Annealing method for reducing indium arsenide surface dot number

An indium arsenide and indium arsenide single crystal technology is applied in chemical instruments and methods, self-solidification methods, chemical reactive gases, etc. The effect of reducing the number of pips, reducing the number of pips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

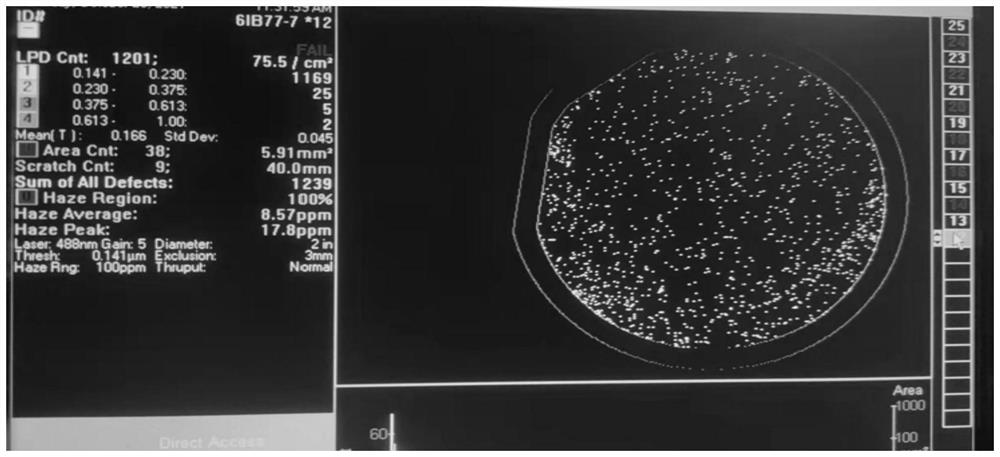

Image

Examples

Embodiment 1

[0027] (1) The non-doped indium arsenide crystal grown by the VGF method is cut into a single wafer with a size of 3 inches by multi-wire cutting, and a clean indium arsenide single crystal wafer is obtained after edging, cleaning and drying.

[0028] (2) Clean the quartz tube and the quartz sample holder in ultrasonic for 10 hours in hydrofluoric acid, then rinse them with deionized water for 10 minutes, put them in a drying oven to dry after rinsing.

[0029] (3) Place the indium arsenide single crystal wafers in an orderly and spaced manner vertically on a clean quartz sample holder, and then place the quartz sample holder horizontally in the quartz tube.

[0030] (4) Vacuum the quartz tube, when its vacuum degree is less than or equal to 10 -3 Pa, sintering and sealing with hydrogen-oxygen flame.

[0031] (5) Put the sealed quartz tube into a horizontal annealing furnace for annealing, which includes heating, constant temperature and cooling stages. When the temperature ...

Embodiment 2

[0033] (1) The non-doped indium arsenide crystal grown by the VGF method is cut into a single wafer with a size of 2 inches by multi-wire cutting, and a clean indium arsenide single crystal wafer is obtained after edging, cleaning and drying.

[0034] (2) The quartz tube and the quartz sample holder were ultrasonically cleaned in aqua regia for 10 hours, then rinsed with deionized water for 10 minutes, and then placed in a drying oven for drying.

[0035] (3) Place the indium arsenide single crystal wafers in an orderly and spaced manner vertically on a clean quartz sample holder, and then place the quartz sample holder horizontally in the quartz tube.

[0036] (4) Vacuum the quartz tube, when its vacuum degree is less than or equal to 10 -3 Pa, sintering and sealing with hydrogen-oxygen flame.

[0037] (5) Put the sealed quartz tube into a horizontal annealing furnace for annealing, which includes heating, constant temperature and cooling stages. When the temperature rises ...

Embodiment 3

[0039] (1) The non-doped indium arsenide crystal grown by the VGF method is obtained by multi-wire cutting to obtain a single wafer with a size of 4 inches. After grinding, cleaning and drying, a clean indium arsenide single crystal wafer is obtained.

[0040] (2) Clean the quartz tube and the quartz sample holder in ultrasonic for 10 hours in hydrofluoric acid, then rinse them with deionized water for 10 minutes, put them in a drying oven to dry after rinsing.

[0041] (3) Place the indium arsenide single crystal wafers in an orderly and spaced manner vertically on a clean quartz sample holder, and then place the quartz sample holder horizontally in the quartz tube.

[0042] (4) Vacuum the quartz tube, when its vacuum degree is less than or equal to 10 -3 Pa, sintering and sealing with hydrogen-oxygen flame.

[0043] (5) Put the sealed quartz tube into a horizontal annealing furnace for annealing, which includes heating, constant temperature and cooling stages. When the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com