Asphalt mixture hydrodynamic pressure scouring test methods and apparatus

A technology of asphalt mixture and dynamic water pressure, which is applied in the direction of measuring devices, adopting mechanical devices, analyzing materials, etc., and can solve the problems that cannot reflect the damage of asphalt pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

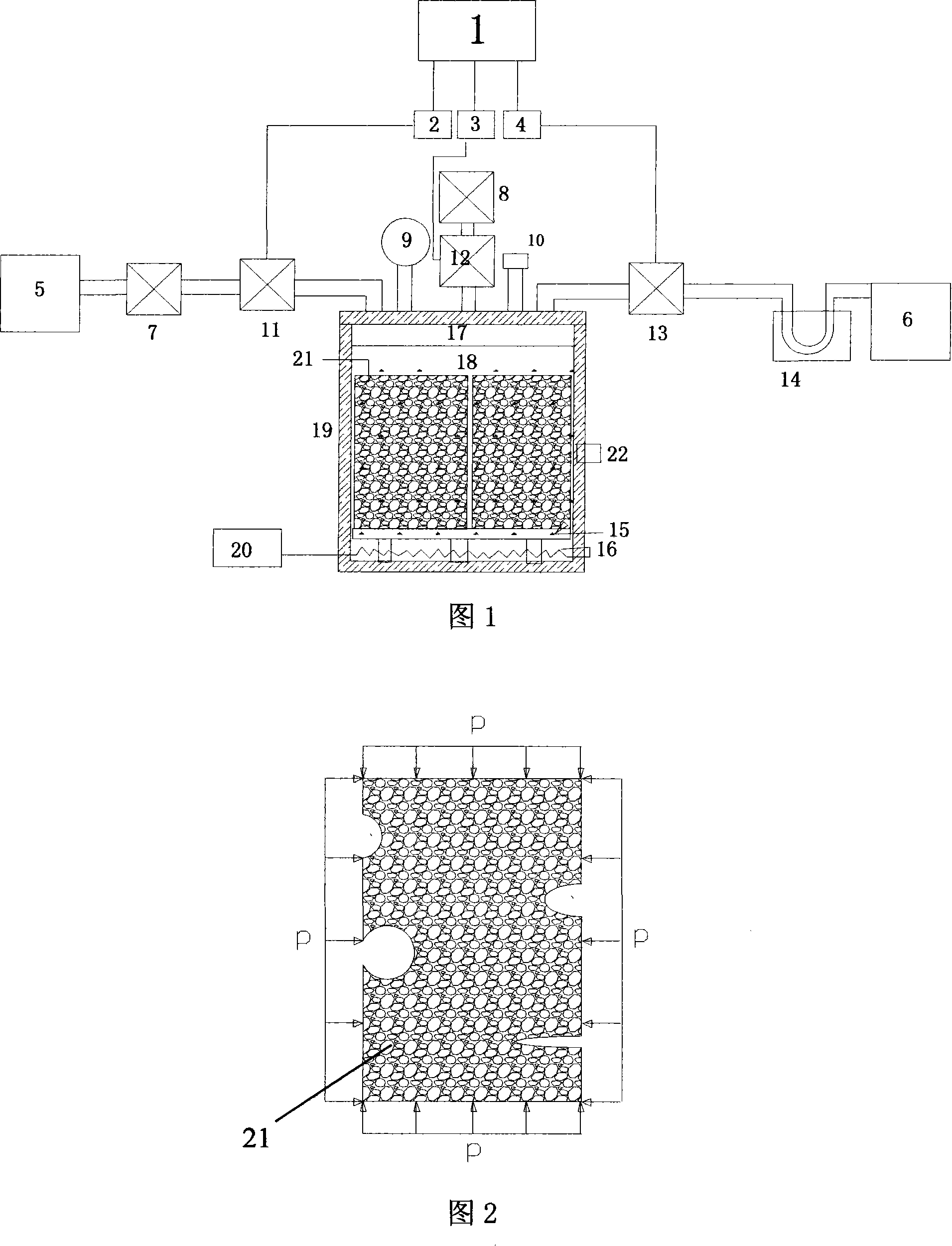

[0046] As shown in Figure 1, the asphalt mixture dynamic water pressure scouring test device includes a closed container 19, an air compressor 5, a vacuum pump 6, a PLC control circuit 1, a positive pressure solenoid valve 11, a solenoid valve 12 for pressure relief, and a vacuum solenoid valve. Valve 13, heating rod 16, intelligent control digital display meter 20, thermal resistance temperature sensor 22;

[0047] The air compressor 5 is connected with the positive pressure solenoid valve 11 through the decompression valve 7, and the loam cake of the airtight container 19 communicates with the positive pressure solenoid valve 11, the pressure relief solenoid valve 12, and the vacuum solenoid valve 13 respectively. A pressure gauge 9 is installed; the vacuum solenoid valve 13 is connected with the vacuum pump 6, and the air pipeline between the vacuum solenoid valve 13 and the vacuum pump 6 is provided with a drier 14; water 18 is housed in the airtight container 19, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com