Composite polarizing plate, laminated optical member, and image display device using them

A technology of polarizers and polarizers, used in polarizing elements, optical elements, optics, etc., can solve problems such as insufficient cohesion of adhesives, and achieve the effects of improving visual recognition, reducing the number of parts, and suppressing poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0174] (a) Polarizing plate with pressure-sensitive adhesive layer

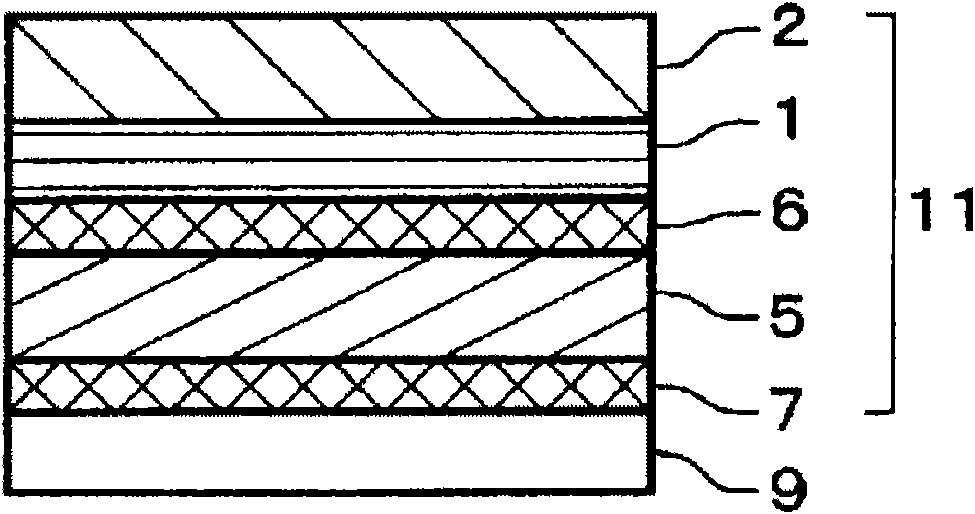

[0175] Prepare a polarizer made of a 25 μm thick film in which iodine is adsorbed and oriented in polyvinyl alcohol, and a transparent protective layer made of a 40 μm thick triacetate cellulose film is bonded to one side of the polarizer via an epoxy-based adhesive Polarizing film. Lay the pressure-sensitive adhesive layer A on its polarizer side to make a structure with a pressure-sensitive adhesive layer of transparent protective layer / polarizer / pressure-sensitive adhesive layer A / peeling film Polarizing film.

[0176] (b) Retardation plate with pressure-sensitive adhesive layer

[0177] Formed from a stretched film of a norbornene-based resin, with a thickness of 40 μm and an in-plane retardation of 140 nm ("Escina Film" manufactured by Sekisui Chemical Co., Ltd.) (λ / 4 plate) The above-mentioned light-diffusing pressure-sensitive adhesive layer A was bonded on one side to produce a phase difference pla...

Embodiment 2

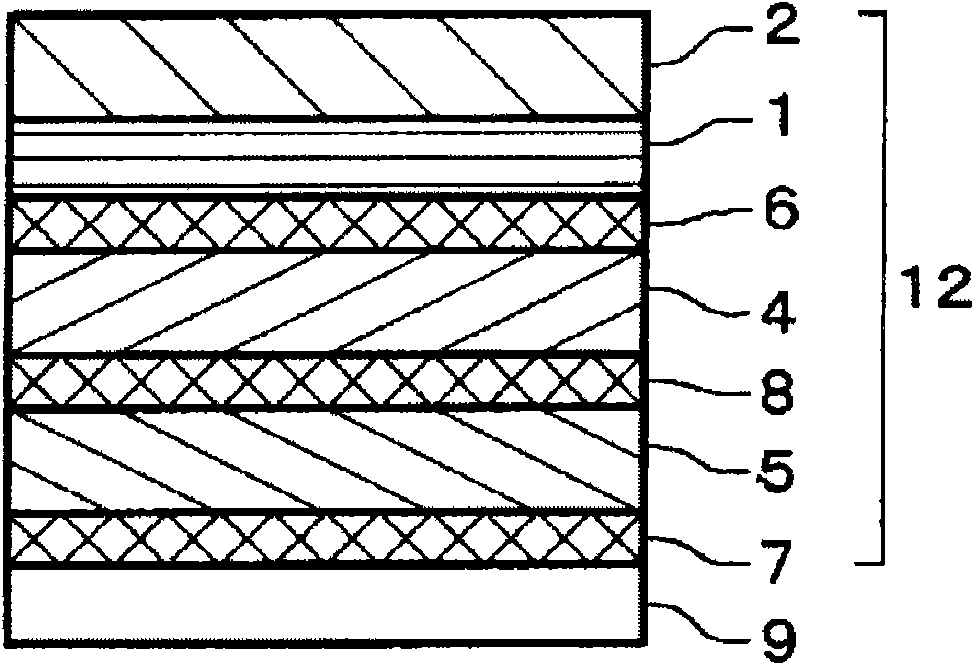

[0185] (a) Polarizing plate with pressure-sensitive adhesive layer

[0186] In the same manner as in (a) of Example 1, a polarizing plate with a pressure-sensitive adhesive layer having a structure of transparent protective layer / polarizer / pressure-sensitive adhesive layer A / peeling film was produced.

[0187] (b) Retardation plate with pressure-sensitive adhesive layer

[0188] Prepare a retardation plate (manufactured by Sekisui Chemical Co., Ltd. " A phase difference plate (λ / 2 plate) with a pressure-sensitive adhesive layer laminated with an acrylic pressure-sensitive adhesive with a thickness of 15 μm on one side of the “Escina film”) (λ / 2 plate). In addition, a retardation plate (manufactured by Sekisui Chemical Co., Ltd.) with a thickness of 28 μm was produced by forming a stretched film of a norbornene-based resin and having an in-plane phase difference of λ / 4 of 90 nm with respect to the light wavelength λ. "Essina film") (λ / 4 plate) is bonded to one side of the lig...

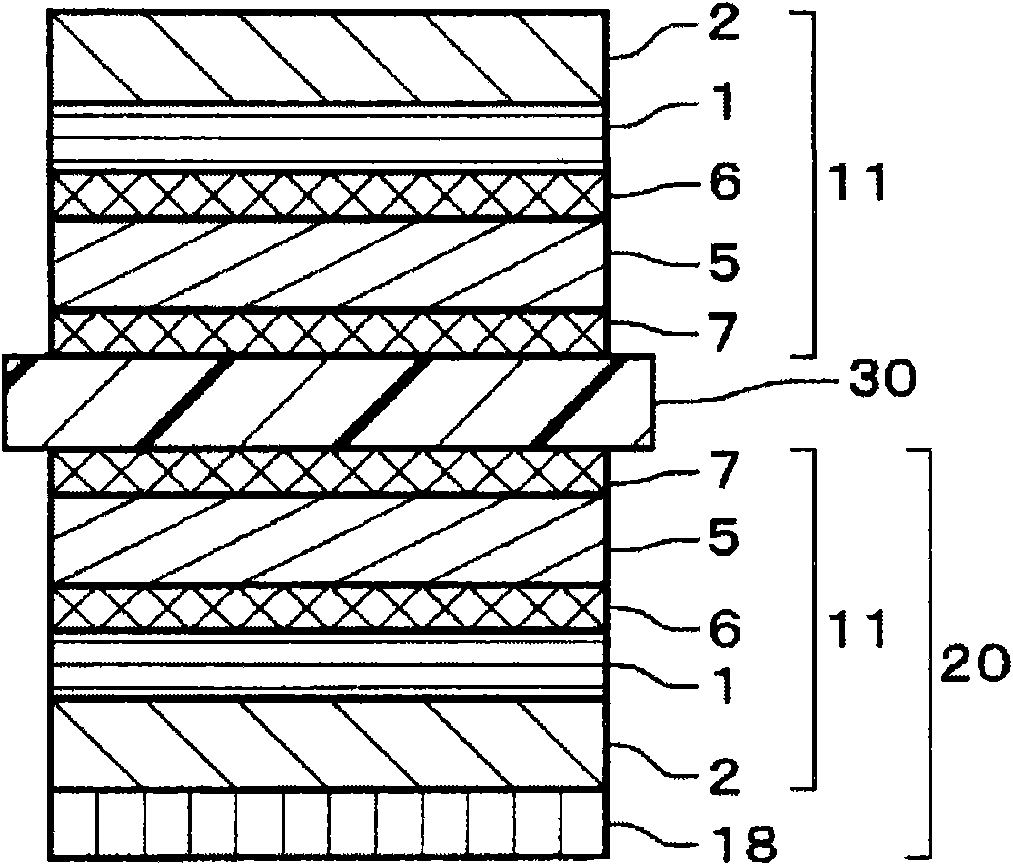

Embodiment 3

[0195] (a) Polarizing plate with pressure-sensitive adhesive layer

[0196] In the same manner as in (a) of Example 1, a polarizing plate with a pressure-sensitive adhesive layer having a structure of transparent protective layer / polarizer / pressure-sensitive adhesive layer A / peeling film was produced.

[0197] (b) Retardation plate with pressure-sensitive adhesive layer

[0198] Formed from a stretched film of norbornene-based resin, it has an in-plane retardation of λ / 2 of 270 nm with respect to the wavelength λ of light, and a retardation plate with a thickness of 33 μm ("Esshi" manufactured by Sekisui Chemical Co., Ltd.) On one side of the film ") (λ / 2 plate), the light-diffusing pressure-sensitive adhesive layer A was bonded to produce a phase difference plate (λ / 2 plate) with a pressure-sensitive adhesive layer. In addition, in the form of a stretched mold of norbornene-based resin, a phase difference plate having an in-plane phase difference of λ / 4 of 90 nm with respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com