95 parts of calcium carbonate, 2-3 parts of glass fiber, 5-7 parts of polylactic acid, 2-3 parts of polydimethylsiloxane, 3-5 parts of epoxidized triglyceride, 3-5 parts of silica sol, 1-1.5 parts of wood tar, 2-3 parts of titanium tetrachloride, 2-3 parts of expanded perlite, and 2.5-3.5 parts of modified titanium dioxide. By adding polydimethylsiloxane, expanded perlite, wood tar and other hydrophobic waterproof compositions and oily high-molecular polymers, the surface of calcium carbonate is changed into hydrophobicity from hydrophilicity, the effect of calcium carbonate with a polymer interface is enhanced, and a modified unsaturated bond gives play to crosslinking effect during processing with a polymer. The hydrophobic lipophilic surface-modified calcium carbonate can be used to fill plastic, rubber, adhesives and the like.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Method for preparing PC-PS blend alloy

InactiveCN101531809BFeatures that make up for poor UV resistanceEnsure transparencyWeather resistanceInorganic particle

The present invention relates to a method for preparing PC-PS blend alloy, comprising the following steps: after coating PC, PS and SiO2 to prepare high polymer, coating TiO2 and the SiO2 to obtain inorganic particles, and then melting the high polymer and the inorganic particles again to obtain the blend alloy. The method is simple and convenient, easy to operate and realize and short in period. The prepared blend alloy has better ultraviolet resistance, wearing resistance and weather resistance.

Owner:TAIYUAN UNIV OF TECH

Special adhesive used for high-temperature resistant electronic circuit pad board and added with organic modified montmorillonite

InactiveCN106244097AImprove densification performanceImprove ductilityNon-macromolecular adhesive additivesProtein adhesivesPolyvinyl alcoholTemperature resistance

The invention discloses a special adhesive used for a high-temperature resistant electronic circuit pad board and added with organic modified montmorillonite, wherein the special adhesive is prepared from the following raw materials by weight: 100-110 parts of corn protein, 8-9 parts of acrylamide, 2-2.5 parts of maleic anhydride, 8-9 parts of ammonium persulfate, a proper amount of sodium hydroxide with the concentration of 40 wt%, a proper amount of distilled water, 50-55 parts of water glass with the modulus of 2.8, 9-10.5 parts of polyvinyl alcohol, 2-3 parts of ethyl silicate, 1.7-2 parts of amino sulfonic acid, 1-1.2 parts of a silane coupling agent kh550, 1-1.4 parts of trisodium phosphate, 5-6 parts of montmorillonite, 0.3-0.4 part of cetyltrimethyl bromide ammonium, a proper amount of anhydrous ethanol, 3-4 parts of magnesium oxide, 2-3 parts of sodium alginate, and a proper amount of dilute hydrochloric acid. According to the present invention, the prepared adhesive has advantages of high strength, improved curing speed, good thermal stability, good high-temperature resistance and good insulating property, and is suitable for the adhesion of the electronic circuit pas board.

Owner:阜阳大可新材料股份有限公司

A modified nitrile butadiene rubber cable material

InactiveCN105968448AImprove reinforcement effectGood chemical stabilityRubber insulatorsInsulated cablesDiethylene triamineMagnesium borate

A modified nitrile butadiene rubber cable material is disclosed. The cable material is prepared from 11-14 parts by weight of magnesium borate crystal whiskers, 10-13 parts by weight of emery powder, 6-8 parts by weight of clay, 2-3 parts by weight of sodium carboxymethylcellulose, 2-2.5 parts by weight of lauric acid, 0.7-1 part by weight of polyoxyethylene ester, 58-65 parts by weight of nitrile butadiene rubber, 3-4 parts by weight of polyethylene wax, 55-60 parts by weight of chloroprene rubber, 0.8-1 part by weight of an antioxidant 1010, 1-2 parts by weight of lauric acid, 55-70 parts by weight of natural rubber, 30-40 parts by weight of hollow glass micro beads, 1-1.3 parts by weight of a silane coupling agent kh550, 12-16 parts by weight of epoxy resin E44, 0.06-0.1 part by weight of diethylenetriamine, 0.1-0.2 part by weight of an accelerant DA, 2.6-3 parts by weight of a silane coupling agent kh570 and a proper amount of distilled water. The cable material is good in thermal stability, excellent in performance and low in raw materials cost, saves resources, can be produced in a large scale and deserves popularization.

Owner:ANHUI CABLE

Novel recycling method of waste amino molding plastic products

The invention discloses a novel recycling method of waste amino molding plastic products. The method employs waste and old amino molding plastic products as raw materials, chopped a cellulose, melamine solid resin and other raw materials are added for processing and modification, and the materials are added into reproduction of products again. The method solves recycling and disposal problems of waste amino molding plastic products, eliminates the disposal methods of burning and landfill, changes environmental pollution caused by the disposal of such articles, turns waste into treasure, and makes certain contribution to protecting environment of the earth.

Owner:LIANYUNGANG ZHONGYI AVIATION MATERIALS

High-capacity flame-retardant master batch

The invention belongs to the field of flame-retardant materials, and discloses a high-capacity flame-retardant master batch which comprises polypropylene, an ethylene copolymer LOTADER 4700, a carbon-forming agent, ammonium polyphosphate, a silane cross-linking agent and an initiator. The carbon forming agent is an allyl substituted triazine carbon forming agent; the components are as follows: 15-25% of polypropylene; 3-5% of low density polyethylene; 5 to 10% of an ethylene copolymer LOTADER 4700; the total amount of the ammonium polyphosphate and the carbon-forming agent is controlled to be 60-75%; 0.05%-0.1% of a silane cross-linking agent with an unsaturated olefinic bond; and 0.05 to 0.1 percent of an initiator. The weight ratio of the ammonium polyphosphate to the carbon-forming agent is 3.5: 1-4: 1. The master batch is good in dispersion uniformity, and the capacity is improved.

Owner:QINGYUAN CITY YICHENG FLAME RETARDANT MATERIALS

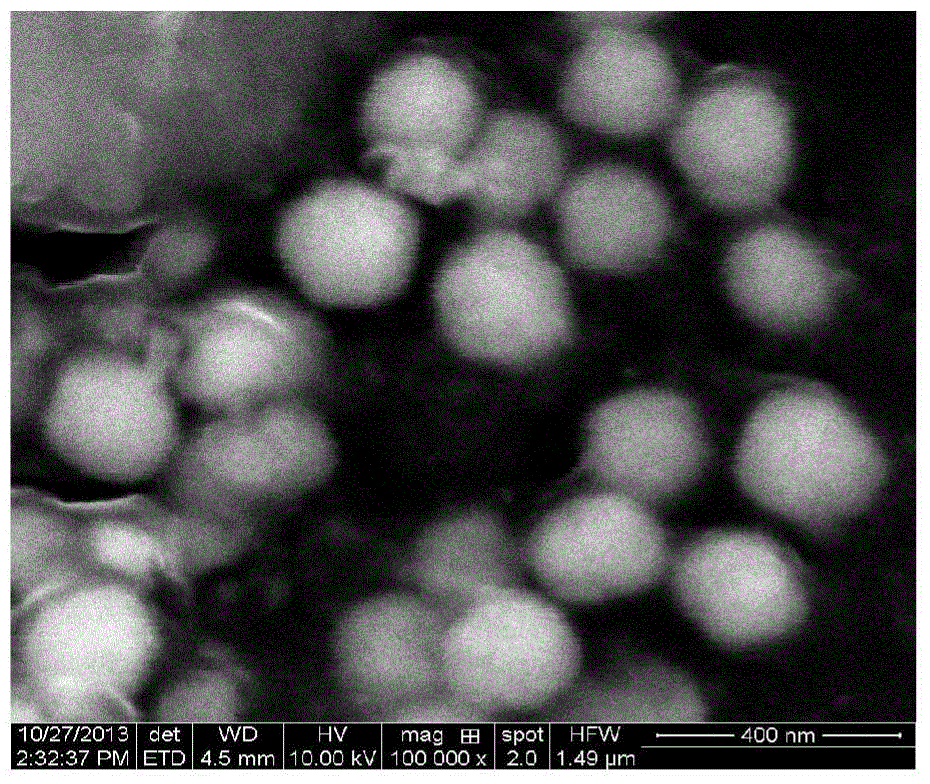

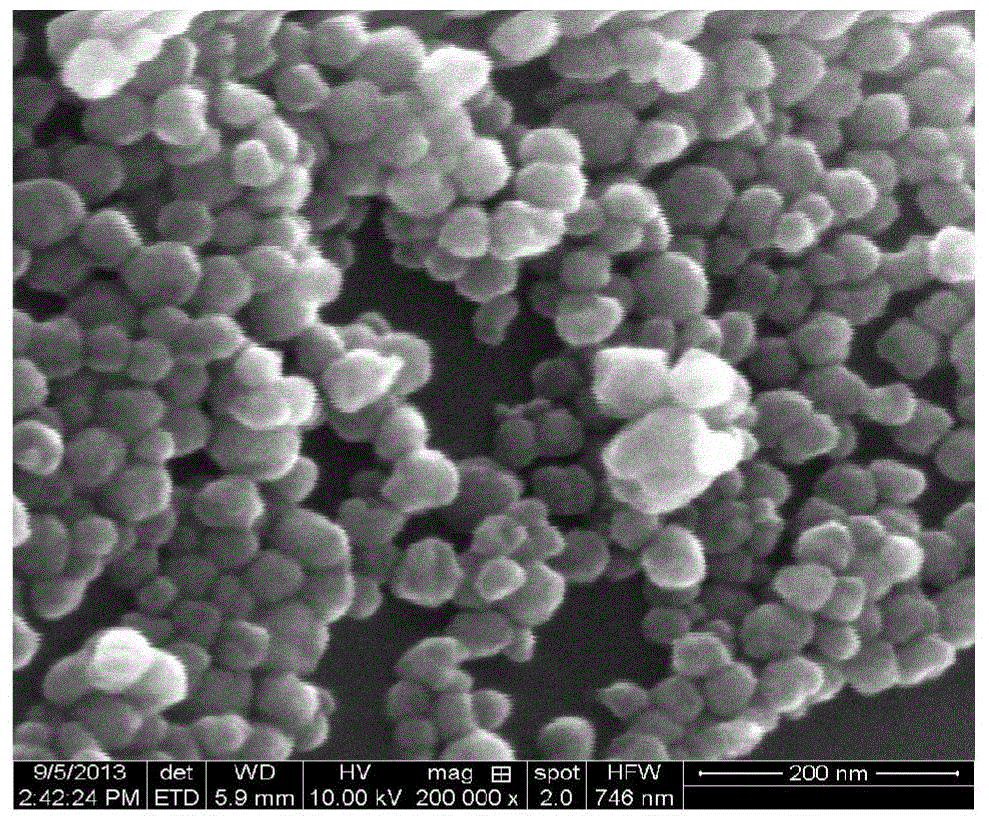

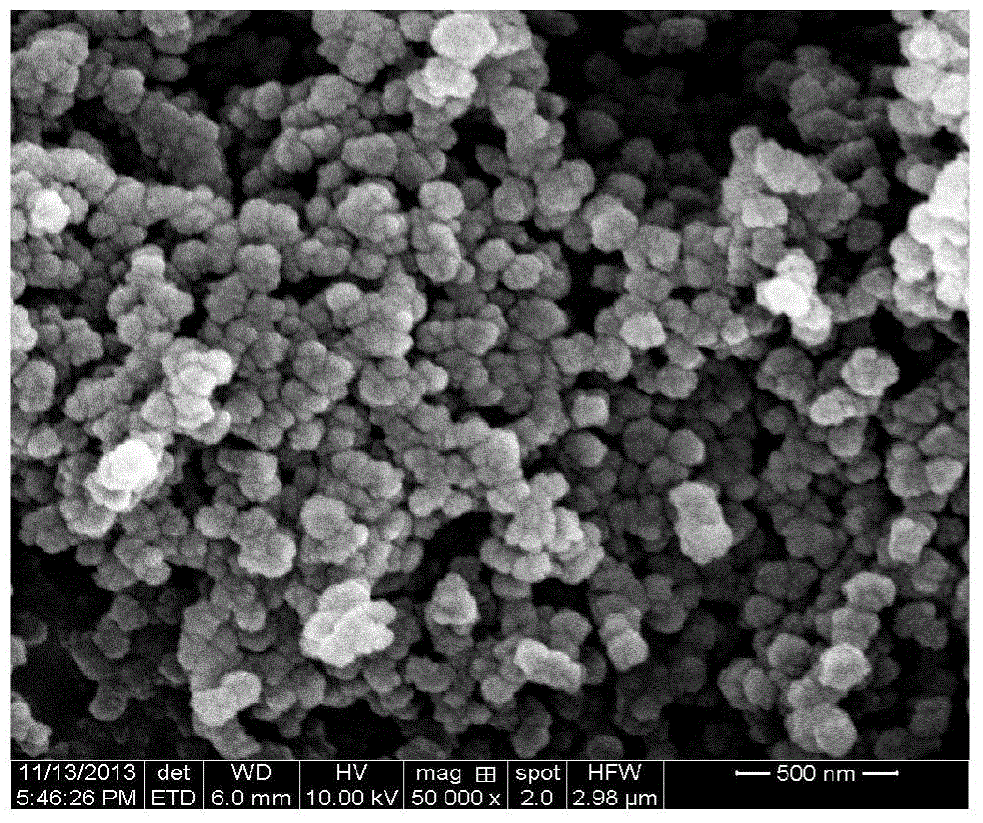

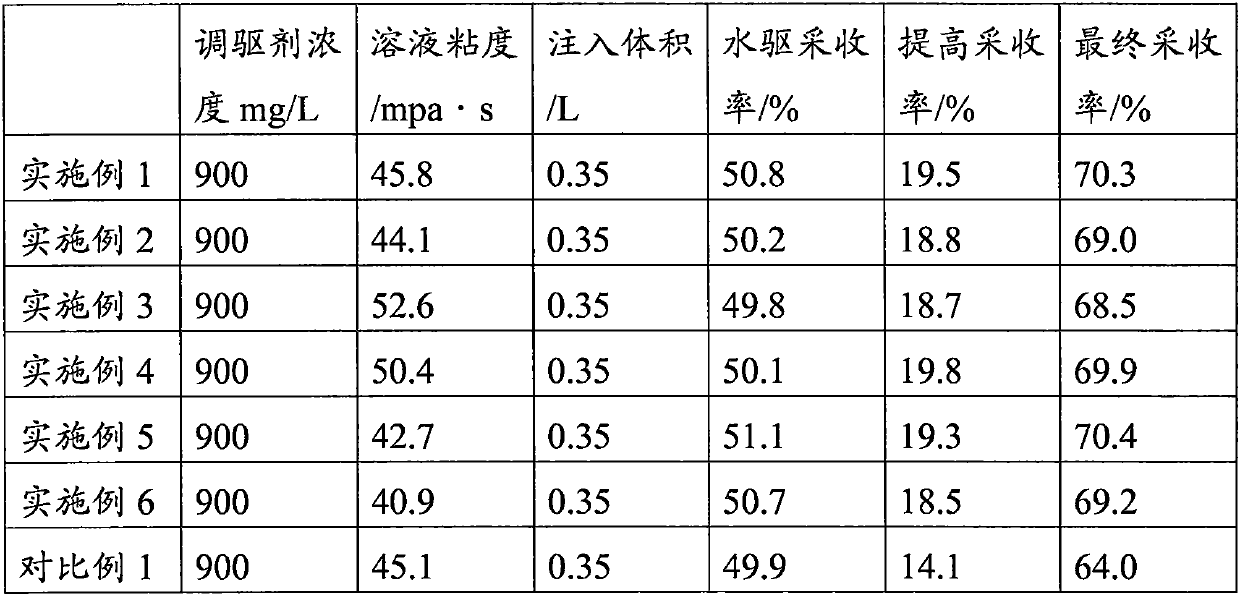

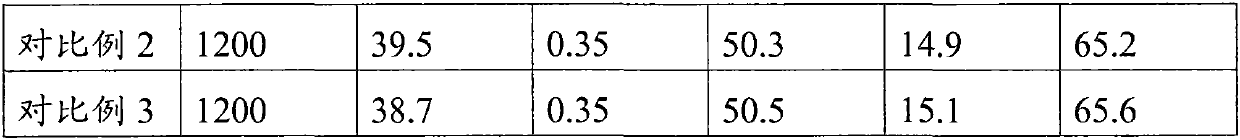

Polymer microsphere modifying and flooding agent and preparation method thereof

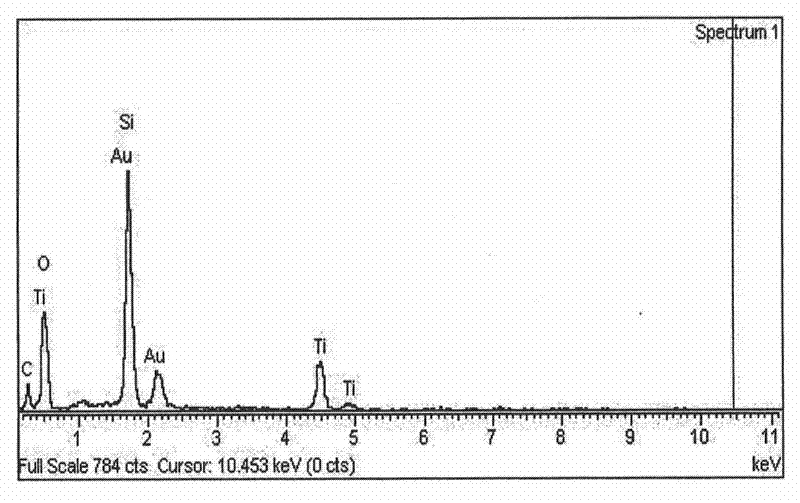

ActiveCN110483688AImprove high temperature resistanceImprove shear resistanceDrilling compositionPotassium persulfateCross-link

The invention discloses a polymer microsphere modifying and flooding agent. The polymer microsphere modifying and flooding agent comprises the following raw materials in parts by weight of 21-25 partsof acrylamide, 5-8 parts of an anionic surfactant, 0.5-1.2 parts of a cross-linking agent, 5-8 parts of an emulsifier, 1.5-2 parts of ammonium persulfate, 0.1-0.5 part of potassium persulfate, 150-250 parts of oil and 100-280 parts of deionized water, and is obtained by uniformly stirring the oil and the emulsifier to form a continuous oil phase; dissolving the acrylamide, the anionic surfactant,the cross-linking agent and part of ammonium persulfate in the deionized water to form a water phase; preparing a potassium persulfate solution and an ammonium persulfate solution; and adding the water phase into the oil phase, adding the ammonium persulfate solution at a low temperature and adding the potassium persulfate solution at a high-temperature, reacting at a constant temperature, and naturally cooling to a room temperature. According to the polymer microsphere modifying and flooding agent provided by the invention, and through the combined reaction of the above materials, the polymer gel microspheres with good gel ductility matched with the pore throat size of the polymer gel microspheres can be synthesized, and the recovery ratio of the petroleum is greatly improved.

Owner:东营市惠好科技开发有限责任公司

Magnetic paper prepared by recycling paper diaper leftover material fibers and preparation method thereof

InactiveCN110438840AImprove magnetismGood strength performanceCoatings with pigmentsSpecial paperFiberSlurry

The invention discloses magnetic paper prepared by recycling leftover material fibers of paper diapers, which comprises a magnetic raw paper layer, and magnetic coatings are arranged on the front surface and the back surface of the magnetic raw paper layer. The magnetic paper solves the problem of low retention rate of Fe3O4 in the existing magnetic paper. The preparation method of the magnetic paper comprises the following steps: 1, crushing paper diaper leftover material fibers, dissolving the crushed paper diaper leftover material fibers in water, sequentially adding polyaluminum chloride,bentonite, zeolite powder and nano ferroferric oxide, fully stirring to obtain a slurry, and defibering the slurry; 2, papermaking the fiber pulp into paper; 3, adding sodium alginate, konjac gum, humic acid, nano Fe3O4 and a silane coupling agent into water, and continuously stirring the mixture for later use of sizing; and 4, sizing the front and back sides of the paper made in the step 2 by using a sizing machine with the sizing agent in the step 3, soaking the sized paper in a calcium chloride solution, taking out the paper, and feeding the paper into a glazing dryer for drying and calendaring treatment. The method is simple and easy to operate.

Owner:SHAANXI UNIV OF SCI & TECH

High-tear-resistance rubber cable material

InactiveCN105985545AImprove reinforcementHigh chemical stabilityRubber insulatorsChemistryGlass microsphere

The invention discloses a high-tear-resistance rubber cable material which is prepared from the following raw materials in parts by weight: 11-13 parts of barium fluoride, 5-7 parts of magnesium carbonate, 7-9 parts of peat soil, 60-66 parts of nitrile-butadiene rubber, 55-60 parts of chloroprene rubber, 3-4 parts of eucalyptus essential oil, 1-1.4 parts of copper naphthenate, 55-70 parts of natural rubber, 2-3 parts of zinc oxide, 30-40 parts of hollow glass microsphere, 2-2.4 parts of argil, 2-3 parts of calcium hydroxide, 1-1.3 parts of silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 part of diethylenetriamine, 0.1-0.2 part of accelerator DA, 2.6-3 parts of silane coupling agent kh570 and a right amount of distilled water. The high-tear-resistance rubber cable material can effectively prevent the cable from cracking, has the advantages of fewer cable short circuits and moisture resistance and prolongs the service life of the cable.

Owner:JING FENG GRP

High-cold-resistance rubber cable material

InactiveCN105985542AImprove reinforcement effectGood chemical stabilityRubber insulatorsDiethylenetriamineGlass microsphere

The invention discloses a high cold-resistant rubber cable material, which is made of the following raw materials in parts by weight: pine oil 2-3, aluminum tripolyphosphate 1-1.4, heavy calcium powder 10-13, tungsten boride 4-5, crushed Glass powder 10‑13, diisodecyl adipate 0.8‑1, ethanolamine 2‑2.5, silicone masterbatch 3‑4, petrolatum 3‑4, ACR anti-impact agent 2‑3, isoprene rubber 60‑67, chlorine Butadiene rubber 55‑60, natural rubber 55‑70, hollow glass microspheres 30‑40, silane coupling agent kh5501‑1.3, epoxy resin E4412‑16, diethylenetriamine 0.06‑0.1, accelerator DA0.1‑0.2 , silane coupling agent kh5702.6‑3, appropriate amount of distilled water; the rubber cable material prepared by the present invention has excellent mechanical properties, good aging resistance, high hardness, and is not easily damaged. It is used as a cable material with good overall performance, long service life, and application prospects widely.

Owner:JING FENG GRP

A high-temperature resistant low-smoke flame retardant rubber cable material

InactiveCN105968451AImprove reinforcement effectGood chemical stabilityRubber insulatorsInsulated cablesFiberFireproofing

A high-temperature resistant low-smoke flame retardant rubber cable material is disclosed. The cable material is prepared from 12-15 parts by weight of friction powder made of cashew nut shell oil, 13-15 parts by weight of barium metaphosphate, 7-8 parts by weight of alumina, 10-13 parts by weight of basalt fibres, 4-5 parts by weight of castor oil, 2-3 parts by weight of dioctyl terephthalate, 3-4 parts by weight of an antioxidant 1035, 3-4 parts by weight of triallyl isocyanurate, 55-65 parts by weight of butadiene-acrylonitrile rubber, 55-60 parts by weight of chloroprene rubber, 2-3 parts by weight of paraffin oil, 3-4 parts by weight of zinc stearate, 55-70 parts by weight of natural rubber, 30-40 parts by weight of hollow glass micro beads, 1-1.3 parts by weight of a silane coupling agent kh550, 12-16 parts by weight of epoxy resin E44, 0.06-0.1 part by weight of diethylenetriamine, 0.1-0.2 part by weight of an accelerant NS, 2.6-3 parts by weight of a silane coupling agent kh570 and a proper amount of distilled water. The cable material is good in fireproofing performance, flame retardant, not liable to combust, low in smoke, long in service lifetime, capable of saving resources and good in practicability.

Owner:ANHUI CABLE

Surface modified calcium carbonate and preparation method thereof

InactiveCN101671494BReduce forceAct quicklyNon-macromolecular adhesive additivesPigment treatment with non-polymer organic compoundsAdhesiveRenewable resource

The invention relates to surface modified calcium carbonate and a preparation method thereof. The surface modified calcium carbonate is prepared by adding tung oil series of derivative modifiers or acetone solution of the modifier into heavy calcium carbonate dry power or light calcium carbonate water suspension for coating for 10-30 minutes at 30-100 DEG C, with the modifier or acetone solution of the modifier being 0.5-2.5 weight percent of the calcium carbonate. The tung oil series of derivative biological surface modifiers used in the invention is renewable resource; the production processis easy to popularize and implement with low cost and no pollution. The modifier contains a carboxyl which can be chemically combined with calcium ions on the surface of calcium carbonate, so that the surface of the calcium carbonate is changed from hydrophilicity to hydrophobicity to enhance the action between the calcium carbonate and interface of polymers; unsaturated bonds of the modifier plays a role of crosslinking during polymer processing; and the modified calcium carbonate can be used for filling plastic, rubber, adhesive and the like, improves the toughness of composite material, reduces the production cost and has wide application prospect on the basis of ensuring the mechanical strength.

Owner:ZHANGJIAJIE HENGLIANG MINING

Recycled paper diaper leftover material fiber reconstituted antibacterial paper and preparation method thereof

InactiveCN110396860AHigh strengthBreaking down SAP barriersSpecial paperWater-repelling agents additionFiberAntibacterial coating

The invention discloses recycled paper diaper leftover material fiber recycled antibacterial paper. The paper comprises an antibacterial raw paper layer, and antibacterial coatings are arranged on thefront face and the back face of the antibacterial raw paper layer. The invention also discloses a preparation method of the antibacterial paper. The method comprises the following steps: 1, pulverizing paper diaper leftover material fibers, dissolving the pulverized fibers into water, sequentially adding polyaluminum chloride, bentonite, zeolite powder and nano titanium dioxide, performing sufficient stirring, and performing defibering to obtain fiber pulp; 2, performing papermaking on the fiber pulp obtained after treatment in the step 1; 3, simultaneously dissolving sodium alginate and konjac glucomannan into water to obtain a mixed solution, so as to obtain a modified sodium alginate sizing agent; 4, sizing the front and back surfaces of the antibacterial raw paper with the sizing agent obtained in the step 3; and 5, soaking the sized paper obtained in the step 4 into a zinc chloride solution for 30 minutes, then performing soaking in water for 10 seconds to obtain antibacterial coatings, taking out the coated paper, and feeding the coated paper into a calendering dryer for drying and calendaring treatment. The method provided by the invention is simple and easy to operate.

Owner:SHAANXI UNIV OF SCI & TECH

Cold-resistant and impact-resistant rubber cable material

InactiveCN105985544AImprove reinforcement effectGood chemical stabilityRubber insulatorsEpoxyPolymer science

The invention discloses a cold-resistant and impact-resistant rubber cable material, prepared from the following raw materials in parts by weight: 5-6 of gas-phase alumina, 58-65 of nitrile rubber, 6-8 of humite, 10-13 of wear-resistant carbon black, 3-4 of magnesia, 4-6 of zinc borate, 2-3 of polytetrafluoroethylene, 55-60 of neoprene, 55-70 of natural rubber, 1-2 of 1,2-hydroxy stearic acid, 30-40 of hollow glass microspheres, 1-1.3 of silane coupling agent kh550, 12-16 of epoxy resin E44, 0.06-0.1 of diethylenetriamine, 0.1-0.2 of accelerant DA, 2.6-3 of silane coupling agent kh570 and a proper amount of distilled water. The cold-resistant and impact-resistant rubber cable material has excellent cold resistance and impact resistance, good oxygen and ozone resistance, aging resistance, long service life, simple preparation process and convenience in actual operation.

Owner:JING FENG GRP

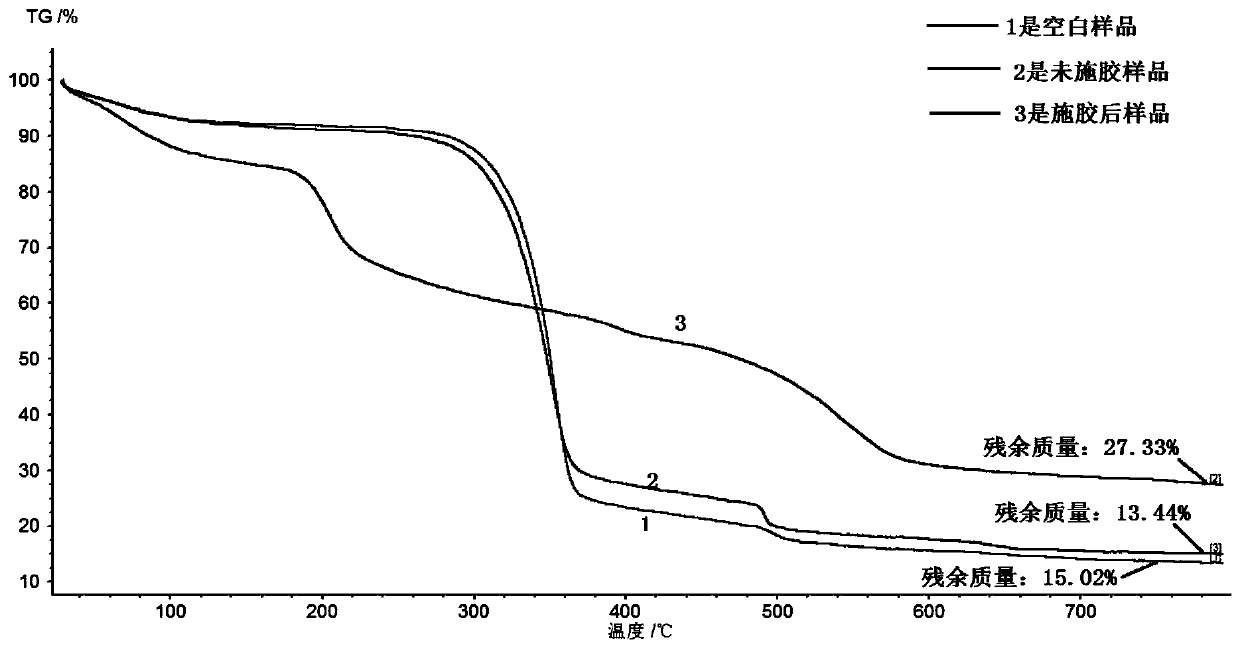

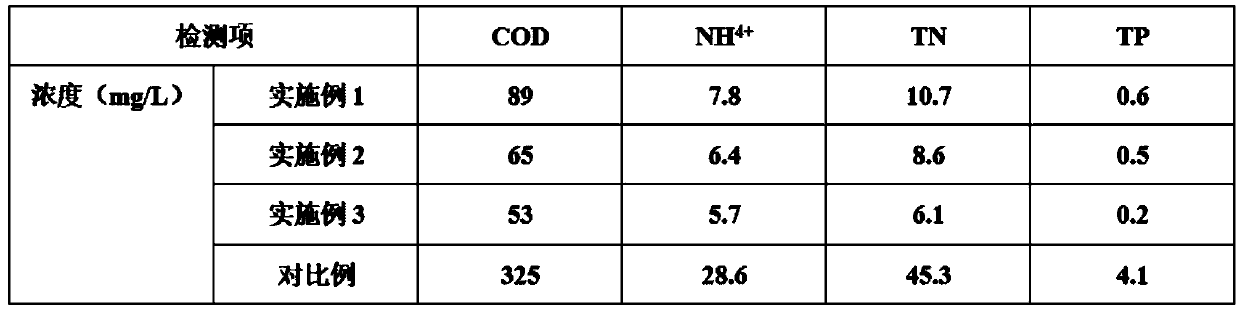

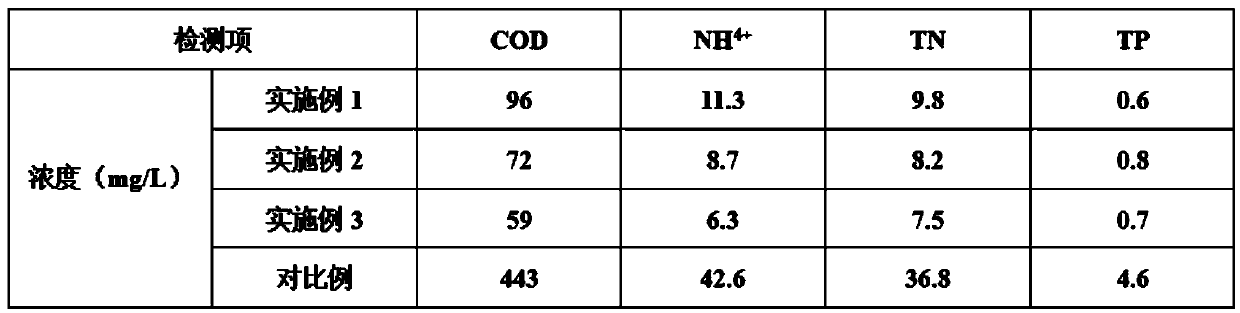

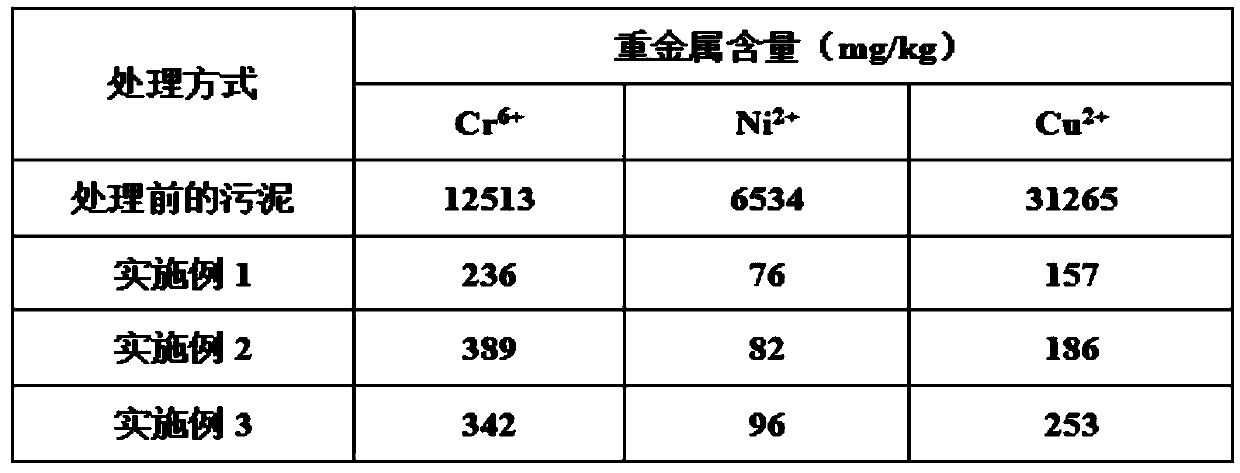

Method for digesting black and odorous river by microbial preparation

InactiveCN110818180ALow toxicityActs as a redox mediatorWater treatment parameter controlMultistage water/sewage treatmentSludgeSewage

The invention relates to the field of black and odorous river digestion, and concretely relates to a method for digesting a black and odorous river by a microbial preparation. The method for digestingthe black and odorous river by the microbial preparation comprises the following steps: (1) pretreatment of the black and odorous river; (2) sewage treatment; (3) sludge treatment; and (4) application of a sludge treatment material. The problems of poor degradation capacity on pollutants such as nitrogen, phosphorus and organic matters, low treatment efficiency and unobvious black and odorous water elimination effect in the process of applying microbial preparations in the prior art to treatment of the black and odorous water are solved. The method for digesting the black and odorous river bythe microbial preparation is perfect, achieves excellent effect, realizes reasonable utilization of wastes, and meets the requirements of the national sustainable development strategy.

Owner:ZHEJIANG WORLD CLEAN ENVIRONMENT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com