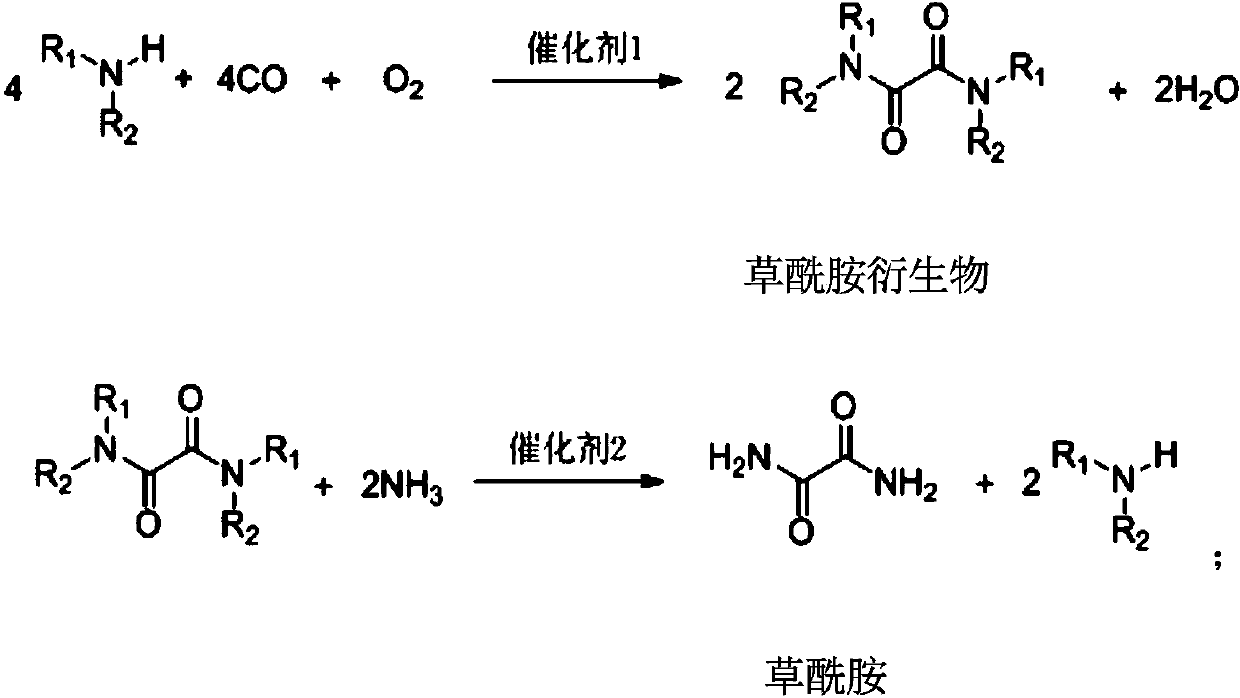

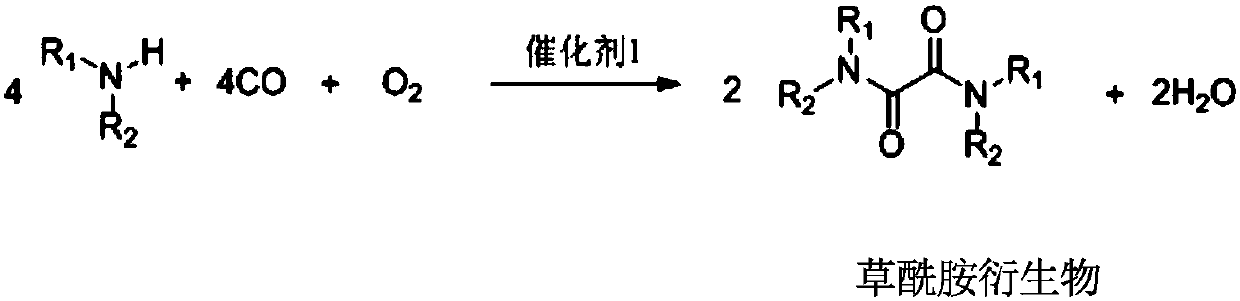

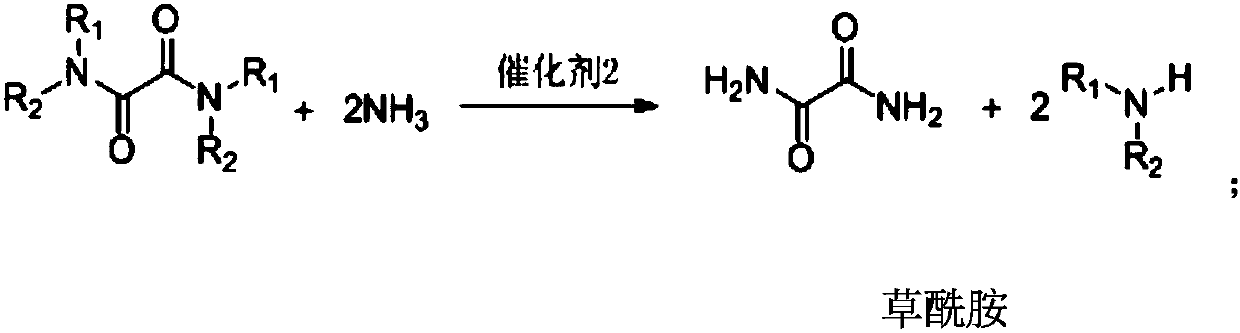

Preparation method of oxamide

A technology for oxamide and amine compounds, applied in the field of preparation of oxamide, can solve problems such as no industrial report, immature technology, etc., and achieve the effects of excellent substrate practicability, simple preparation process and high atomic economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1. Preparation of catalyst

[0035] The preparation method of catalyst among the present invention is example with the preparation process of catalyst 1-6, and 1-3 is the preparation technology of catalyst 1, and 4-12 is the preparation technology of catalyst 2, is embodied as follows:

Embodiment 1

[0036] Embodiment 1: Catalyst 1-1

[0037] Weigh 2.13g copper nitrate pentahydrate and 3.22g anhydrous palladium chloride, add to a round bottom flask, add 20wt% NH 4The OH solution was completely dissolved, and 15 g of pseudo-boehmite was added, and stirred at room temperature for 2 h. Afterwards, filter with suction, wash with distilled water until neutral, dry at 120°C for 12 hours, roast in a muffle furnace at 450°C for 3 hours, grind and sieve (80-100 mesh), and obtain the active catalyst 1-1 provided by the present invention.

Embodiment 2

[0038] Embodiment 2: Catalyst 1-2

[0039] Weigh 2.13g copper nitrate pentahydrate, 3.22g anhydrous palladium chloride, 15g pseudoboehmite, add to a round bottom flask, add 20mL distilled water to stir the solution to disperse, use 10wt% NaOH solution as precipitant for precipitation, and precipitate to pH About 10, heat up to 80°C for aging for 4h. After cooling down, filter with suction, wash with distilled water until neutral, dry at 120°C for 12 hours, roast in a muffle furnace at 450°C for 3 hours, grind and sieve (80-100 mesh), and then obtain the active catalyst 1-2 provided by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com