Modified calcium carbonate with high specific surface area and preparation method thereof

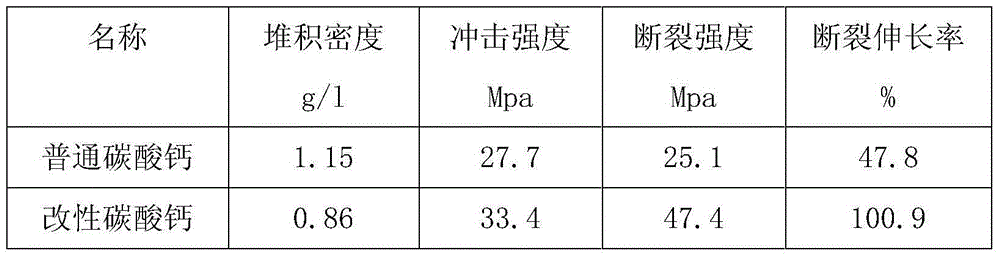

A high specific surface area, calcium carbonate technology, applied in chemical instruments and methods, dyed low-molecular organic compound treatment, dyed high-molecular organic compound treatment, etc., can solve the problems of composite material mechanical properties decline, interface defects, uniform dispersion, etc. Achieve the effect of stable product quality, low production cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below through specific examples.

[0015] A modified calcium carbonate with a high specific surface area is prepared from the following raw materials in parts by weight (kg): calcium carbonate 90, methyl methacrylate 4, melamine resin 5, propylene glycol sebacate polyester 3, coconut shell Activated carbon 2, fly ash 2, ammonium bicarbonate 1, turpentine 2, polysorbate 801, modified titanium dioxide 2.5;

[0016] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): nano titanium dioxide 50, mica powder 2, pulverized zeolite molecular sieve 4, ferrocene 5, mineral fiber 3, sodium pyrophosphate 2, pure acrylic emulsion 3, ring Butyl oxyoleate 3, phosphate ester 2, water 50; the preparation method is to first add pure acrylic emulsion, nano-titanium dioxide, mica powder, crushed zeolite molecular sieve, mineral fiber, and water to form a suspens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com