High-weather-resistance solar cell back plate and manufacturing method thereof

A technology of solar cells and weather resistance, which is applied in the direction of chemical instruments and methods, circuits, electronic equipment, etc., can solve the problems of low requirements for equipment and reaction conditions, poor adhesion and weather resistance, and poor interlayer peel strength, etc., to achieve Improve the anti-ultraviolet aging ability, not easy to fall off, and improve the compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

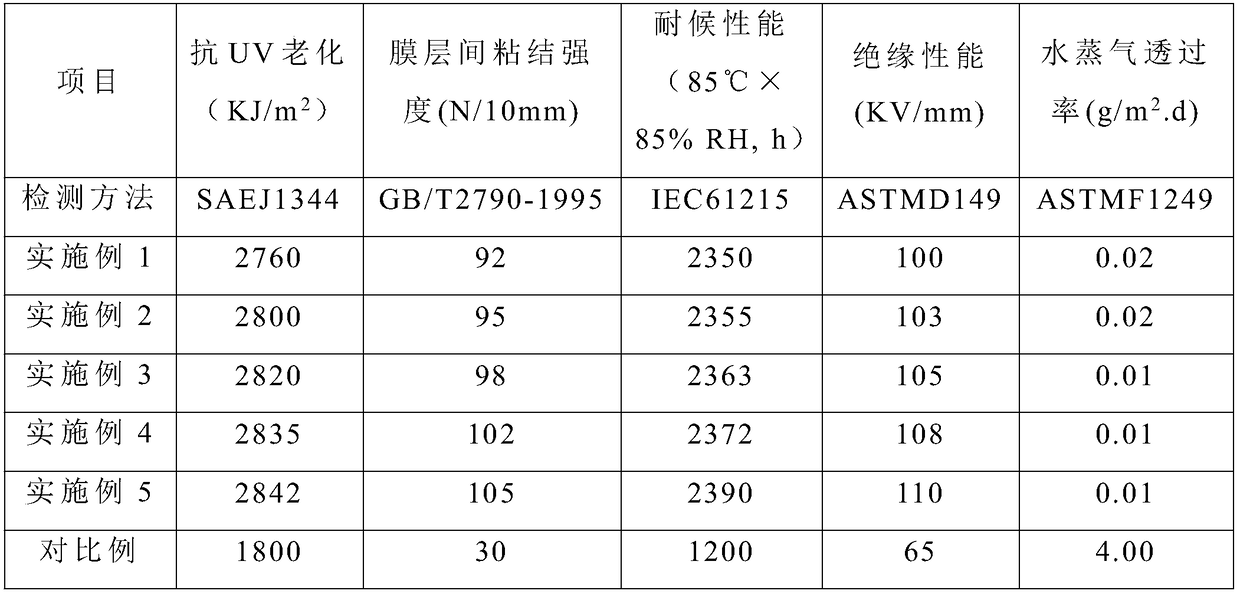

Examples

Embodiment 1

[0034] A high weather-resistant solar cell back sheet includes a first weather-resistant layer, an insulation and barrier layer, and a second weather-resistant layer from the inside to the outside, the first weather-resistant layer and the insulation and barrier layer, the insulation and barrier layer and the second The weather-resistant layers are respectively bonded by an adhesive layer; the first weather-resistant layer and the second weather-resistant layer are both silicon fluorene-based fluorine-containing resin material layers; the insulation and barrier layers are polyethylene terephthalate (PET) layer; the adhesive layer is a blend layer of ethylene-vinyl acetate copolymer and JD919 amino tetrafunctional epoxy resin.

[0035] The preparation method of the silicon fluorene-based fluorine-containing resin material includes the following steps:

[0036] 1) Combine 10 g of methyl vinyl silicon fluorene, 3 g of butadiene, 10 g of hexafluorobutyl methacrylate, 5 g of 2-vinylison...

Embodiment 2

[0045] A high weather-resistant solar cell back sheet includes a first weather-resistant layer, an insulation and barrier layer, and a second weather-resistant layer from the inside to the outside, the first weather-resistant layer and the insulation and barrier layer, the insulation and barrier layer and the second The weather-resistant layers are respectively bonded by an adhesive layer; the first weather-resistant layer and the second weather-resistant layer are both silicon fluorene-based fluorine-containing resin material layers; the insulation and barrier layers are polyethylene terephthalate (PET) layer; the adhesive layer is a blend layer of ethylene-vinyl acetate copolymer and JD919 amino tetrafunctional epoxy resin.

[0046] The preparation method of the silicon fluorene-based fluorine-containing resin material includes the following steps:

[0047] 3) Combine 10 g of methyl vinyl silicon fluorene, 3.5 g of butadiene, 10 g of hexafluorobutyl methacrylate, 6 g of 2-vinylis...

Embodiment 3

[0056] A high weather-resistant solar cell back sheet includes a first weather-resistant layer, an insulation and barrier layer, and a second weather-resistant layer from the inside to the outside, the first weather-resistant layer and the insulation and barrier layer, the insulation and barrier layer and the second The weather-resistant layers are respectively bonded by an adhesive layer; the first weather-resistant layer and the second weather-resistant layer are both silicon fluorene-based fluorine-containing resin material layers; the insulation and barrier layers are polyethylene terephthalate (PET) layer; the adhesive layer is a blend layer of ethylene-vinyl acetate copolymer and JD919 amino tetrafunctional epoxy resin.

[0057] The preparation method of the silicon fluorene-based fluorine-containing resin material includes the following steps:

[0058] 1) Mix 10 g of methyl vinyl silicon fluorene, 4.2 g of butadiene, 10 g of hexafluorobutyl methacrylate, 6.5 g of 2-vinylison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com