Method for preparing ferric oxide ceramic thin film on the surface of three-dimensional network silicon carbide

A technology of networked silicon carbide and ceramic thin films is applied in the field of materials to achieve the effects of short preparation cycle, simple preparation method and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ferric nitrate is mixed with 0.1mol / L ferric nitrate solution, and urea is added in solution, and the add-on of urea is urea in molar ratio: iron ion=2: 1; The solution that will obtain is heated up under stirring condition, and stirring speed is 100rpm , heat up to 40°C, keep warm for 25min, then cool to room temperature, let stand for 7h, then heat to 70°C, keep warm for 40min to obtain iron-containing sol.

[0028] The three-dimensional network silicon carbide is immersed in the iron-containing sol under vacuum conditions for 30 minutes, then taken out and dried at room temperature for 25 minutes, heated to 55°C for 10 minutes, heated to 75°C for 40 minutes, and the coating is completed.

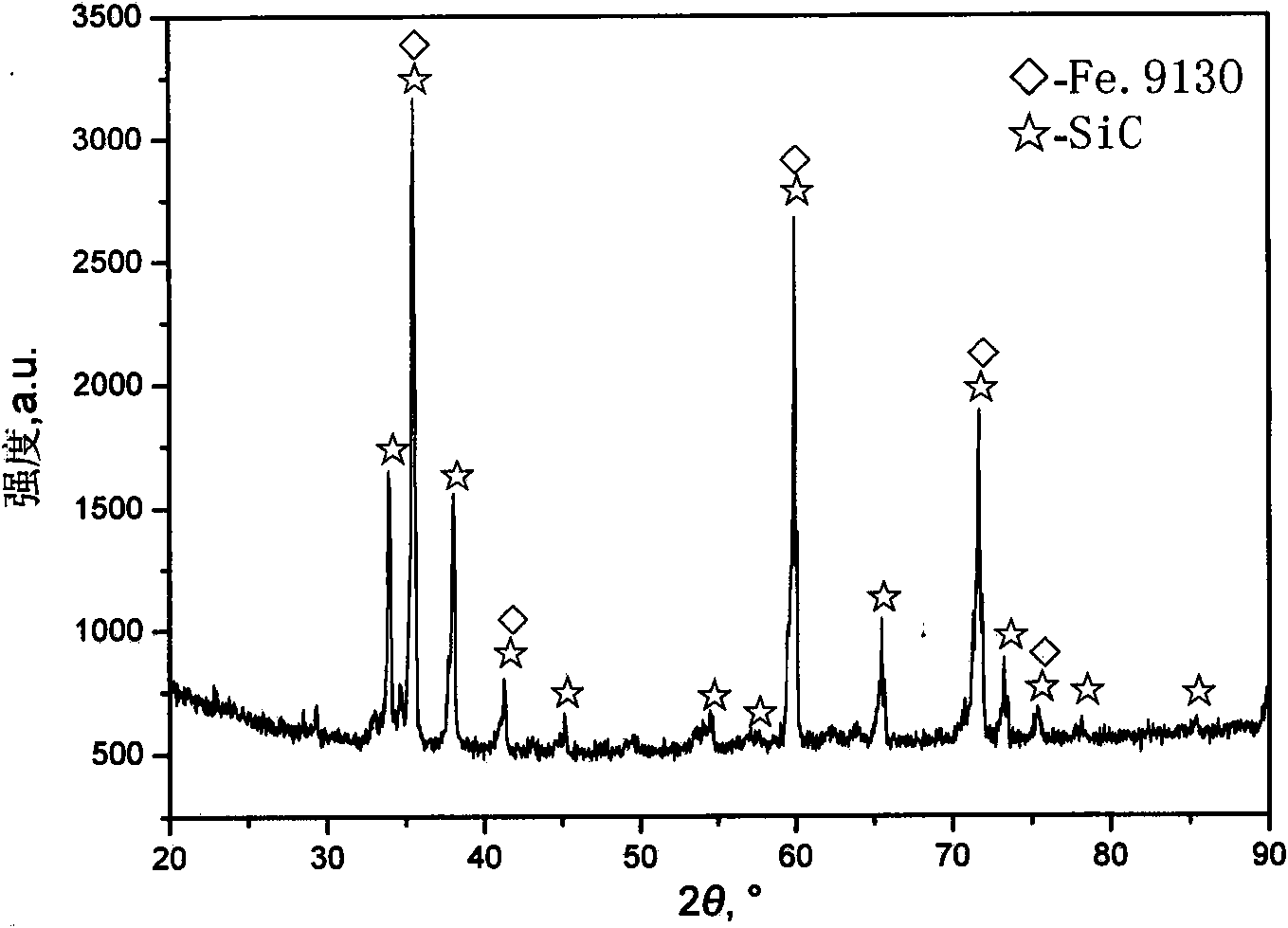

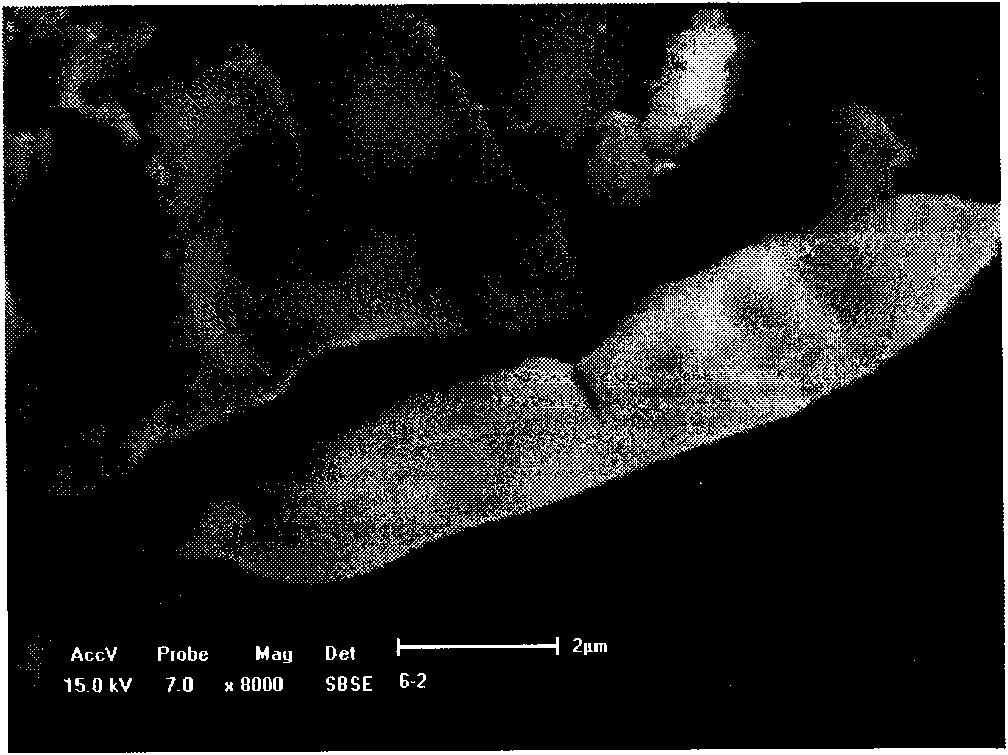

[0029] The three-dimensional network silicon carbide coated with iron-containing sol was heated to 120°C for 80 minutes, 250°C for 170 minutes, and 400°C for 200 minutes; the heating rate was 2°C / min. A uniform and dense iron oxide film is obtained on the surface of the three-dimen...

Embodiment 2

[0031] Ferric nitrate is mixed with 0.3mol / L ferric nitrate solution, and urea is added in solution, and the add-on of urea is urea in molar ratio: iron ion=3: 1; The solution that will obtain is heated up under stirring condition, and stirring speed is 160rpm , heat up to 50°C, keep warm for 30min, then cool to room temperature, let stand for 7.5h, then heat to 80°C, keep warm for 30min to obtain iron-containing sol.

[0032] The three-dimensional network silicon carbide is immersed in the iron-containing sol under vacuum conditions for 25 minutes, then taken out and dried at room temperature for 15 minutes, heated to 50°C for 15 minutes, heated to 85°C for 30 minutes, and the coating is completed.

[0033] The three-dimensional network silicon carbide coated with iron-containing sol was heated to 140°C for 60 minutes, 300°C for 150 minutes, and 450°C for 170 minutes; the heating rate was 5°C / min. A uniform and dense iron oxide film is obtained on the surface of the three-dim...

Embodiment 3

[0035] Ferric nitrate is mixed with 0.5mol / L ferric nitrate solution, and urea is added in solution, and the add-on of urea is urea in molar ratio: iron ion=4: 1; The solution that will obtain is heated up under stirring condition, and stirring speed is 200rpm , heated up to 55°C, kept warm for 35min, then cooled to room temperature, stood still for 6.5h, then heated to 95°C, kept warm for 20min, and iron-containing sol was obtained.

[0036] The three-dimensional network silicon carbide is immersed in the iron-containing sol under vacuum conditions for 20 minutes, then taken out and dried at room temperature for 10 minutes, heated to 46°C for 25 minutes, heated to 90°C for 20 minutes, and the coating is completed.

[0037] The three-dimensional network silicon carbide coated with iron-containing sol was heated to 180°C for 50 minutes, 340°C for 100 minutes, and 600°C for 150 minutes; the heating rate was 8°C / min. A uniform and dense iron oxide film is obtained on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com