Surface-treated modified calcium carbonate and preparation method thereof

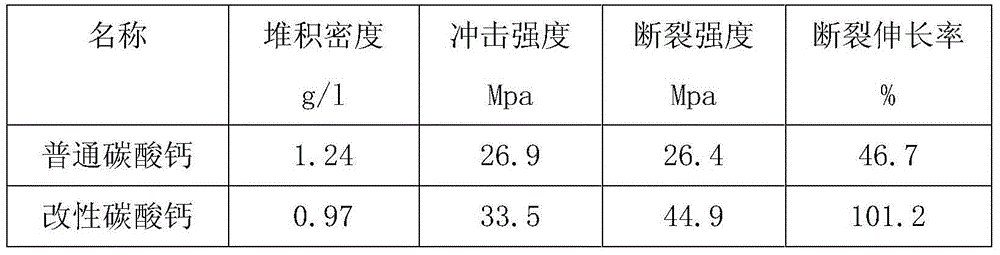

A surface treatment, calcium carbonate technology, applied in inorganic pigment treatment, chemical instruments and methods, dyeing low molecular organic compound treatment and other directions, can solve the problems of poor compatibility, different interface properties, material mechanical properties decline, etc. Good sex, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below through specific examples.

[0015] A surface-treated modified calcium carbonate prepared from the following raw materials in parts by weight (kg): calcium carbonate 85, glyceryl tristearate 1, polyaspartic acid 1.5, rosin resin 3, nylon 664, Palmitic acid 1, crushed palm fiber 2, mullite 2, hydroxypropyl cellulose 1, titanate coupling agent TC-WT0.8, modified titanium dioxide 2.5;

[0016] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): nano titanium dioxide 50, mica powder 2, pulverized zeolite molecular sieve 4, ferrocene 5, mineral fiber 3, sodium pyrophosphate 2, pure acrylic emulsion 3, ring Butyl oxyoleate 3, phosphate ester 2, water 50; the preparation method is to first add pure acrylic emulsion, nano-titanium dioxide, mica powder, crushed zeolite molecular sieve, mineral fiber, and water to form a suspension, and then imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com