Carbon brush for truck starting motor as well as manufacture method and application thereof

A technology for starting motors and carbon brushes, which is applied in the manufacture of brushes, circuits, and current collectors. It can solve the problems of large sparks and the life of carbon brushes cannot meet the requirements of use, and achieve the goals of improving service life, ensuring service life, and high conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

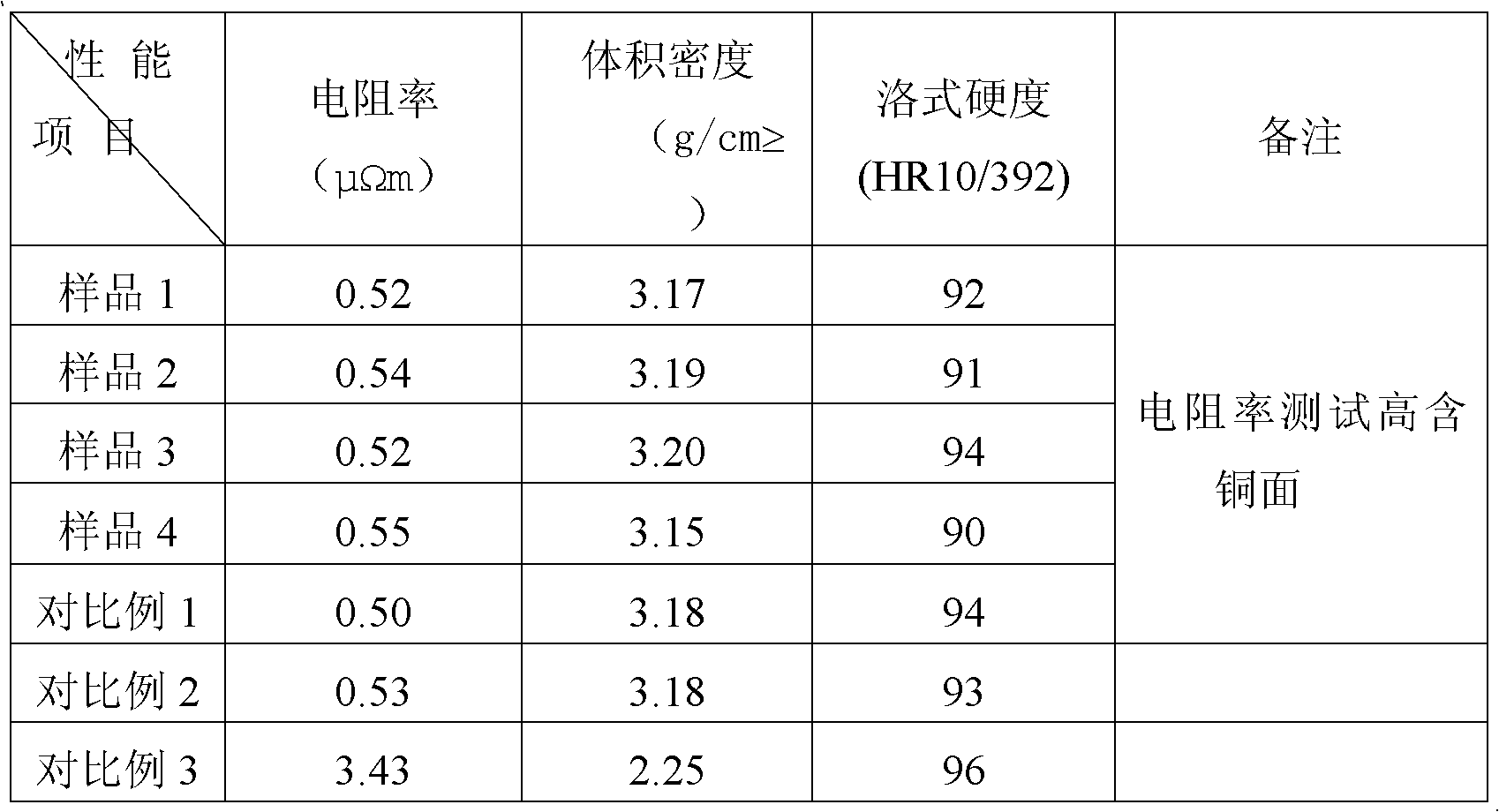

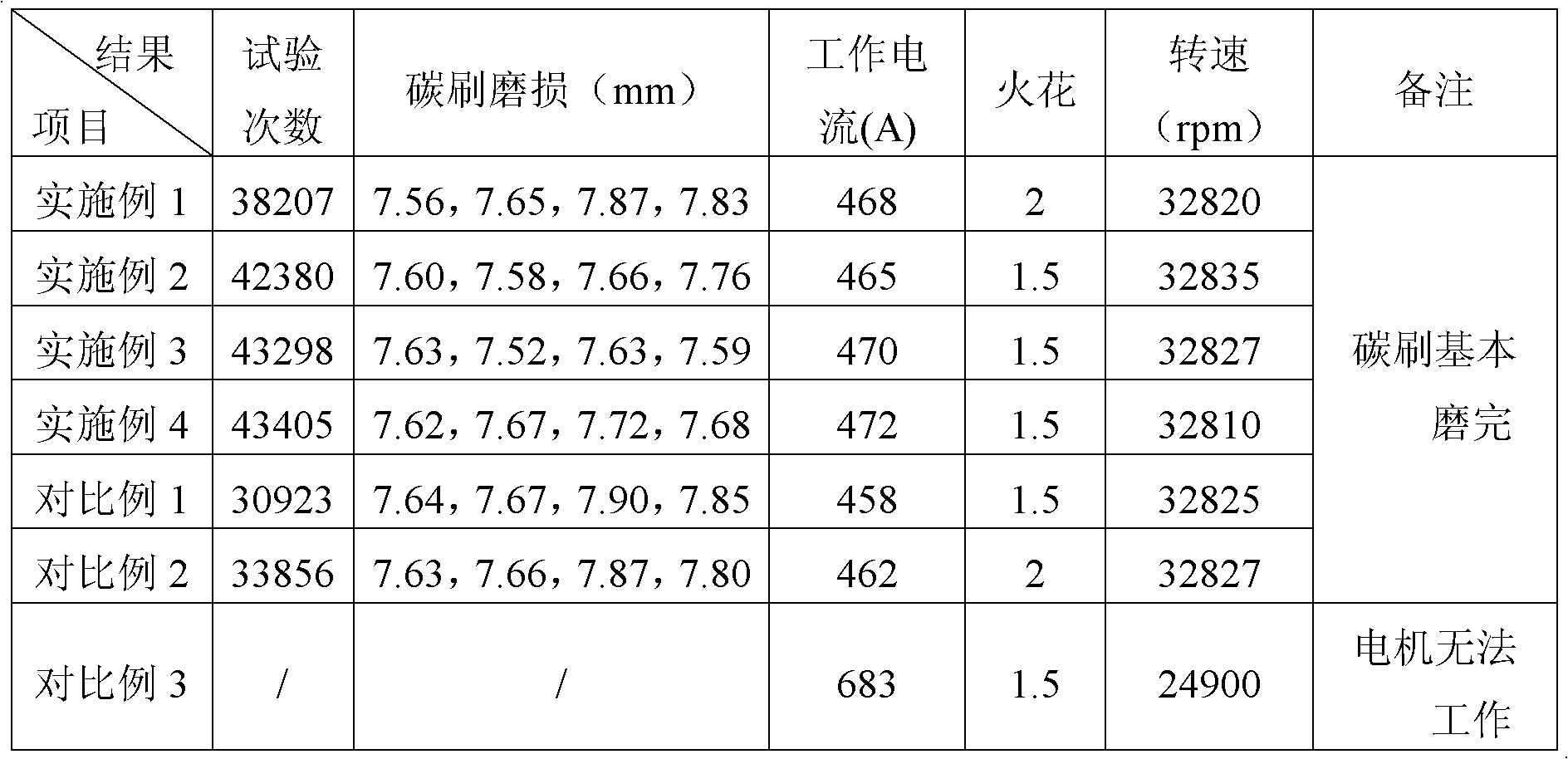

Embodiment 1

[0025] Graphite powder 78%, phenolic resin 20%, phosphoric acid 2%, after mixing at room temperature for 0.5 hours, add 30% (based on dry powder weight) alcohol, mix at 90-100°C for 1 hour, then crush , and sieved to obtain a one-stage colloidal powder. The first-stage colloidal powder 39%, copper powder 58%, molybdenum disulfide 3%, mixed at room temperature for 1 hour to make pressed powder A; the first-stage colloidal powder 70%, copper powder 27%, molybdenum disulfide 3% , and mixed at room temperature for 1 hour to make compressed powder B. Compressed powder A and compressed powder B were pressed into a double-layer product under a unit pressure of 4 MPa by twice feeding method, and sample 1 was produced through high temperature heat treatment at 750°C.

Embodiment 2

[0027] Graphite powder 76%, phenolic resin 20%, phosphoric acid 4%, after mixing at room temperature for 0.5 hours, add 30% (based on dry powder weight) alcohol, mix at 90-100°C for 1 hour, and then crush , and sieved to obtain a one-stage colloidal powder. The first-stage colloidal powder 39%, copper powder 58%, molybdenum disulfide 3%, mixed at room temperature for 1 hour to make pressed powder A; the first-stage colloidal powder 70%, copper powder 27%, molybdenum disulfide 3% , and mixed at room temperature for 1 hour to make compressed powder B. Compressed powder A and compressed powder B were pressed into a double-layer product under a unit pressure of 4 MPa by two feeding methods, and sample 2 was produced through a high temperature heat treatment at 750°C.

Embodiment 3

[0029] Graphite powder 73%, phenolic resin 20%, phosphoric acid 7%, after mixing at room temperature for 0.5 hours, add 30% (based on dry powder weight) alcohol, mix at 90-100°C for 1 hour, then crush , and sieved to obtain a one-stage colloidal powder. The first-stage colloidal powder 39%, copper powder 58%, molybdenum disulfide 3%, mixed at room temperature for 1 hour to make pressed powder A; the first-stage colloidal powder 70%, copper powder 27%, molybdenum disulfide 3% , and mixed at room temperature for 1 hour to make compressed powder B. Compressed powder A and compressed powder B were pressed into a double-layer product under a unit pressure of 4 MPa by twice feeding method, and sample 3 was prepared by high temperature heat treatment at 750°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com