Hydrophobic lipophilic surface-modified calcium carbonate and preparation method thereof

A surface modification, hydrophobic and lipophilic technology, applied in chemical instruments and methods, fibrous fillers, dyeing physical treatment, etc., can solve problems such as large specific surface area, high surface energy, and performance degradation of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

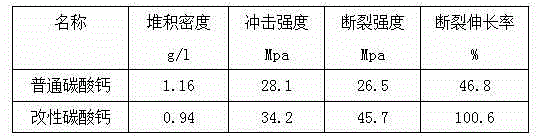

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below through specific examples.

[0015] A hydrophobic and lipophilic surface-modified calcium carbonate, prepared from the following raw materials in parts by weight (kg): calcium carbonate 90, glass fiber 2, polylactic acid 5, polydimethylsiloxane 2, epoxidized glycerin Triester 3, silica sol 3, wood tar 1, titanium tetrachloride 2, expanded perlite 2, modified titanium dioxide 2.5;

[0016] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): nanometer titanium dioxide 50, mica powder 2, crushed zeolite molecular sieve 4, ferrocene 5, mineral fiber 3, sodium pyrophosphate 2, pure acrylic emulsion 3, ring Butyl oxyoleate 3, phosphate ester 2, water 50; the preparation method is to first add pure acrylic emulsion, nano-titanium dioxide, mica powder, crushed zeolite molecular sieve, mineral fiber, and water to form a suspension, and then imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com