Integrated processing technique for waste water in breadboard production

A technology for the production of waste water and treatment process, which is applied in metallurgical waste water treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc. It can solve the problems that the discharge cannot be stably up to the standard, and it is not as good as the treatment of electroplating waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

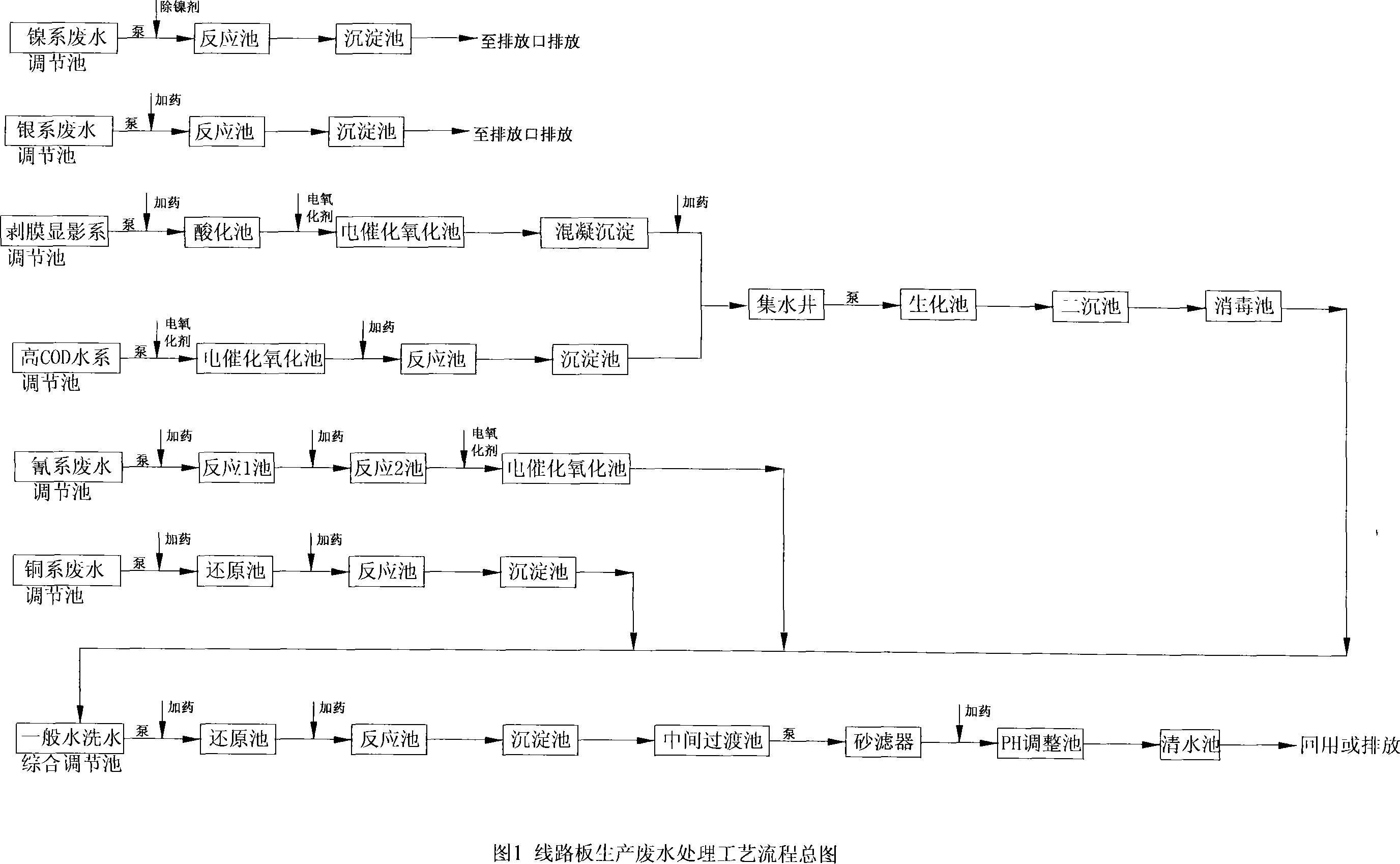

[0123] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0124] According to the characteristics of the circuit board production process, the waste water can be divided into cyanide waste water, nickel waste water, copper waste water, ink stripping and development waste water, high COD waste water, silver waste water and general washing water according to the nature of the waste water. The waste water is collected separately and specially treated. The specific treatment process is as follows:

[0125] After the nickel-based wastewater is collected and added with a nickel-removing agent for chemical coagulation and precipitation, the concentration of nickel can be effectively controlled below 1.0 mg / l, and it can be directly discharged to the discharge outlet.

[0126] After the silver-based wastewater is collected, add NaOH to adjust the pH value to about 9, and then add PAC, PAM, Na 2 After chemical coagulation and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com