Hot isostatic pressing preparation method of high-density molybdenum-copper alloy

A technology of molybdenum-copper alloy and hot isostatic pressing, which is applied in the field of materials, can solve the problems of airtightness, uneven composition distribution, and low relative density of devices that affect the thermal conductivity of materials, and achieve good thermal conductivity and uniform distribution of two phases , high densification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

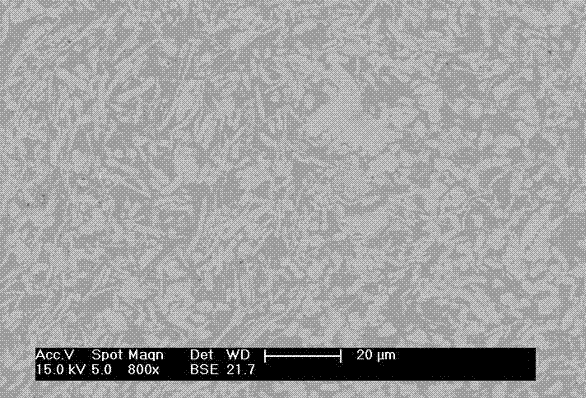

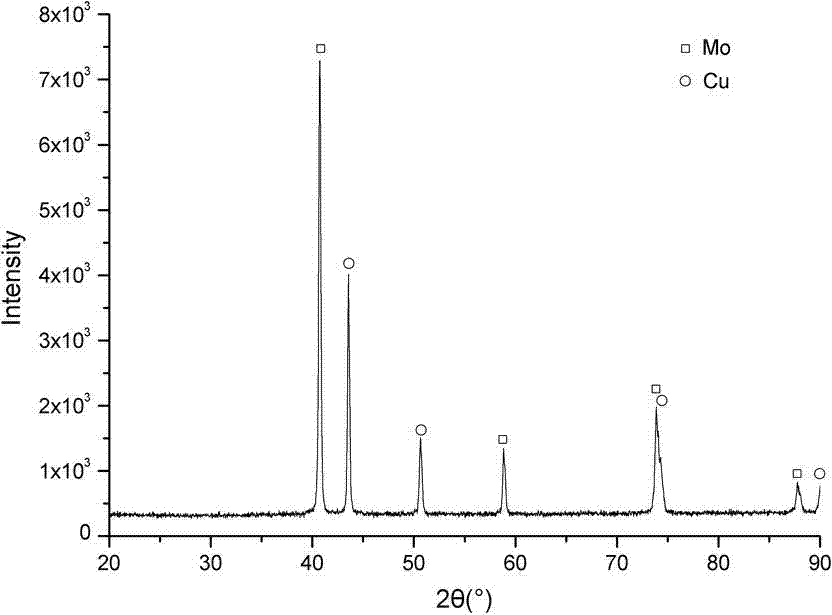

[0040]The raw materials are weighed according to the following weight percentages: molybdenum powder 50%, copper powder 50%. Put the weighed raw materials (ie, molybdenum powder and copper powder) into a stainless steel ball mill tank for ball milling, using tungsten alloy balls for ball milling, and the ball milling time is 18 hours to obtain a mixed powder. The obtained mixed powder was put into a soft mold for cold isostatic pressing, the cold isostatic pressing pressure was 240 MPa, the temperature was 18°C, and the time was 10 minutes to obtain a cold compact. Take out the cold compact from the soft film, carry out hydrogen reduction, and complete the pre-sintering process at the same time. The hydrogen reduction process is as follows: heat preservation at 280°C for 1h, and heat preservation at 700°C for 0.5h. Put the reduced compact into a metal sheath, heat and degas it, and seal it in a vacuum sheath. Put it in the hot isostatic pressing equipment for hot isostatic p...

Embodiment 2

[0043] The raw materials are weighed according to the following weight percentages: molybdenum powder 55%, copper powder 45%. Put the weighed raw materials into a stainless steel ball mill tank for ball milling, using tungsten alloy balls for ball milling, and the ball milling time is 20 hours to obtain mixed powder. The obtained mixed powder was put into a soft mold for cold isostatic pressing, the cold isostatic pressing pressure was 260 MPa, the temperature was 20°C, and the time was 15 minutes to obtain a cold compact. Take out the cold compact from the soft film, carry out hydrogen reduction, and complete the pre-sintering process at the same time. The hydrogen reduction process is as follows: heat preservation at 350°C for 1h, and heat preservation at 700°C for 1h. Put the reduced compact into a metal sheath, heat and degas it, and seal it in a vacuum sheath. Put the cold-pressed billet containing the metal sheath in the hot isostatic pressing equipment for hot isostat...

Embodiment 3

[0046] The raw materials are weighed according to the following weight percentages: molybdenum powder 45%, copper powder 55%. Put the weighed raw materials into a stainless steel ball mill tank for ball milling, using tungsten alloy balls for ball milling, and the ball milling time is 16 hours to obtain mixed powder. Put the obtained mixed powder into a soft mold for cold isostatic pressing, the cold isostatic pressing pressure is 250MPa, the temperature is 20°C, and the time is 8min, to obtain a cold compact. Take out the cold compact from the soft film, carry out hydrogen reduction, and complete the pre-sintering process at the same time. The hydrogen reduction process is as follows: heat preservation at 300°C for 1 hour, and heat preservation at 730°C for 1 hour. Put the reduced compact into a metal sheath, heat and degas it, and seal it in a vacuum sheath. Put it in the hot isostatic pressing equipment for hot isostatic pressing and densification sintering. The hot isost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature yield strength | aaaaa | aaaaa |

| Room temperature yield strength | aaaaa | aaaaa |

| Room temperature yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com