Perforation, fracturing integrated method and its technique pipe

A process pipe string and fracturing technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of complex operation procedures, high development cost, long cycle, etc., and achieve simple supporting tools and convenient construction. Simple, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

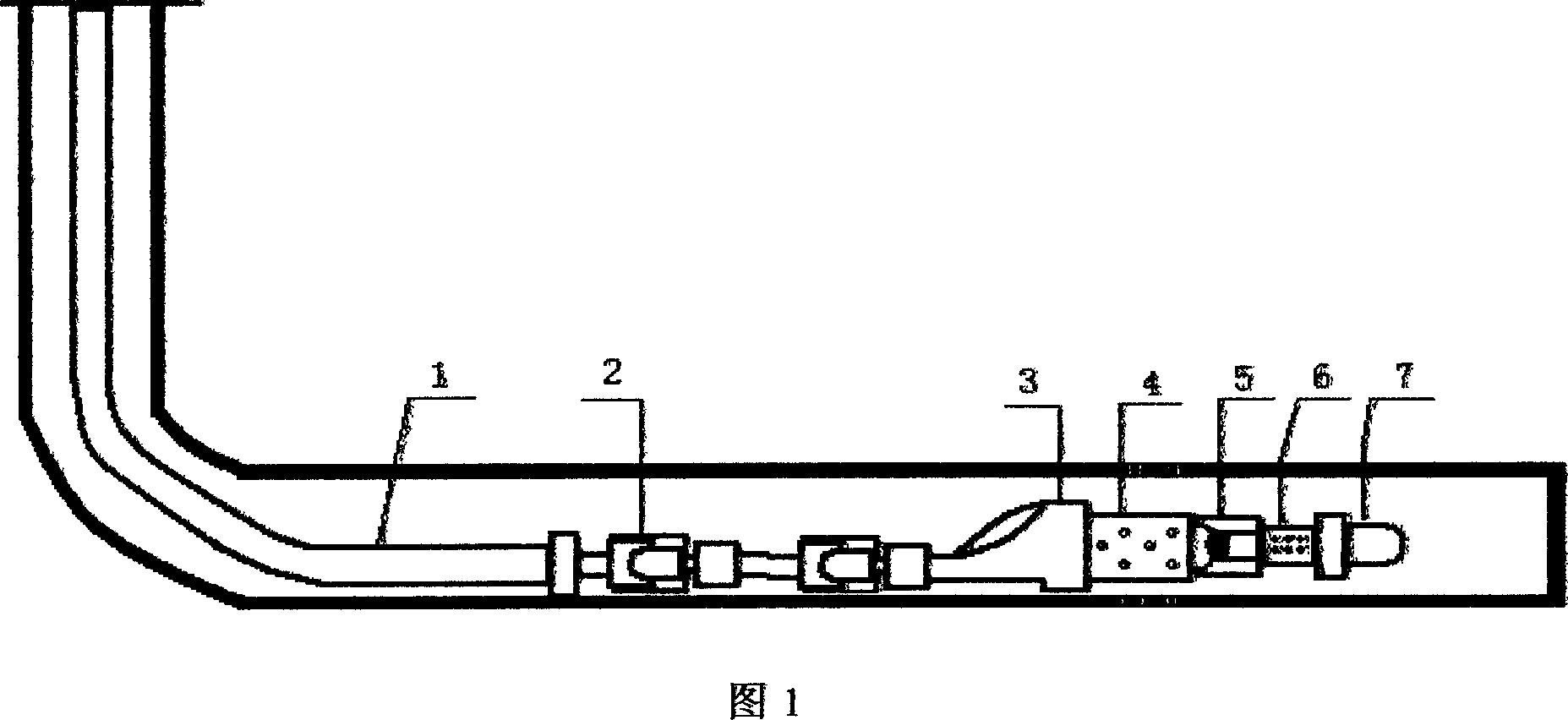

[0018] A. Lower the entrance hole and the integrated process string of fracturing, and lower the hydraulic ejector 4 to the position where the perforation is required;

[0019] B. Positive washing: Wash the well with well washing fluid before perforating, with a displacement of 1000l / min, until the water quality of the inlet and outlet is consistent;

[0020] C. Hydraulic jet perforation: Inject the perforating fluid from the tubing (the fracturing fluid carries the sand with the original rubber, the proppant is 40 mesh quartz sand, and the sand concentration is 120kg / m 3 ), when the sand-carrying liquid is 250m away from the nozzle, the displacement is increased and the perforation is sprayed. When perforating, the perforating liquid is injected from the tubing and returned from the oil and the collar;

[0021] D. Hydraulic jet fracturing: After the hydraulic jet perforation is completed, the fracturing fluid is injected from the tubing. At the same time, the oil jacket annulus i...

Embodiment 2

[0023] A. Lower the entrance hole and the integrated process string of fracturing, and lower the hydraulic ejector 4 to the position where the perforation is required;

[0024] B. Positive washing: Wash the well with well washing fluid before perforating, and the washing and discharging volume is 500l / min, until the water quality of the inlet and outlet is consistent;

[0025] C. Hydraulic jet perforation: inject the perforating fluid from the tubing (the fracturing fluid carries the sand with the original rubber, the proppant is 60 mesh quartz sand, and the sand concentration is 120kg / m 3 ), when the sand-carrying liquid is 200m away from the nozzle, the displacement is increased and the perforation is sprayed. When perforating, the perforating liquid is injected from the tubing and returned from the oil and the collar;

[0026] D. Hydraulic jet fracturing: After the hydraulic jet perforation is completed, the fracturing fluid is injected from the tubing. At the same time, the oi...

Embodiment 3

[0028] A. Lower the entrance hole and the integrated process string of fracturing, and lower the hydraulic ejector 4 to the position where the perforation is required;

[0029] B. Positive washing: Wash the well with well washing fluid before perforating, with a displacement of 210l4min, until the inlet and outlet water quality is consistent;

[0030] C. Hydraulic jet perforation: Inject the perforating fluid from the tubing (the fracturing fluid carries sand with the original rubber, the proppant is 47 mesh quartz sand, and the sand concentration is 120kg / m 3 ), when the sand-carrying liquid is 230m away from the nozzle, the displacement is increased and the perforation is sprayed. When perforating, the perforating liquid is injected from the tubing and returned from the oil and the collar;

[0031] D. Hydraulic jet fracturing: After the hydraulic jet perforation is completed, the fracturing fluid is injected from the tubing. At the same time, the oil jacket annulus is injected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com