Knot disengaging mechanism and method of knotter

A knotter and detachment technology, applied in the application field of knotter, can solve problems such as equipment damage, achieve production efficiency guarantee, reduce the process of manual grinding of contact surfaces, and reduce the effect of unsmooth detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

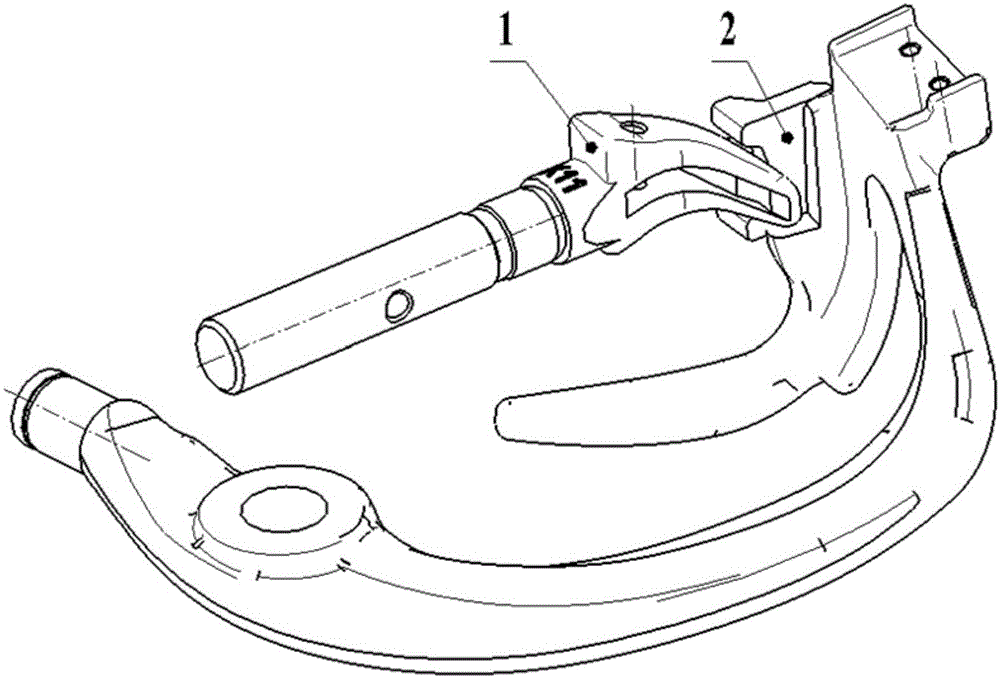

[0019] The realization of the unknotting mechanism and the unknotting method: such as figure 1 , 2 as shown,

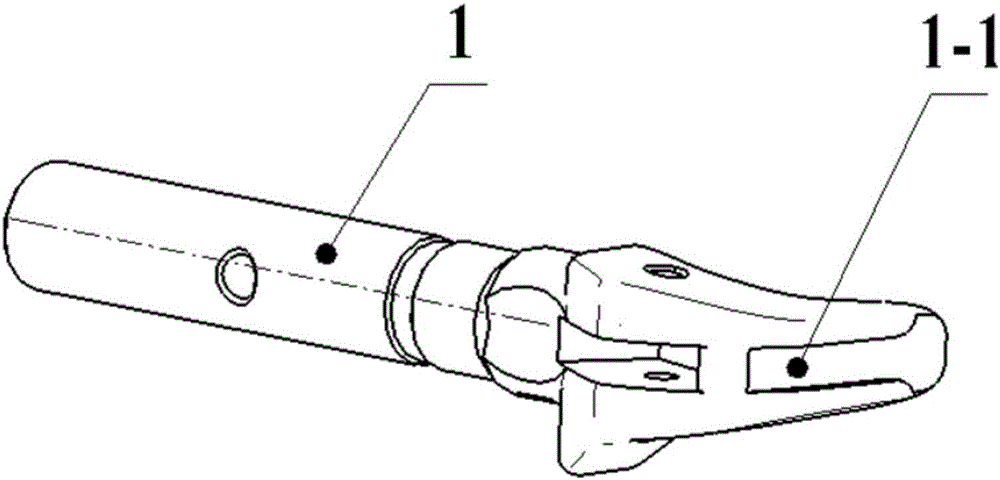

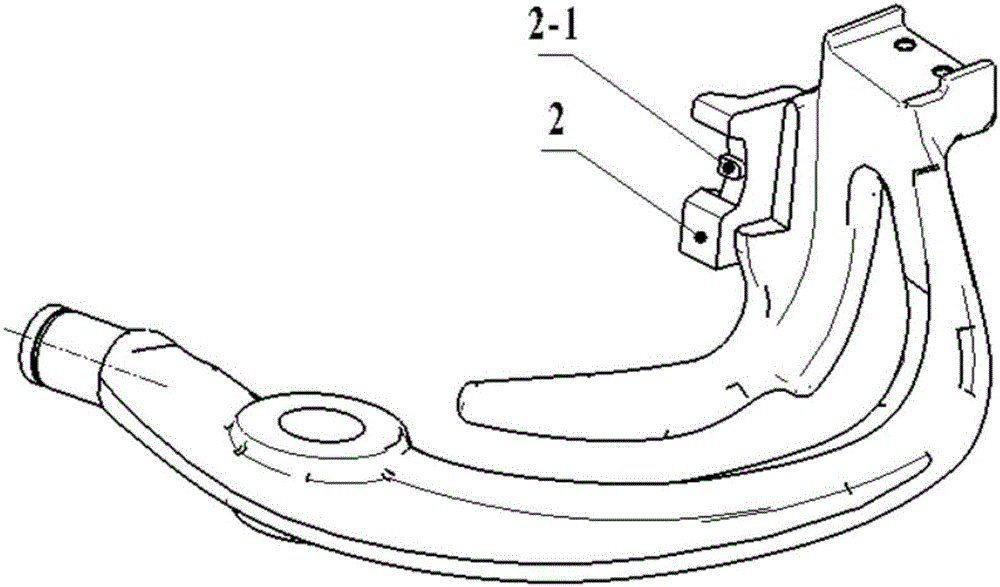

[0020] A long groove 1-1 is processed on the arc-shaped back of the knotting nozzle 1, and a protrusion 2-1 is processed on the original contact surface of the tool holder 2 with the knotting nozzle 1, and the width is wider than the groove 1-1 Slightly narrow, when assembled, the top of the protrusion 2-1 does not contact the bottom of the groove 1-1, the protrusion 2-1 can move along the groove 1-1, and the two can move relatively freely without interference or jamming.

[0021] When knotting, drive the knotting nozzle 1 to rotate around its own rotation axis to tie the knot. At this time, the knot is wrapped around the knotting nozzle 1, and then drive the knife rest 2 to rotate again, so that the protrusion 2 on the knife rest 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com