Recycled paper diaper leftover material fiber reconstituted antibacterial paper and preparation method thereof

A technology of scraps and diapers, which is applied in the field of pulp and paper making, can solve the problems of superabsorbent resin barrier, low paper strength, and high difficulty, and achieve the effects of improving social and economic benefits, good strength performance, and saving transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a method for preparing the above-mentioned recycled diaper scrap fiber reconstituted antibacterial paper, the specific steps are as follows:

[0057] Step 1, pulverizing the leftover fiber of the diaper and dissolving it in water, then adding polyaluminum chloride, bentonite, zeolite powder, and nano-titanium dioxide in order to fully stir, and then dispersing to obtain a fiber slurry;

[0058] In step 1, the amount of polyaluminum chloride added is 0.5% to 0.8% of the fiber mass of diaper scraps; the amount of bentonite added is 0.3% to 1.0% of the mass of diaper scrap fibers; the amount of zeolite powder added is 0.5% of the mass of diaper scrap fibers. 0.1% to 0.5%; the amount of nano-titanium dioxide added is 10% to 40% of the fiber mass of diaper scraps;

[0059] In step 1, use the deflagging machine to decompose the slurry, and the rotating speed is 25000 revolutions;

[0060] Step 2, papermaking the fiber slurry obtained after...

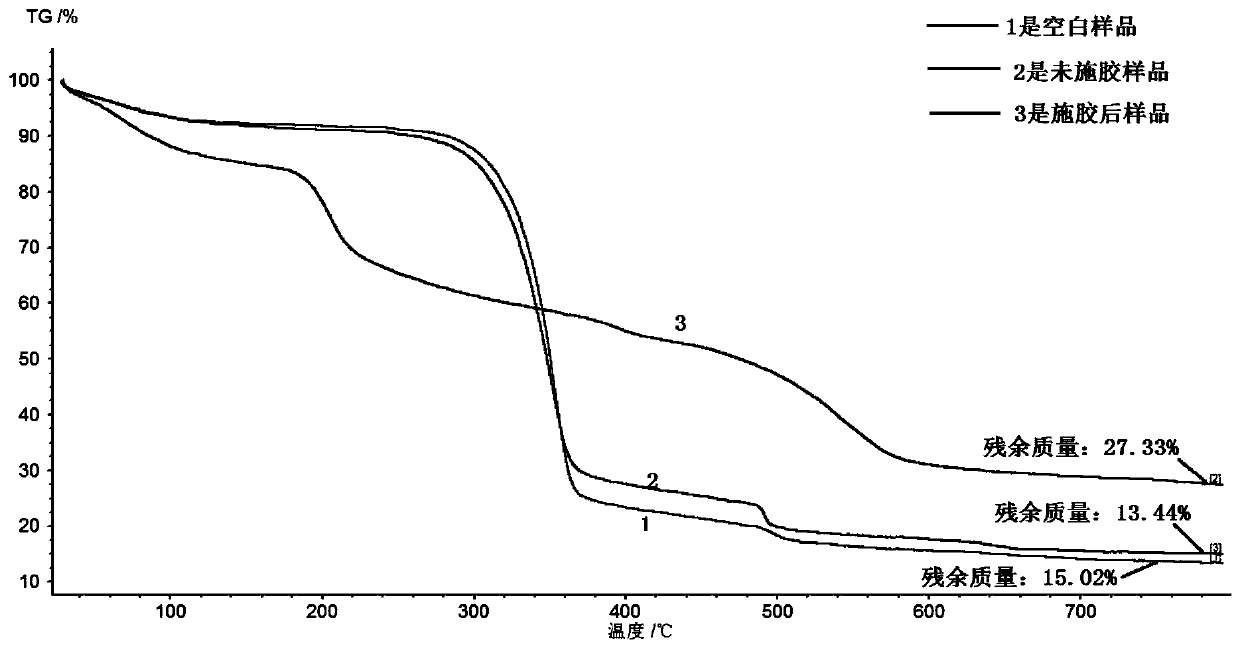

Embodiment 1

[0075] 1) The crushed absorbent layer of diaper scraps was collected as the raw material for the experiment, and the raw material came from a diaper manufacturer.

[0076] 2) Take 2.6 grams of the pulverized sample of paper diaper scrap fiber, add it to 500ml of water, use the 260 type deflagger machine produced by Sweden AB L&W company to decompose the slurry, decompose at 25000 rpm, add water until the concentration of the slurry reaches 0.5%, and use a paper sampler Papermaking and drying at 105° C. were performed to prepare paper sheets, which were used as blank samples.

[0077] 3) Take 2.6 grams of diaper scrap fiber pulverized sample, add 300ml of water, and weigh 0.5% polyaluminum chloride relative to the diaper scrap fiber mass, 1.0% bentonite relative to the diaper scrap fiber mass, and 1.0% bentonite relative to the diaper scrap fiber mass. 0.5% zeolite powder of the fiber quality, 40% nano-titanium dioxide relative to the fiber quality of paper diaper scraps, and a...

Embodiment 2

[0081] Take 2.6 grams of the pulverized sample of diaper scrap fiber, add it to 300ml of water, and weigh 0.6% of polyaluminum chloride relative to the mass of diaper scrap fiber, 0.5% of bentonite relative to the mass of diaper scrap fiber, and 0.5% of the weight of diaper scrap fiber. 0.3% zeolite powder, 30% nano-titanium dioxide relative to the quality of paper diaper scrap fiber, and add it to the fiber slurry, add water to 500ml, stir evenly, and then use the 260 type produced by Sweden AB L&W company The deflaking machine decomposes the pulp, decomposes at 25,000 rpm, puts it into the paper sample picker after the fiber decompression is completed, adds water until the concentration of the pulp on the Internet reaches 0.5%, drains the water to make it a wet paper web, and then manually presses it with a press roller, and finally Put it into a paper sheet dryer, and dry it at a temperature of 105°C for 5 minutes under a vacuum of 0.06 MPa. After drying, put it in a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com