Surface modified calcium carbonate and preparation method thereof

A technology of surface modification and surface modifier, applied in the field of calcium carbonate, can solve the problems of unsatisfactory modification effect, stay in the research stage, few action points, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Dissolve 2.5g of tung oil anhydride in 5ml of acetone to form an acetone solution, add 100g of light calcium carbonate aqueous suspension into a high-speed dispersing mixer, add the acetone solution of tung oil anhydride at 80°C, mix well, stir and coat After 30 minutes, dehydration, drying, crushing and sieving are carried out after the coating is completed, and the modified light calcium carbonate is obtained, and the activation degree is >99%.

Embodiment 2

[0018] Add 100g of heavy calcium carbonate dry powder into a high-speed disperser, add 2.0g of oleic acid at 100°C, fully mix and coat for 20 minutes, dry, pulverize, and sieve after coating to obtain modified heavy calcium carbonate calcium carbonate.

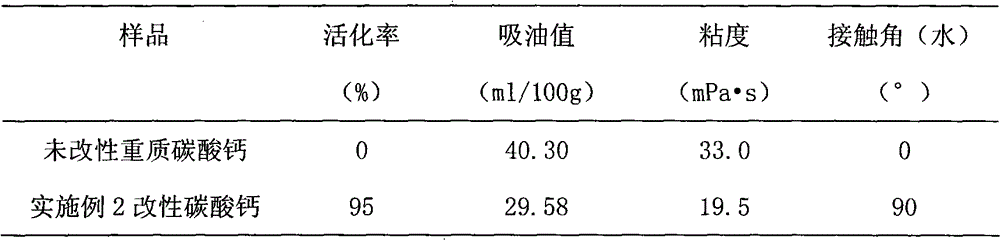

[0019] Table 1 Modification effects of modifiers

[0020]

[0021] Table 1 shows that its activation rate of the modified calcium carbonate obtained in Example 2 reaches 95%, and the calcium carbonate surface has changed from hydrophilic to hydrophobic.

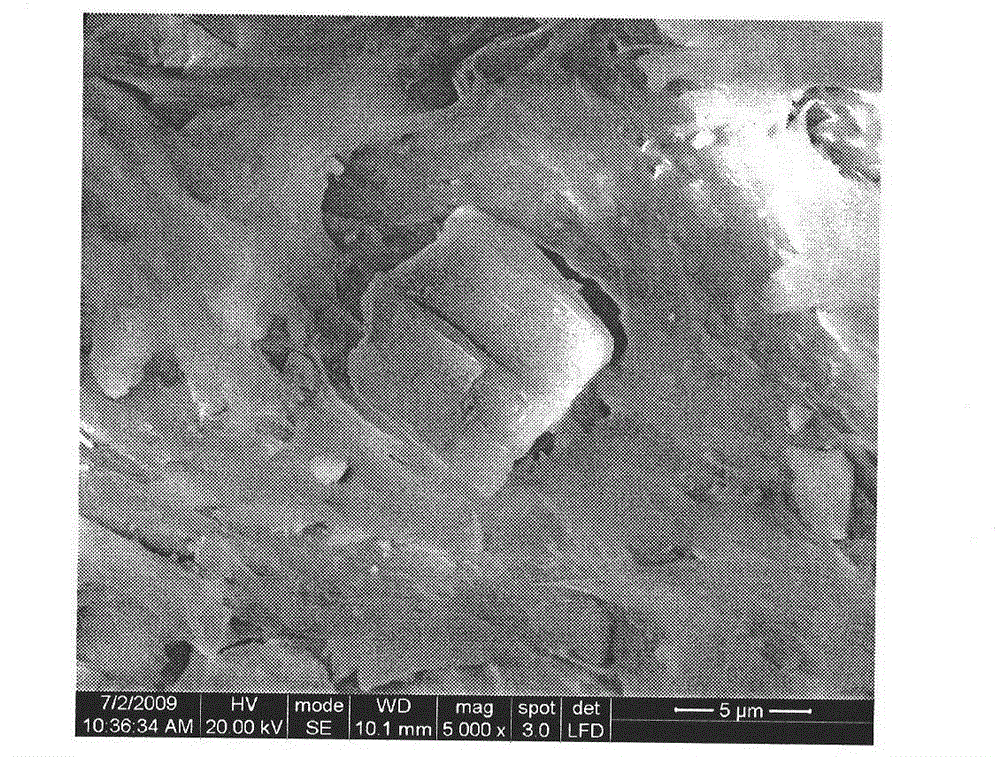

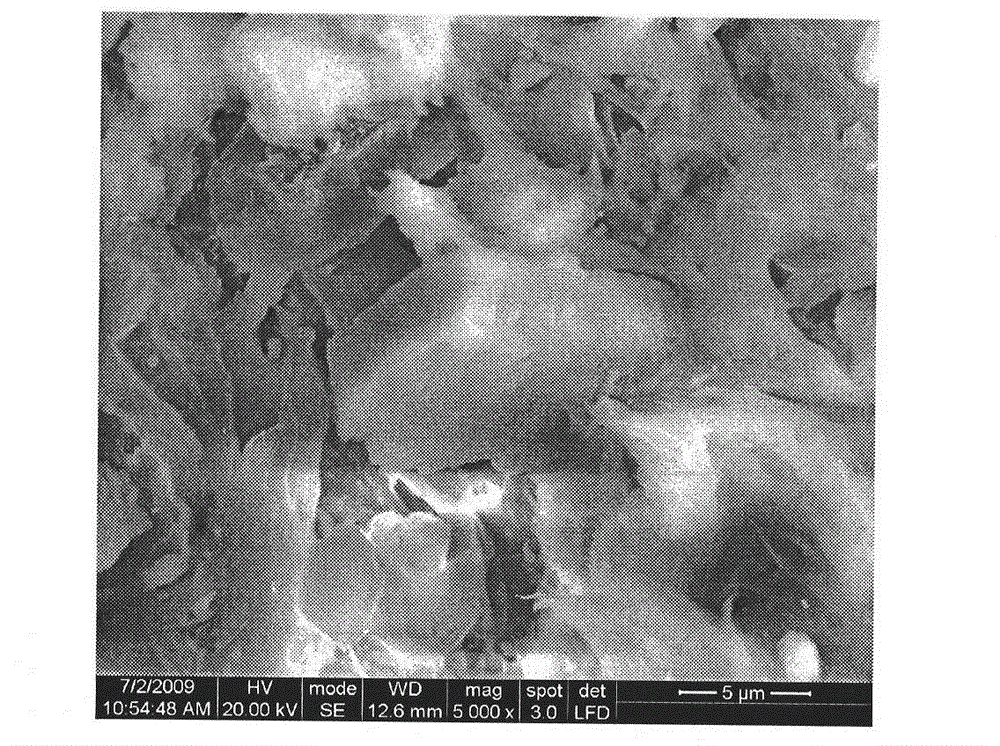

[0022] Unmodified heavy calcium carbonate is easy to agglomerate, unevenly dispersed, the gap between particles is large, and the oil absorption value is high; the modified calcium carbonate penetrates into the interior of the particles or covers the surface due to the coating of a modifier on the surface. The gap between the particles is reduced, the bulk density is reduced, and the oil absorption value is reduced.

[0023] Unmodified heavy calcium carbonate is not easy...

Embodiment 3

[0026] Dissolve 1.5g of citric acid anhydride in 5ml of acetone to form an acetone solution. Add 100g of heavy calcium carbonate dry powder into the high-speed disperser, add the acetone solution of citronic anhydride at 50°C, mix and coat thoroughly for 20 minutes, after the coating is completed, dry, pulverize, and sieve to obtain the modified product. of heavy calcium carbonate.

[0027] The activation degree is more than 95%, the oil absorption value is 28.29ml / 100g, the contact angle of water on it is 99°, and the viscosity drop rate of the liquid paraffin suspension is 55% of the unmodified one. It shows that the surface of modified calcium carbonate has changed from hydrophilic to hydrophobic, and its dispersibility is greatly improved, and the degree of particle agglomeration is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com