Electrochemical machining tool and method for machining a product using the same

A technology of electrochemical machining and tools, applied in electrochemical machining equipment, machining electrodes, electric machining equipment, etc., can solve the problem of machining axial dynamic pressure generating grooves and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will now be described in detail with reference to the accompanying drawings. For some components, their illustration and description are omitted where their presence is not necessary for those skilled in the art to understand the present invention.

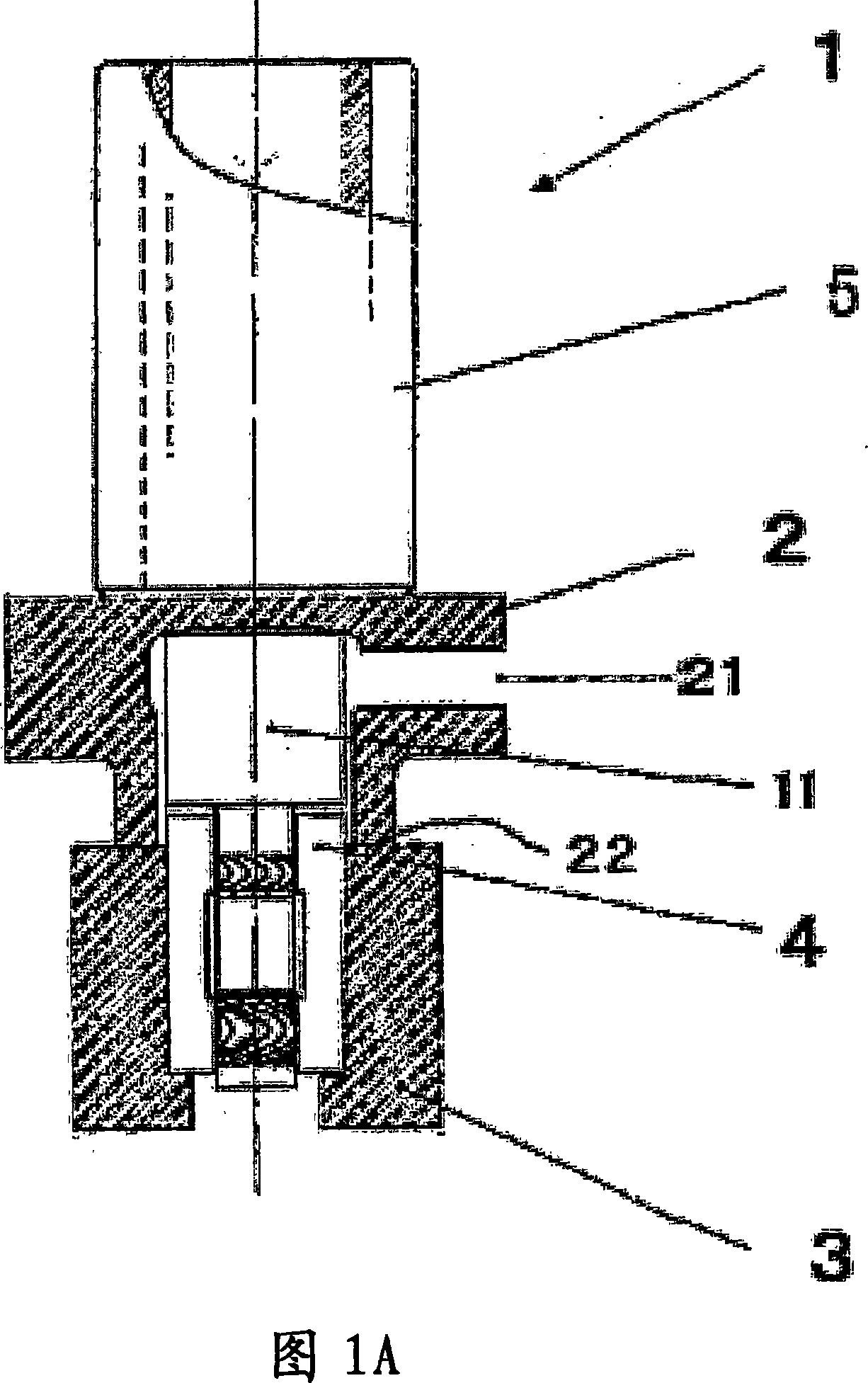

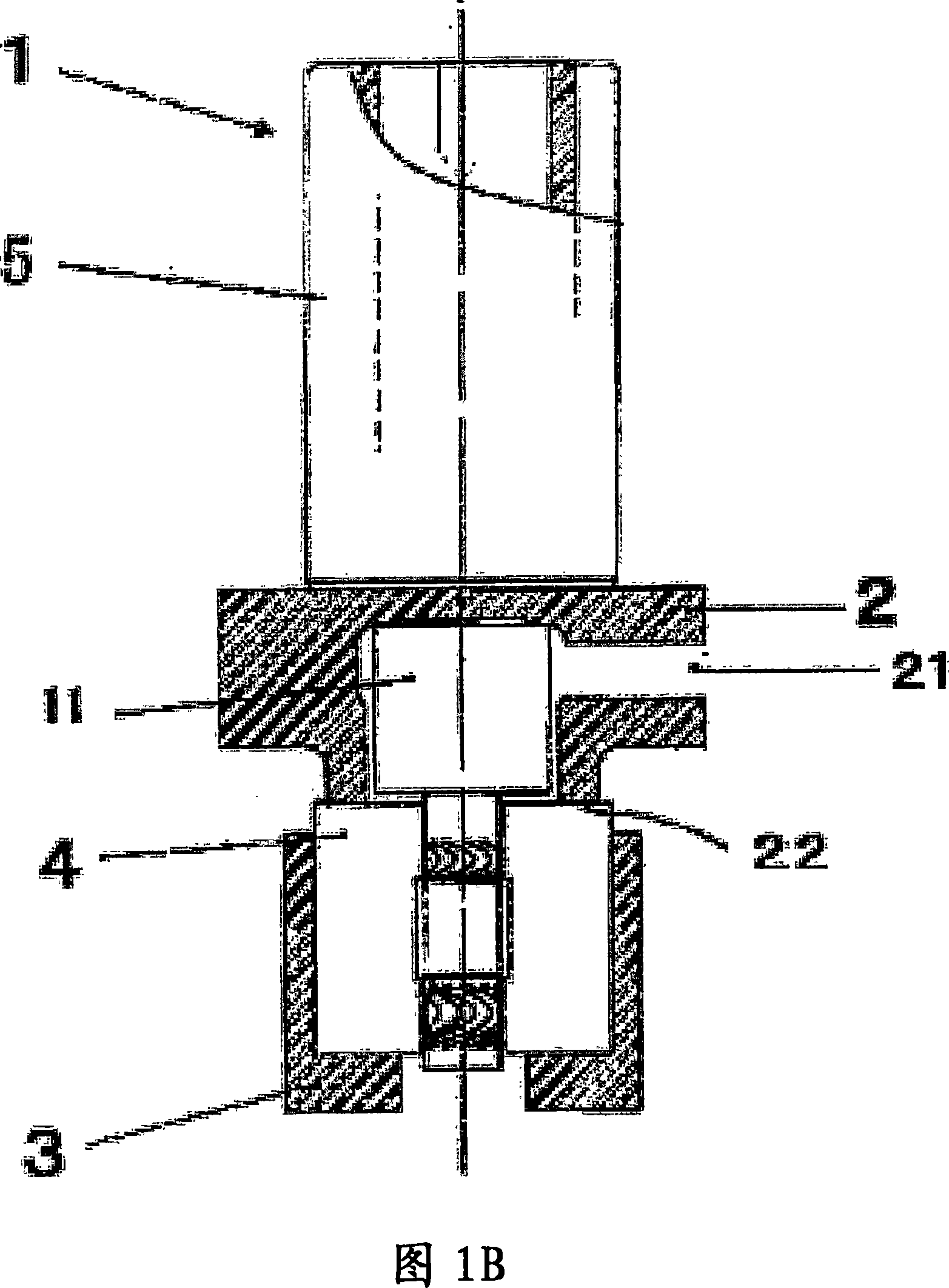

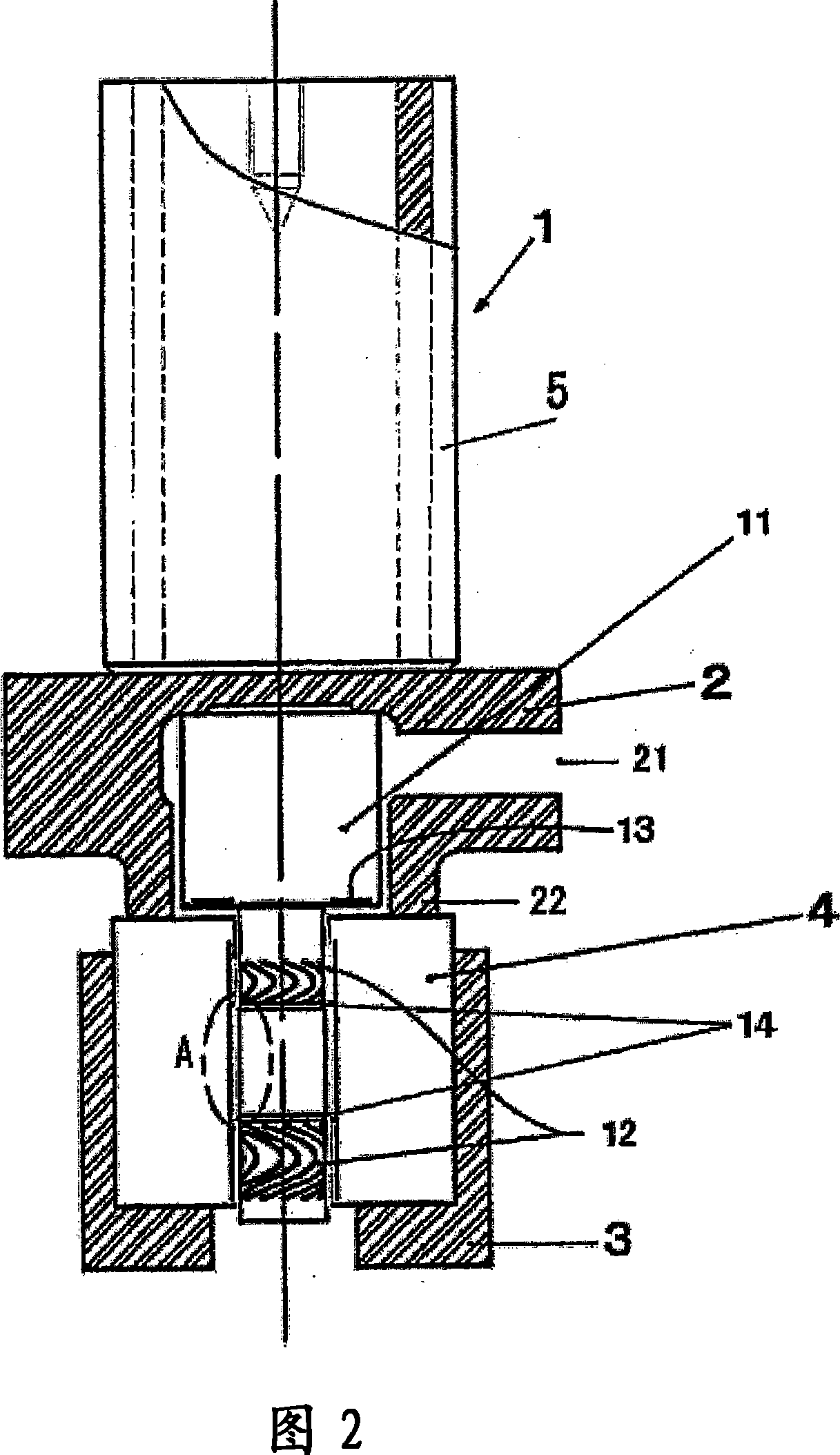

[0034] 1A and 1B show two views of an electrochemical machining tool 1 . The protrusion 22 of the insulating guide tool 2 shown in FIG. 1A abuts on the seat cover support tool 3 . As shown in FIG. 1B , the protrusion 22 rests on the workpiece, such as the seat cover 4 .

[0035] As shown in FIG. 1A, FIG. 1B and FIG. 2, the electrochemical machining tool 1 includes an electrode body 11, a machining electrode 12 for forming a radial dynamic pressure generating groove in the seat cover 4, and a machining electrode 12 for forming a radial dynamic pressure generating groove in the seat cover 4. Machining electrodes 13 for axial dynamic pressure generating grooves and deburring processing electrodes 14 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com