Air column bag equipment driving unit and air column bag machining equipment thereof

A technology of equipment driving and processing equipment, which is applied in the field of machinery, can solve problems affecting production capacity, unreasonable design, and high maintenance difficulty, and achieve the effects of increasing production capacity, reducing processing and manufacturing difficulty, and optimizing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

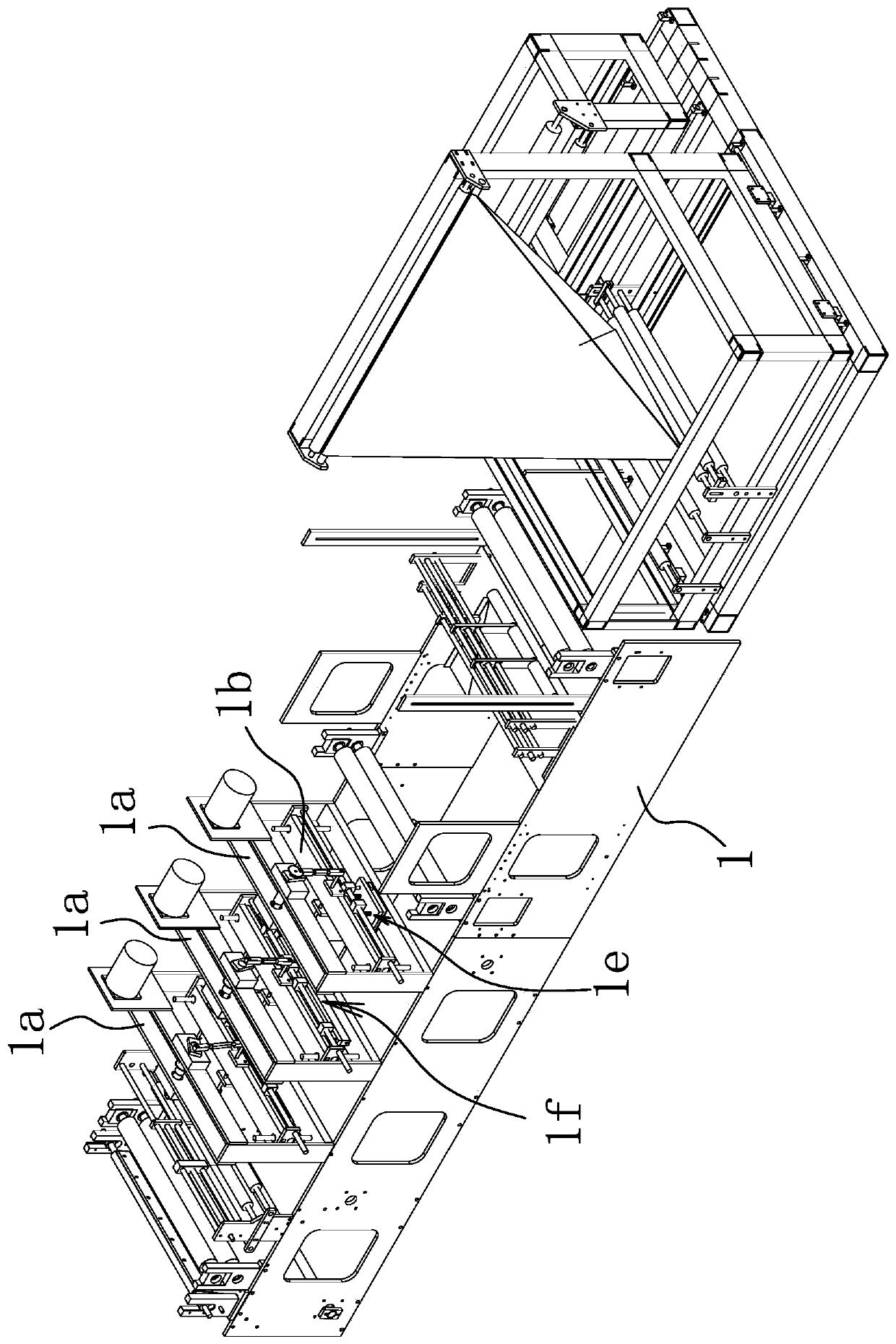

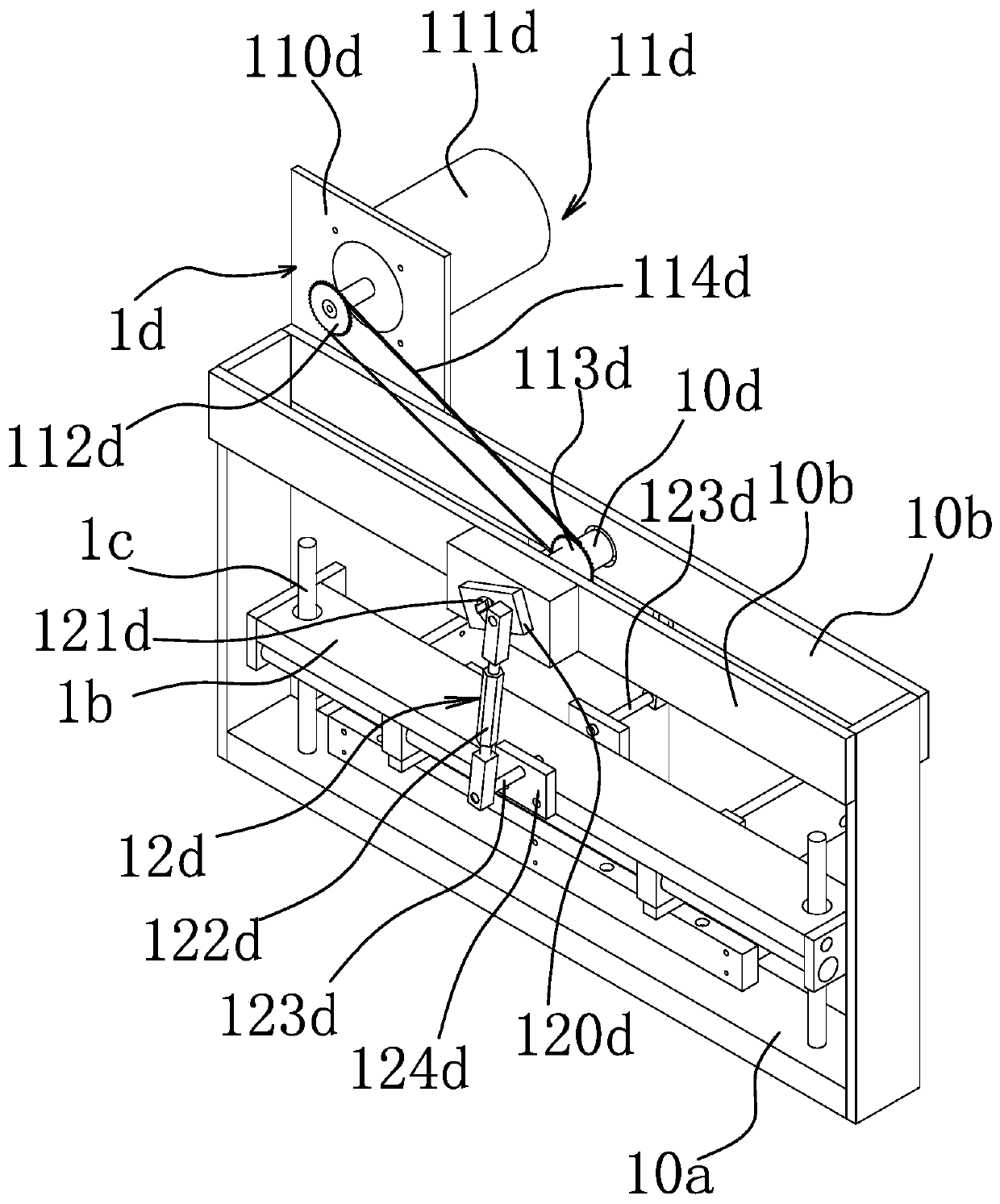

[0058] Such as figure 2 As shown, the driving unit of the air column bag equipment includes a fixed outer frame 1a, and the fixed outer frame 1a is vertically fixed on the frame 1;

[0059] Such as image 3 As shown, the actuator mounting plate 1b, the actuator mounting plate 1b is horizontally located in the fixed outer frame 1a and can be lifted in the vertical direction;

[0060] The vertical guide mechanism 1c is connected to the actuator mounting plate 1b and the fixed outer frame 1a, and is used to improve the lifting stability of the actuator mounting plate 1b;

[0061] Lifting drive mechanism 1d, the lifting drive mechanism 1d is fixed on the top of the fixed outer frame 1a and connected to the middle of the actuator mounting plate 1b, and the lifting drive mechanism 1d drives the actuator mounting plate 1b to reciprocate up and down in the vertical direction.

[0062] Further, the lifting drive mechanism 1d is an eccentric lifting drive mechanism.

[0063] Specifi...

Embodiment 2

[0132] The principle of this embodiment is basically the same as Embodiment 1, and the different structures are:

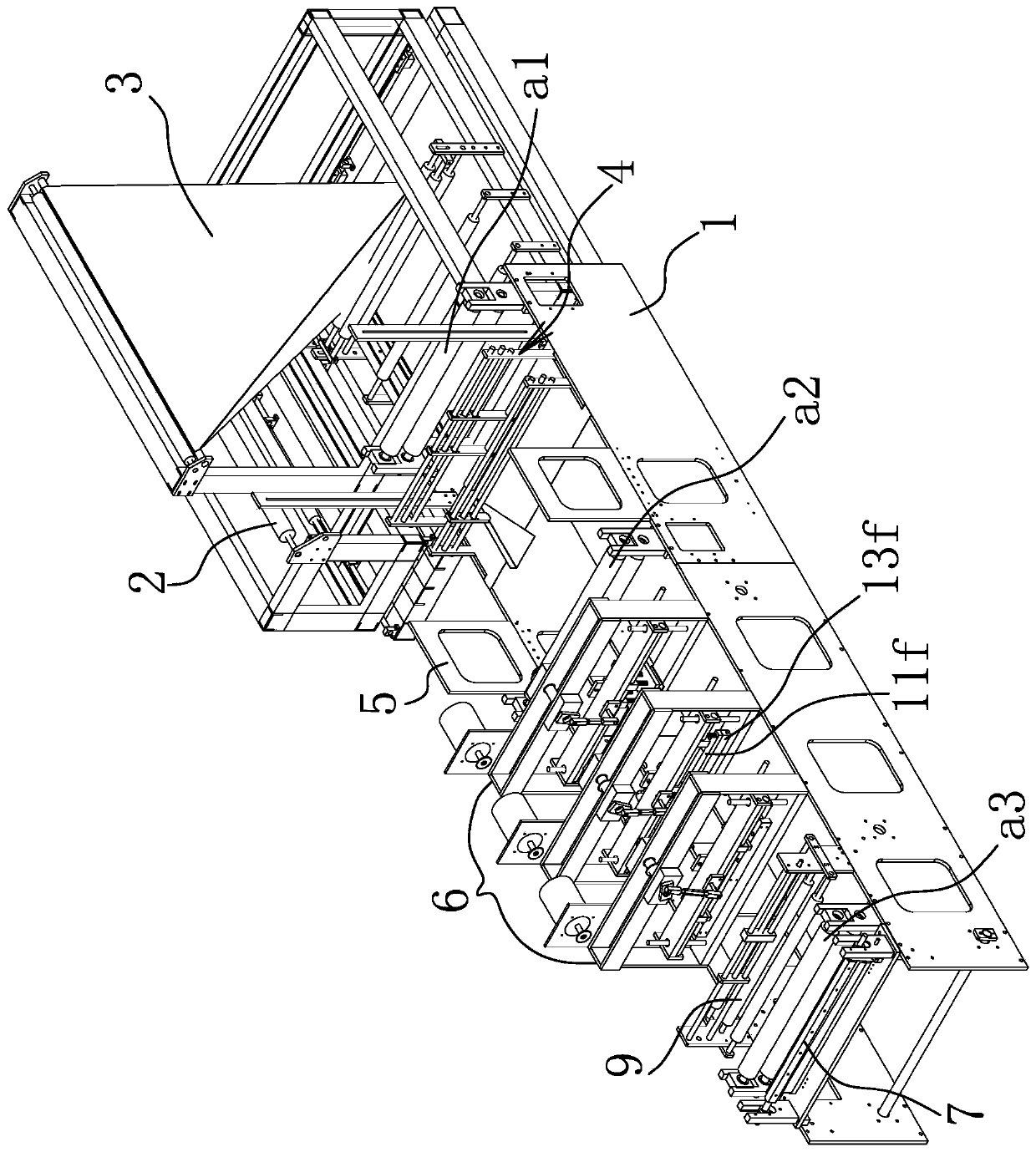

[0133] Such as Figure 13 As shown, the air column bag processing equipment includes a frame 1, and an unwinding unit 2, a corner folding unit 3, a hemming unit 4, a material storage unit 5, a processing unit 6 and a winding unit 8 are sequentially arranged on the frame 1, The processing unit 6 includes at least three fixed outer frames 1a and is sequentially fixed on the frame, and the fixed outer frames 1a are vertically fixed on the frame 1;

[0134] The actuator mounting plate 1b, the actuator mounting plate 1b is horizontally located in the fixed outer frame 1a and can be raised and lowered in the vertical direction;

[0135] The vertical guide mechanism 1c is connected to the actuator mounting plate 1b and the fixed outer frame 1a, and is used to improve the lifting stability of the actuator mounting plate 1b;

[0136] Lifting drive mechanism 1d, the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com