A method for eliminating residual stress of diamond composite sheet

A technology of diamond composite sheet and residual stress, which is applied in the direction of process efficiency improvement, furnace, heat treatment equipment, etc., can solve the problems of not being suitable for cutting and grinding into other shapes, and can not be used for cutting tools, so as to eliminate residual stress and improve the quality of finished products. rate, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The diamond composite sheet described in Example 1 is the product of Zhongnan Diamond Co., Ltd., the brand is ZB1208×1.5 (for mines); the diamond composite sheet described in Example 2 is the product of Zhongnan Diamond Co., Ltd., the brand is ZT10A-Φ45× 1.6×0.5 (for cemented carbide tools); the diamond composite sheet described in Example 3 is a product of Zhongnan Diamond Co., Ltd., and the brand name is ZT10H2-Φ45×1.6×0.5 (for woodworking tools).

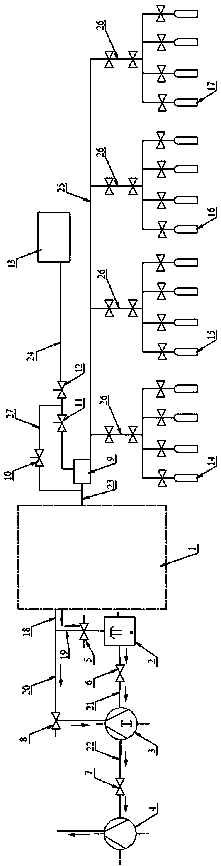

[0020] The vacuum heating furnace described in the following examples, such as image 3 As shown, it includes a furnace body 1, a vacuum pumping system and an air charging system; the vacuum pumping system includes a diffusion pump 2, a Roots pump 3, a slide valve vacuum pump 4 and a main exhaust pipe 18 communicated with the furnace body. The air extraction pipeline 18 is divided into two branches, i.e. the first air extraction pipeline 19 and the second air extraction pipeline 20, the first air extraction pipeline 19 is ...

Embodiment 2

[0032] A method for eliminating residual stress of a diamond composite sheet, comprising the following steps: placing the diamond composite sheet in a vacuum heating furnace, and evacuating until the pressure in the furnace is 5×10 -3 Pa, start the gradient temperature rise, and keep the pressure in the furnace at 5×10 for the first 20 minutes of the gradient temperature rise. -3 Pa, then fill in the mixed gas, and finally make the temperature in the furnace 560°C and the pressure in the furnace 3 MPa, and keep it for 180 minutes, stop heating, wait for the temperature in the furnace to drop to 50°C, discharge the gas in the furnace after 10 minutes, and turn on Furnace door, take out the diamond composite sheet.

[0033] Wherein, the mixed gas is composed of the following components in volume percentage: 0.1% hydrogen, 1.0% methane, 0.1% carbon dioxide, and the balance is nitrogen.

[0034] The process of the gradient heating is shown in Table 2:

[0035] Table 2 The spec...

Embodiment 3

[0038] A method for eliminating residual stress of a diamond composite sheet, comprising the following steps: placing the diamond composite sheet in a vacuum heating furnace, and evacuating until the pressure in the furnace is 5×10 -3 Pa, start the gradient temperature rise, and keep the pressure in the furnace at 5×10 for the first 40 minutes of gradient temperature rise -3 Pa, then fill in the mixed gas, and finally make the temperature in the furnace 800°C and the pressure in the furnace 1 MPa, and keep it for 60 minutes, stop heating, wait for the temperature in the furnace to drop to 50°C, discharge the gas in the furnace after 10 minutes, and turn on Furnace door, take out the diamond composite sheet.

[0039] Wherein, the mixed gas is composed of the following components in volume percentage: 3.0% hydrogen, 8.0% methane, 1.5% carbon dioxide, and the balance is nitrogen.

[0040] The process of the gradient heating is shown in Table 3:

[0041] Table 3 The specific p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com