Recovery method of extractant in extract

A recovery method and extraction liquid technology are applied in the field of extraction agent recovery in extraction liquid, which can solve the problems of low value of extraction agent, increased production cost of enterprises, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The present invention is described in further detail through the embodiments in conjunction with the accompanying drawings:

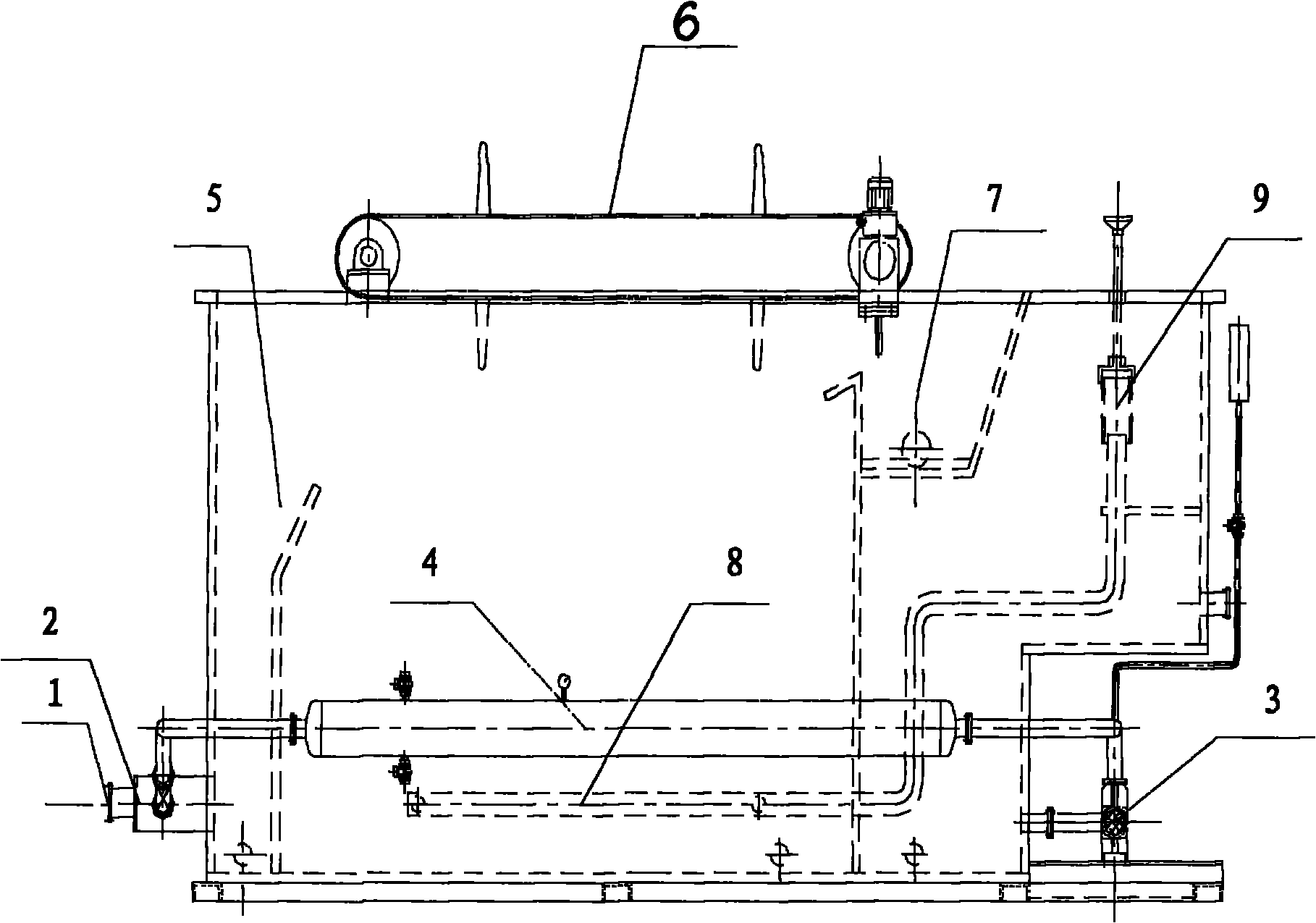

[0015] attached figure 1 It is a schematic diagram of the operation flow chart of the equipment designed for adopting the technology involved in the present invention.

[0016] The extraction liquid enters the gas / liquid mixing chamber 2 from the water inlet 1 at the bottom of the equipment, and the gas / liquid mixture in the high-pressure gas dissolving device 3 is cut, pressurized and swirled to form a 100% gas-saturated liquid, which is released by decompression In the contact reaction tube 4, dense microbubbles with a diameter and bubble spacing of less than 40 μm are formed, and then enter the gas / liquid mixing chamber 2 to fully contact and adhere to the organic phase in the extraction liquid and float up. The entire floating process is concentrated on the reaction diversion In the reaction area defined by the tank 5, the microbubbles and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com