Ferulic acid-collagen antimicrobial film, and preparation method and application thereof

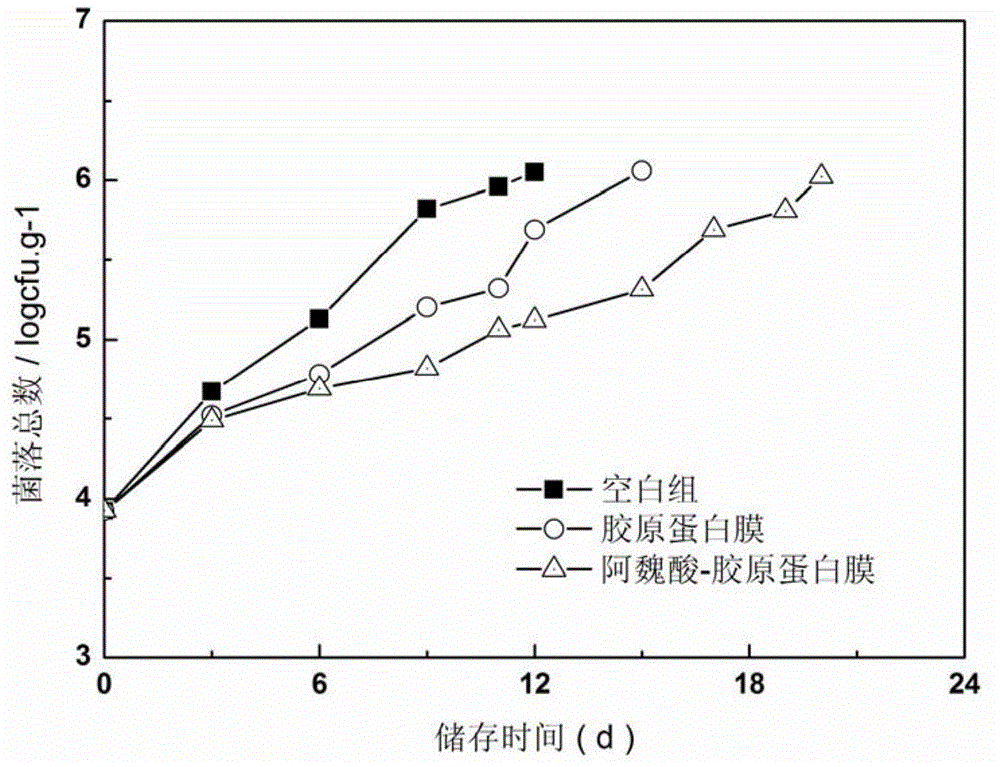

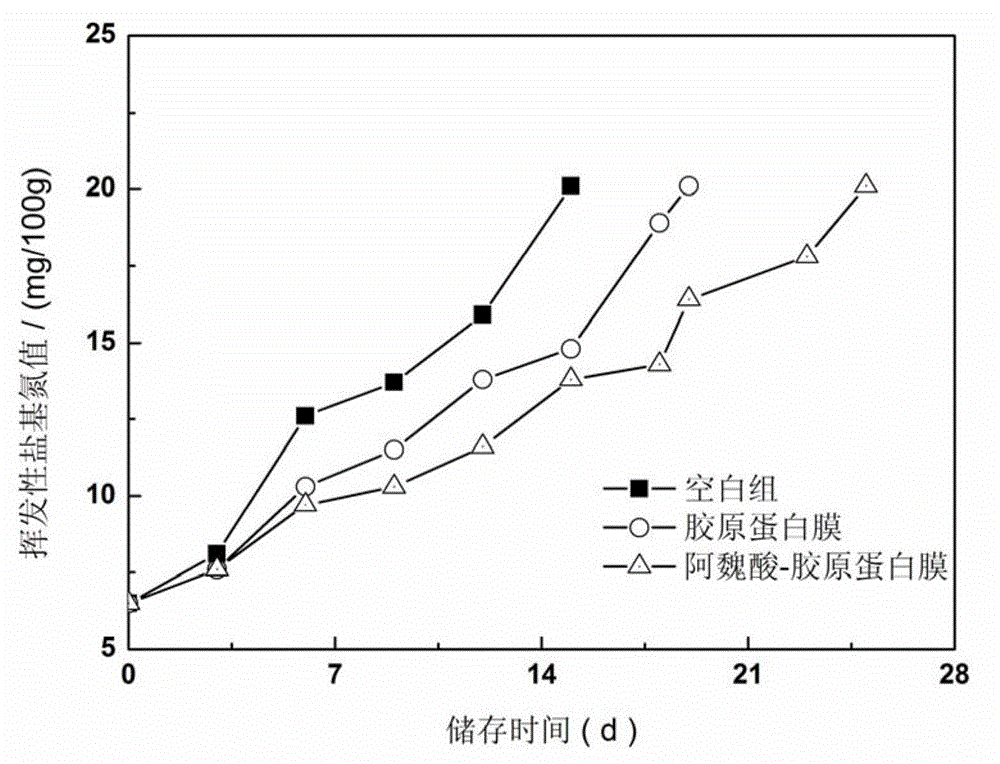

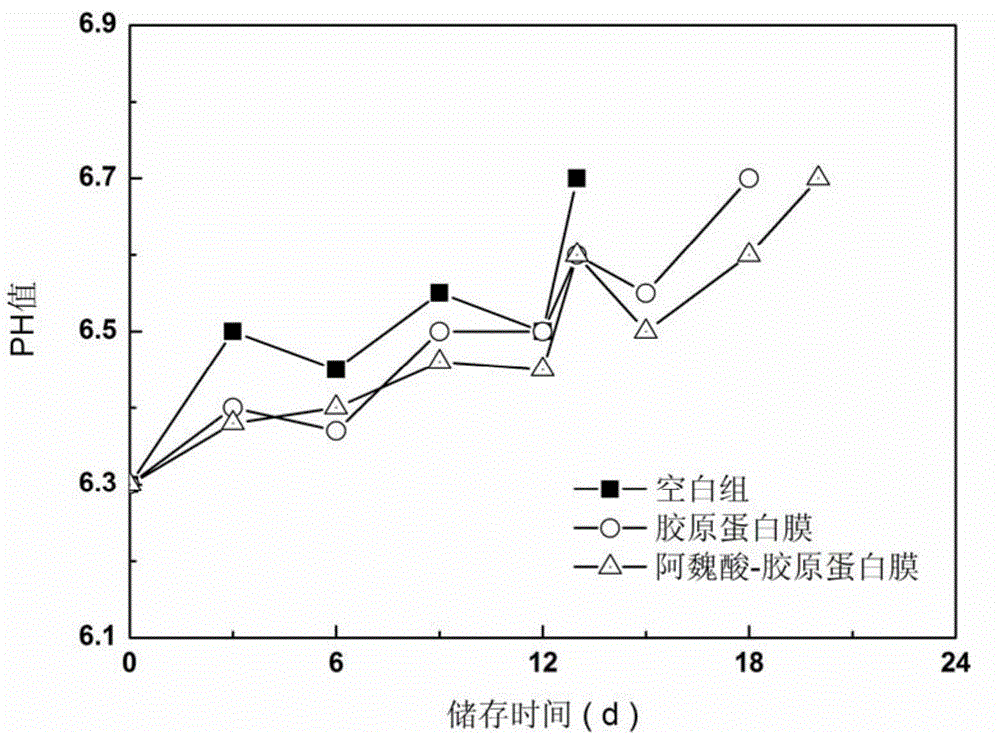

A collagen and ‐collagen technology, applied in the field of green food processing, can solve the problems of preparing antibacterial film with ferulic acid and collagen, and achieve the effect of changing the surface gas environment, strong antibacterial ability, and improving barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add collagen to water, stir and dissolve under the condition of heat treatment temperature of 60℃~70℃, add glycerin, dialdehyde starch, sodium alginate and ferulic acid in sequence, the concentration of collagen is 10% based on the mass concentration in the solution , ferulic acid is 0.28%, glycerin is 2.83%, dialdehyde starch is 0.41%; sodium alginate is 0.6%. Heat treatment at 60°C for 25 minutes, place in a stirring defoamer to remove air bubbles, and then cast on a plexiglass plate. After the film-forming liquid is cooled, bake in an oven at 60°C for 5 hours, and cool at room temperature. Then peel off the film to prepare the ferulic acid-collagen antibacterial film. The thickness of the formed film was 0.21 mm.

[0034] An evaluation team of 5 people was established. In a non-interfering environment, the sensory testing of the formed film is shown in Table 1. The transparency, gloss, surface smoothness and odor of the formed film are all good, and the film is easy...

Embodiment 2

[0061] A method for preparing a ferulic acid-collagen antibacterial film: adding collagen to water, stirring and dissolving at a heat treatment temperature of 70°C, adding glycerin, dialdehyde starch, sodium alginate and ferulic acid in sequence, and using In terms of mass concentration, collagen concentration is 6%, ferulic acid is 0.30%, glycerin is 2.40%, dialdehyde starch is 0.60%; sodium alginate is 0.40%. Heat treatment at 70°C for 20 minutes, place in a stirring defoamer to remove air bubbles for 18 minutes, then cast on a plexiglass plate, after the film-forming liquid is cooled, bake in an oven at 60°C for 5 hours, and cool at room temperature , and then uncover the film to prepare the ferulic acid-collagen antibacterial film. The thickness of the formed film was 0.21 mm. The results of sensory testing of the film are shown in Table 1. Referring to Xiao et al. pumpkin-soybean protein isolate composite edible film (Journal of Zhongkai College of Agricultural Engineer...

Embodiment 3

[0063] A method for preparing a ferulic acid-collagen antibacterial film: adding collagen to water, stirring and dissolving at a heat treatment temperature of 65° C., adding glycerin, dialdehyde starch, sodium alginate and ferulic acid in sequence, to the solution In terms of mass concentration, collagen concentration is 14%, ferulic acid is 0.14%, glycerin is 2.80%, dialdehyde starch is 0.28%; sodium alginate is 1.68%. Heat treatment at 65°C for 30 minutes, place in a stirring defoaming machine to remove air bubbles for 19 minutes, then cast on a plexiglass plate, bake in an oven at 60°C for 4 hours after the film-forming liquid is cooled, and cool at room temperature , and then uncover the film to prepare the ferulic acid-collagen antibacterial film. The thickness of the formed film was 0.21 mm. The results of sensory testing of the film are shown in Table 1. Referring to the method of pumpkin-soybean protein isolate composite edible film by Xiao et al. (Journal of Zhongka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com