Method for preparing arbitrary concentration, racemic dl-lactic acid by mixing method

A technology of racemization and mixing, applied in organic chemistry methods, organic chemistry, etc., can solve the problems that the inherent quality of DL-lactic acid products cannot be guaranteed, and achieve controllable key quality indicators, controllable concentration, and reliable product application effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

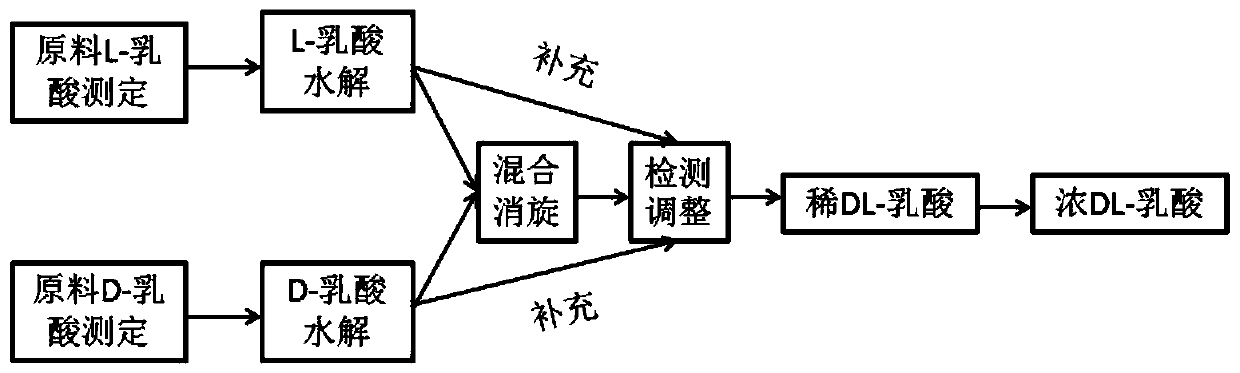

Method used

Image

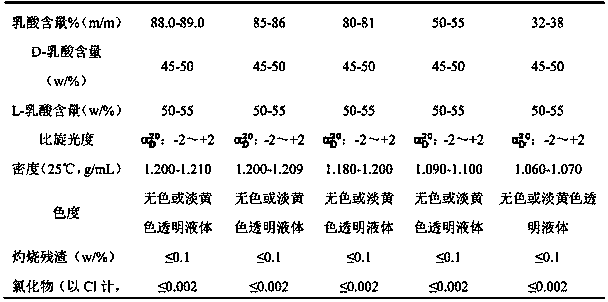

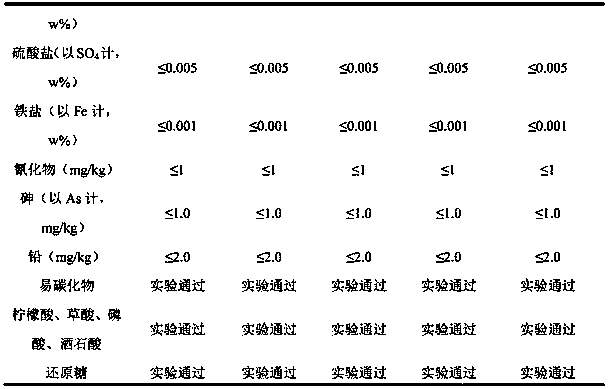

Examples

Embodiment 1

[0028] 1. Preparation of dilute DL-lactic acid

[0029] A. After the cleaning of the system equipment is completed, 1000Kg of L-lactic acid (L-lactic acid accounts for 98.64%, D-lactic acid accounts for 1.36%, optical rotation -14, and the total content of lactic acid is 90.27%) that has completed the evaluation (acceptance) is input once into the reaction tank, add 1600kg of distilled water to dilute under stirring state, so that the lactic acid content is controlled between 32-38%. Start the reactor heating device, heat up to 55.5°C under continuous stirring, drop in 3kg 767 activated carbon for injection, and continue stirring for 30 minutes. Put the feed liquid into the transfer tank at one time and keep it warm for 3 hours. During the period, take samples and filter at any time to measure the specific rotation. When the rotation is -3.5, filter the feed liquid in the transfer tank through a candle filter and then input it for leveling. Can. After the feeding is complete...

Embodiment 2

[0051] 1. Preparation of dilute DL-lactic acid. Method is with embodiment 1.

[0052] 2. Preparation of concentrated DL-lactic acid

[0053] (1) After pouring 5500kg of the prepared dilute DL-lactic acid into the reaction tank at one time, turn on the stirring device of the reaction tank.

[0054] (2) Check the vacuum system matched with the reaction tank, open the cooling water valve of the spiral wound tube condenser, start the water circulation vacuum pump, and turn on the reaction tank heating device until the system pressure drops to 2700-2000Pa.

[0055] (3) When the system pressure is 2400-2200Pa, when the temperature of the material in the reaction tank rises to 85-90°C (corresponding to the target content according to experience), stop heating, remove and stop the vacuum.

[0056] (4) Add 3kg of 767 activated carbon for injection and stir for 5-10min.

[0057] (5) Input the feed liquid into the transfer tank at one time, keep the feed liquid at 50-80°C for 15 minut...

Embodiment 3

[0064] 1. Preparation of dilute DL-lactic acid. Method is with embodiment 1.

[0065] 2. Refining of dilute DL-lactic acid

[0066] (1) After pouring 5000kg of the prepared dilute DL-lactic acid into the reaction tank at one time, turn on the stirring device of the reaction tank.

[0067] (2) Check the vacuum system matched with the reaction tank, open the cooling water valve of the spiral wound tube condenser, start the water circulation vacuum pump, and turn on the reaction tank heating device until the system pressure drops to 2700-2000Pa.

[0068] (3) When the system pressure is 2400-2200Pa, when the temperature of the material in the reaction tank rises to 85-90°C (corresponding to the target content), stop heating, remove and stop the vacuum.

[0069] (4) Add 3kg of 767 activated carbon for injection, and stir for 5-10 minutes.

[0070] (5) Input the feed liquid into the transfer tank at one time, keep the feed liquid at 50-80°C for 15 minutes.

[0071] (6) The materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical rotation | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com