A kind of preparation method of high electromagnetic shielding hollow microsphere reinforced az91 magnesium matrix composite material

A technology of hollow microspheres and electromagnetic shielding, applied in the field of preparation of hollow microspheres reinforced AZ91 magnesium-based composite materials, can solve problems such as hollow microsphere structure damage, achieve recycling, high electromagnetic shielding efficiency, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

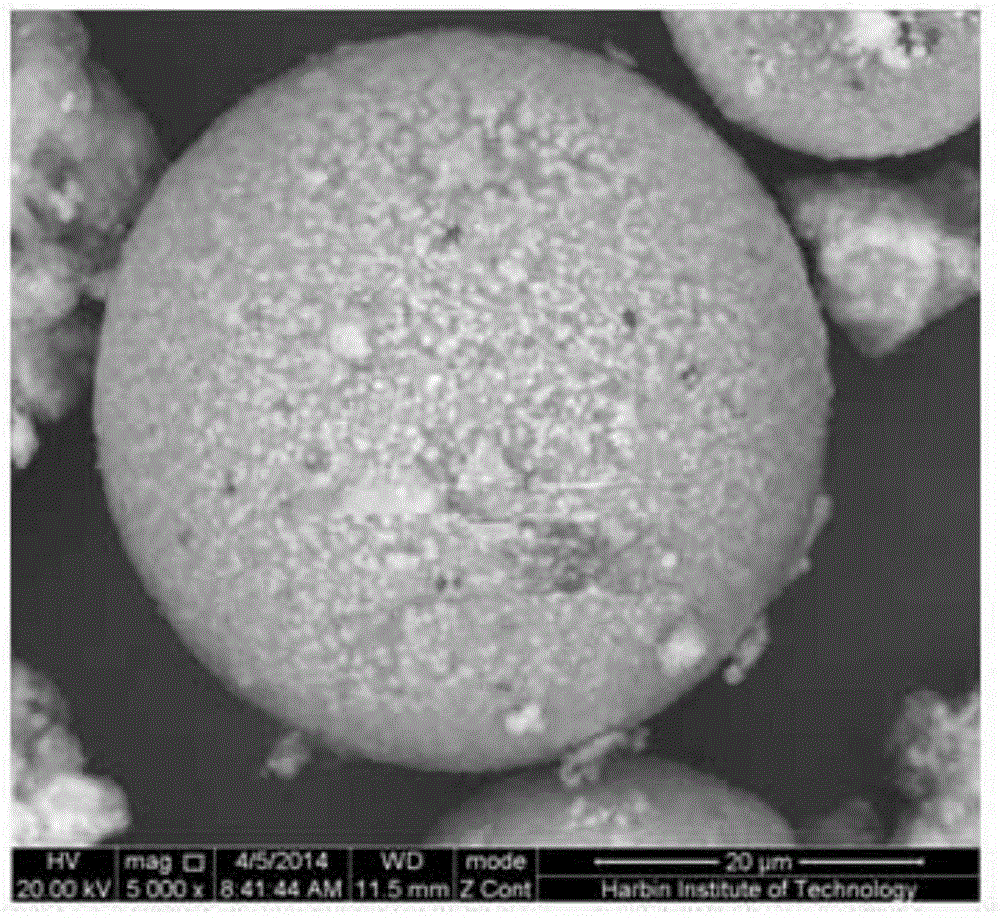

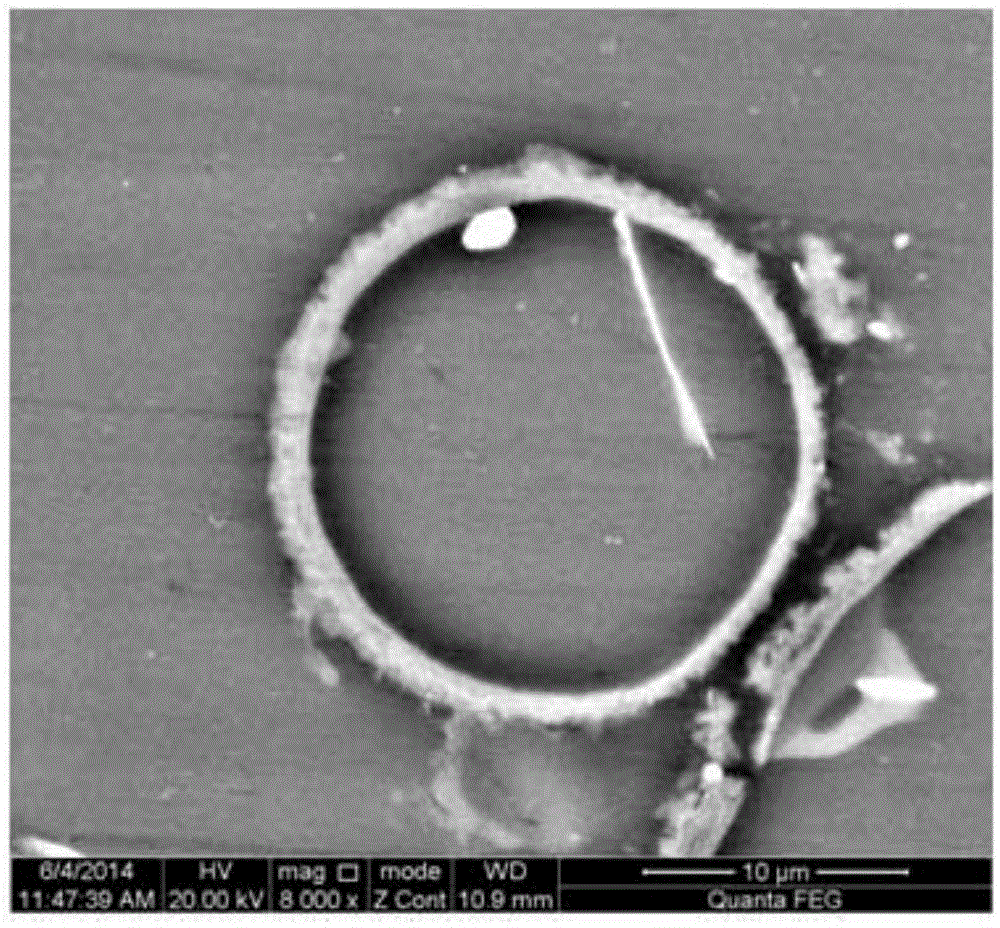

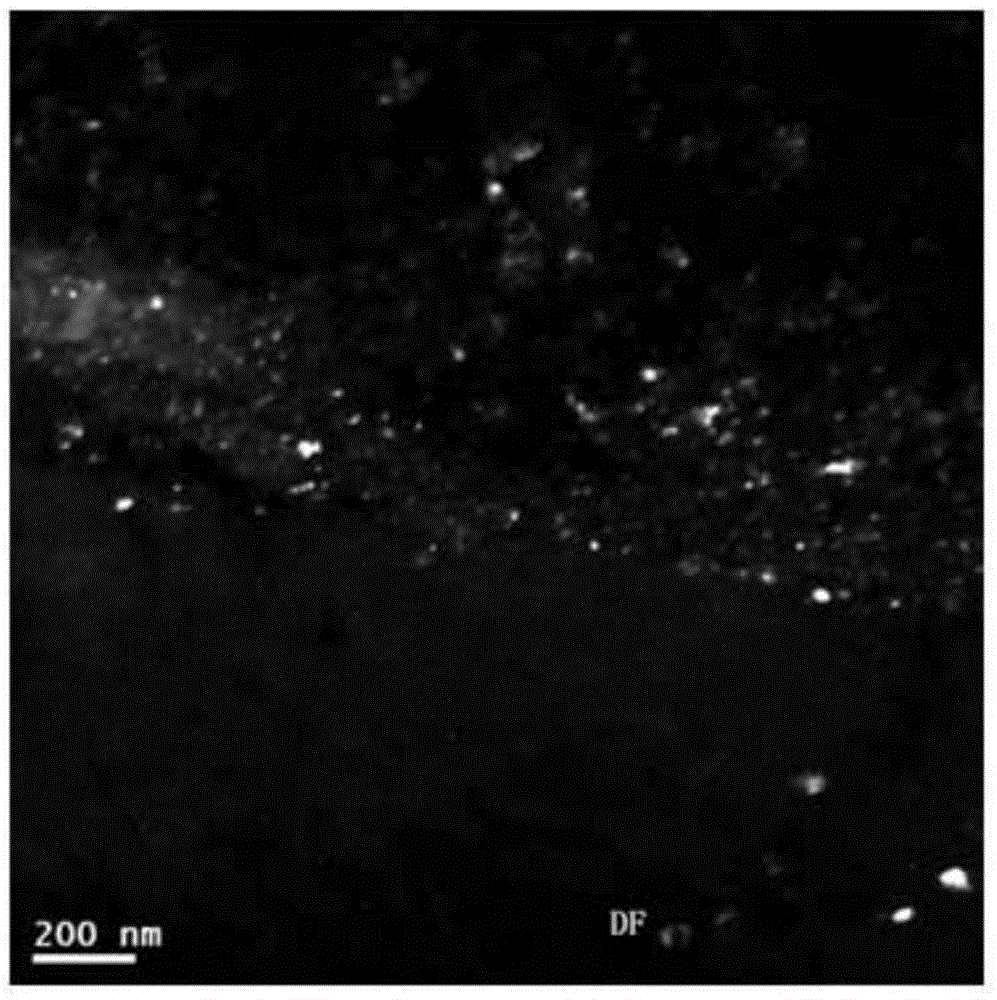

[0020] Specific implementation mode 1: The preparation method of the hollow microsphere reinforced AZ91 magnesium-based composite material with high electromagnetic shielding in this embodiment is carried out according to the following steps:

[0021] 1. Take the hollow beads with an average particle size of 100 microns, wash them with water, and then dry the hollow beads at 105°C for use; add quicklime to the beaker, add water to the beaker and react for 30 minutes, then wrap it with plastic film Hold the mouth of the beaker, age for 12 hours, filter with a 200-mesh sieve, weigh the mass of slaked lime particles remaining on the sieve, and calculate Ca(OH) 2 Ca(OH) in solution 2 The quality of the water and the quality of the water;

[0022] Second, then in Ca(OH) 2 The hollow microbeads and water treated in step 1 are added to the solution to obtain a mixed solution. The mixture is reacted at 95°C for 12 hours. After the reaction, the hollow beads are washed in sufficient distille...

specific Embodiment approach 2

[0025] Specific embodiment two: this embodiment is different from specific embodiment one in that the mass ratio of quicklime to water in step one is 1:8-10. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: this embodiment is different from specific embodiment one or two in: the Ca(OH) described in step two 2 Ca(OH) in solution 2 The mass ratio of the hollow microbeads is 1:5-8. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com