Glass fiber-reinforced polypropylene resin composition and molded body of same

A technology of resin composition and polypropylene, which is applied in the field of glass fiber reinforced polypropylene resin composition and its molded body, can solve mold pollution, obvious uneven tiger stripes, no consideration of mold pollution resistance, Mold release property molding Appearance The molded body has high temperature exudation resistance and rigidity/impact strength, etc., and achieves the effect of excellent high temperature exudation resistance, high rigidity, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

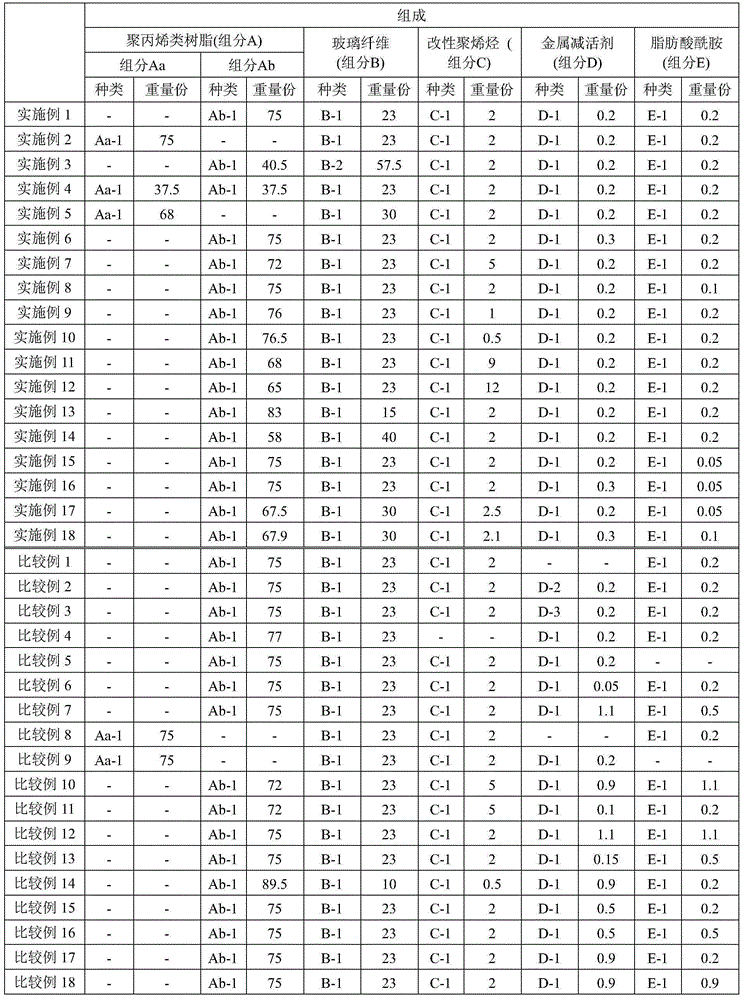

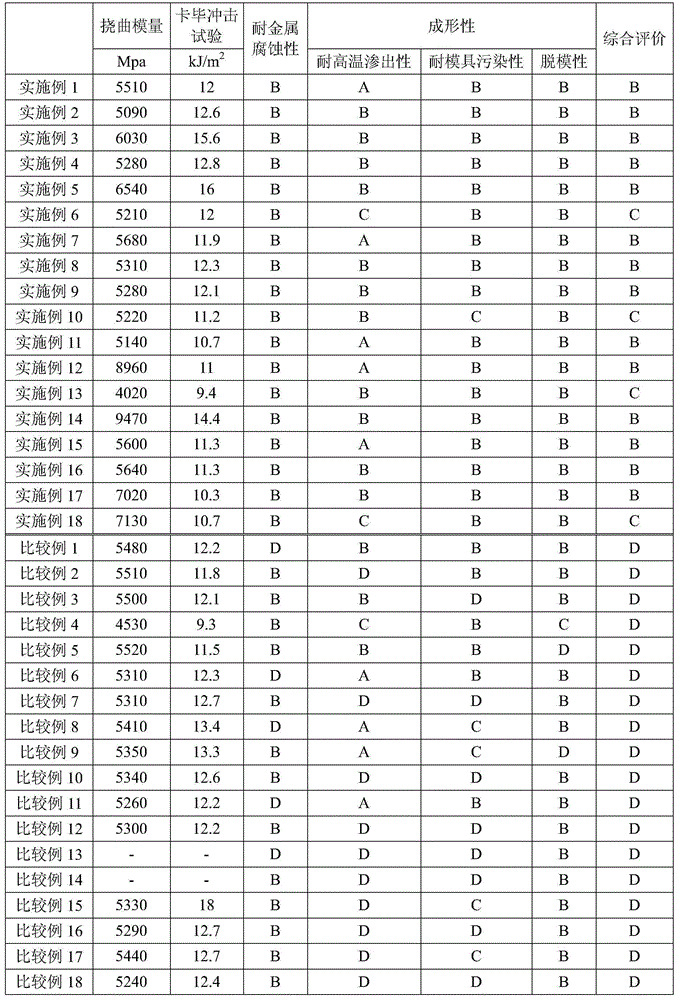

Embodiment 1-18 and comparative example 1-18

[0300] (1) Production of glass fiber reinforced polypropylene resin composition

[0301] Component A to Component E were mixed with the following additives based on the respective compositions shown in Table 1, and the resulting mixture was kneaded and pelletized under the following conditions to produce a glass fiber-reinforced polypropylene-based resin composition.

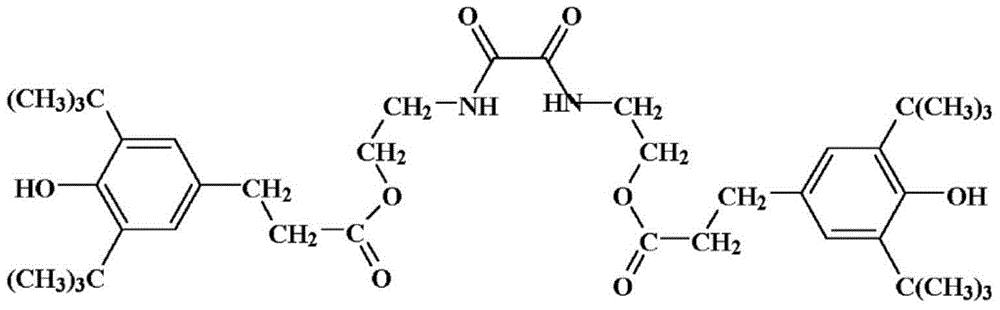

[0302] Here, 0.1 parts by weight of IRGANOX1010 manufactured by BASFSE, 0.05 parts by weight of IRGAFOS168 manufactured by BASFSE, 0.05 parts by weight of bis -2,2,6,6-tetramethyl-4-piperidinyl sebacate and 0.2 parts by weight of 2-(2'-hydroxy-3'-tert-butyl-5'-tolyl)-5 - Chlorobenzotriazoles.

[0303] Kneading machine: Twin-screw extruder "TEX30α" manufactured by TheJapan SteelWorks, LTD.

[0304] Mixing conditions: temperature = 180°C, screw revolutions = 300rpm, discharge speed = 10kg / hour

[0305] Component B-1 was fed from the middle side of the extruder. The average length of Component B-1 contained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com