Sand based permeable dry mix and mixture thereof

A technology for mixing materials and mixtures, applied in the field of concrete, can solve problems such as short construction allowable delay time and environmental pollution, and achieve the effects of solving ready-mixed production and prohibiting on-site mixing, convenient use and rich varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

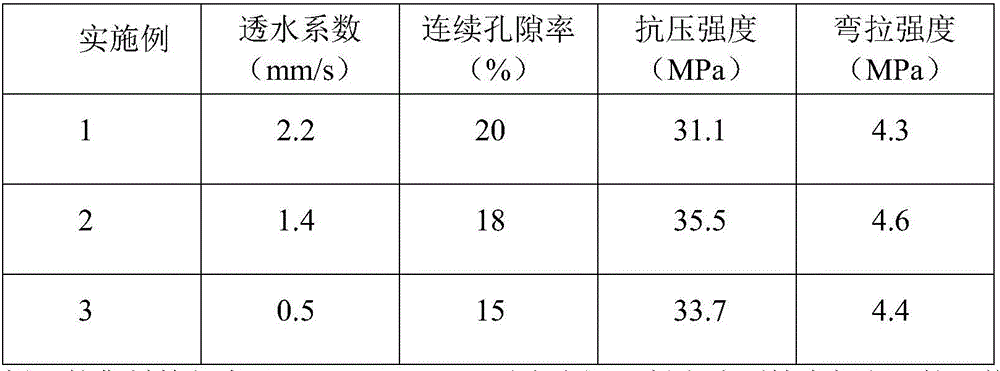

Embodiment 1

[0028] A sand-based water-permeable dry-mixed mixture, including the following raw materials by weight: 300 parts of P.O42.5 cement, 60 parts of S95 grade slag powder, 18 parts of SR type ecological permeable concrete enhancer, particle size 2.5-5mm 1648 parts of aggregate, 0.62 parts of polycarboxylic acid water-reducing agent powder, 0.38 parts of hydroxypropyl methyl cellulose ether, and 0.38 parts of regulator.

[0029] All the above-mentioned raw materials are dried and kept dry after cooling. The above-mentioned raw materials are mixed according to the formula amount to prepare a sand-based permeable dry-mixed mixture, which is sealed and stored.

[0030] When in use, water is added to the sand-based permeable dry-mixed mixture to prepare a sand-based permeable mixture. In this embodiment, the weight of water added is 5.4% of the weight of the dry-mixed mixture.

Embodiment 2

[0032] A sand-based water-permeable dry-mixing material, including the following raw materials by weight: 360 parts of P.O42.5 cement, 30 parts of S95 grade slag powder, 25 parts of SR type ecological permeable concrete enhancer, particle size 1.25-2.5 mm aggregates 1495 parts, polycarboxylic acid water reducing agent powder 0.81 parts, hydroxypropyl methyl cellulose ether 0.41 parts, regulator 0.41 parts, iron oxide green 15 parts.

[0033] All the above-mentioned raw materials are dried and kept dry after cooling. The above-mentioned raw materials are mixed according to the formula amount to prepare a sand-based permeable dry-mixed mixture, which is sealed and stored.

[0034] When in use, water is added to the sand-based permeable dry-mixed mixture to obtain a sand-based permeable mixture. In this embodiment, the weight of the added water is 5.6% of the weight of the dry-mixed mixture.

Embodiment 3

[0036] A sand-based water-permeable dry-mixed mixture, including the following raw materials by weight: 320 parts of P.O42.5 cement, 40 parts of S95 grade slag powder, 23 parts of SR type ecological permeable concrete enhancer, particle size 0.63-1.25 mm aggregate 1483 parts, polycarboxylic acid water reducer powder 0.77 parts, hydroxypropyl methyl cellulose ether 0.38 parts, regulator 0.38 parts.

[0037] All the above-mentioned raw materials are dried and kept dry after cooling. The above-mentioned raw materials are mixed according to the formula amount to prepare a sand-based permeable dry-mixed mixture, which is sealed and stored.

[0038] When in use, water is added to the sand-based permeable dry-mixed mixture to obtain a sand-based permeable mixture. In this embodiment, the weight of water added is 6.0% of the weight of the dry-mixed mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com