Ultrasonic-assisted laser spot welding device and method

A laser spot welding and ultrasonic assisted technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that it is difficult to achieve the expected effect, the temperature and mechanical conditions of the workpiece preheating are difficult to control, etc., and achieve continuous ultrasonic assistance. Laser spot welding, the effect of eliminating residual stress and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

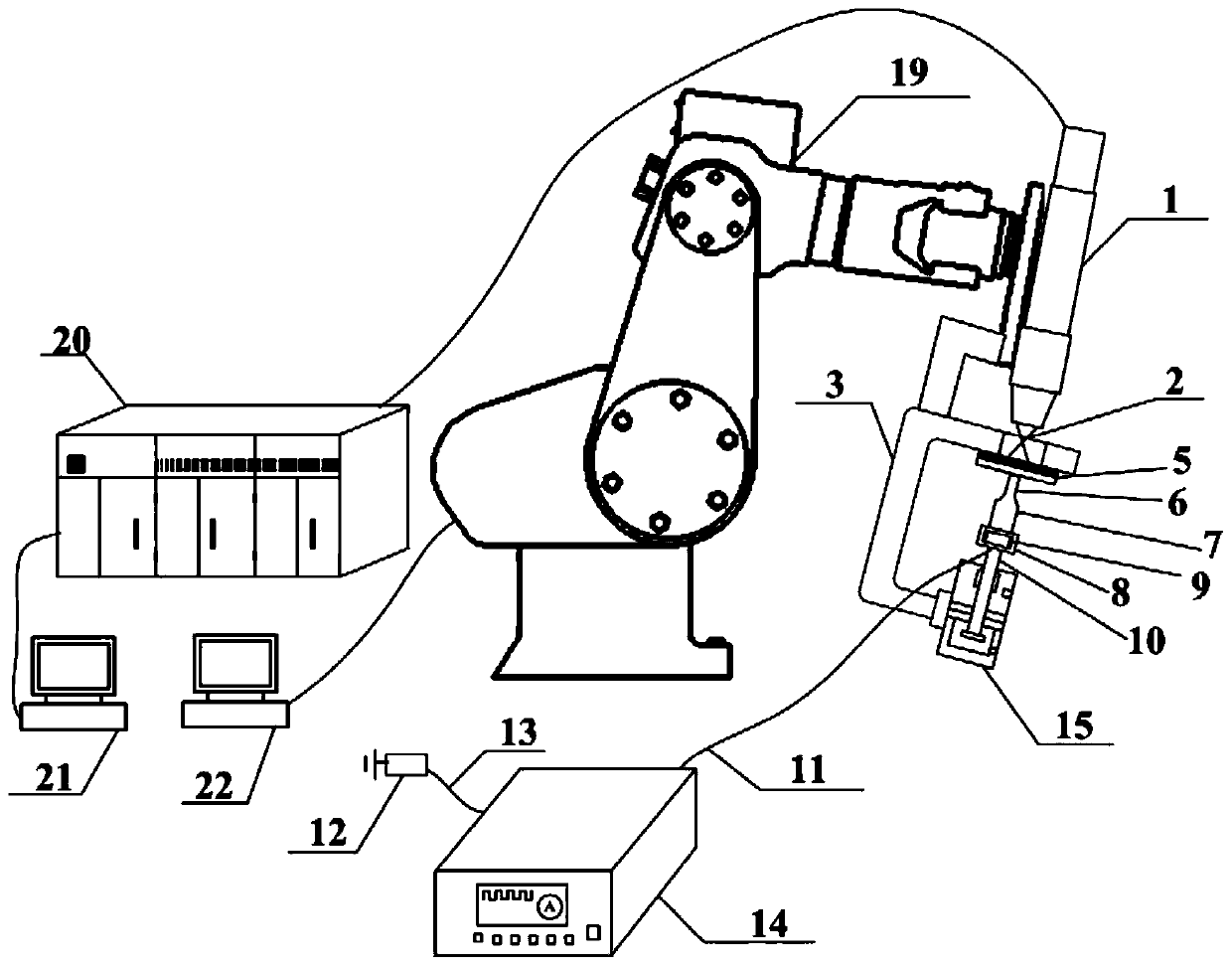

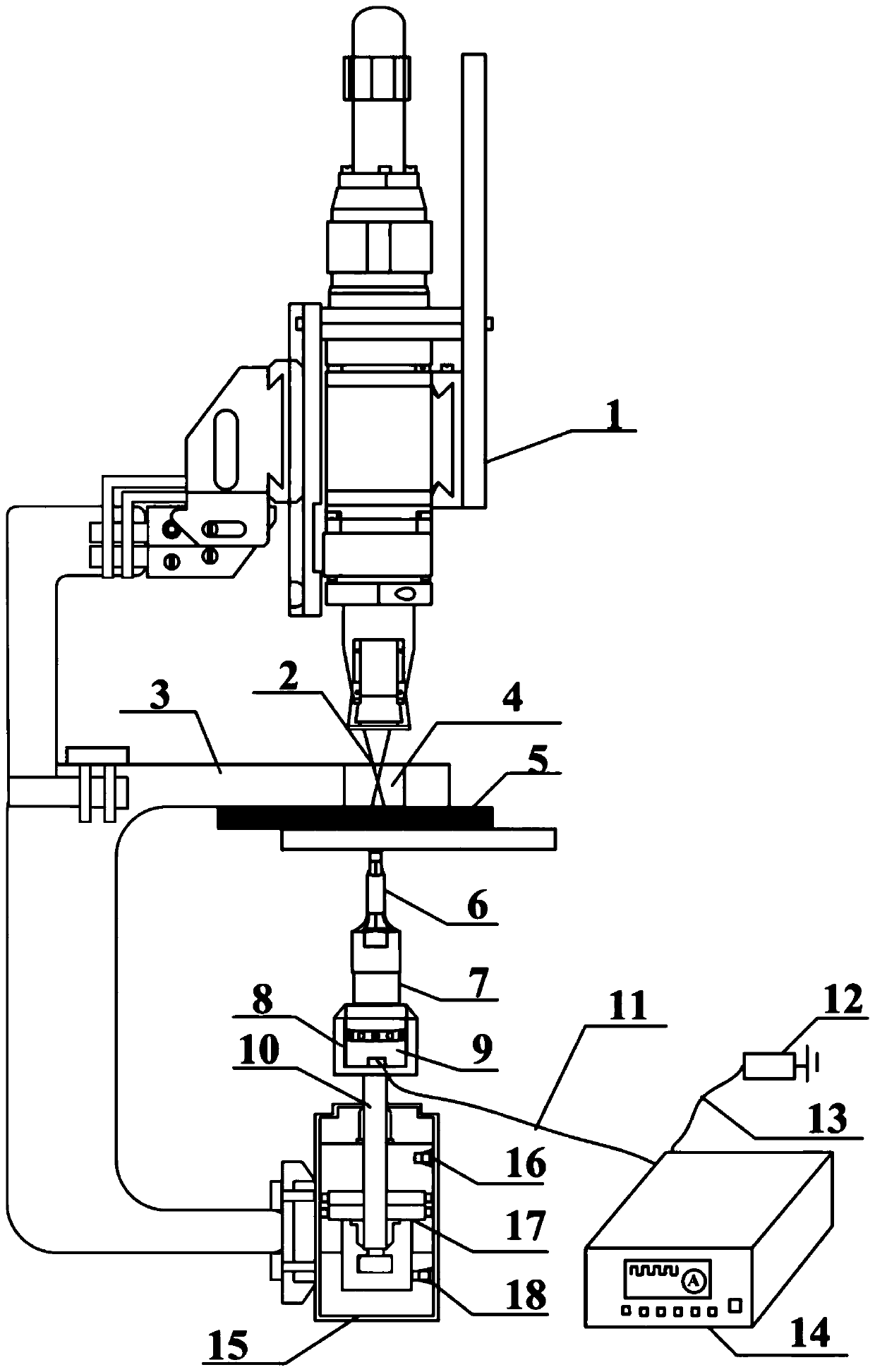

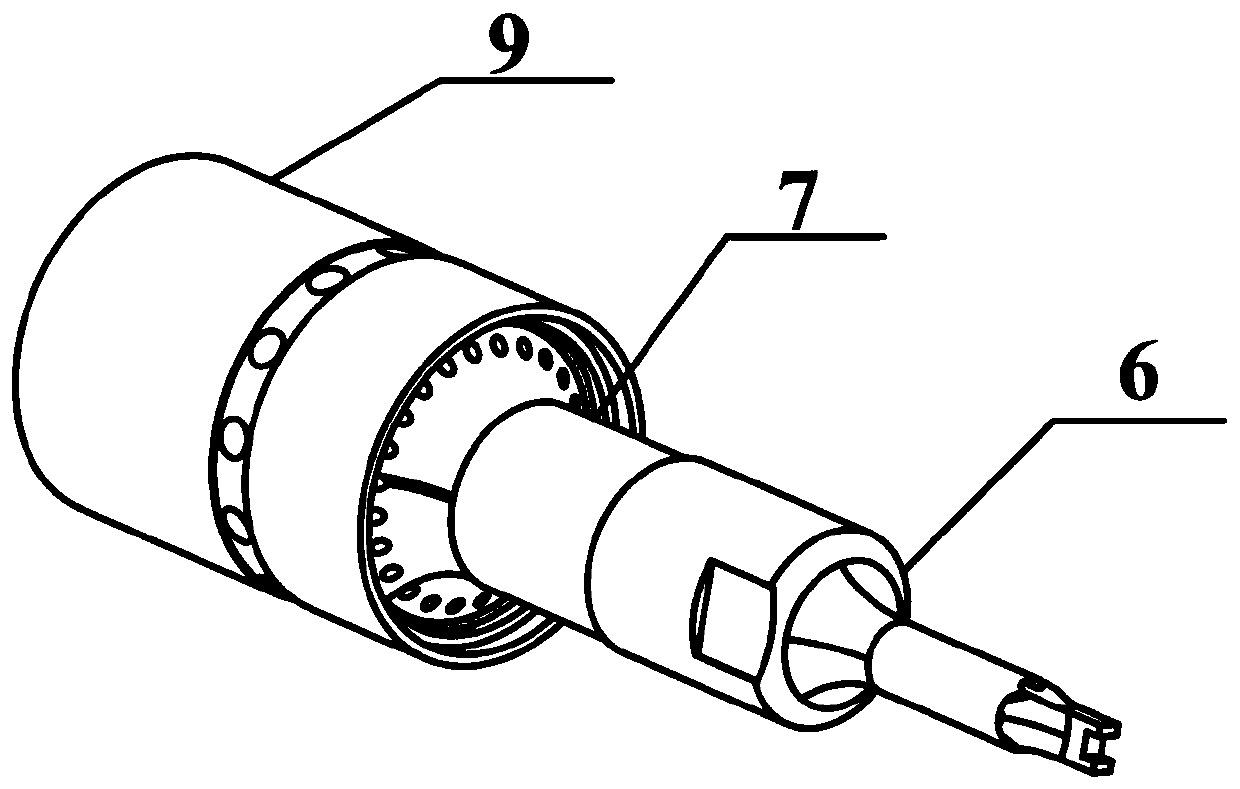

[0039] Such as Figure 1-3 As shown, the ultrasonic-assisted laser spot welding device of the present invention includes: a laser welding head 1, a C-shaped frame 3, a six-axis linkage robot 19, a laser 20, an ultrasonic vibration device and a pneumatic transmission system. The laser welding head 1 is installed on the six-axis linkage robot 19 and connected with the laser 20; the C-shaped frame 3 is installed under the laser welding head 1, and the upper end of the C-shaped frame 3 is provided with an opening 4, and the laser 2 emitted by the laser welding head 1 can Pass through the opening 4 and irradiate onto the metal material 5 to be welded below the opening 4; the pneumatic transmission system is fixed on the lower end of the C-shaped frame 3, and the ultrasonic vibration device is installed on the pneumatic transmission system. The laser 20 is also connected to a laser control system 21 , and the six-axis linkage robot 19 is also connected to a robot control system 22 ....

Embodiment 2

[0046] Example 2 Ultrasonic-assisted laser spot welding of dissimilar metals between high-strength steel and 5083 aluminum alloy

[0047] The device of Example 1 was used to weld high-strength steel and 5083 aluminum alloy.

[0048] (1) The welding materials are high-strength steel with a thickness of 3mm and 5083 aluminum alloy with a thickness of 5mm. First, use acetone to remove the surface oil of the two metal materials to be welded, and then put the aluminum alloy into sodium hydroxide and nitric acid respectively for alkali Washing and pickling to remove the oxide film.

[0049] (2) Use a short-pulse laser beam to perform laser surface texturing on one surface of the high-strength steel, and ablate a circular array of micro-pits on the surface of the metal material ( Figure 5 ), the average power of the laser beam is 20W, the pulse frequency is 20kHz, the scanning speed is 140mm / s, the average diameter of micro pits is 220-250μm, the depth is 150-180μm, and the surface...

Embodiment 3

[0056] Example 3 Ultrasonic-assisted laser spot welding of 304 stainless steel and magnesium alloy dissimilar metals

[0057] The device of Example 1 is used to weld 304 stainless steel and magnesium alloy.

[0058] (1) The welding metal materials are 304 stainless steel with a thickness of 2mm and magnesium alloy with a thickness of 5mm. First, use acetone to remove the surface oil stains of the two metal materials to be welded, and then put the magnesium alloy into dilute hydrochloric acid and sodium hydroxide for acidification. Washing and alkaline washing to remove the oxide film.

[0059] (2) Laser surface texturing is performed on one surface of 304 stainless steel with an ultrashort pulse laser beam, and groove-shaped micro-pits are ablated on the surface of the metal material ( Figure 6 ), the average power of the laser beam is 100W, the pulse frequency is 200kHz, the scanning speed is 150mm / s, the micro pit width is 200-230μm, the depth is 160-200μm, and the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com