Technology for treating initiating explosive material production waste water

A technology for treating process and producing wastewater, which is applied in the fields of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

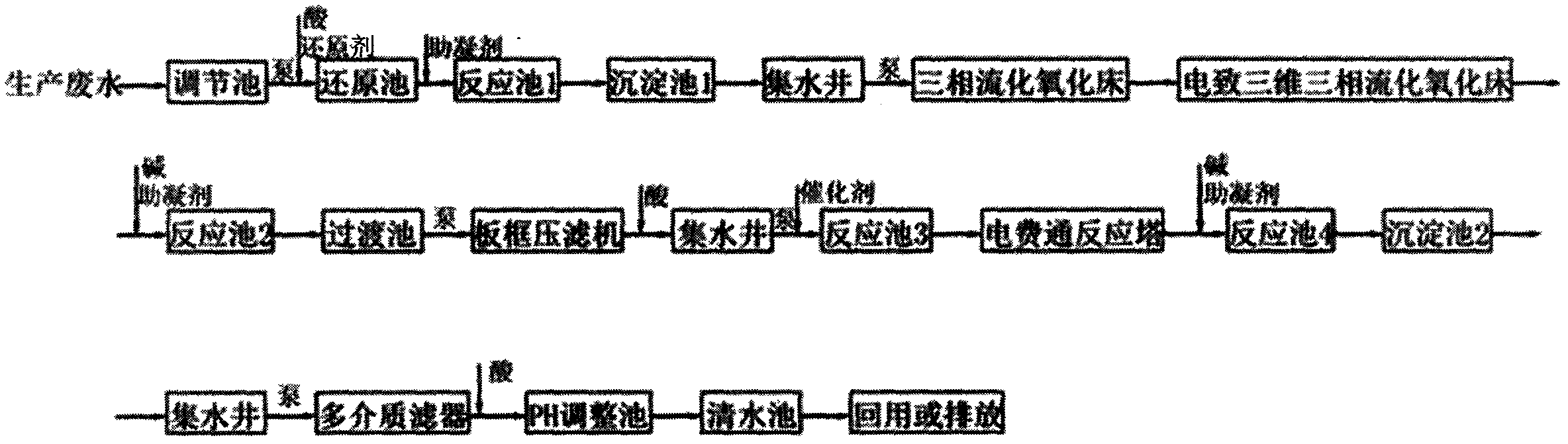

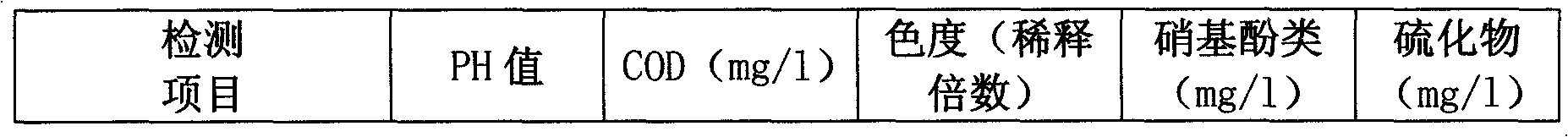

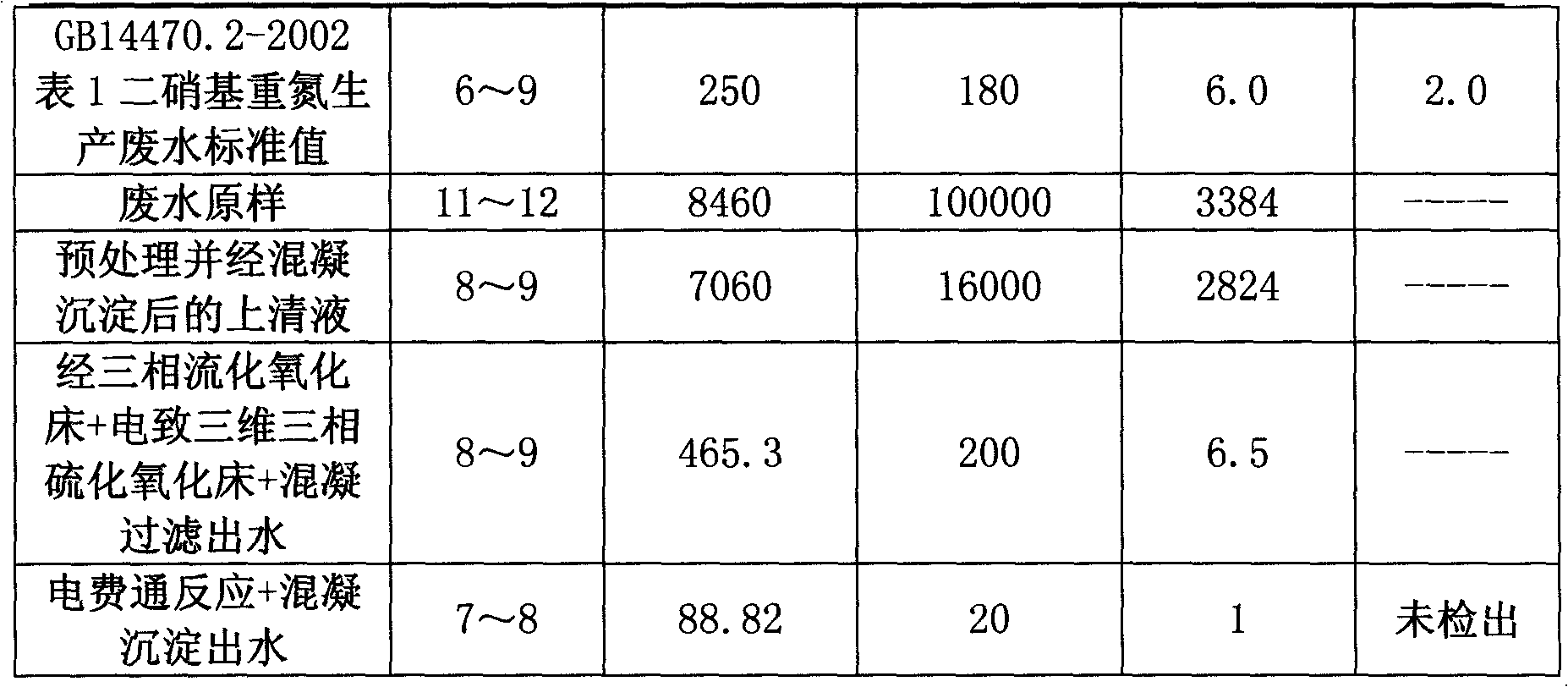

[0034] refer to figure 1 , according to the characteristics of the pyrotechnic agent production process, the wastewater generated in each process is collected into the adjustment tank for treatment. The specific treatment process is as follows: pump the wastewater from the adjustment tank into the reduction tank, add hydrochloric acid to adjust the pH value to ≤2, and add The reducing agent, the effluent flows into the reaction tank 1, and the coagulant PAM is added in the reaction tank 1, the effluent flows into the sedimentation tank 1 for mud-water separation, and the supernatant flows into the water collection well, and the waste water of the water collection well is pumped to the three-phase vulcanization oxidation The bed is oxidized for 3 hours, the effluent flows into the electro-induced three-dimensional three-phase fluidized oxidation bed, stays in the bed for 2.5 hours, and Ca(OH) is added to the effluent 2 Adjust the pH to 8-9, coagulation aid, the water after coag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com