Damping and noise-reduction drive plate assembly for electromagnetic clutch

A technology of electromagnetic clutch and drive plate, applied in the direction of magnetic drive clutch, clutch, non-mechanical drive clutch, etc., can solve the problems of large axial deformation resistance, short service life, high production cost, slow down the pull-in speed, improve the use The effect of longevity and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

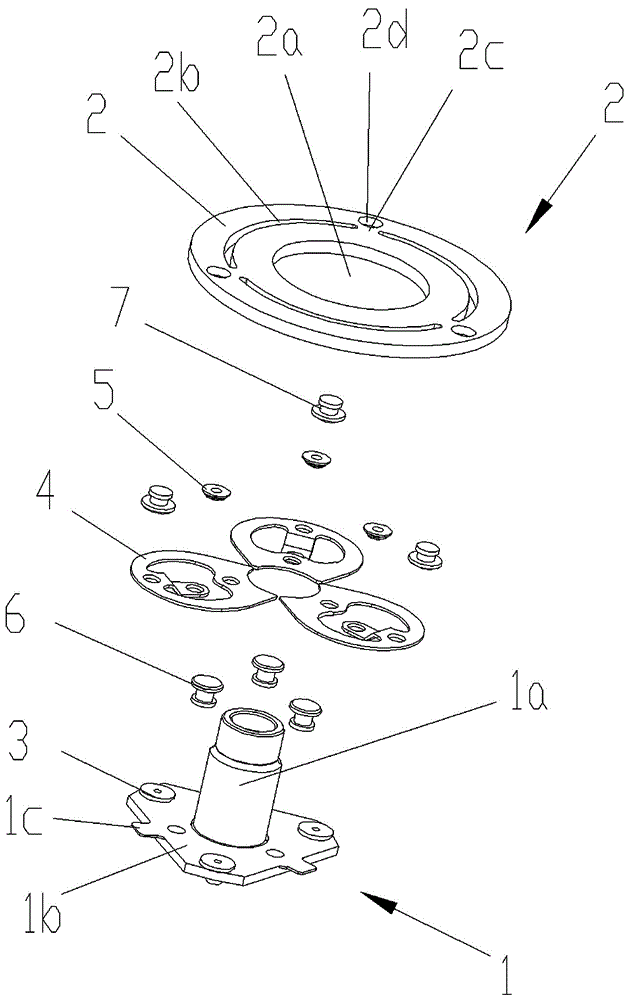

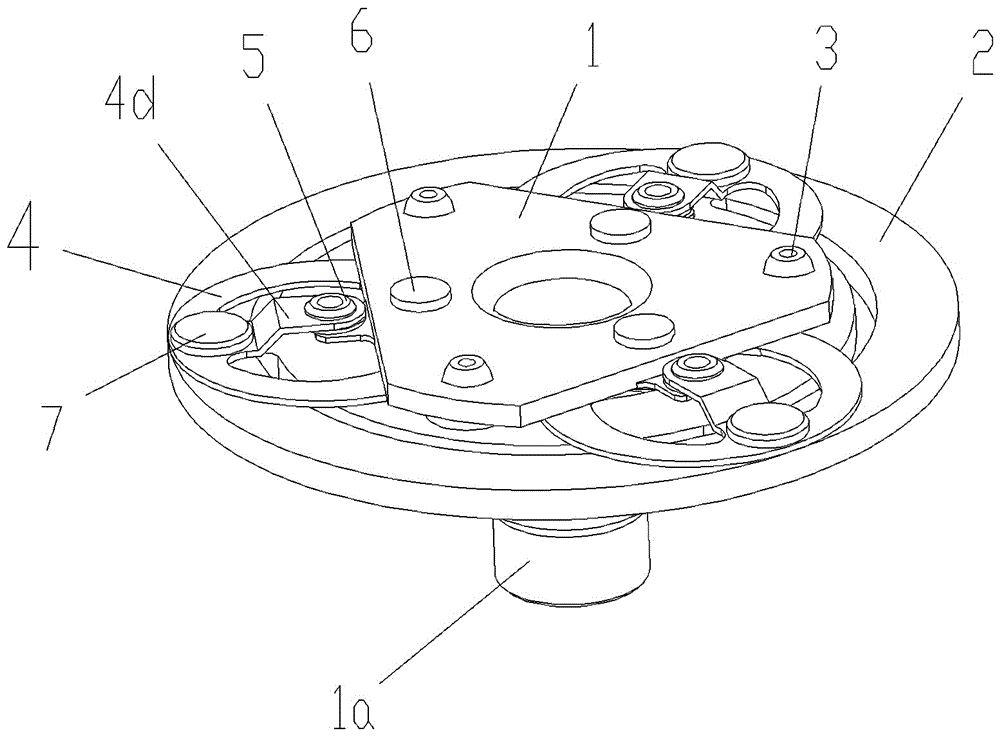

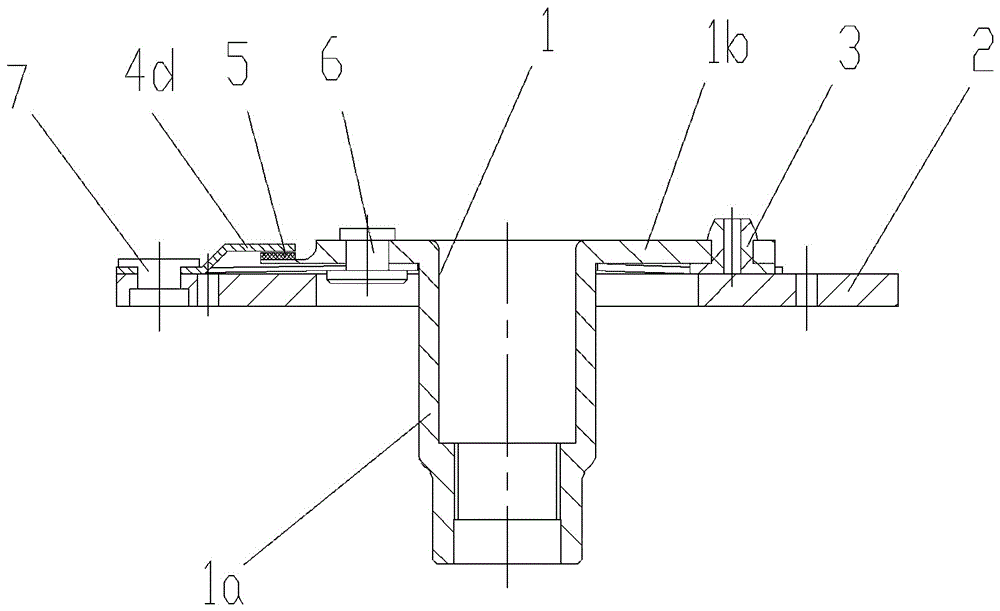

[0024] Embodiment one, as figure 1 , figure 2 with image 3 As shown, the present invention provides a shock-absorbing and noise-reducing drive plate assembly for electromagnetic clutches, including a spline key 1 composed of a sleeve 1a and a flange 1b, and the compressor is connected by a spline in the sleeve 1a the main axis. The flange 1b is a triangular plate structure, an arc-shaped chamfer 1d is provided at each corner of the flange 1b, and a first installation is provided on the flange 1b close to each chamfer 1d. In the hole 1e, a support plate 1c is provided outside the center of each side of the flange 1b, and each support plate 1c is arranged on the side close to the sleeve 1a. The plate 1c is a rectangular plate, and the support plate 1c It has an integral structure with the flange plate 1b. A second mounting hole 1f is provided on the flange 1b adjacent to each supporting plate 1c. A first silencer plug 3 is installed in each first installation hole 1e, the...

Embodiment 2

[0031] Embodiment two, reed 4 described in embodiment one can also adopt following structure, as Figure 7 with Figure 8 As shown, the annular spring plate 4a adopts a straight plate 4m structure, and a sound damping plate 4d is provided on one side of the straight plate 4m.

[0032] The basic principle of shock absorption and noise reduction of the present invention: the electromagnet is energized to generate a magnetic field, the suction cup 2 is attracted to the pulley, and as the suction cup 2 moves, the reed 4 riveted with it also moves accordingly, and the second silencer plug 5 and the reed 4 synchronous movement, and after the second silencing plug 5 moves, it will quickly contact with the support plate 1c, squeeze the second silencing plug 5 to deform, under the obstruction of the support plate 1c, the second silencing plug 5 is compressed by force, effectively hindering The movement of the reed 4 hinders the suction speed of the suction cup 2, thereby effectively r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com