Method for coating surface of reinforcement in composite material

A composite material and surface coating technology, applied in the field of reinforcement surface coating, can solve the problems of incomplete coverage, uneven structure, poor compactness, etc., and achieve the effect of improved wettability, excellent mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

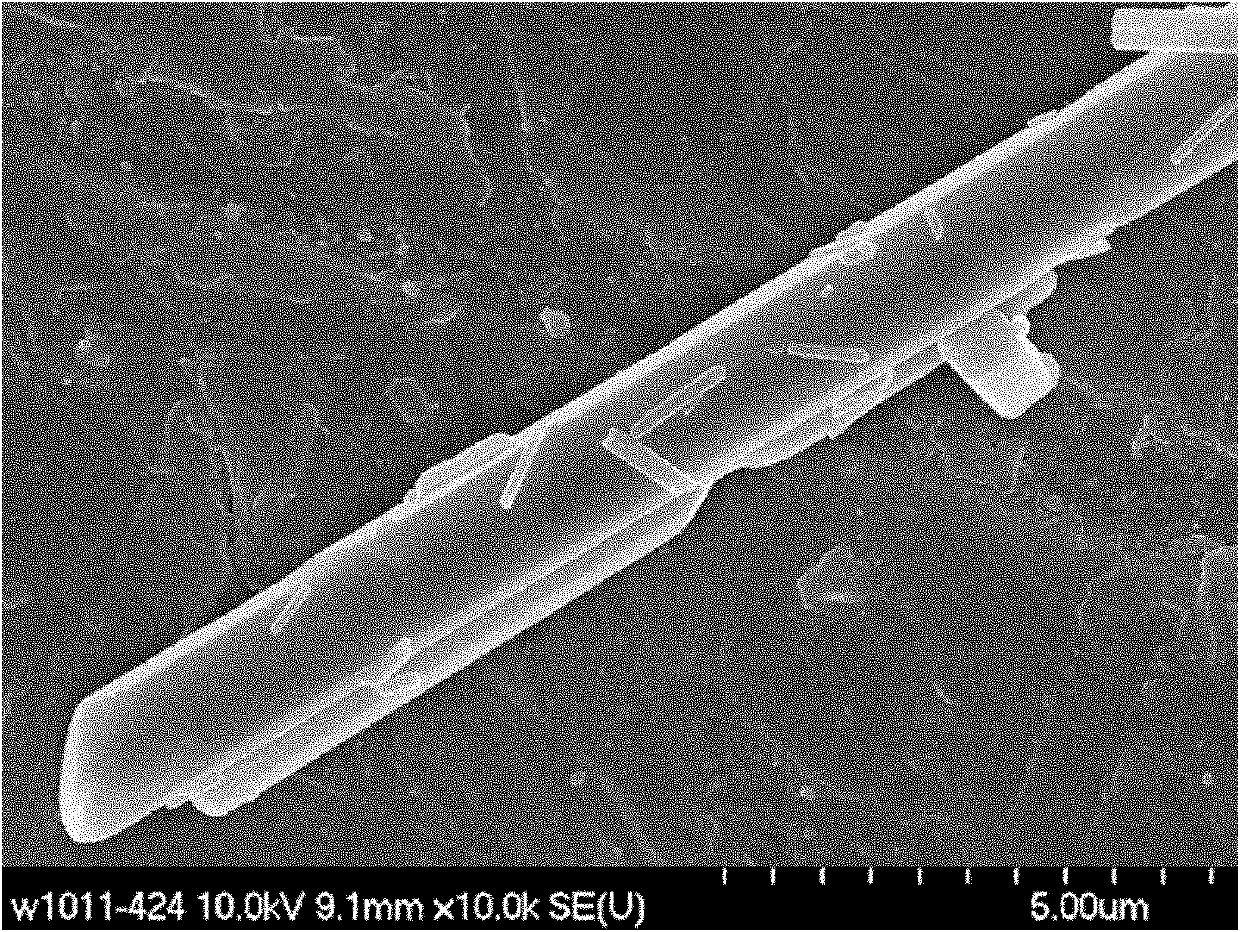

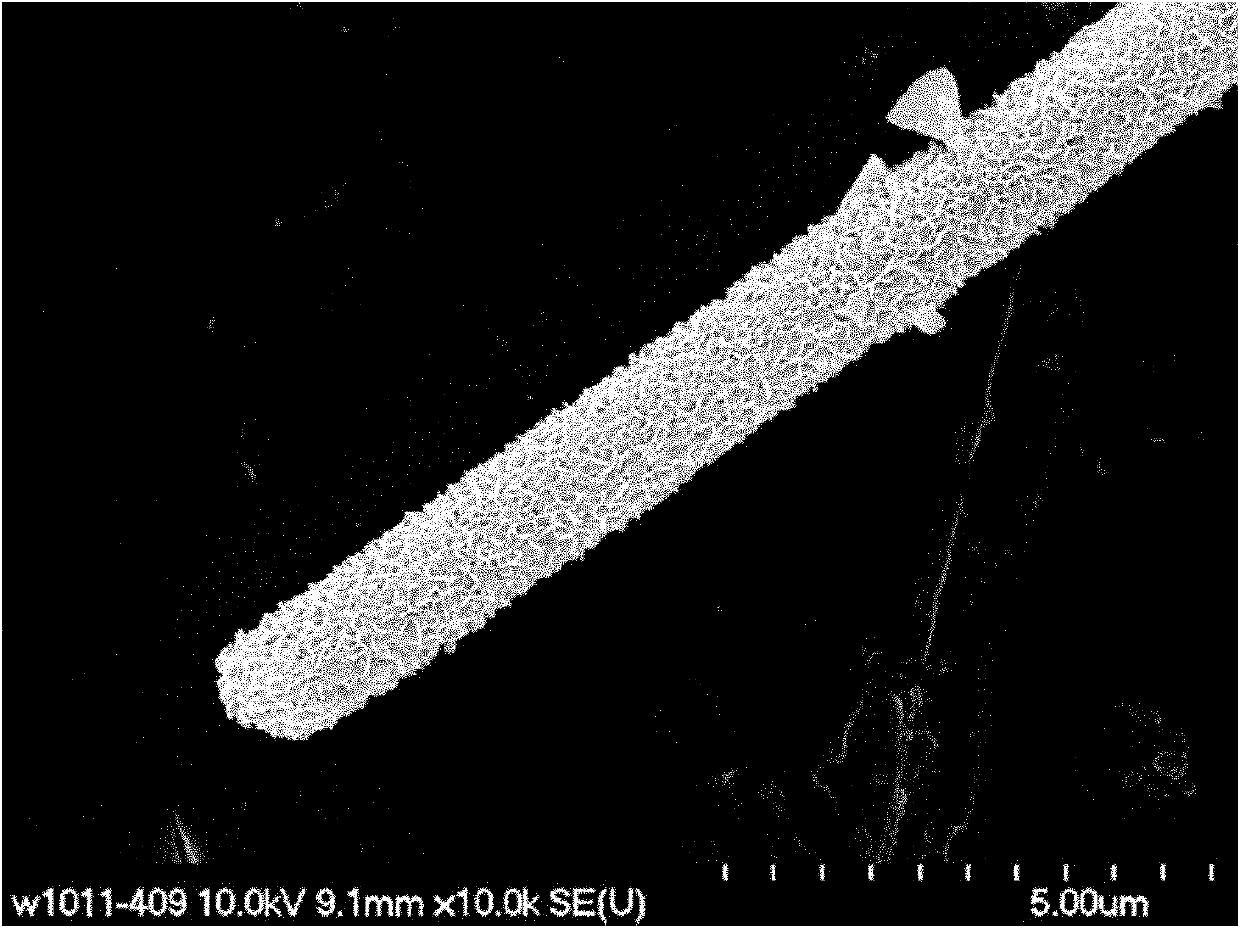

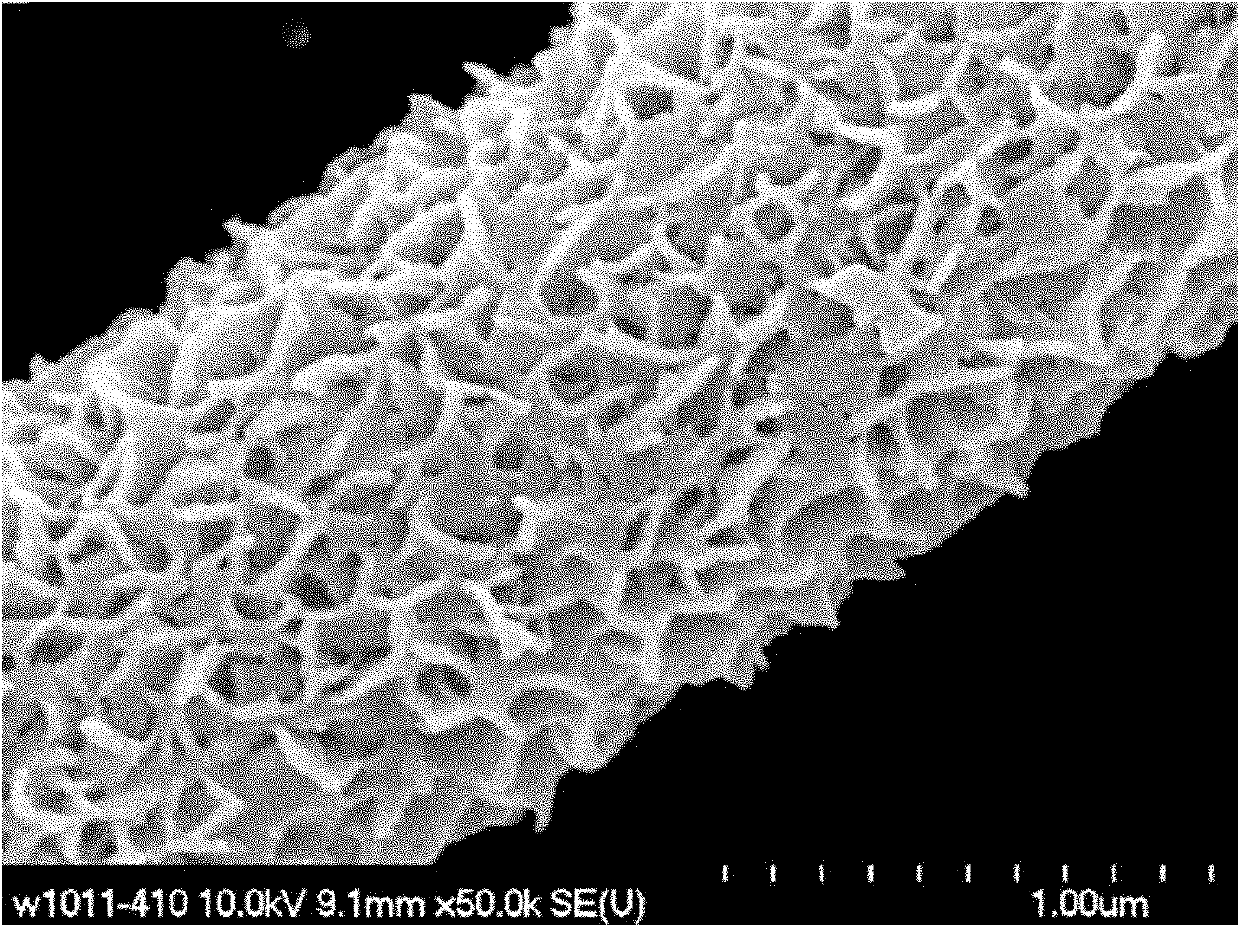

[0008] Specific Embodiment 1: The method for coating the reinforcement surface in the composite material in this embodiment is realized according to the following steps: 1. Mix 5-80 parts of reinforcement and 20-95 parts of metal powder in parts by mass, and then place Perform ultrasonic cleaning in absolute ethanol for 5 minutes to obtain a mixed powder; 2. Pour the mixed powder into distilled water or saline solution to obtain a mixture, and then heat it at a temperature of 50-200°C for 10 minutes-5 hours, and stir to obtain a suspension Turbid liquid, after static precipitation for 1 to 2 minutes, remove the precipitate, take the suspended matter, that is, the reinforcement; 3. Place the reinforcement in a sintering furnace, and sinter for 0.5 to 3 hours at a sintering temperature of 400 to 1000 ° C to complete the composite Surface coating of the reinforcement in the material; the reinforcement in step 1 is borate whisker, silicon carbide whisker, silicon carbide particles,...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, 5 parts of reinforcement and 95 parts of metal powder are mixed in parts by mass. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, 80 parts of reinforcement and 20 parts of metal powder are mixed in parts by mass. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com