Patents

Literature

38results about How to "Control interface response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

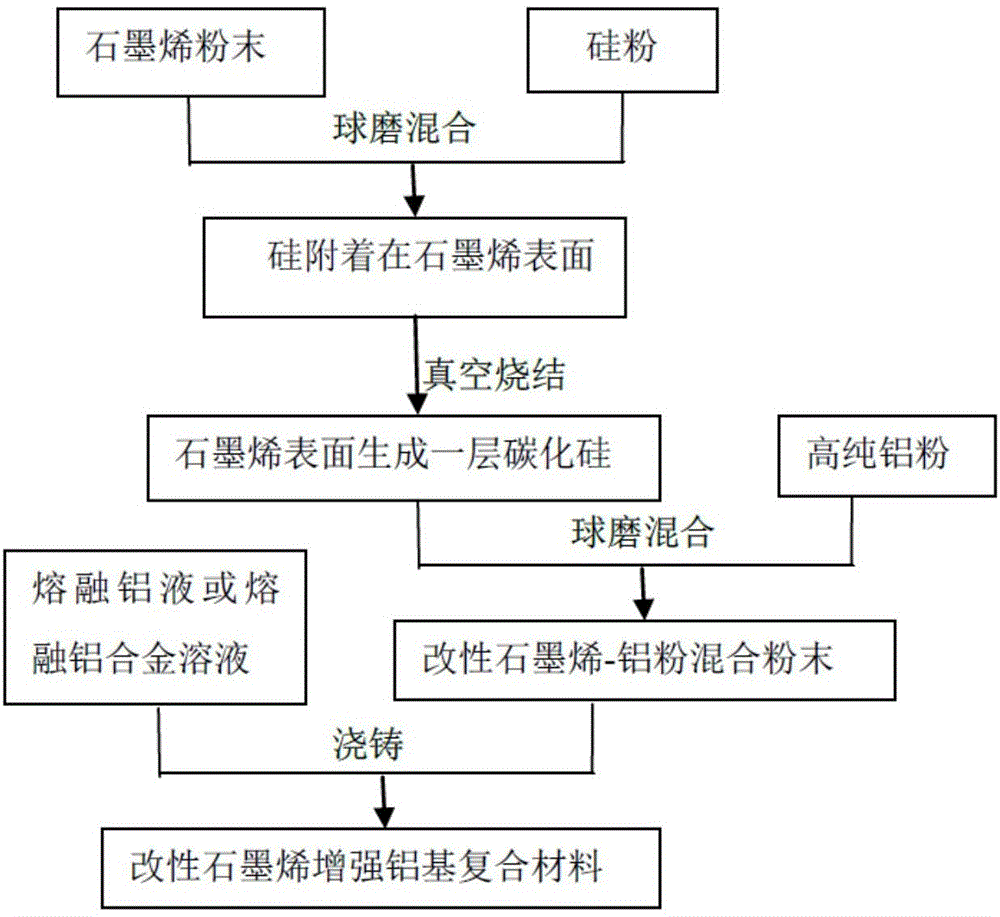

Modified graphene-reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a modified graphene-reinforced aluminum matrix composite material and a preparation method thereof. The method includes the steps that graphene powder, silica powder, grinding balls and stearic acid are placed into a ball grinding mill, liquid nitrogen is filled in till all the grinding balls are immersed and then ball milling is performed, and mixed powder is obtained and dried; the dried mixed powder is sintered, so that modified graphene is obtained; the modified graphene, high-purity aluminum powder, grinding balls and stearic acid are put into the ball grinding mill, liquid nitrogen is filled in for ball milling, modified graphene-aluminum powder mixed powder is obtained, and drying is further performed; and the dried modified graphene-aluminum powder mixed powder is added into a molten aluminum or molten aluminum alloy solution to be evenly stirred, and casting is carried out. By the adoption of the method, graphene is modified, good wettability between the graphene and an aluminum matrix can be obtained, and the bonding strength of the graphene and the aluminum matrix is improved. By blending different molten aluminum or molten aluminum alloy solutions, graphene-reinforced aluminum matrix composite material billets of various specifications can be obtained by means of casting, and batch production is achieved.

Owner:YINBANG CLAD MATERIAL

Method for preparing high-performance high-temperature-resisting nanometer composite permanent magnet

ActiveCN102655050AImprove temperature stabilityControl interface responsePermanent magnetsInductances/transformers/magnets manufactureThermal deformationBall mill

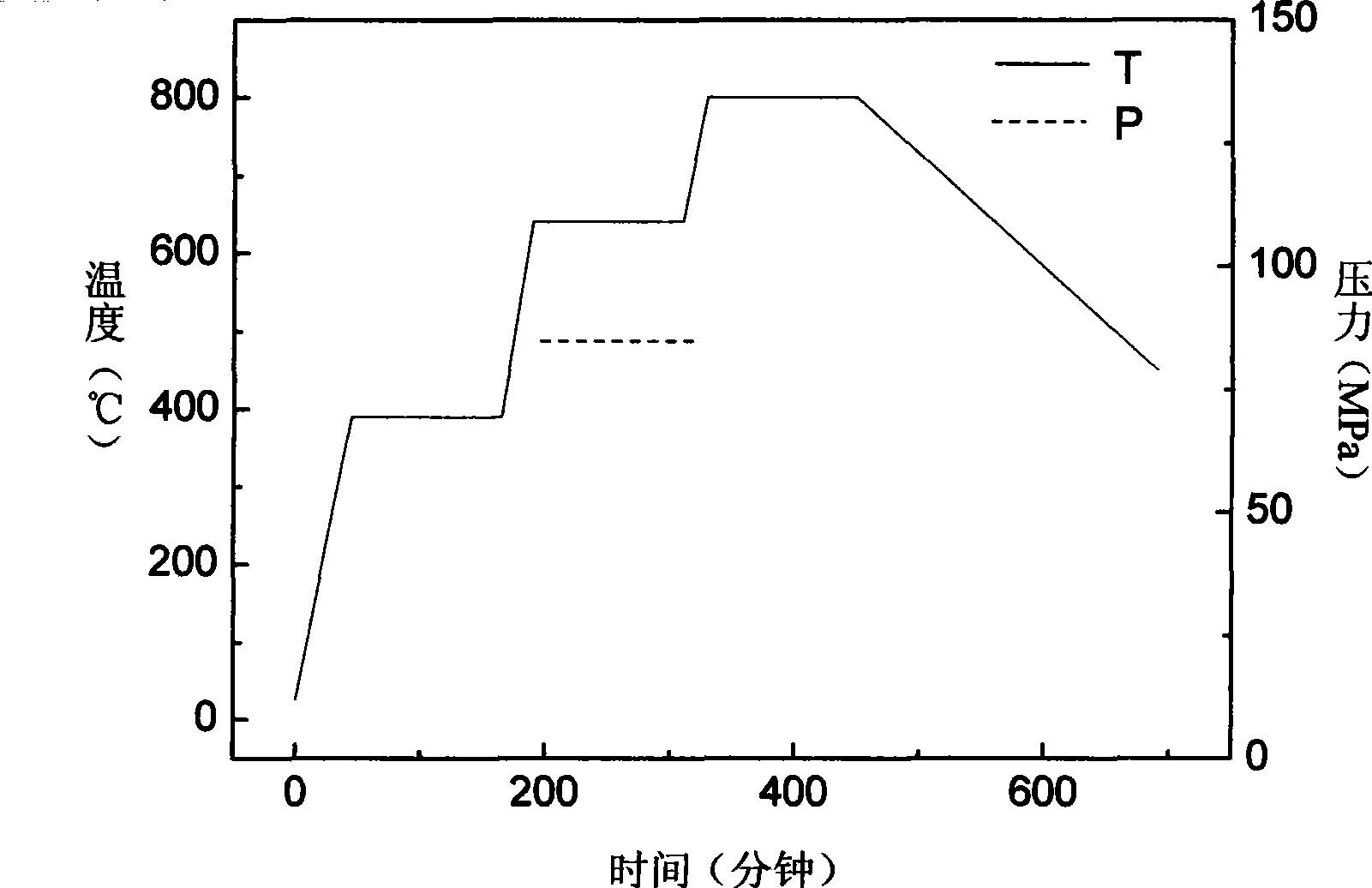

The invention discloses a method for preparing a high-performance high-temperature-resisting nanometer composite permanent magnet, relating to preparation techniques of permanent magnetic materials. The method mainly comprises the following steps of: (1) weighing each element raw material according to elements of NdFeB alloy, mixing the element raw materials, melting the mixed raw material in vacuum, and rapidly quenching to prepare thin belts; (2) preparing SmCo ally rapidly quenched belts through the step (1); (3) respectively carrying out high-energy ball milling on the NdFeB and the SmCo alloy rapidly quenched belt to prepare corresponding nanometer crystal alloy powder; (4) mixing the NdFeB and the SmCo nanometer crystal alloy powder according to certain proportion, adding a crystal boundary nanometer modifier to be uniformly distributed on the surfaces of the NdFeB and the SmCo powders to obtain composite powder with the uniformly mixed three; (5) pressing the composite powder to form moulded blanks; (6) carrying out discharge plasma sintering on the moulded blanks to prepare a nanometer composite magnet; and (7) carrying out thermal deformation on the nanometer composite magnet to improve the degree of orientation and obtain the high-performance high-temperature-resisting nanometer composite permanent magnet. The method has the advantages of simple process and easiness in operation, and is suitable for large-scale batch production.

Owner:朗峰新材料启东有限公司

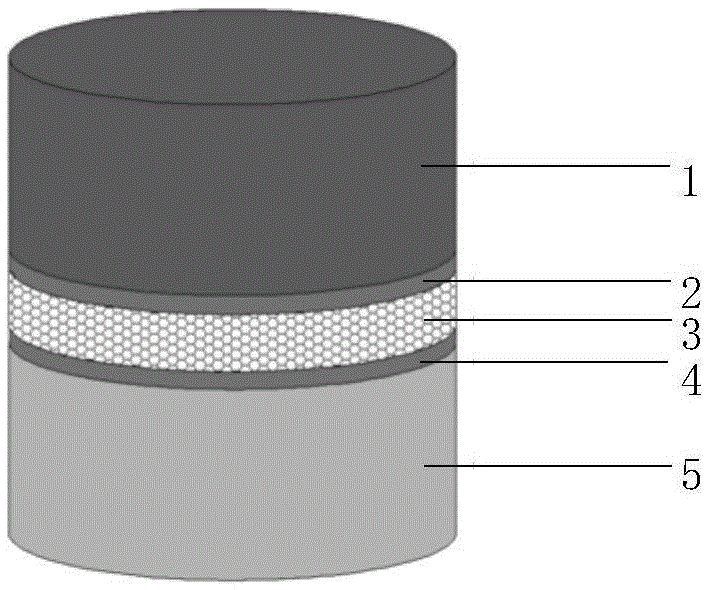

Ceramic and metal brazing composite component and preparing method thereof

InactiveCN105537712AHigh strengthImprove thermal fatigue performanceSoldering apparatusWelding/soldering/cutting articlesMetalworkingThermal fatigue

The invention provides a ceramic and metal brazing composite component. The composite component comprises metal, ceramic and a middle layer formed between to-be-welded faces of the ceramic and the metal; the middle layer comprises upper layer brazing filler metal, foam metal and lower layer brazing filler metal. The invention further provides a preparing method of the composite component. The preparing method comprises the steps that the upper layer brazing filler metal, the lower layer brazing filler metal and the foam metal are machined into an upper brazing filler metal layer, a lower brazing filler metal layer and a foam metal layer with the areas close to the area of the to-be-welded faces; the lower brazing filler metal layer, the foam metal layer, the upper brazing filler metal layer and to-be-welded metal are sequentially placed on the to-be-welded ceramic surface, and a certain pressure is applied to complete assembling; and an assembled sample is heated under the vacuum condition, is subject to heat preservation for a certain time, and then is cooled. The composite component has the excellent strength and thermal fatigue performance. According to the preparing method, existing materials can be directly used, complex pretreatment is avoided, and firm bonding between ceramic and metal can be achieved.

Owner:BEIHANG UNIV

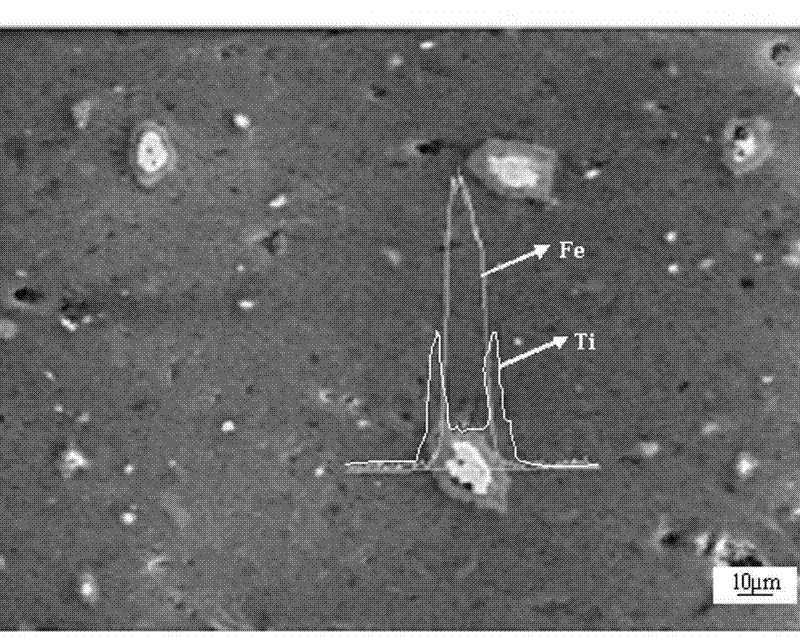

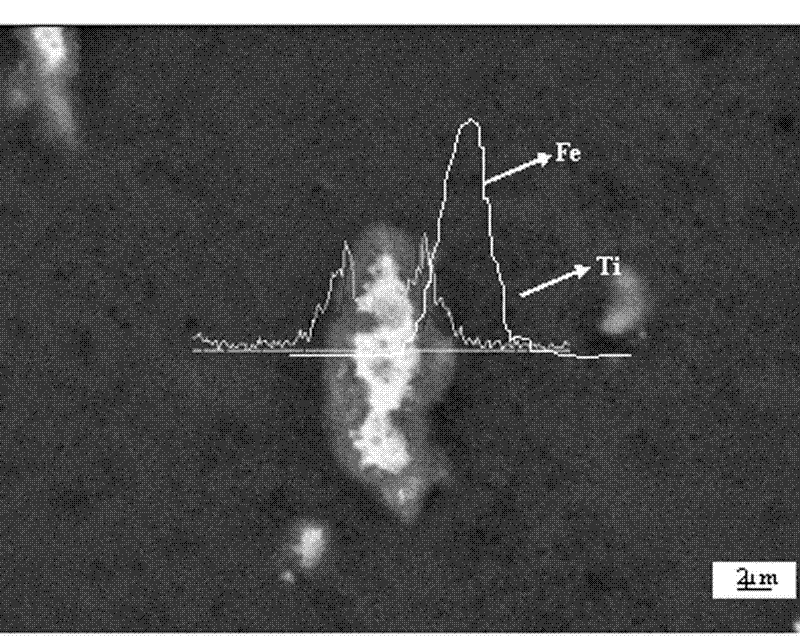

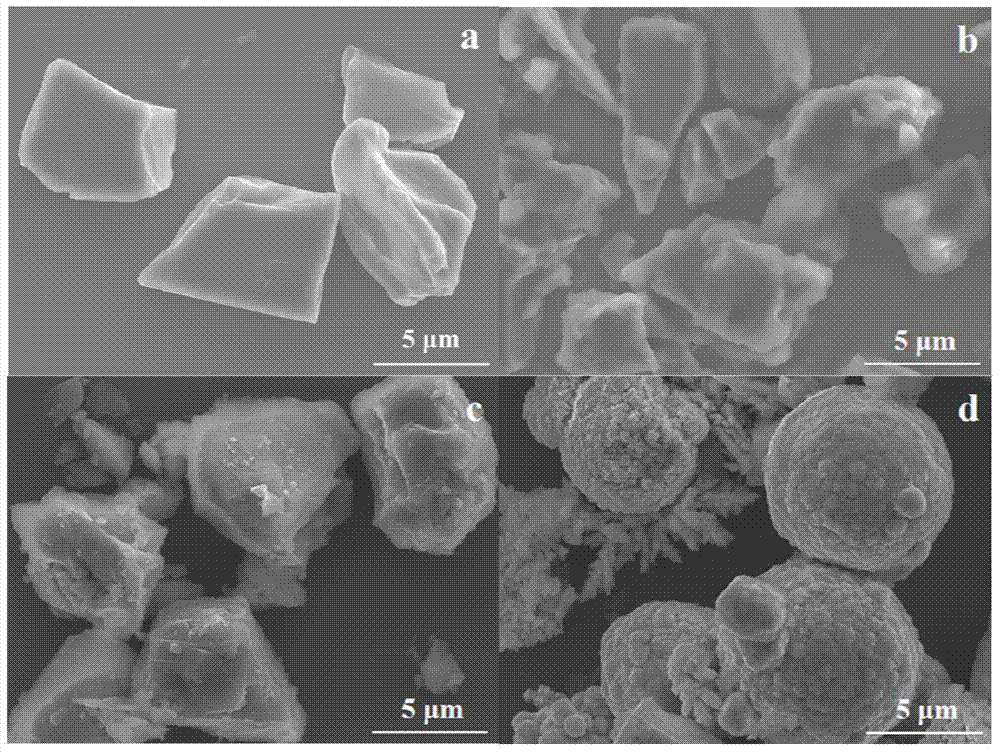

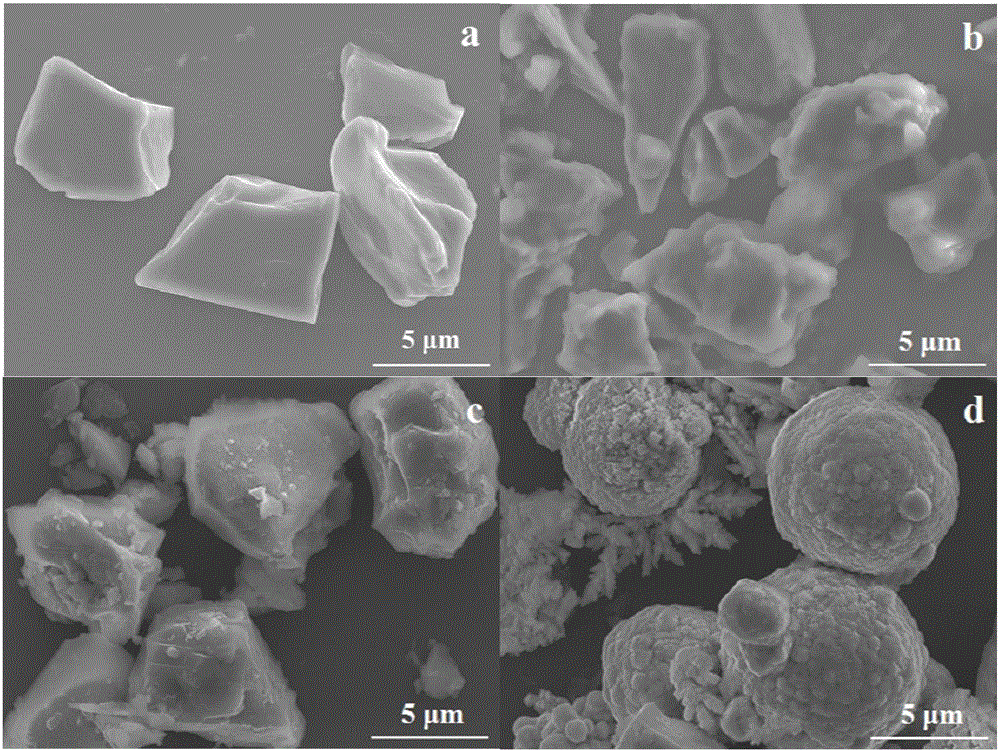

Method for preparing titanium-iron particle reinforced hydroxyapatite-based bioceramic material

The invention discloses a method for preparing a titanium-iron particle reinforced hydroxyapatite-based bioceramic material and belongs to the technical field of materials. The method comprises the following steps: mixing titanium powder and iron powder, mixing and finely grinding by ball milling and obtaining composite powder; mixing the composite powder with hyaluronic acid (HA) powder to obtain mixed powder, uniformly mixing by ball milling in absolute ethanol serving as a medium, drying under a condition of a temperature of 80+ / -5 DEG C to remove ethanol and obtaining HA / Ti-Fe powder; and subjecting HA / Ti-Fe powder to unidirectional press forming or cold isostatic press forming, sintering under vacuum conditions and obtaining the titanium-iron particle reinforced hydroxyapatite-based bioceramic material. The method disclosed by the invention is simple in process and low in cost, and can realize industrial production easily; and the prepared bioceramic material has excellent mechanical performance and biological performance.

Owner:NORTHEASTERN UNIV

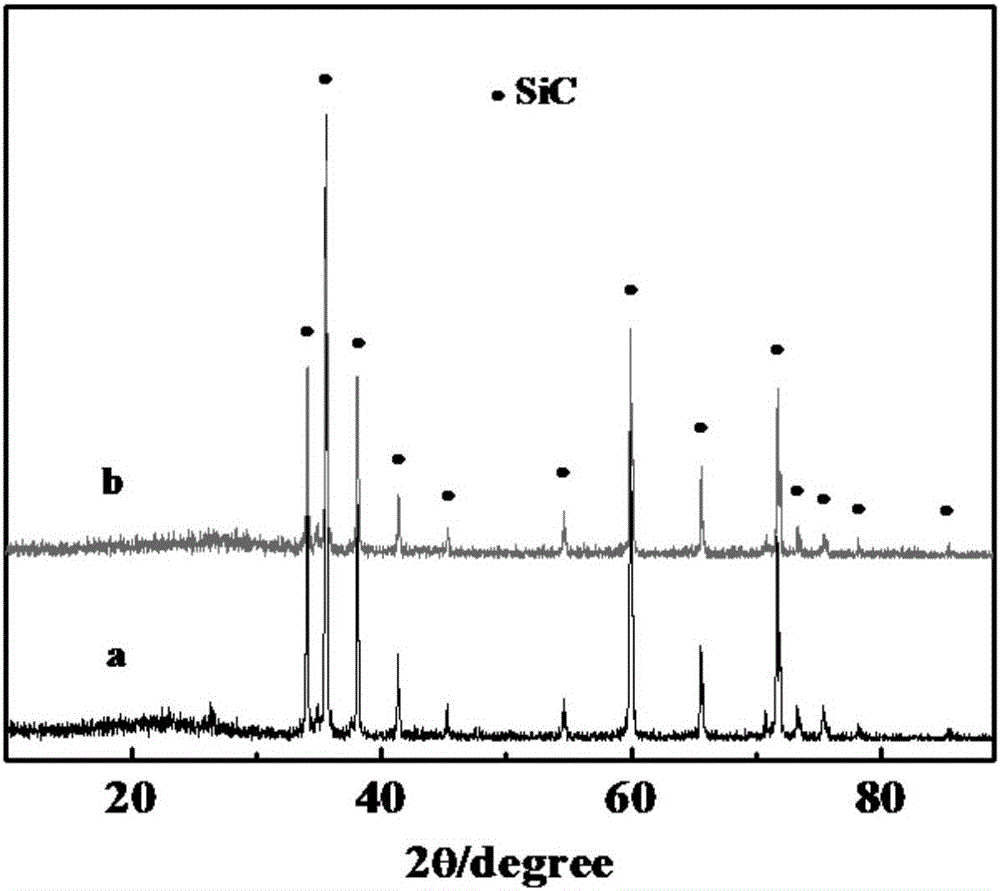

Low temperature glass phase enhanced SiCp/Cu composite material and preparation method thereof

ActiveCN104294071AImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

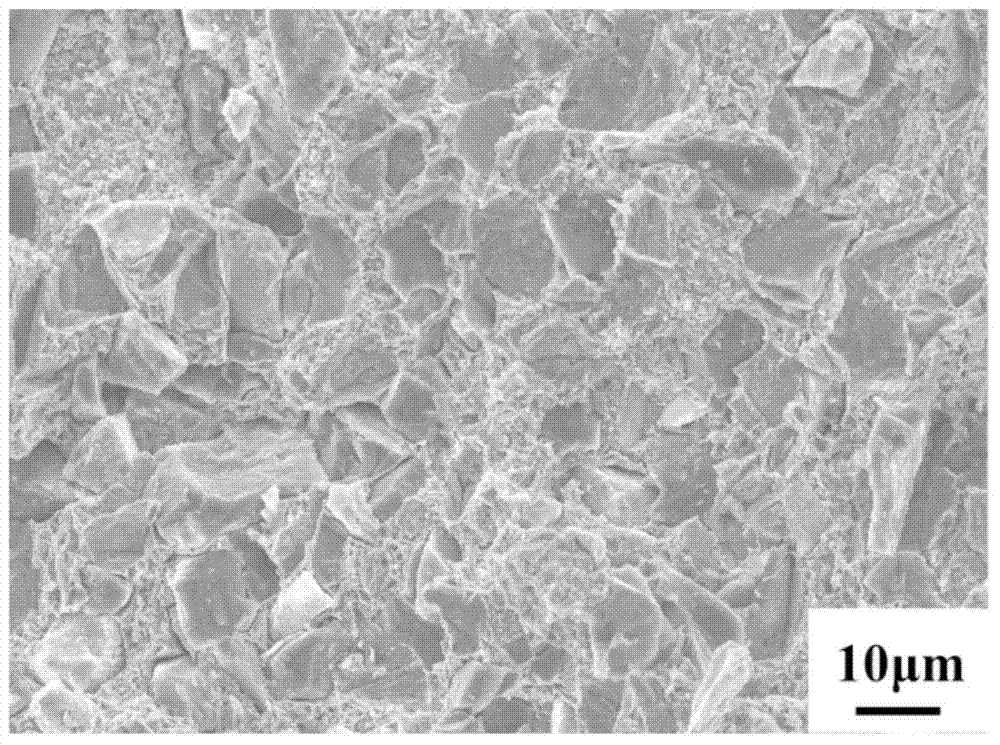

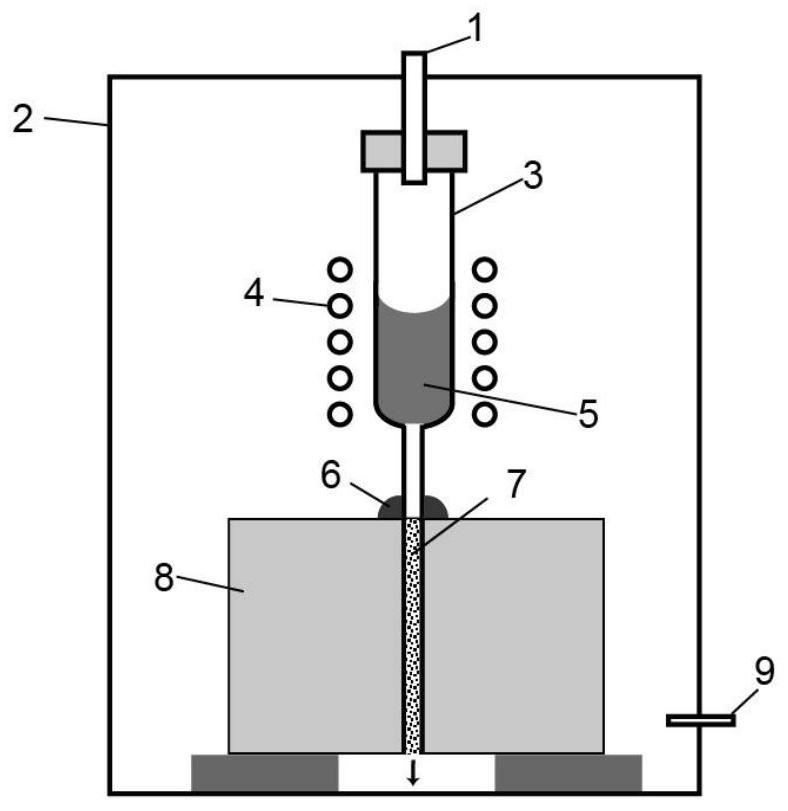

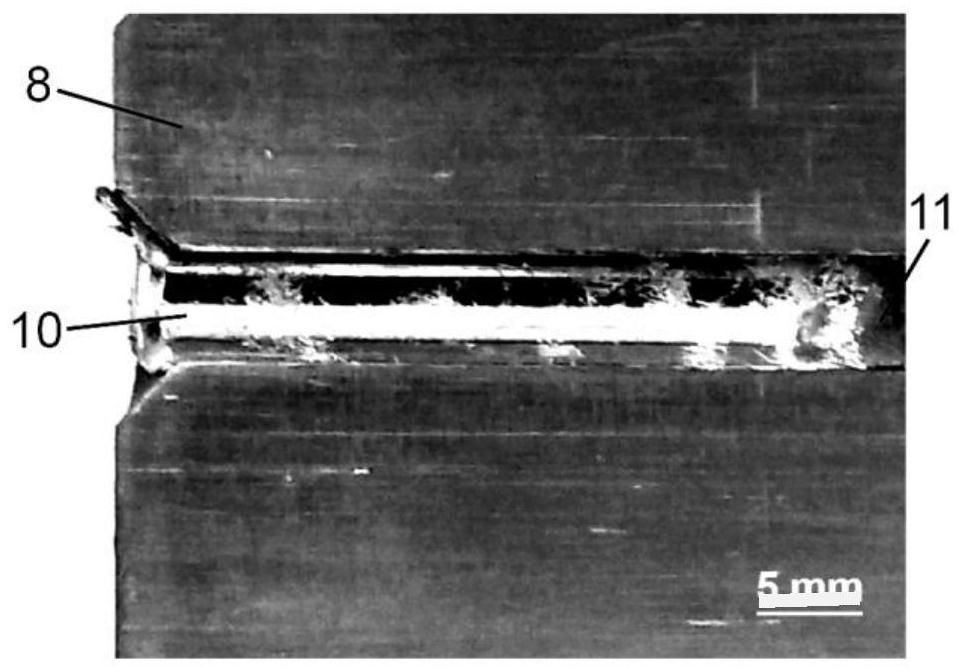

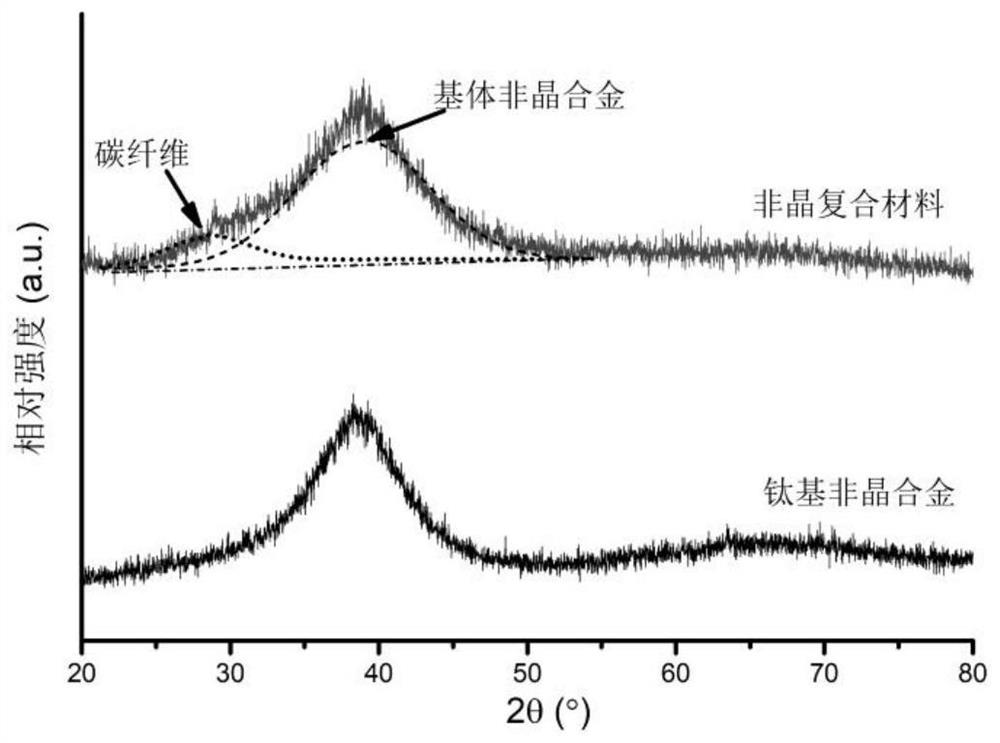

Method for preparing chopped carbon fiber reinforced amorphous composite material and a device thereof

The invention discloses a method for preparing a chopped carbon fiber reinforced amorphous composite material and a device thereof, and relates to the technical field of forming an amorphous compositematerial by contacting fibers with molten metal and performing rapid solidification. The method adopts a chemical plating method to improve the wettability of the carbon fibers, a carbon fiber preform is prepared through a copper mold, furthermore, the chopped carbon fiber reinforced amorphous composite material is prepared by using a vacuum low-pressure casting method, namely a spray casting method, and the defects that in the prior art, the fiber agglomeration phenomenon caused by non-uniform dispersion of reinforced fibers in a matrix or an interface structure with brittleness equal to that generated by the carbon fibers and the matrix at an interface, the method is only suitable for a traditional magnesium alloy matrix, a high cooling speed cannot be achieved, an amorphous matrix cannot be obtained, and the amorphous composite material cannot be prepared for various amorphous alloy matrixes needing vacuum melting are overcome.

Owner:HEBEI UNIV OF TECH

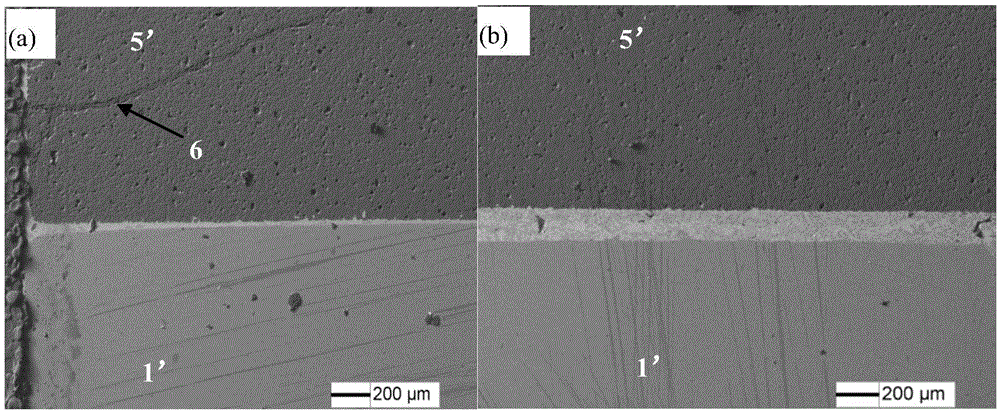

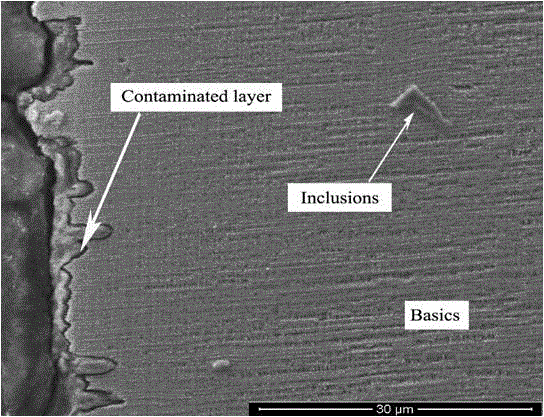

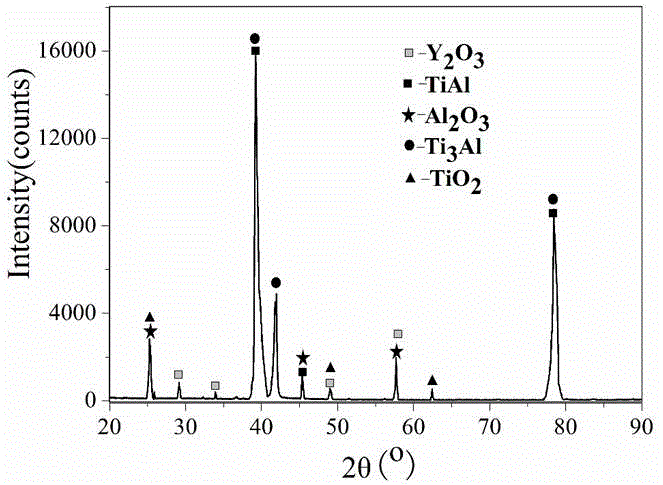

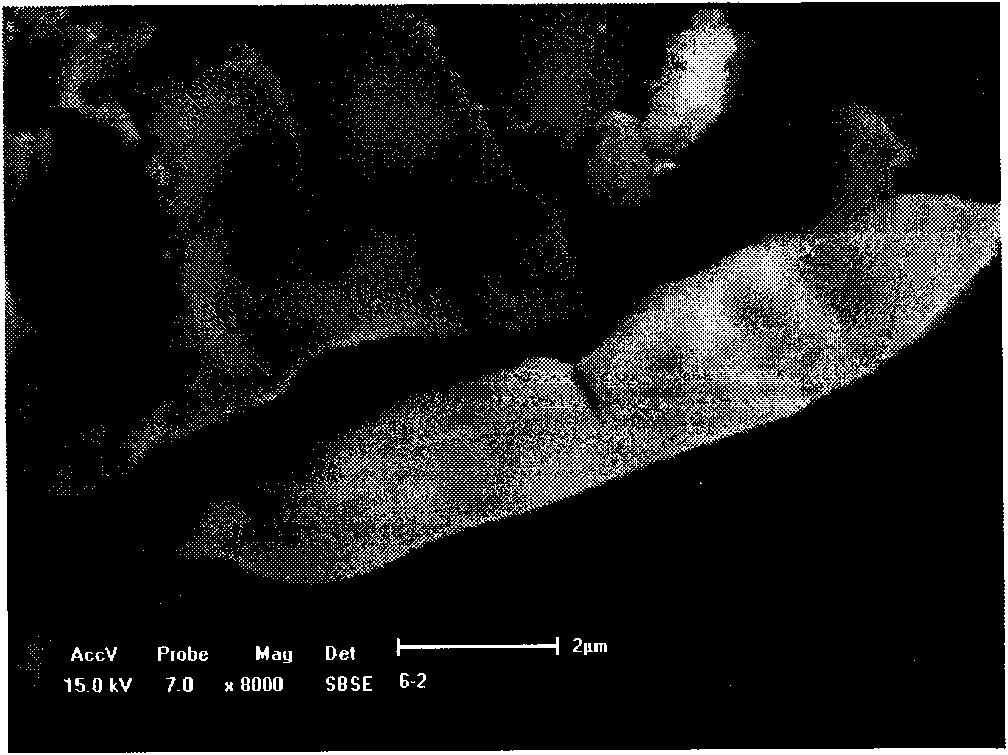

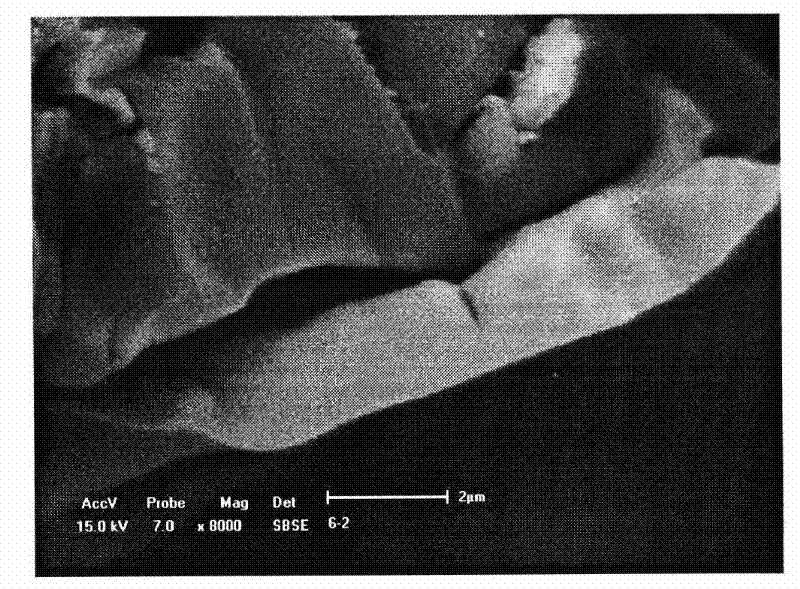

Process for reducing reaction of directional solidification titanium-aluminum alloy castings and casting mold coatings

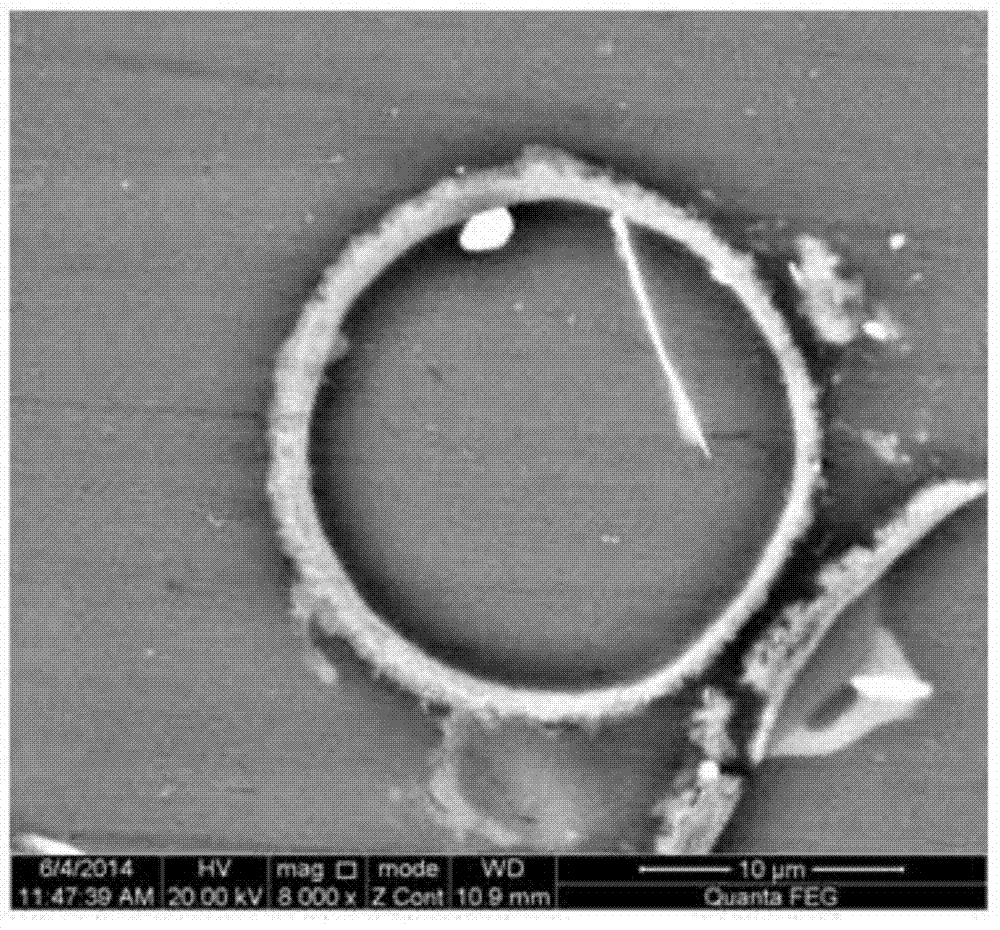

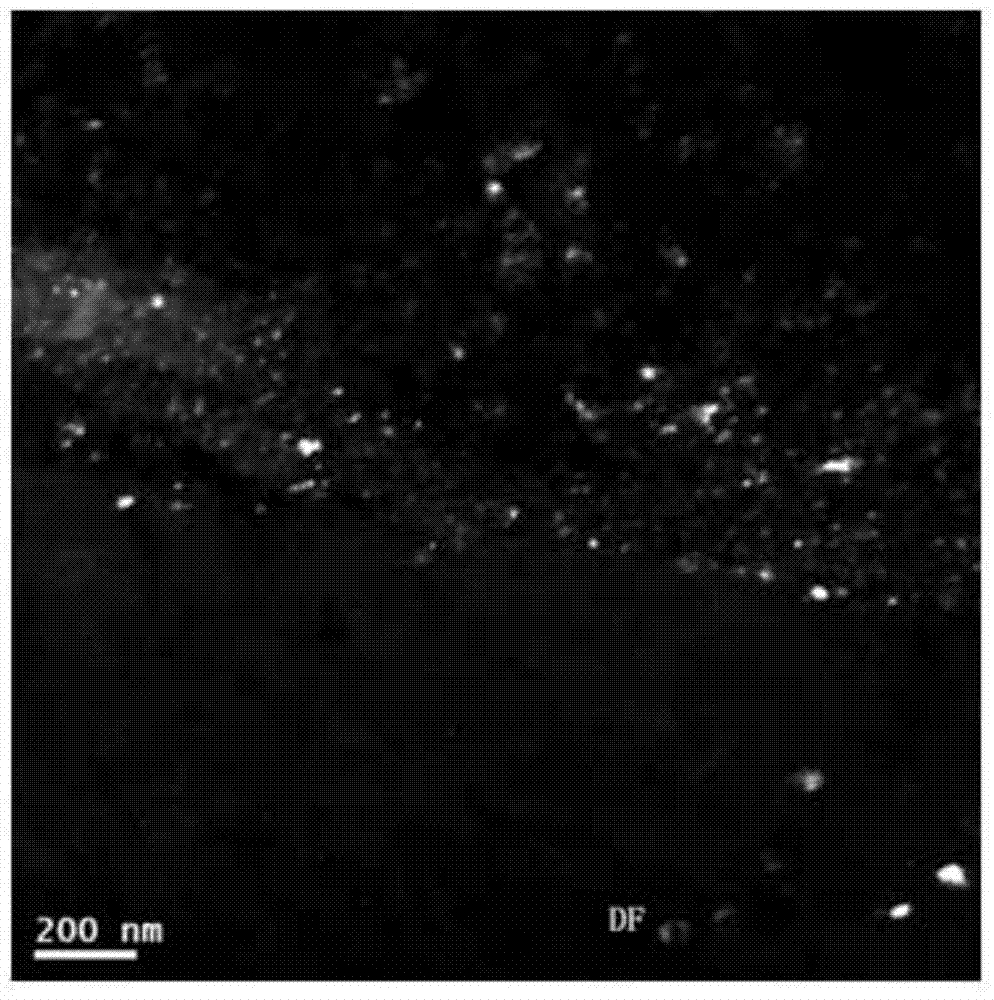

ActiveCN105543618ADirectional solidification process optimizationHigh quality and precisionPolycrystalline material growthFrom frozen solutionsReaction layerMicrometer

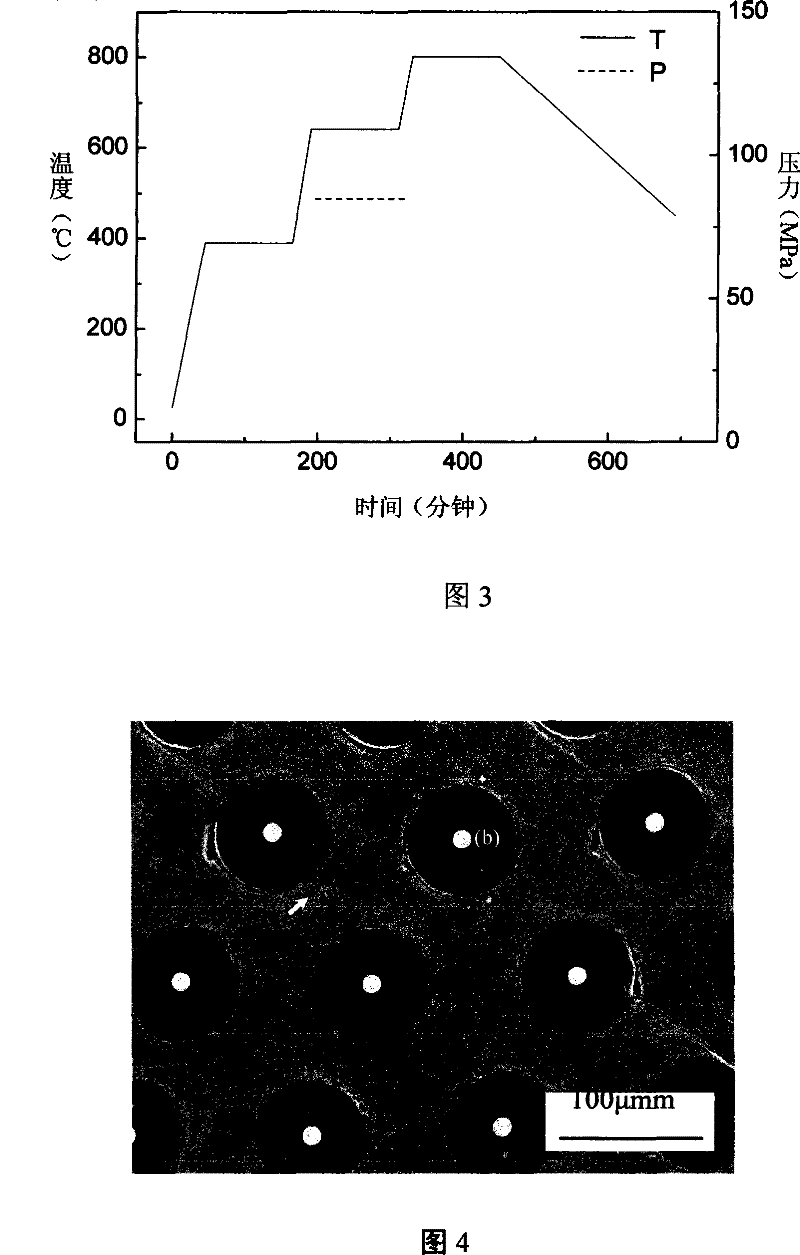

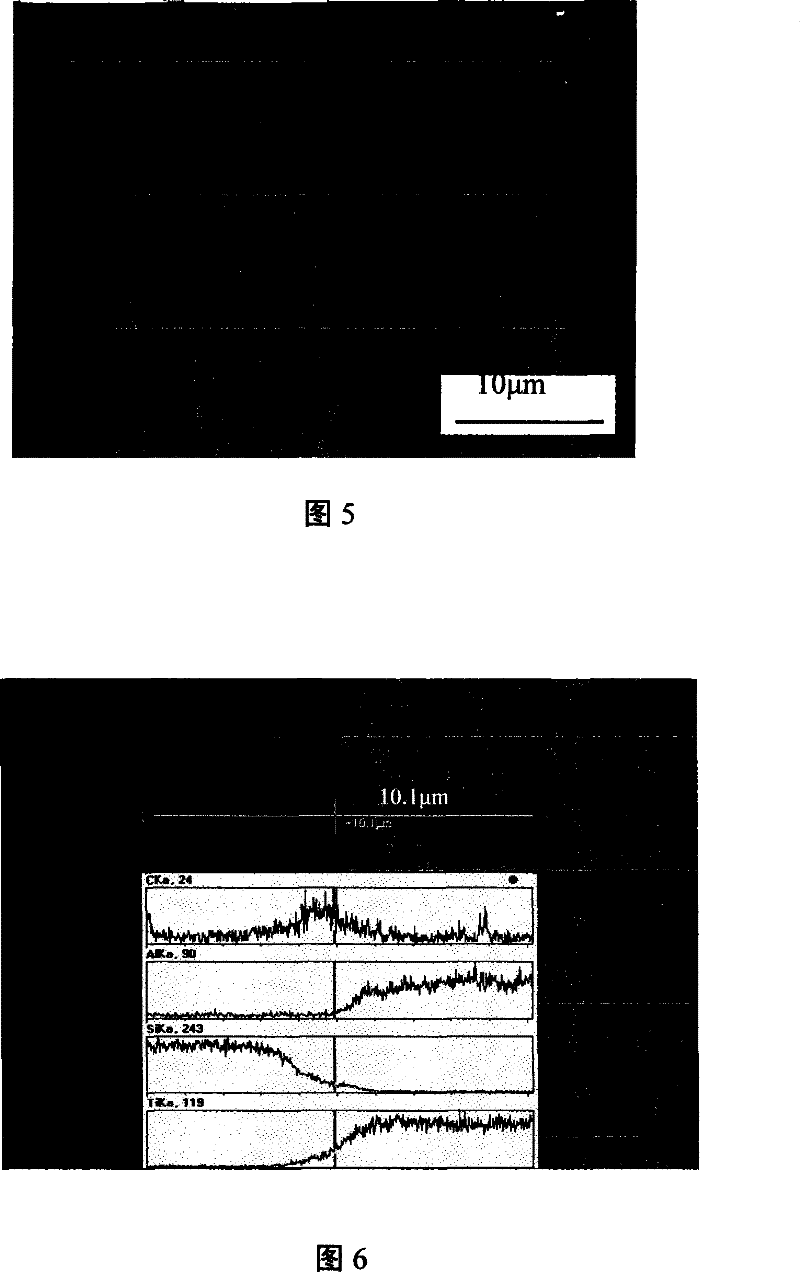

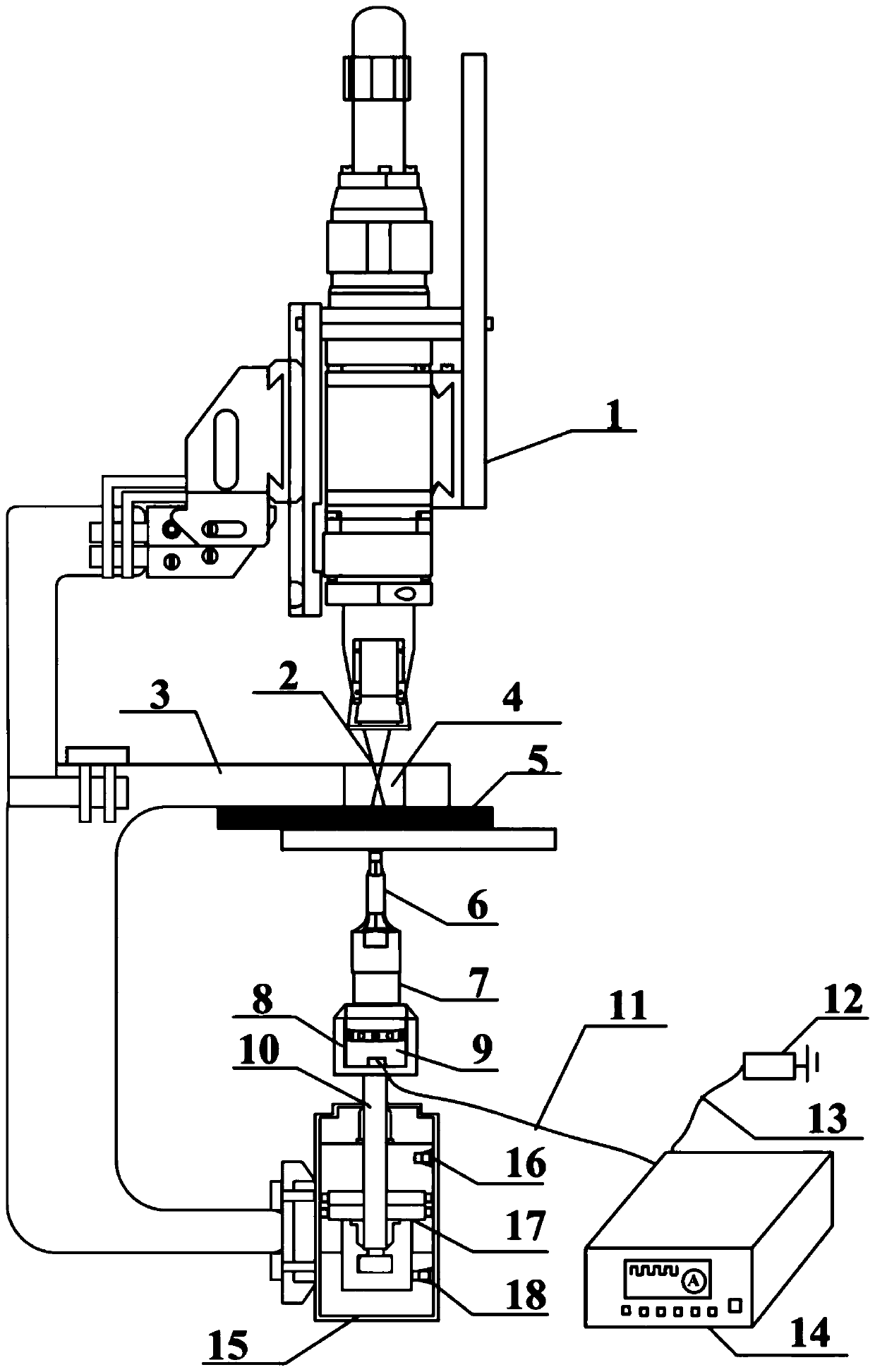

The invention researches a process for reducing the reaction of directional solidification titanium-aluminum alloy castings and casting mold coatings, and belongs to a directional solidification casting method of a high-temperature structural alloy. The invention aims at providing optimal process parameters during titanium-aluminum alloy preparation achieved through directional solidification, the interface reaction between an alloy melt and casting mold materials is weakened to be minimum when the heat preservation time is 30 minutes and the drawing speed is 60 micrometers per second by means of design of directional solidification parameters of a Ti-48Al-7Nb-2.5V-1.0Cr alloy, the reaction layer thickness is reduced to be less than 10 micrometers, the surfaces of the castings are smooth, and internal contamination is little. The process is characterized in that the time of contact between the melt and casting molds is shortened, and the problems that when the drawing speed is high, the number of crystalline grains is increased and the deviation between the direction of the crystalline grains and the axial direction is large are solved. The process is reasonable and low in cost, can not influence the directional solidification structure orientation of a titanium-aluminum alloy, and can be applied to the directional solidification process of the titanium-aluminum alloy.

Owner:CHINA UNIV OF MINING & TECH

Preparation of titanium-aluminum compound based composite material

InactiveCN101469400ALow preparation temperatureReduce thermal stress cracksVacuum evaporation coatingSputtering coatingTitaniumThermal expansion

The invention provides a method for preparing a titanium aluminum compound base composite material, which is characterized by comprising: firstly, alternatively depositing a simple substance layer Ti and a simple substance layer Al on the external surface of SiC fiber; and secondly, performing pressing by adopting vacuum heat pressing or hot isostatic pressing at a certain temperature, and forming a composite material by diffusion bonding. The method effectively reduces the preparation temperature of the Ti-Al compound base composite material, remarkably reduces the thermal stress crack caused by the difference between the coefficients of thermal expansion in the process of cooling a basal body, and ensures that the interface reaction between the basal body and the fiber is controlled well. The method has great expected economical values and social values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

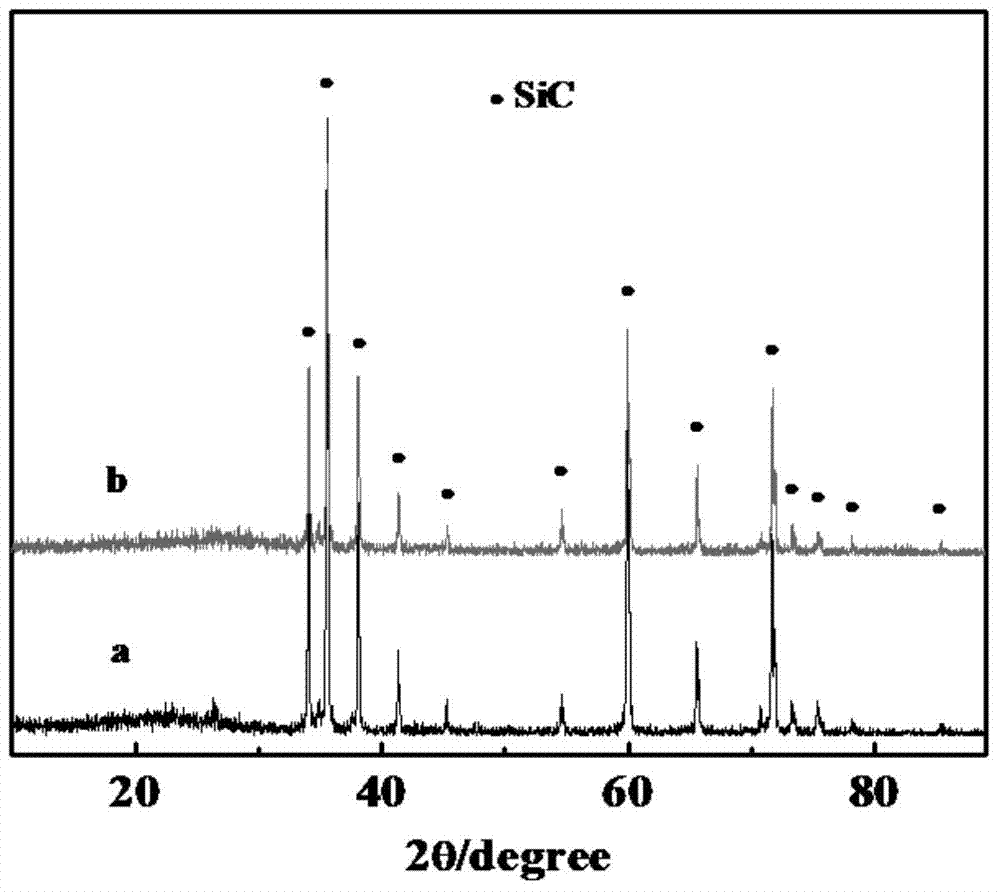

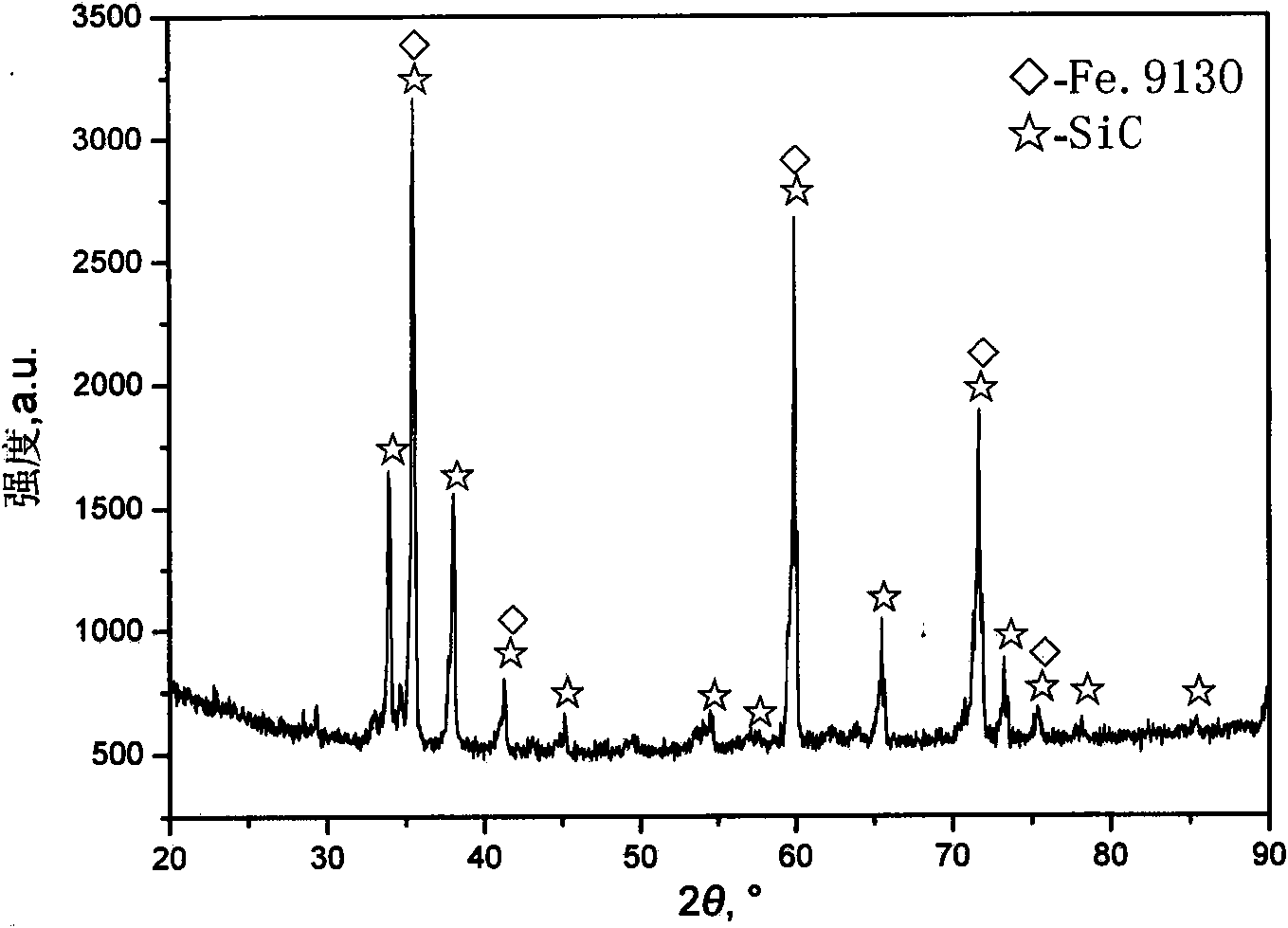

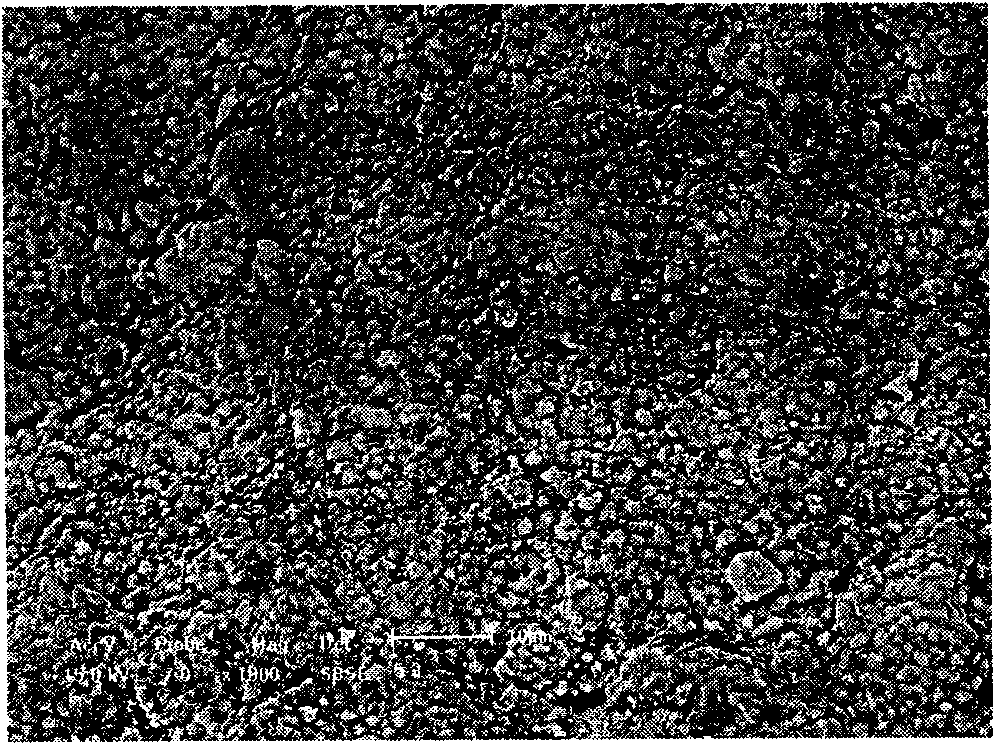

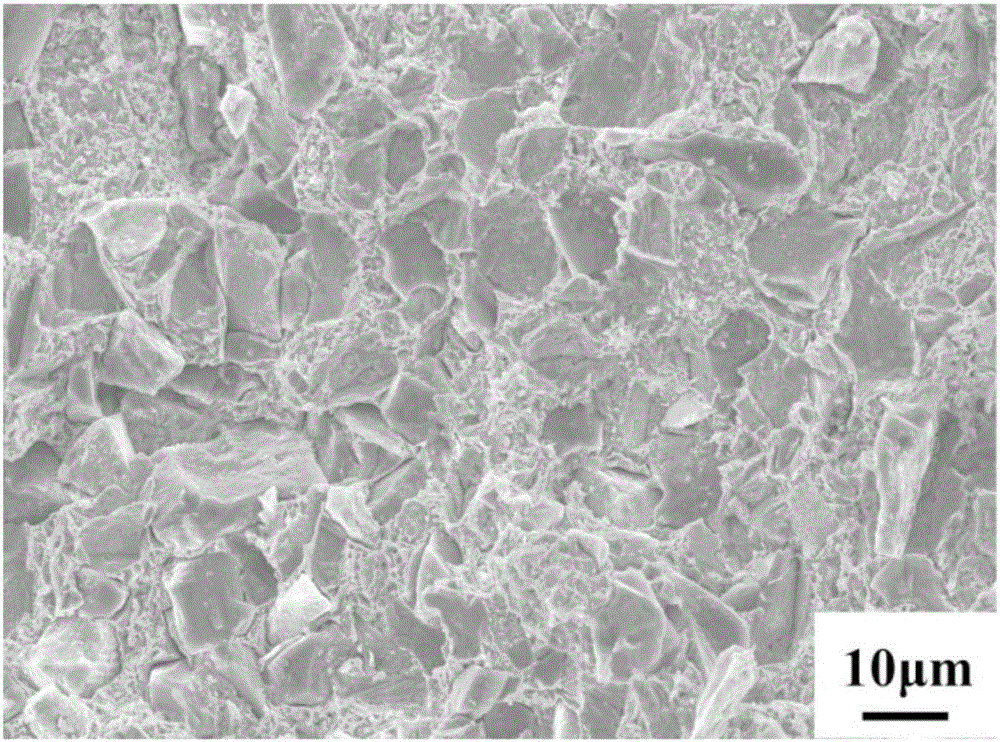

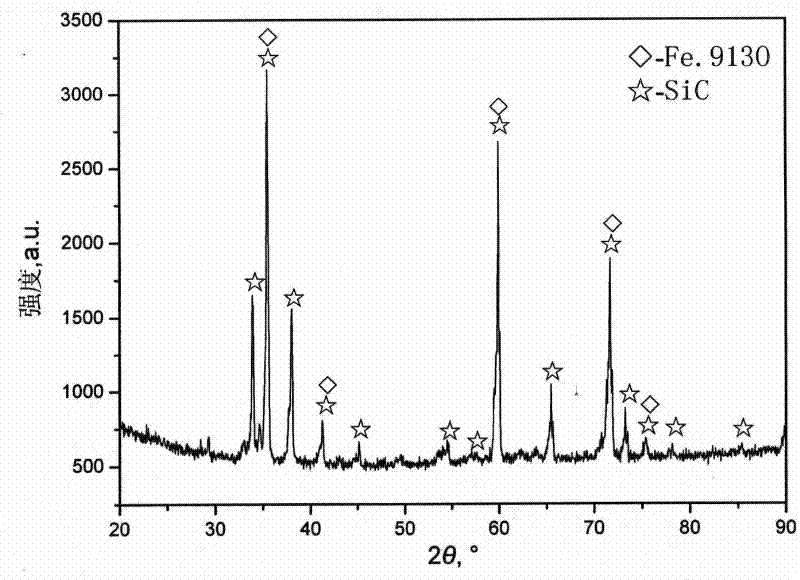

Method for preparing ferric oxide ceramic thin film on the surface of three-dimensional network silicon carbide

A method for preparing a ferric oxide ceramic thin film on the surface of three-dimensional network silicon carbide belongs to the material technical field, and comprises the following steps: (1) a sol-gel method is adopted for preparing iron sol; (2) a vacuum impregnation method is adopted for coating on 3D-SiC; and (3) the three-dimensional network silicon carbide coated by the iron sol is sintered. The invention uses the low-cost raw material, the simple preparation method and the short preparation period to prepare the uniform and compact ferric oxide ceramic thin film with low porosity on the 3D-SiC matrix surface; the thin film has stronger bonding strength with the matrix and has excellent thermal shock resistance, thus realizing to control the interface reaction of the 3D-SiC / steel.

Owner:NORTHEASTERN UNIV

Preparation method of high-coercive-force and high-stability neodymium iron boron magnet

ActiveCN106158203ALow rare earth contentImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsHigh energyMetallurgy

The invention provides a preparation method of a high-coercive-force and high-stability neodymium iron boron magnet. The preparation method comprises the following steps: preparing materials according to components of a NdFeB alloy to obtain a master alloy ingot and rapidly quenching to prepare a thin strip; preparing the rapidly-quenched thin strip into nano-crystal alloy powder; weighing and preparing materials according to an alloy nominal composition Sm2Fe17; carrying out high-energy ball milling to obtain nano-crystal alloy powder; carrying out nitriding treatment on the Sm2Fe17 nano-crystal alloy powder in high-purity N2 gas or NH3 gas to obtain Sm2Fe17Nx nano-crystal alloy powder; mixing the NdFeB and the Sm2Fe17Nx nano-crystal alloy powder at a ratio to obtain compound powder which is uniformly mixed; carrying out magnetic field orientation on the compound powder and press-molding to form a blank; and carrying out spark plasma sintering on the blank to prepare a NdFeB / Sm2Fe17Nx magnet. With the adoption of the preparation method of the high-coercive-force and high-stability neodymium iron boron magnet, the use amount of rare earth is reduced and the cost is relatively low; and high-temperature-resisting neodymium iron boron magnet can be prepared through the preparation method, so that the market requirements are met.

Owner:浙江凯文磁业有限公司

Method for modifying high-wettability coating on surface of metal-based compound material reinforcement

InactiveCN101899631AThe process is simple and easy to controlLow equipment requirementsVacuum pumpingMetal matrix composite

The invention discloses a method for modifying a high-wettability coating on the surface of a metal-based compound material reinforcement. The method comprises the following steps of: 1, by a common coating preparation method, forming a metal oxide coating, of which reducibility is lower than that of magnesium, on the surface of the reinforcement; 2, and placing the reinforcement coated with the metal oxide coating and pure magnesium in a vacuum furnace in a way of placing the pure magnesium on the bottom of the furnace and placing the reinforcement above the pure magnesium, vacuum-pumping the furnace, keeping the vacuum degree below 10Pa, heating the furnace to 600 to700 DEG C, and keeping the temperature for 5 to 60 minutes so as to allow the magnesium steam and the metal oxide coating on the surface of the reinforcement to undergo an oxidation-reduction reaction to generate a compound layer formed by an inner layer made of compounds and an outer layer made of reduced metal. The method has the advantages of simple and controllable process, low equipment requirements, low cost, wide application range, high mechanical and physical properties and the like.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

A kind of SICP/CU composite material reinforced by low temperature glass phase and preparation method thereof

ActiveCN104294071BImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Ti-Al/B4C-based marine composite material and preparation method thereof

The invention discloses a Ti-Al / B4C-based marine composite material and a preparation method thereof. The Ti-Al / B4C-based marine composite material comprises B4C powder, a Ti-Al intermetallic compound, a boride, and carbon nano-tubes. The preparation method of the Ti-Al / B4C-based marine composite material comprises the following steps of carrying out ball milling mixing of the raw materials and absolute ethanol as a medium, carrying out vacuum drying to obtain mixed powder, putting the mixed powder into a graphite mold, carrying out hot-pressed sintering, carrying out heat preservation, and cooling to obtain the Ti-Al / B4C-based marine composite material. The Ti-Al / B4C-based marine composite material has a low preparation cost, can be obtained by the simple preparation method, and has low density, high strength and good corrosion resistance.

Owner:TAIYUAN UNIV OF TECH

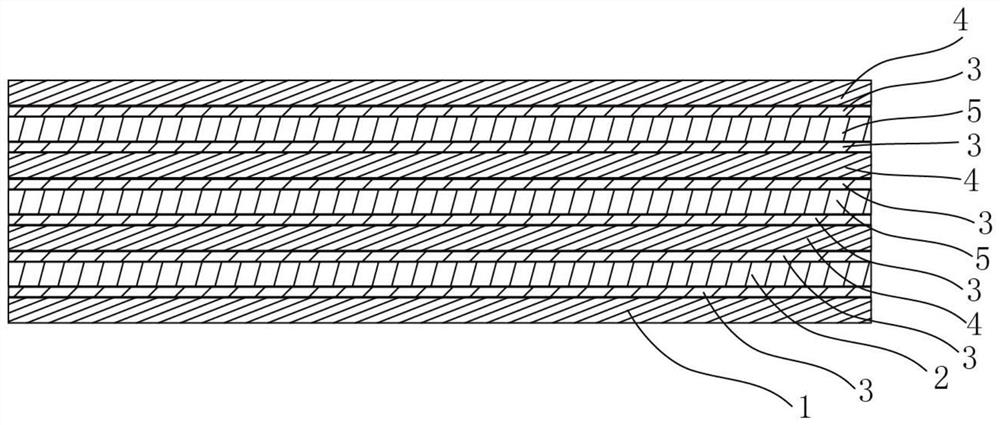

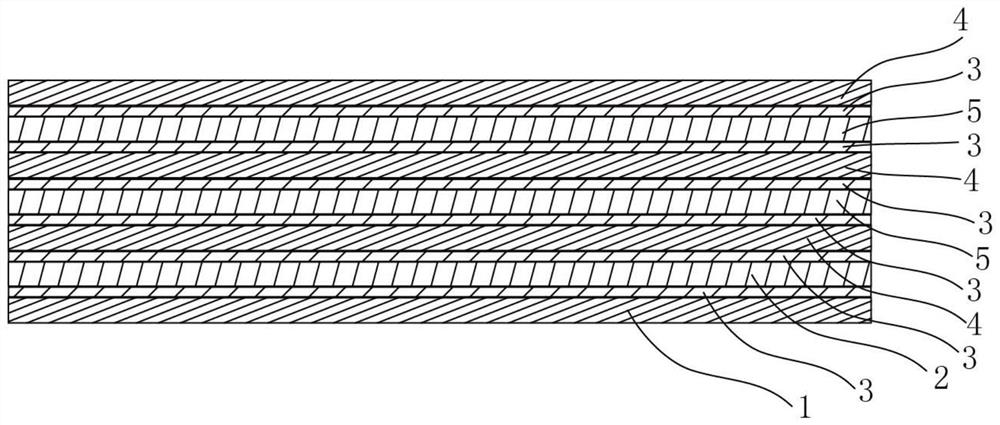

Ti/X metal ceramic with laminated structure and preparation method of Ti/X metal ceramic

ActiveCN112077320AImprove ductilityImprove heat resistanceAdditive manufacturing apparatusIncreasing energy efficiencyChemical compatibilityTitanium

The invention provides Ti / X metal ceramic with a laminated structure and a preparation method of the Ti / X metal ceramic. The Ti / X metal ceramic with the laminated structure sequentially comprises a Tilayer, a Ti-X transition layer, an X layer, a Ti-X transition layer, a Ti layer... a Ti-X transition layer, an X layer, a Ti-X transition layer and a Ti layer from bottom to top. The Ti / X metal ceramic with the laminated structure has the characteristics of toughness of titanium, hardness of an X nano material and the like, and has good ductility, heat resistance, wear resistance and impact resistance. According to the Ti / X metal ceramic with the laminated structure and the preparation method of the Ti / X metal ceramic, printing is carried out layer by layer through 3D printing equipment according to the stacking sequence of the Ti layer-X layer-Ti layer-X layer-Ti layer, an interface between the Ti layers and the X layers is subjected to rapid cold processing treatment through ultra-strong pulse energy beams or particle beams, and the Ti-X transition layers combining the Ti layers and the X layers are formed; and the problems of poor chemical compatibility and wettability of a titanium nano material and the X nano material can be solved, compounding of the Ti nano material and the X nano material can be well achieved, and then the Ti / X metal ceramic which is high in interface bonding and has the laminated structure is formed.

Owner:上海梁为科技发展有限公司

Method for preparing high-performance high-temperature-resisting nanometer composite permanent magnet

ActiveCN102655050BImprove temperature stabilityControl interface responsePermanent magnetsInductances/transformers/magnets manufactureThermal deformationBall mill

The invention discloses a method for preparing a high-performance high-temperature-resisting nanometer composite permanent magnet, relating to preparation techniques of permanent magnetic materials. The method mainly comprises the following steps of: (1) weighing each element raw material according to elements of NdFeB alloy, mixing the element raw materials, melting the mixed raw material in vacuum, and rapidly quenching to prepare thin belts; (2) preparing SmCo ally rapidly quenched belts through the step (1); (3) respectively carrying out high-energy ball milling on the NdFeB and the SmCo alloy rapidly quenched belt to prepare corresponding nanometer crystal alloy powder; (4) mixing the NdFeB and the SmCo nanometer crystal alloy powder according to certain proportion, adding a crystal boundary nanometer modifier to be uniformly distributed on the surfaces of the NdFeB and the SmCo powders to obtain composite powder with the uniformly mixed three; (5) pressing the composite powder to form moulded blanks; (6) carrying out discharge plasma sintering on the moulded blanks to prepare a nanometer composite magnet; and (7) carrying out thermal deformation on the nanometer composite magnet to improve the degree of orientation and obtain the high-performance high-temperature-resisting nanometer composite permanent magnet. The method has the advantages of simple process and easiness in operation, and is suitable for large-scale batch production.

Owner:朗峰新材料启东有限公司

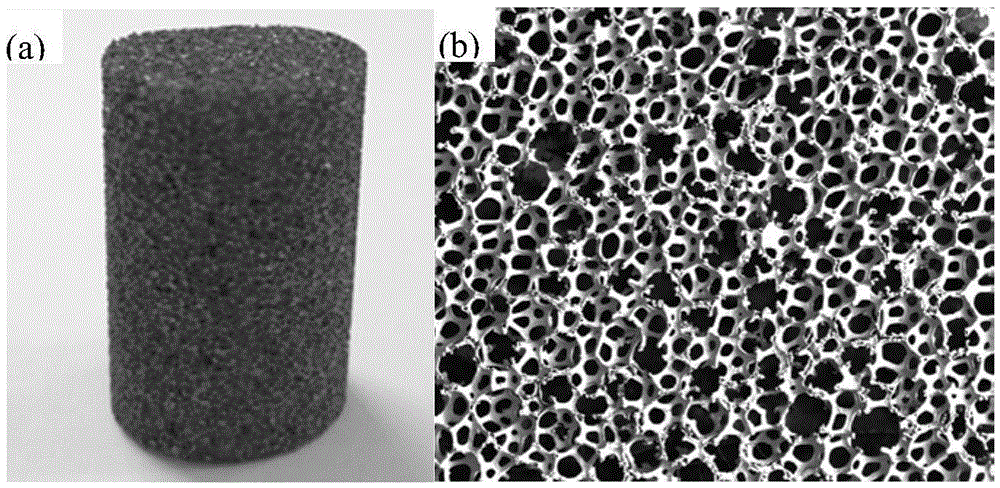

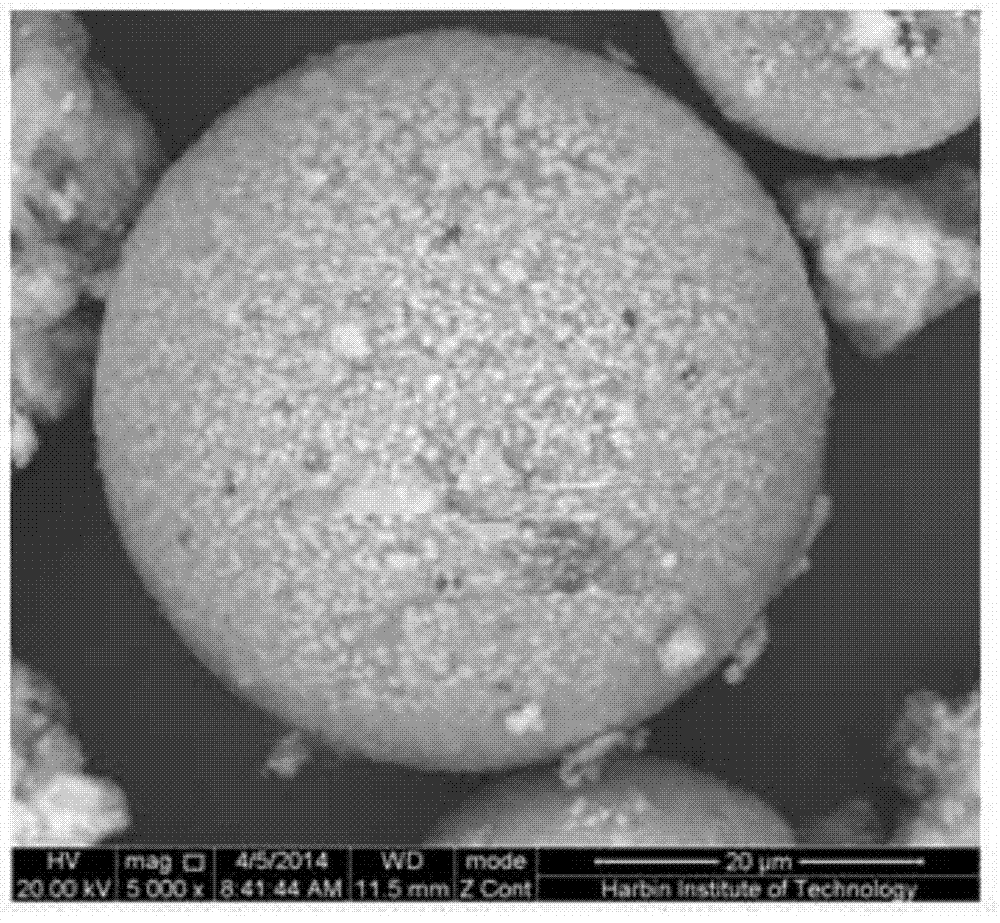

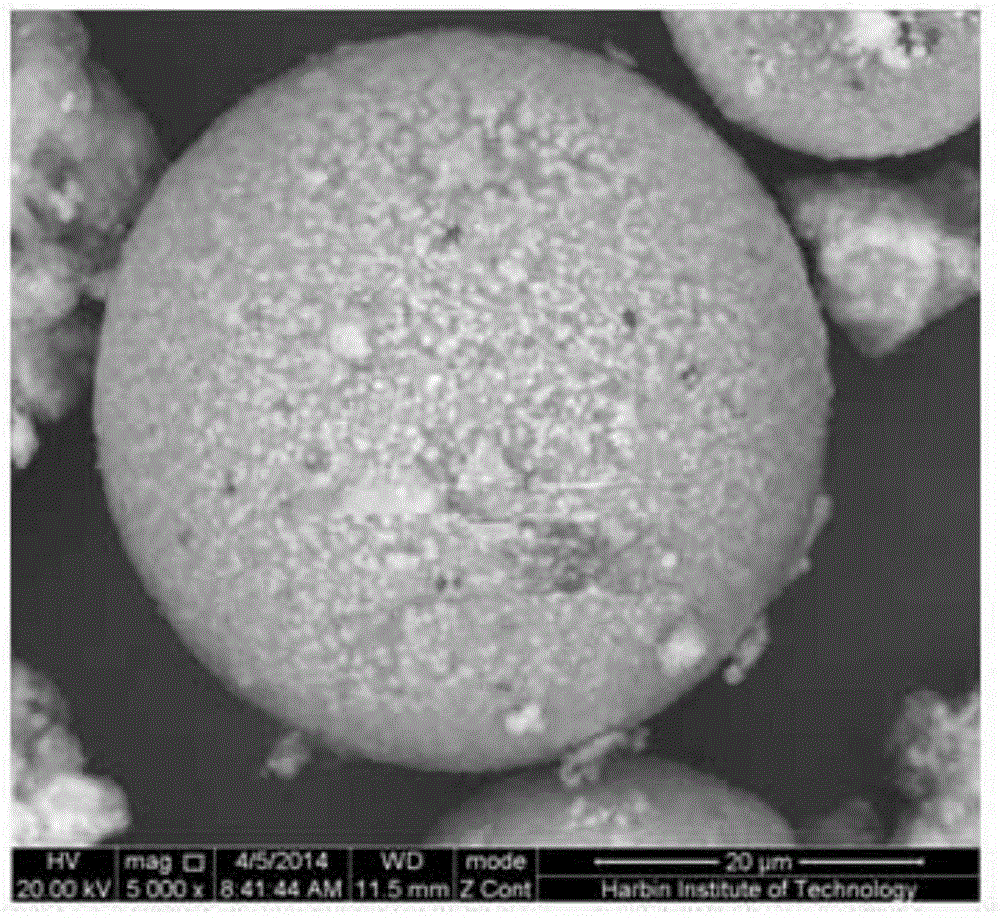

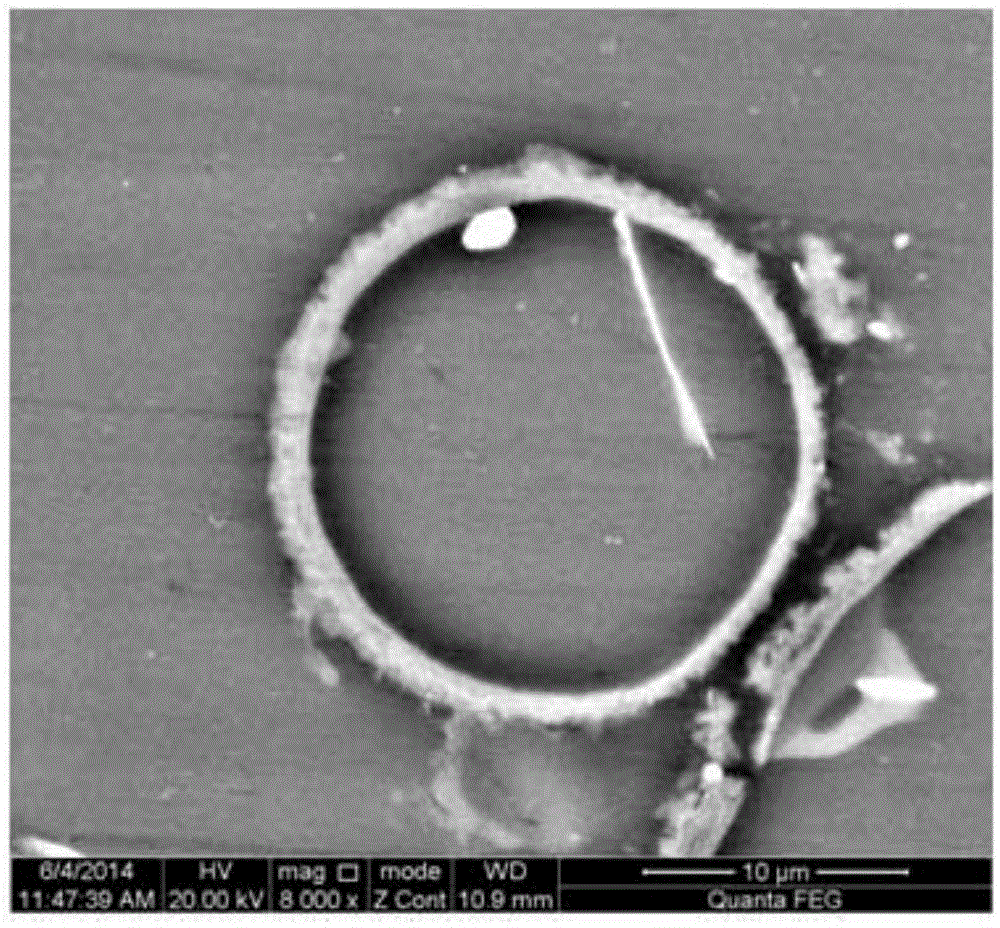

Preparation method of high-electromagnetic-shielding hollow micro-sphere enhanced AZ91 magnesium matrix composite

InactiveCN104120296AImprove electromagnetic shielding performanceComplete structureMagnesium matrix compositeElectromagnetic shielding

The invention relates to a preparation method of a high-electromagnetic-shielding hollow micro-sphere enhanced AZ91 magnesium matrix composite and relates to a preparation method of a hollow micro-sphere enhanced AZ91 magnesium matrix composite. The preparation method is used for solving the problems that structures of hollow micro-spheres are seriously damaged in the preparation process of an existing composite material. The method comprises the following steps: firstly, adding water into quick lime to react, aging, and calculating the weight of Ca(OH)2 and water in a Ca(OH)2 solution; secondly, adding the hollow micro-spheres and water to obtain a mixed solution, cleaning the hollow micro-spheres after reaction, and drying to obtain surface-coated hollow micro-sphere particles; thirdly, melting an AZ91 magnesium alloy, removing surface oxide scales, cooling, preserving heat, adding the hollow micro-sphere particles, stirring, rising temperature, and molding to obtain the magnesium matrix composite of which the hollow micro-sphere surface appearance is relatively complete. According to the prepared composite disclosed by the invention, the appearance of the hollow micro-spheres in the composite is kept relatively well, and the electromagnetic shielding effectiveness reaches 79-82dB. The preparation method disclosed by the invention is used for preparing the magnesium matrix composite.

Owner:HARBIN INST OF TECH

Low-cost rare-earth-free nanocomposite permanent-magnetic material and preparation method thereof

The invention provides a low-cost rare-earth-free nanocomposite permanent-magnetic material and a preparation method thereof. A chemical formula of the low-cost rare-earth-free nanocomposite permanent-magnetic material is Mn<53-x>Al<45>C<2>W<x> / (Fe<l-y>Co<y>)<2>B. The preparation method comprises the steps of: burdening a pure metal raw material according to the name of an Mn<53-x>Al<45>C<2>W<x> alloy to obtain a master alloy ingot and fabricating a thin strip; carrying out vacuum heat treatment on a quick quenched strip to obtain a tau-phase Mn<53-x>Al<45>C<2>W<x> alloy; carrying out burdening according to (Fe<l-y>Co<y>)<2>B alloy ingredients to obtain the master alloy ingot and fabricating the thin strip; carrying out high-energy ball-milling on the quick quenched strip of the Mn<53-x>Al<45>C<2>W<x> alloy and the quick quenched strip of the (Fe<l-y>Co<y>)<2>B alloy which are subjected to heat treatment to prepare nanocrystalline alloy powder; carrying out spark plasma sintering on the obtained nanocomposite powder to obtain a full-dense nanocomposite permanent-magnetic material; and carrying out thermal deformation on the sintered nanocomposite permanent-magnetic material, improving the degree of orientation and obtaining the low-cost rare-earth-free anisotropic nanocomposite permanent-magnetic material. The prepared permanent-magnetic material does not contain a rare-earth element; the raw material cost is effectively reduced; and meanwhile, the technology is simple, easy to operate and suitable for large-scale mass production.

Owner:CHINA JILIANG UNIV

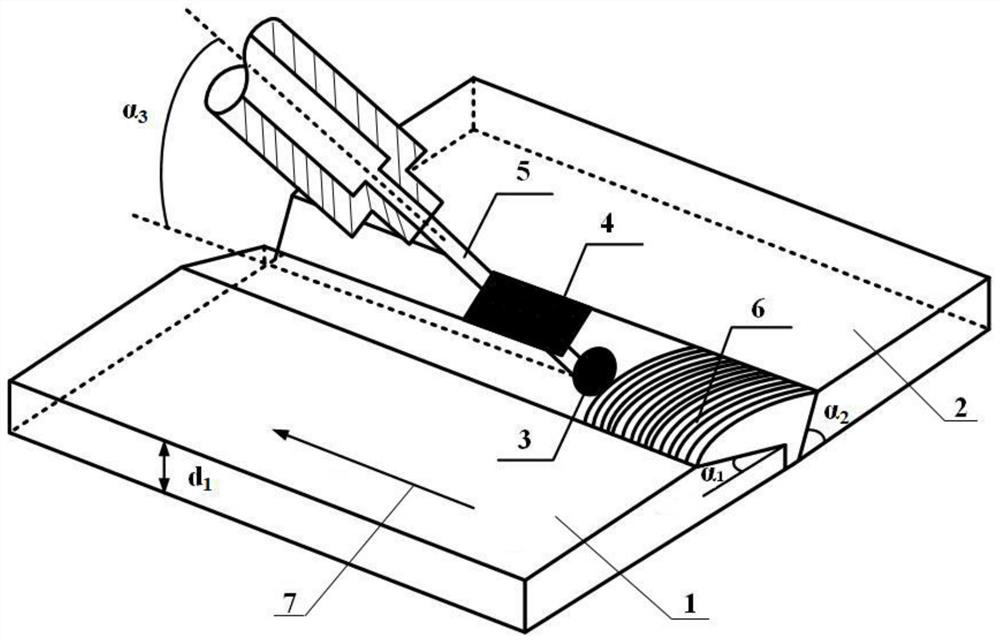

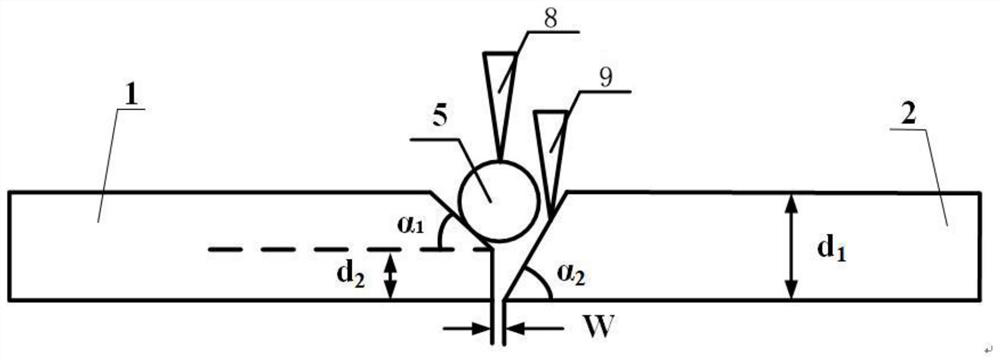

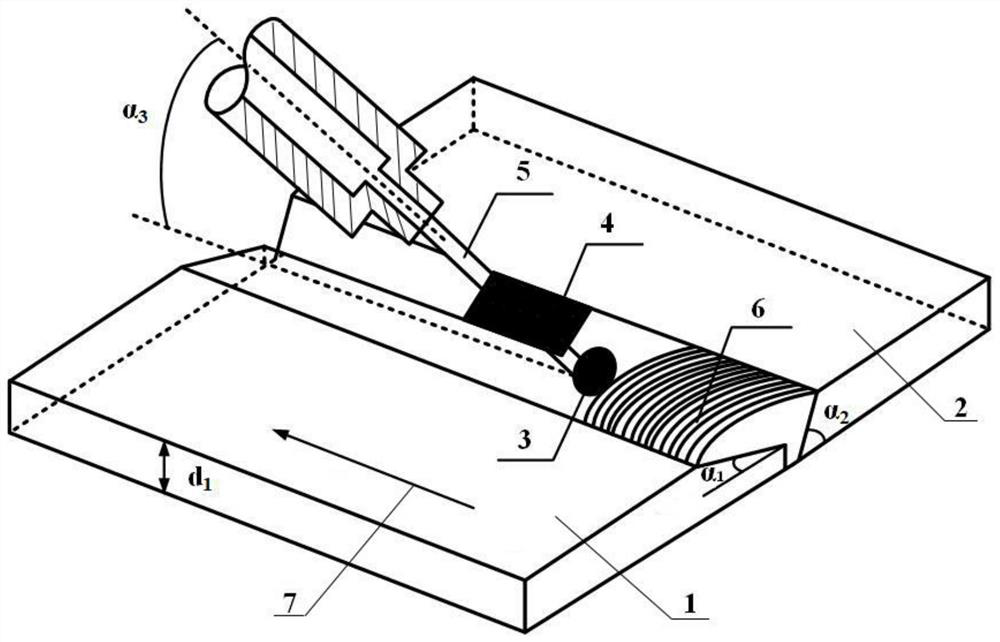

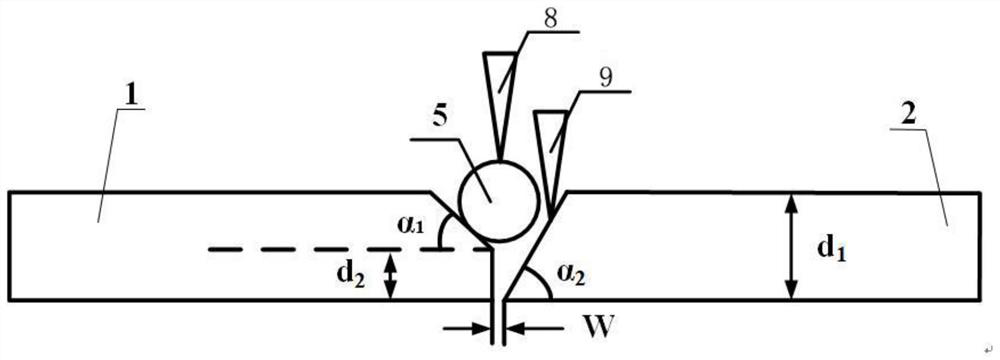

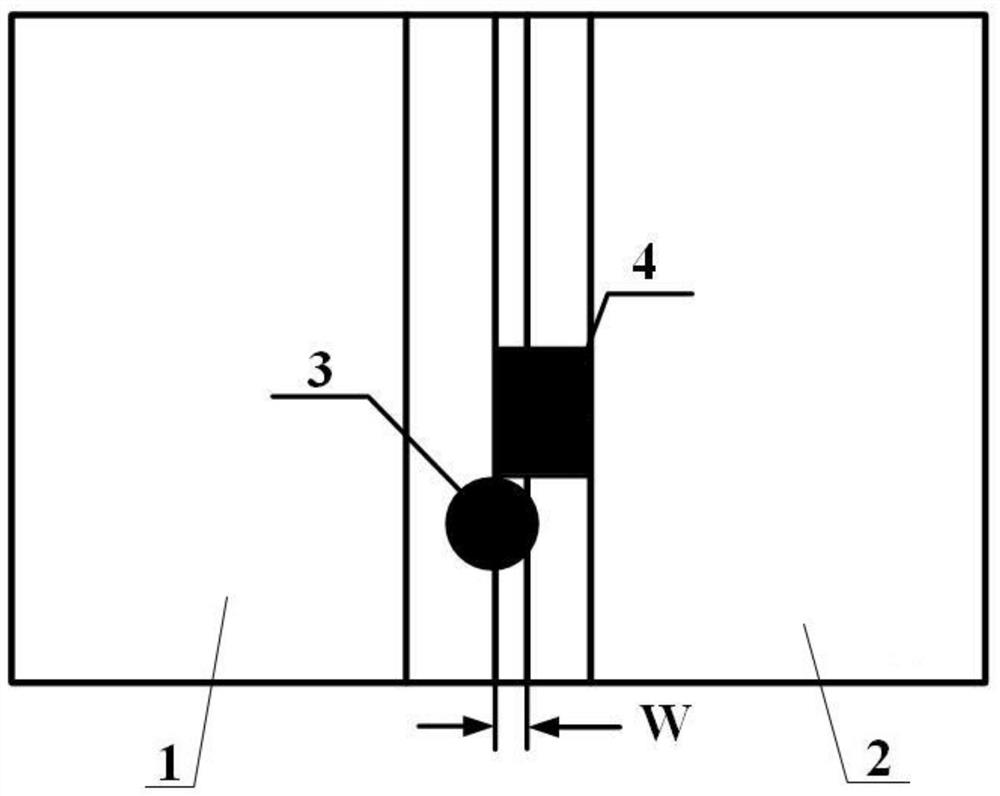

Laser wire filling welding method for medium-thickness plate aluminum/steel dissimilar metal

InactiveCN113172339AImprove liquidityImprove distributionMetal working apparatusLaser beam welding apparatusButt jointLight beam

The invention provides a laser wire filling welding method for medium-thickness plate aluminum / steel dissimilar metal. The laser wire filling welding method comprises the following steps that (1) a Y-shaped groove and a V-shaped groove are formed in a to-be-welded aluminum plate and a to-be-welded steel plate which are equal in thickness respectively, and the Y-shaped groove, the V-shaped groove, the upper surface and the lower surface of the aluminum plate and the upper surface and the lower surface of the steel plate are deeply cleaned; (2) the to-be-welded aluminum plate and the to-be-welded steel plate are placed on a welding clamp to be clamped and fixed, and a welding joint is a butt joint; (3) the positions of a main light beam and an auxiliary light beam are adjusted, and the light beam power is set; and (4) process parameters are set, and once the welding process parameters are determined, the welding process parameters are kept unchanged in the welding process. According to the welding method, laser wire filling is adopted so that the absorptivity of the aluminum alloy can be improved, the welding process is stabilized, crack forming conditions are prevented, the mechanical property of a welding seam is improved, temperature field distribution of a welding joint can be effectively adjusted, interface reaction can be controlled favorably, and meanwhile, the defect that the side wall is not fused is overcome, and the strength of the welding joint is improved.

Owner:JILIN UNIV

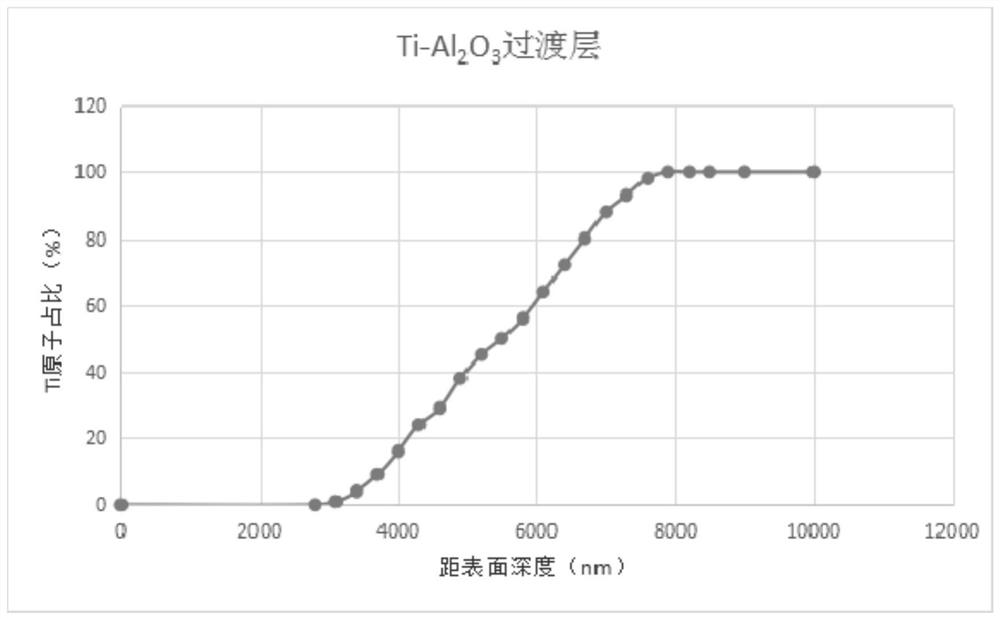

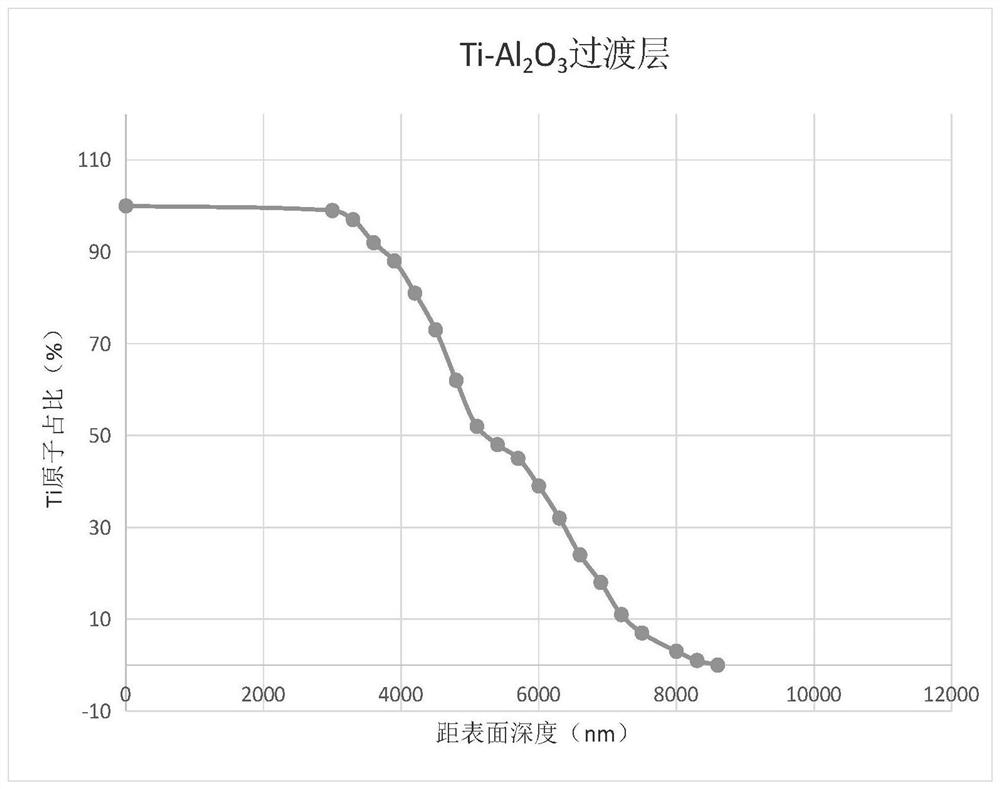

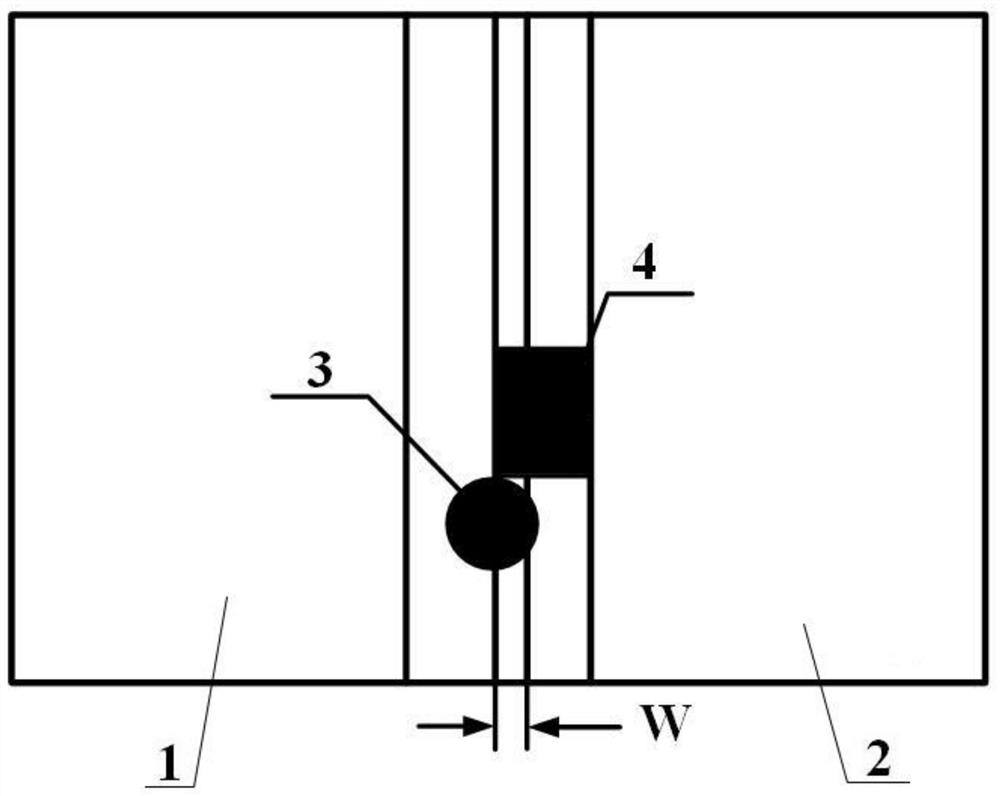

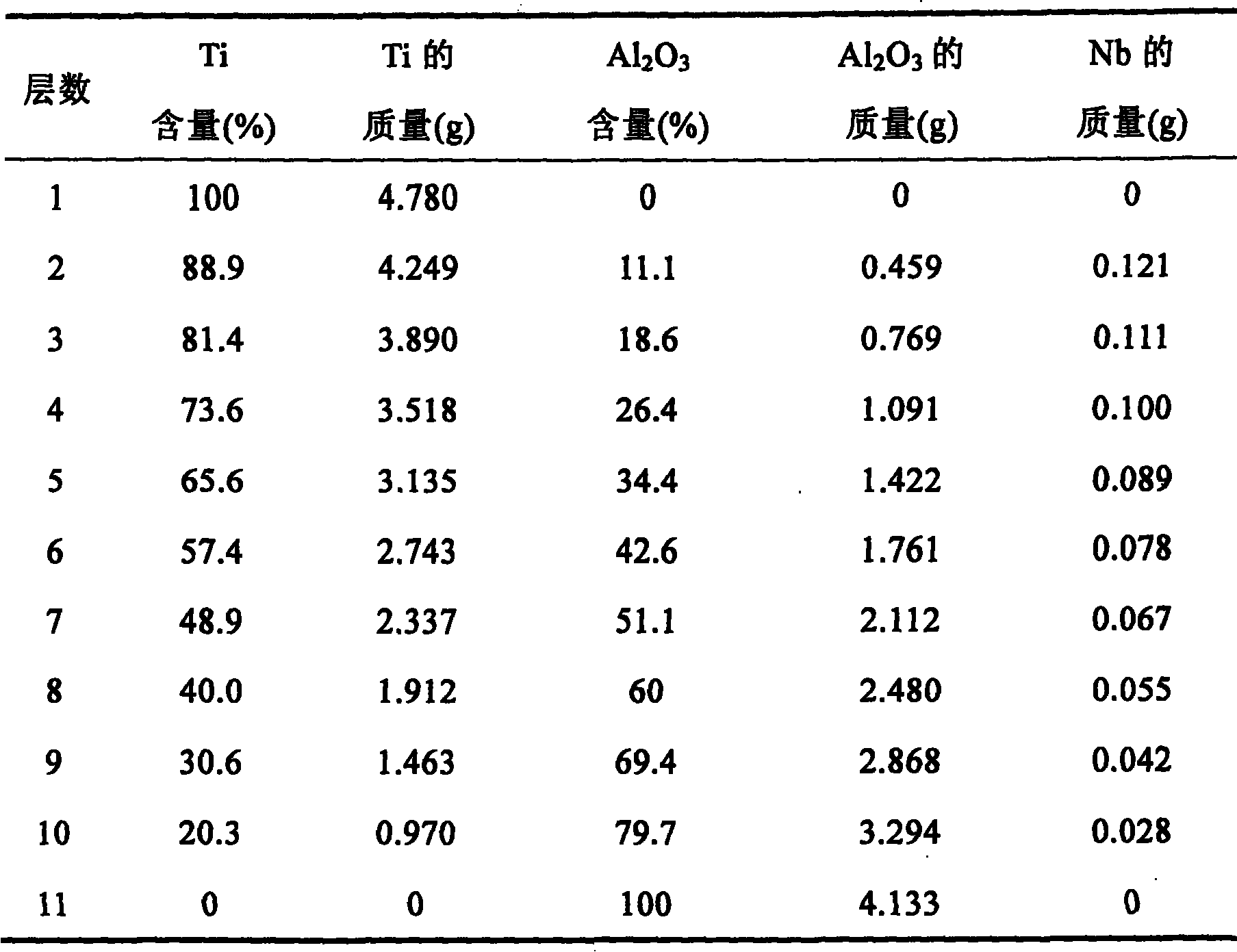

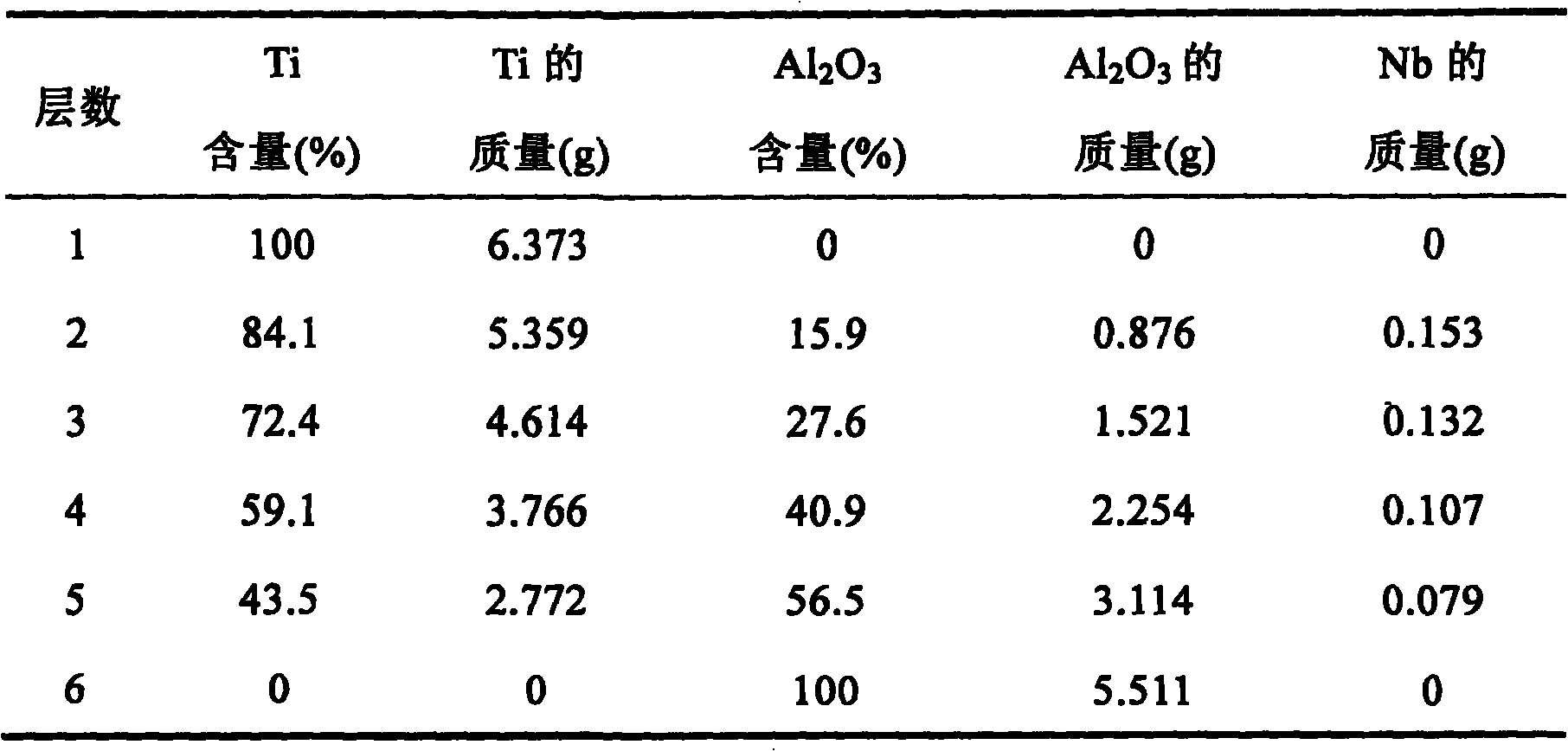

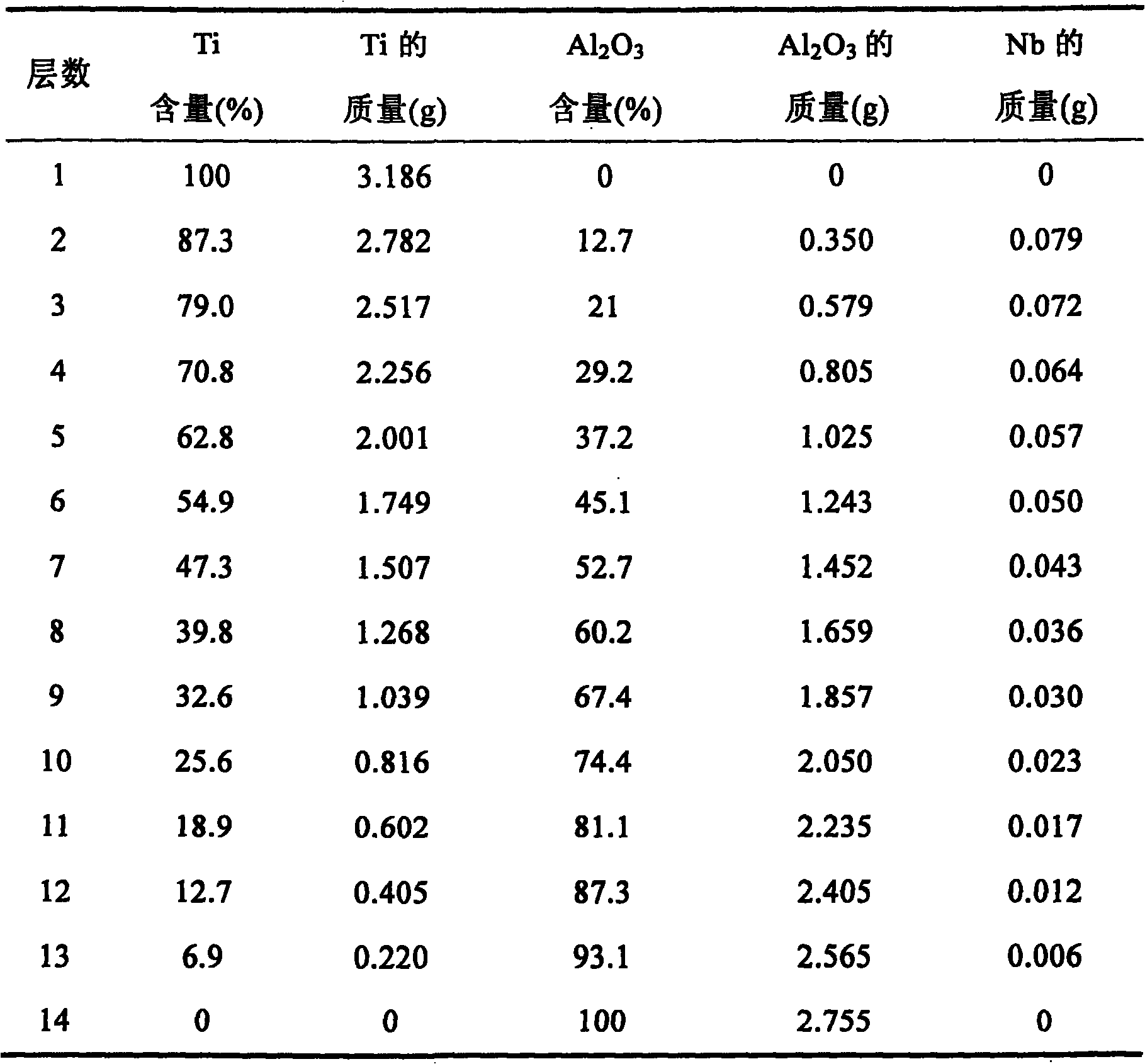

Ti/Al2O3 composite material for wave impedance gradient flying plate and manufacture thereof

InactiveCN100449029CImprove mechanical propertiesControl interface responseGradient materialGraphite

The present invention relates to one kind of gradient Ti / Al2O3 composite material for the intermediate layer of wave impedance flying plate. The gradient composite material is produced through the steps of mixing material, pressure forming, setting the gradient material inside graphite mold and fast plasma discharge sintering. The material contains Ti in 45-69 wt%, alpha-Al2O3 in 30-50 wt%, and Nb in 0.5-5 wt%. In the gradient material, Ti content is decreased gradiently from maximum value to zero, alpha-Al2O3 content is increased from zero to maximum, and Nb content is decreased, with the Ni content in both the top and bottom layers being zero. The composite material of the present invention has tightly combined interface, integral structure, high compactness, wave impedance distribution index of 2-3, capacity of obtaining good quasi-isoentropic compression waveform, excellent weldability and other advantages.

Owner:UNIV OF JINAN

A laser wire-filling welding method for aluminum/steel dissimilar metals in medium and thick plates

InactiveCN113172339BImprove liquidityImprove distributionMetal working apparatusLaser beam welding apparatusThick plateButt joint

The invention provides a method for laser wire-filling welding of medium-thick aluminum / steel dissimilar metals, which comprises the following steps: (1) making Y-shaped grooves and V-shaped grooves respectively on aluminum plates and steel plates of equal thickness to be welded, and Deep cleaning of the Y-shaped groove, V-shaped groove, and the upper and lower surfaces of the aluminum plate and steel plate; (2) Place the aluminum plate and steel plate to be welded on the welding fixture for clamping and fixing, and the welding joint form is a butt joint; (3) Adjust The position of the main beam and the auxiliary beam, setting the beam power; (4) setting the process parameters, and once the welding process parameters are determined, they will remain unchanged during the welding process. The welding method uses laser wire filling to increase the absorption rate of the aluminum alloy, stabilize the welding process, prevent the conditions for crack formation, and improve the mechanical properties of the weld, and the welding method can effectively adjust the temperature field distribution of the welded joint, which is beneficial to control Interfacial reaction, while solving the defect of unfused sidewall, improving the strength of welded joints.

Owner:JILIN UNIV

A kind of low-cost rare earth-free nanocomposite permanent magnetic material and preparation method thereof

The invention provides a low-cost rare-earth-free nanocomposite permanent-magnetic material and a preparation method thereof. A chemical formula of the low-cost rare-earth-free nanocomposite permanent-magnetic material is Mn<53-x>Al<45>C<2>W<x> / (Fe<l-y>Co<y>)<2>B. The preparation method comprises the steps of: burdening a pure metal raw material according to the name of an Mn<53-x>Al<45>C<2>W<x> alloy to obtain a master alloy ingot and fabricating a thin strip; carrying out vacuum heat treatment on a quick quenched strip to obtain a tau-phase Mn<53-x>Al<45>C<2>W<x> alloy; carrying out burdening according to (Fe<l-y>Co<y>)<2>B alloy ingredients to obtain the master alloy ingot and fabricating the thin strip; carrying out high-energy ball-milling on the quick quenched strip of the Mn<53-x>Al<45>C<2>W<x> alloy and the quick quenched strip of the (Fe<l-y>Co<y>)<2>B alloy which are subjected to heat treatment to prepare nanocrystalline alloy powder; carrying out spark plasma sintering on the obtained nanocomposite powder to obtain a full-dense nanocomposite permanent-magnetic material; and carrying out thermal deformation on the sintered nanocomposite permanent-magnetic material, improving the degree of orientation and obtaining the low-cost rare-earth-free anisotropic nanocomposite permanent-magnetic material. The prepared permanent-magnetic material does not contain a rare-earth element; the raw material cost is effectively reduced; and meanwhile, the technology is simple, easy to operate and suitable for large-scale mass production.

Owner:CHINA JILIANG UNIV

Method for preparing ferric oxide ceramic thin film on the surface of three-dimensional network silicon carbide

Owner:NORTHEASTERN UNIV LIAONING

A kind of preparation method of high coercive force and high stability NdFeB magnet

ActiveCN106158203BLow rare earth contentImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsHigh energyRare earth

The invention provides a preparation method of a high-coercive-force and high-stability neodymium iron boron magnet. The preparation method comprises the following steps: preparing materials according to components of a NdFeB alloy to obtain a master alloy ingot and rapidly quenching to prepare a thin strip; preparing the rapidly-quenched thin strip into nano-crystal alloy powder; weighing and preparing materials according to an alloy nominal composition Sm2Fe17; carrying out high-energy ball milling to obtain nano-crystal alloy powder; carrying out nitriding treatment on the Sm2Fe17 nano-crystal alloy powder in high-purity N2 gas or NH3 gas to obtain Sm2Fe17Nx nano-crystal alloy powder; mixing the NdFeB and the Sm2Fe17Nx nano-crystal alloy powder at a ratio to obtain compound powder which is uniformly mixed; carrying out magnetic field orientation on the compound powder and press-molding to form a blank; and carrying out spark plasma sintering on the blank to prepare a NdFeB / Sm2Fe17Nx magnet. With the adoption of the preparation method of the high-coercive-force and high-stability neodymium iron boron magnet, the use amount of rare earth is reduced and the cost is relatively low; and high-temperature-resisting neodymium iron boron magnet can be prepared through the preparation method, so that the market requirements are met.

Owner:浙江凯文磁业有限公司

A kind of preparation method of high electromagnetic shielding hollow microsphere reinforced az91 magnesium matrix composite material

InactiveCN104120296BImprove electromagnetic shielding performanceComplete structureMagnesium matrix compositeElectromagnetic shielding

Owner:HARBIN INST OF TECH

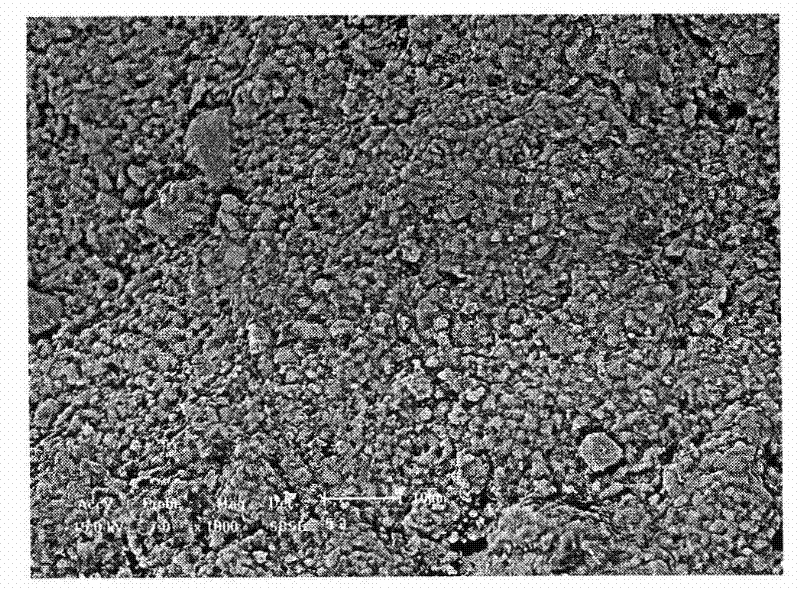

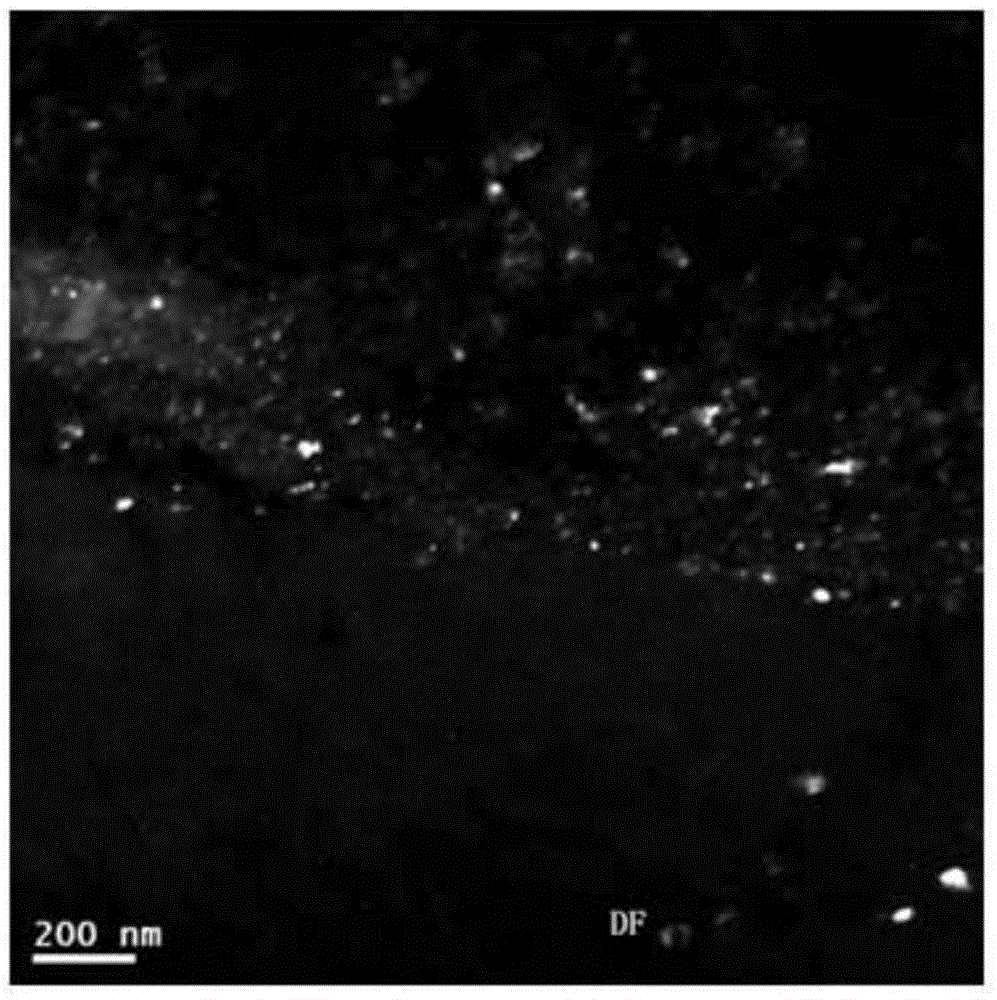

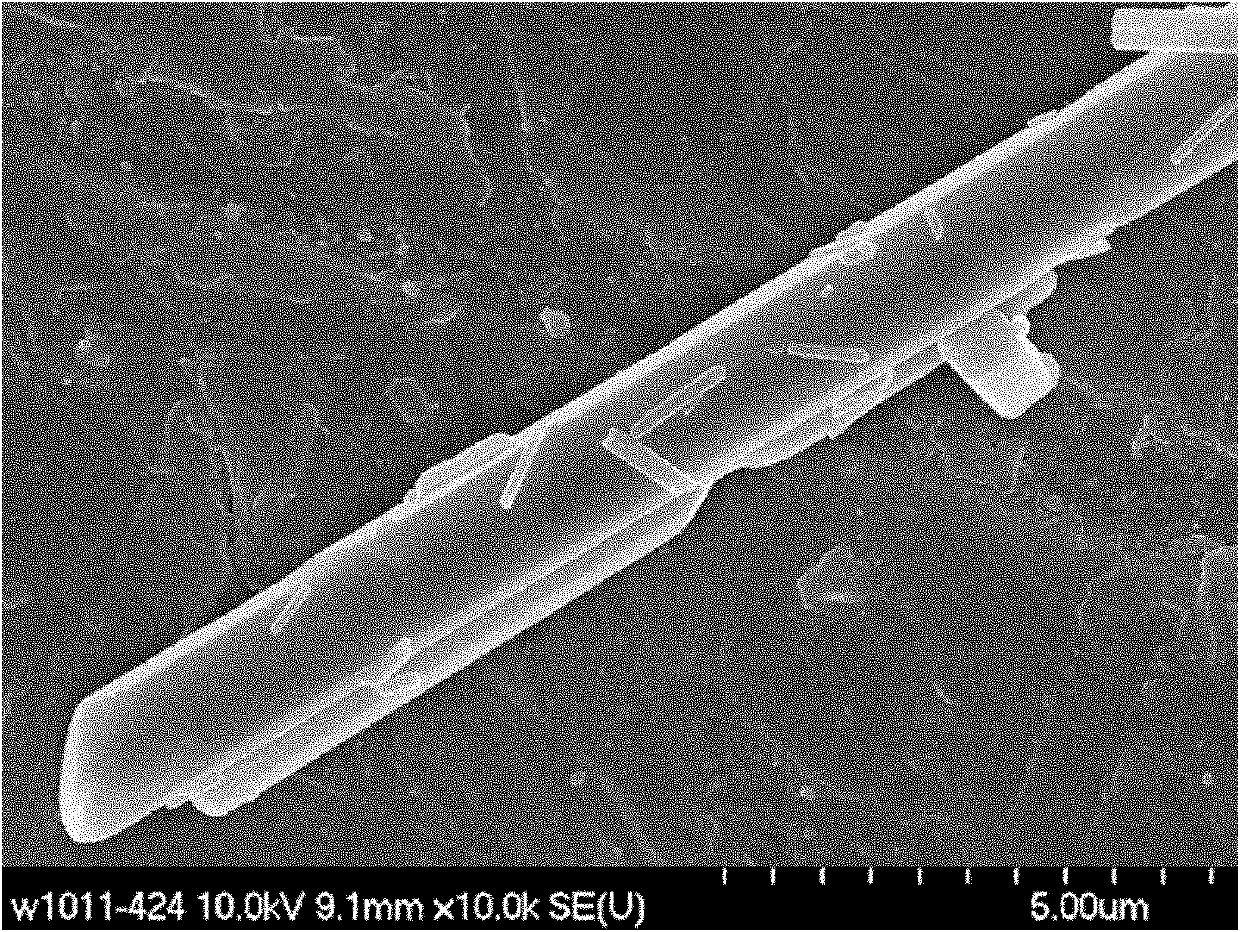

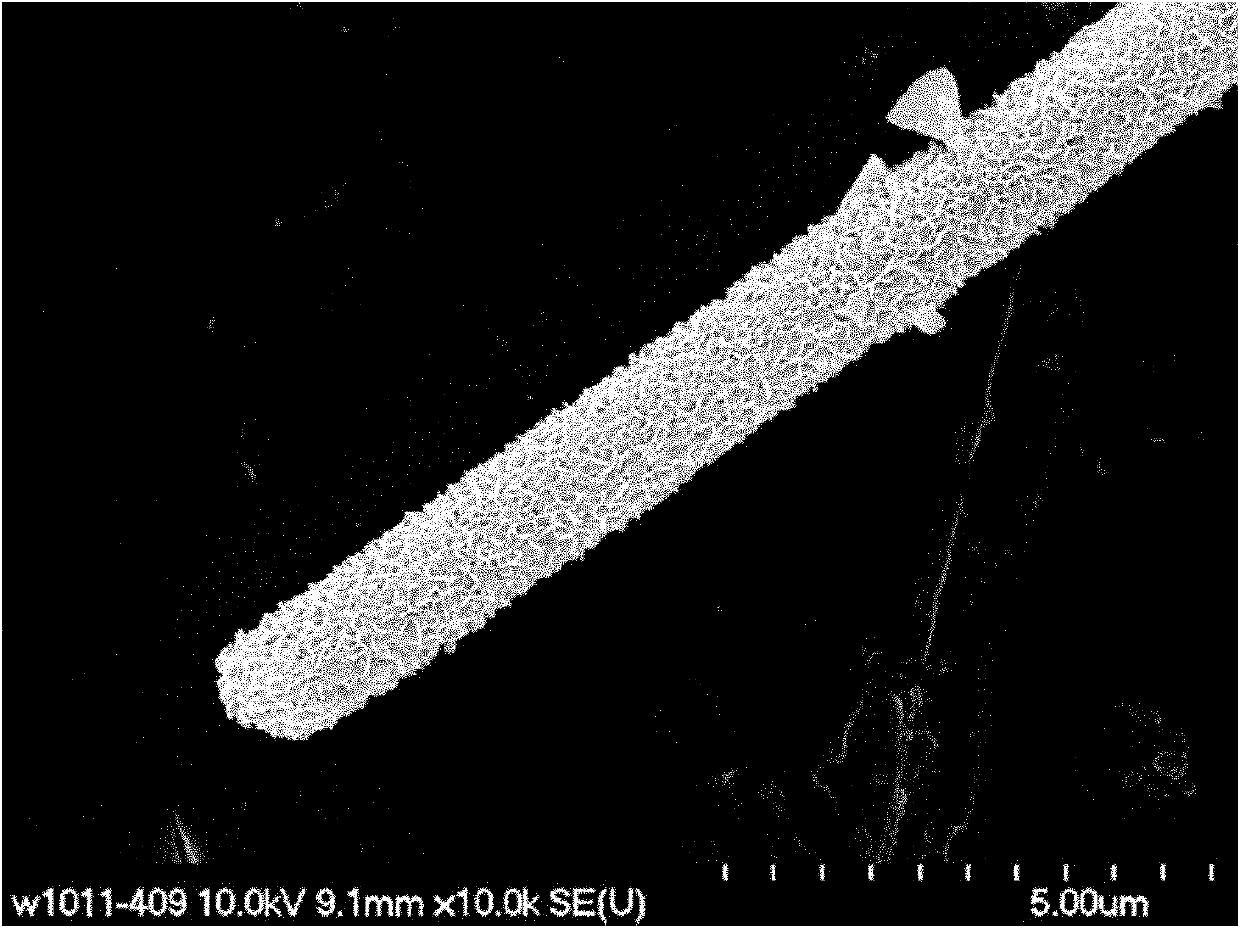

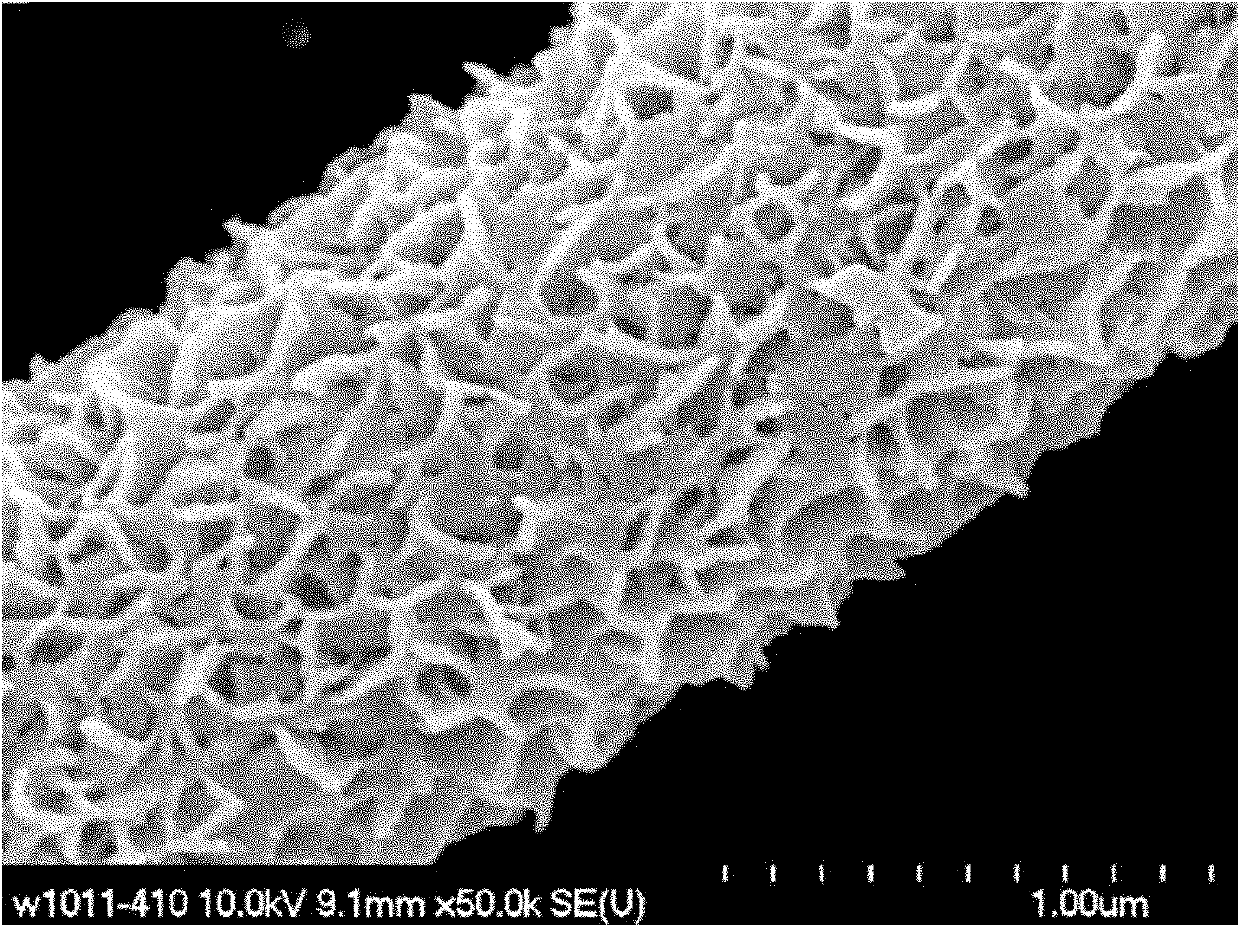

Method for coating surface of reinforcement in composite material

The invention discloses a method for coating a surface of reinforcement in a composite material, and relates to a method for coating a surface of reinforcement. The method can be used for solving the problems of coated tissue non-uniformity, poor compactness and coverage incompleteness in the conventional method for coating the surface of the reinforcement. The method comprises the following steps: 1, mixing reinforcement with metal powder, and obtaining mixed powder after ultrasonic cleaning; 2, pouring the mixed powder into distilled water or a salt solution, heating, coating, and then taking out the reinforcement; and 3, sintering the reinforcement. According to the method for coating the surface of the reinforcement in the composite material, a netlike structural coating is uniformly covered on the surface of the coated reinforcement, and the coating has small and compact tissues; and in the later composite material preparation process, the wetting property between the reinforcement and a substrate is greatly promoted, and the interface reaction between the reinforcement and the substrate is effectively controlled. By utilizing the method for coating the surface of the reinforcement in the composite material, the surface state of the reinforcement can be preferably regulated, and a technical guarantee is provided for the later prepared composite material to achieve excellent mechanical property.

Owner:HARBIN INST OF TECH

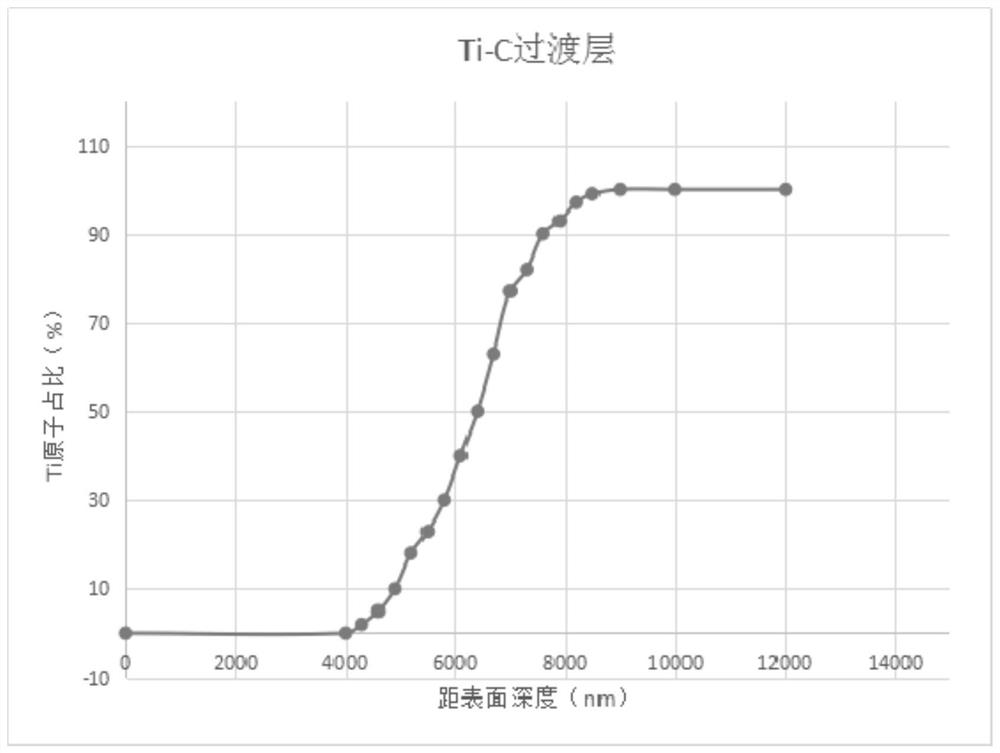

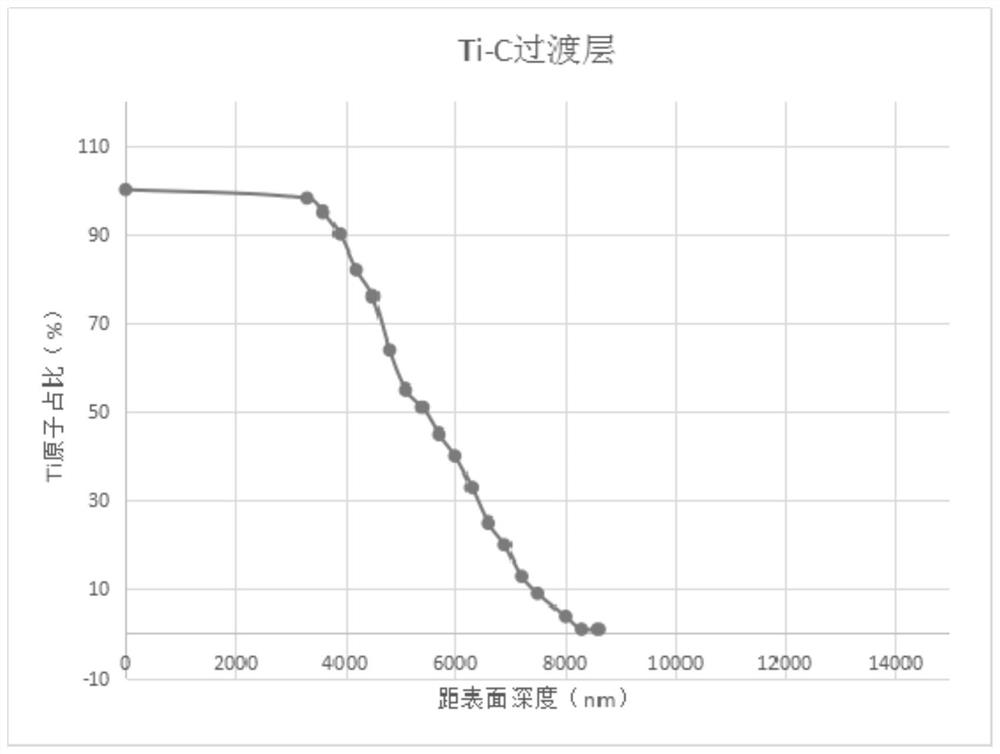

TiC ceramic with laminated structure, and preparation method of TiC ceramic

ActiveCN112062571AD-D bond is firmImprove wear resistanceAdditive manufacturing apparatusParticle beamChemical compatibility

The invention provides a TiC ceramic with a laminated structure, and a preparation method of the TiC ceramic. The TiC ceramic with the laminated structure sequentially comprises a Ti layer, a Ti-C gradual change transition layer, a C layer, a Ti-C gradual change transition layer, a Ti layer... a Ti-C gradual change transition layer, a C layer, a Ti-C gradual change transition layer and a Ti layerfrom bottom to top. The TiC ceramic with the laminated structure has the toughness of titanium and the hardness of carbon, and has good ductility, heat resistance, wear resistance and impact resistance. According to the invention, printing is conducted layer by layer through 3D printing equipment according to the stacking sequence of the Ti layer, the C layer, the Ti layer, the C layer and the Tilayer, and an interface between the Ti layer and the C layer is subjected to rapid cold machining treatment through ultra-strong pulse energy beams or particle beams to form a Ti-C gradient transitionlayer combining the Ti layer and the C layer is formed, so that the problems of poor chemical compatibility and wettability of a titanium nano material and a carbon nano material can be solved, compounding of the titanium nano material and the carbon nano material can be well achieved, and then the TiC ceramic which is high in interface bonding and has a laminated structure is formed.

Owner:上海梁为科技发展有限公司

Preparation of titanium-aluminum compound based composite material

InactiveCN101469400BLow preparation temperatureReduce thermal stress cracksVacuum evaporation coatingSputtering coatingCrazingTitanium

The invention provides a method for preparing a titanium aluminum compound base composite material, which is characterized by comprising: firstly, alternatively depositing a simple substance layer Ti and a simple substance layer Al on the external surface of SiC fiber; and secondly, performing pressing by adopting vacuum heat pressing or hot isostatic pressing at a certain temperature, and forming a composite material by diffusion bonding. The method effectively reduces the preparation temperature of the Ti-Al compound base composite material, remarkably reduces the thermal stress crack caused by the difference between the coefficients of thermal expansion in the process of cooling a basal body, and ensures that the interface reaction between the basal body and the fiber is controlled well. The method has great expected economical values and social values.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for modifying high-wettability coating on surface of metal-based compound material reinforcement

InactiveCN101899631BThe process is simple and easy to controlLow equipment requirementsVacuum pumpingMetal matrix composite

The invention discloses a method for modifying a high-wettability coating on the surface of a metal-based compound material reinforcement. The method comprises the following steps of: 1, by a common coating preparation method, forming a metal oxide coating, of which reducibility is lower than that of magnesium, on the surface of the reinforcement; 2, and placing the reinforcement coated with the metal oxide coating and pure magnesium in a vacuum furnace in a way of placing the pure magnesium on the bottom of the furnace and placing the reinforcement above the pure magnesium, vacuum-pumping the furnace, keeping the vacuum degree below 10Pa, heating the furnace to 600 to700 DEG C, and keeping the temperature for 5 to 60 minutes so as to allow the magnesium steam and the metal oxide coating on the surface of the reinforcement to undergo an oxidation-reduction reaction to generate a compound layer formed by an inner layer made of compounds and an outer layer made of reduced metal. The method has the advantages of simple and controllable process, low equipment requirements, low cost, wide application range, high mechanical and physical properties and the like.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

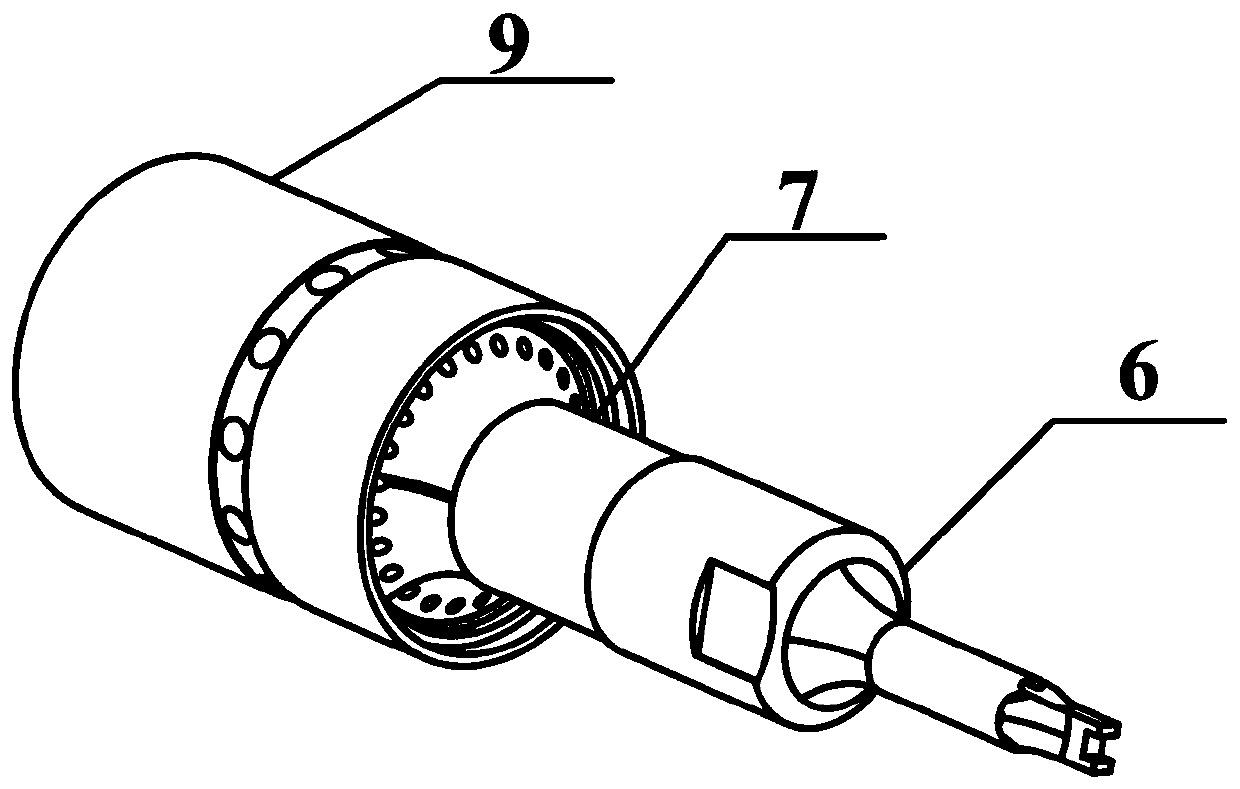

Ultrasonic-assisted laser spot welding device and method

ActiveCN108381039BReduce or eliminate residual stressControl interface responseLaser beam welding apparatusUltrasonic assistedMetallic materials

The invention discloses an ultrasonic-assisted laser spot welding device and method. The device comprises: a laser welding head, a C-shaped frame, a six-axis linkage robot, a laser, an ultrasonic vibration device and a pneumatic transmission system; the laser welding head is installed on a six-axis On the linkage robot, it is connected with the laser; the C-shaped frame is installed under the laser welding head, and the upper end of the C-shaped frame is provided with an opening. The laser emitted by the laser welding head can pass through the opening and irradiate the metal material to be welded below the opening; The pneumatic transmission system is fixed on the lower end of the C-shaped frame, and the ultrasonic vibration device is installed on the pneumatic transmission system. The invention introduces high-frequency ultrasonic energy into welding, effectively controls interface reaction and strengthens melt flow, improves interface wettability, refines weld grains, and subsequent ultrasonic vibration is more helpful to reduce or eliminate weld and The residual stress of the connection surface improves the connection strength.

Owner:CHANGCHUN UNIV OF SCI & TECH

Smelting method for improving the cleanliness of heavy rail steel

ActiveCN108950119BImprove cleanlinessImprove fatigue and mechanical propertiesManufacturing convertersSodium carbonateSmelting process

The invention discloses a smelting method for improving the cleanliness of heavy rail steel and belongs to the technical field of steel metallurgy. The technical problem solved by the invention is that existing domestic heavy rail steel cleanliness can not meet the requirements of high-speed railways. The method comprises the steps of liquid iron pretreating, converter smelting, LF refining, RH refining and continuous casting and performs blowing smelting on the liquid iron taking active lime, silica sand, high-magnesium lime, steel smelting sludge pellet and sodium carbonate as slag making materials in the converter smelting process, and the content of P is controlled to be 0.003% or below. By means of the above steps of the smelting method for improving the cleanliness of the heavy railsteel, the content of elements in a steel rail can be controlled as P less than or equal to 0.0060%, S less than or equal to 0.0030%, O less than or equal to 0.0010%, N less than or equal to 0.0050% and H less than or equal to 0.00015%, P+S+O+N+H is less than or equal to 160 ppm, the grade of inclusion is less than or equal to 1.0 grade, the cleanliness of the heavy rail steel is significantly improved, and the smelting method for improving the cleanliness of the heavy rail steel has certain social benefits and is worth popularizing and applying.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com