Methods for enclosing a thermoplastic package

a thermoplastic and package technology, applied in the field of circuit packages, can solve the problems of damage or deformation of plastic, high cost of process, limited thermal conductivity of the resulting alloy, etc., and achieve the effects of improving electrical and thermal conductivity and mechanical integrity, low cost, and low piece coun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The contents of application Ser. No. 10 / 767,309, filed Jan. 29, 2004, and the contents of provisional Application No. 60 / 443,470, filed Jan. 29, 2003, are hereby incorporated by reference.

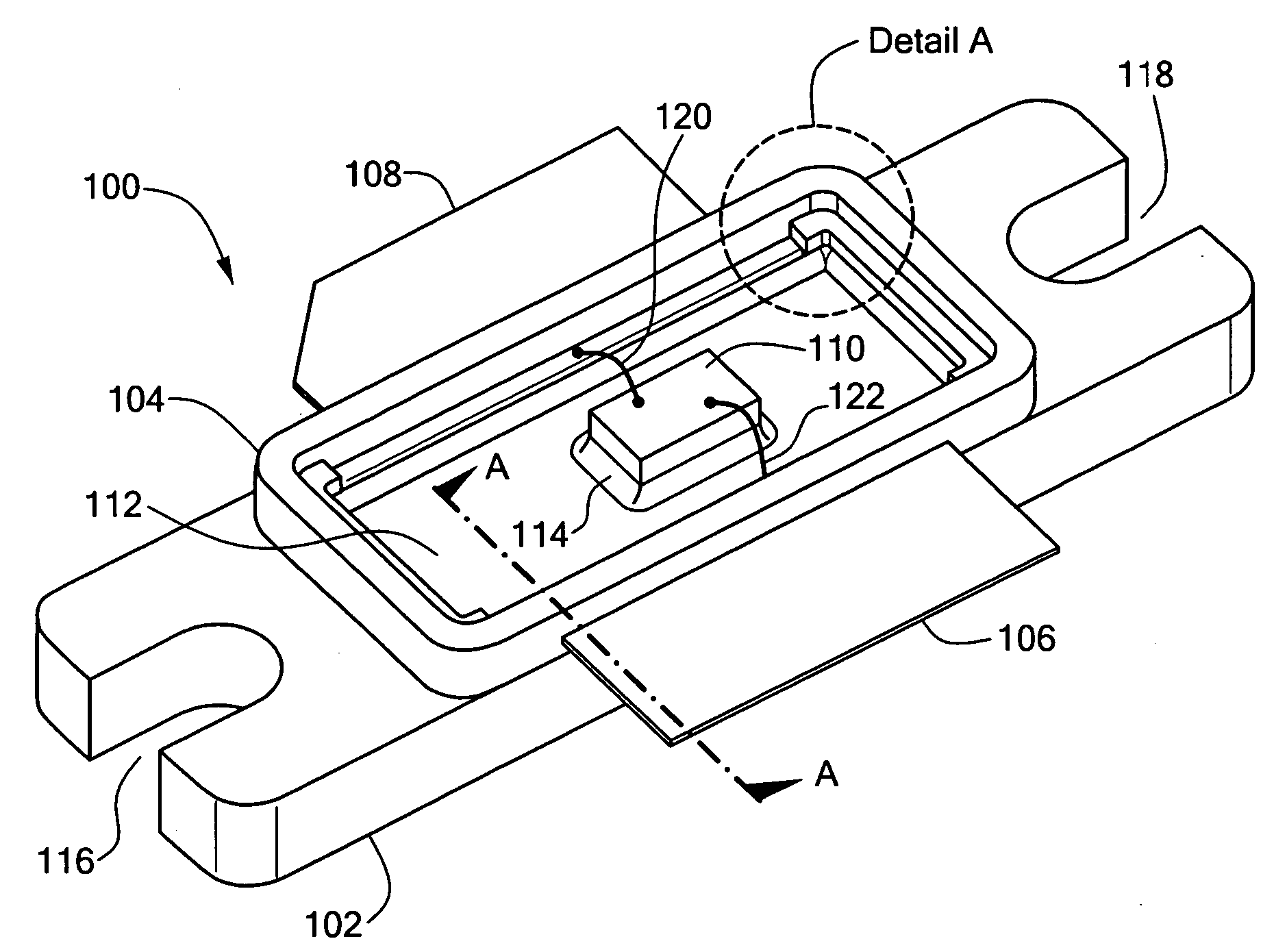

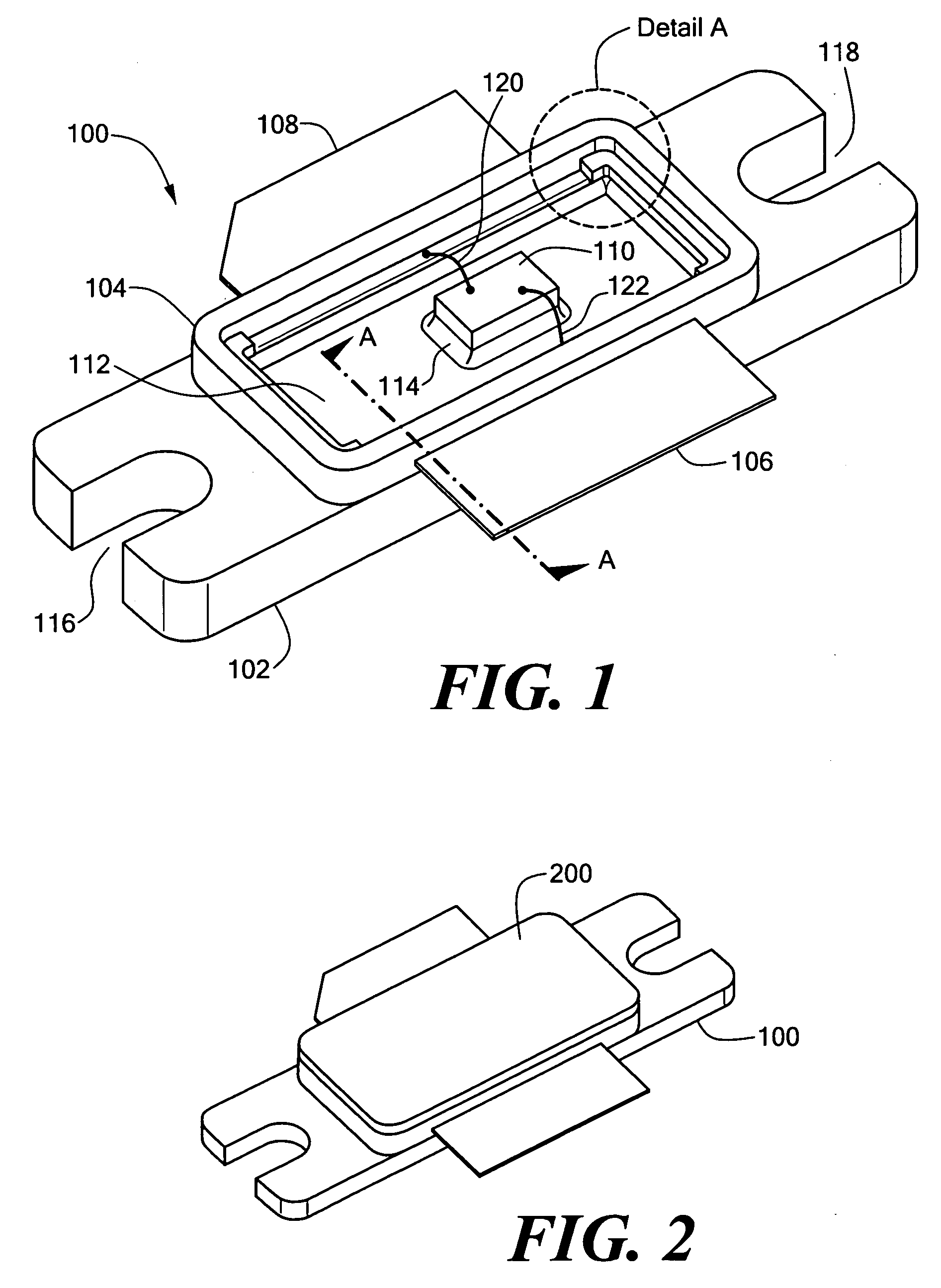

[0038] The present invention provides a low piece-count circuit package that can withstand high die-attach temperatures and can provide a hermetically sealed air cavity for a die, without the use of adhesives. FIG. 1 shows an exemplary circuit package 100, according to one embodiment of the present invention. For clarity, the circuit package 100 is shown without a lid. The circuit package 100 includes a flange 102, a frame 104 and two leads 106 and 108. The frame 104 electrically insulates the leads 106 and 108 from the flange 102 and each other. A die 110 is attached to a die-attach area 112, such as by eutectic solder 114. For clarity, FIG. 1 shows only one die, although typically two or more die can be attached to the die-attach area 112.

[0039] The eutectic solder 114 electrically bonds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com