Fluorescence microscopy method to generate multi-layer polished sections by utilizing Fresnel biprism and device

A Fresnel double prism and light sheet technology, applied in microscopes, optics, optical components, etc., can solve the problems of slow image acquisition rate, small penetration depth, uneven illumination of single-layer light microscopy technology, etc., to achieve The effect of fast image acquisition rate and large penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

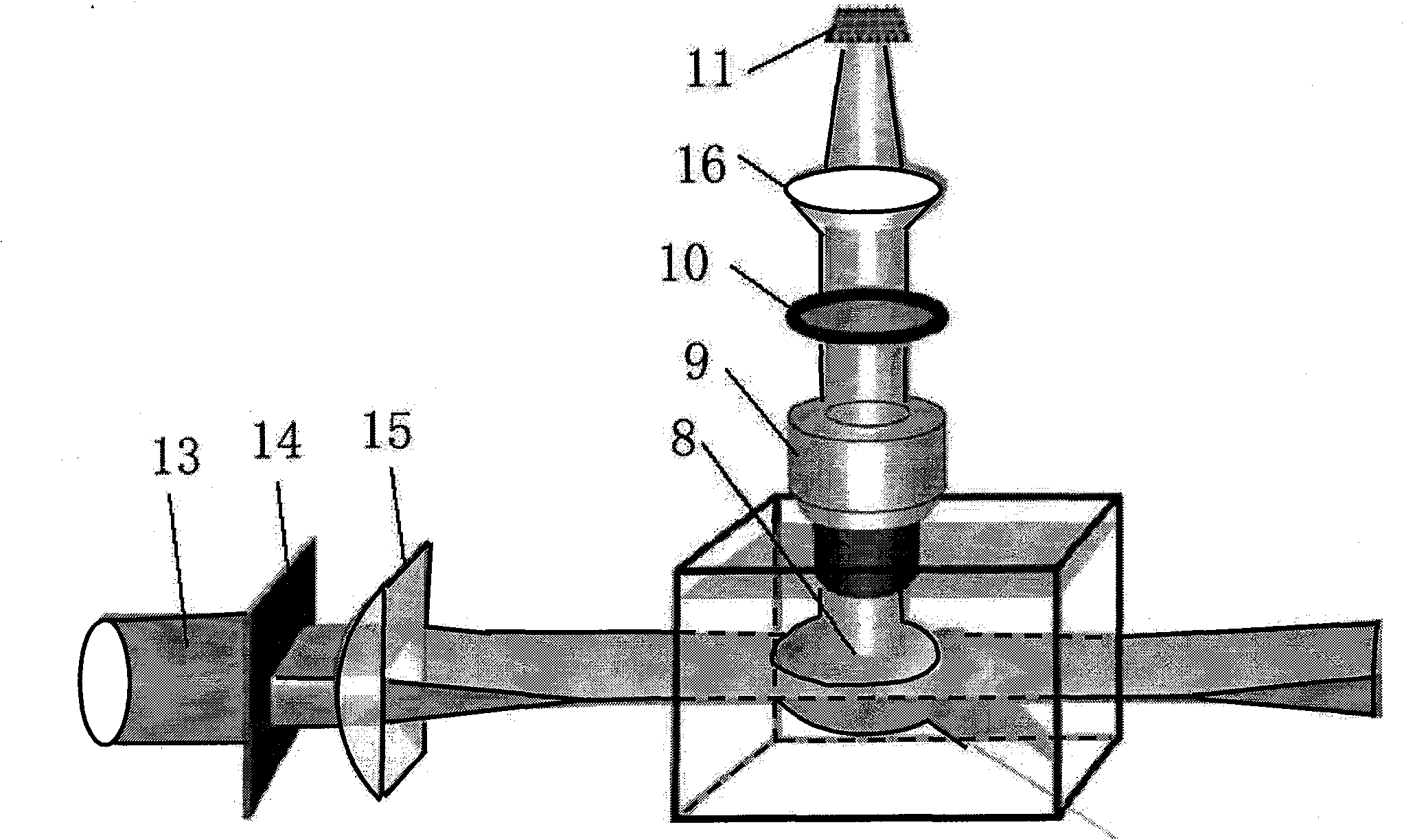

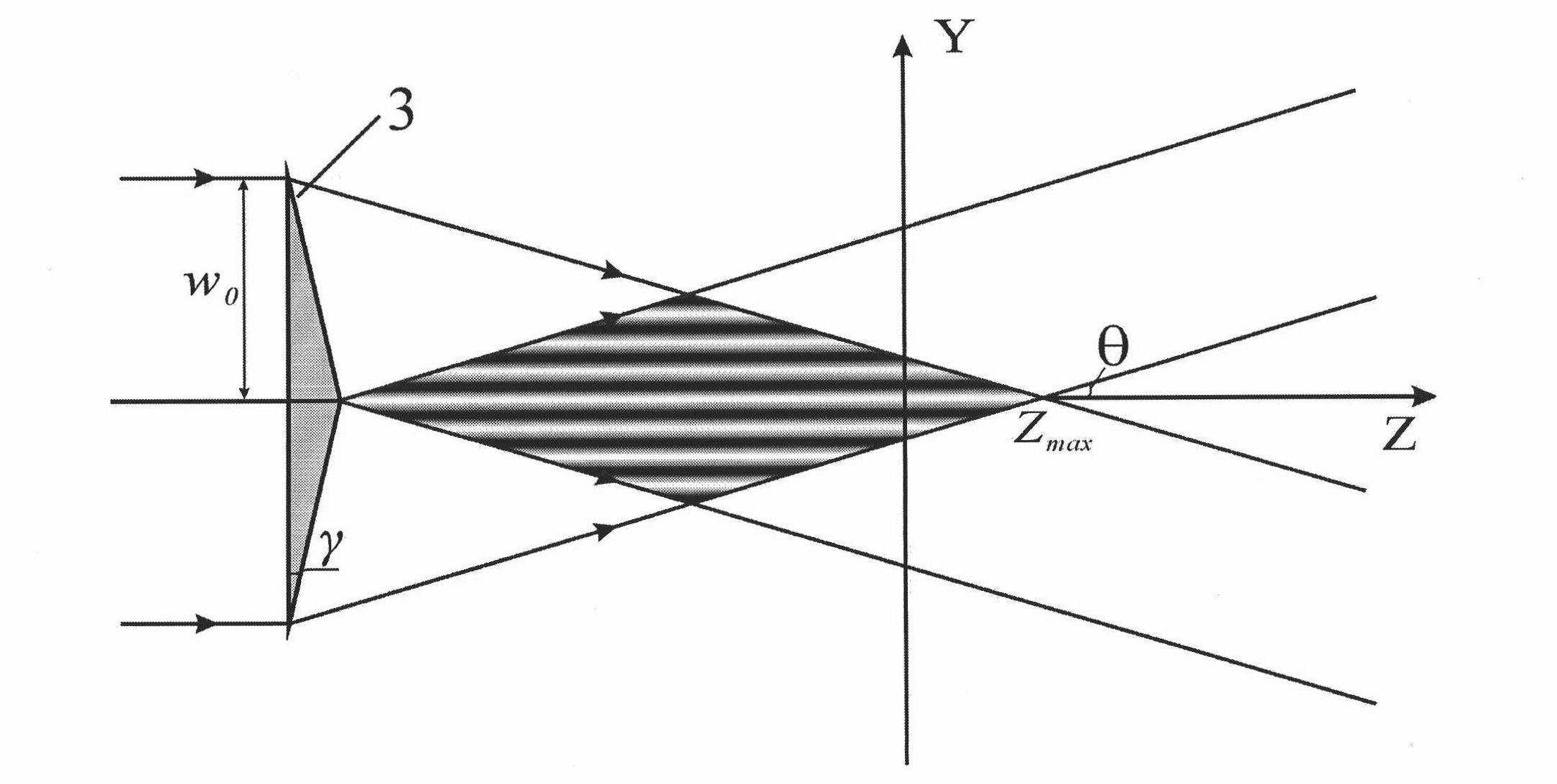

[0075] Embodiment: select the Fresnel double prism of base angle=5 ° in the experiment, material refractive index n=1.5, laser wavelength=532nm, can obtain the spacing Δ=6m of light sheet by formula (2), and the microscopic objective lens Depth of field is typically less than 6m, so there is no crosstalk between individual light sheets. The radius w of the incident laser beam 0 = 2mm, lens L 1 focal length f 1 =75mm, lens L 2 focal length f 2 =75mm, d 1 =5mm, into formula (4) can get Z max =141mm, Z min =107mm, which greatly increases the working distance of the system and facilitates the placement of components such as sample stages and microscope objectives.

[0076] A glass plate of thickness t is placed behind lens L2. The glass plate will not change the beam angle but will produce a phase difference between the two beams participating in the interference:

[0077] δ = 2 π λ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com